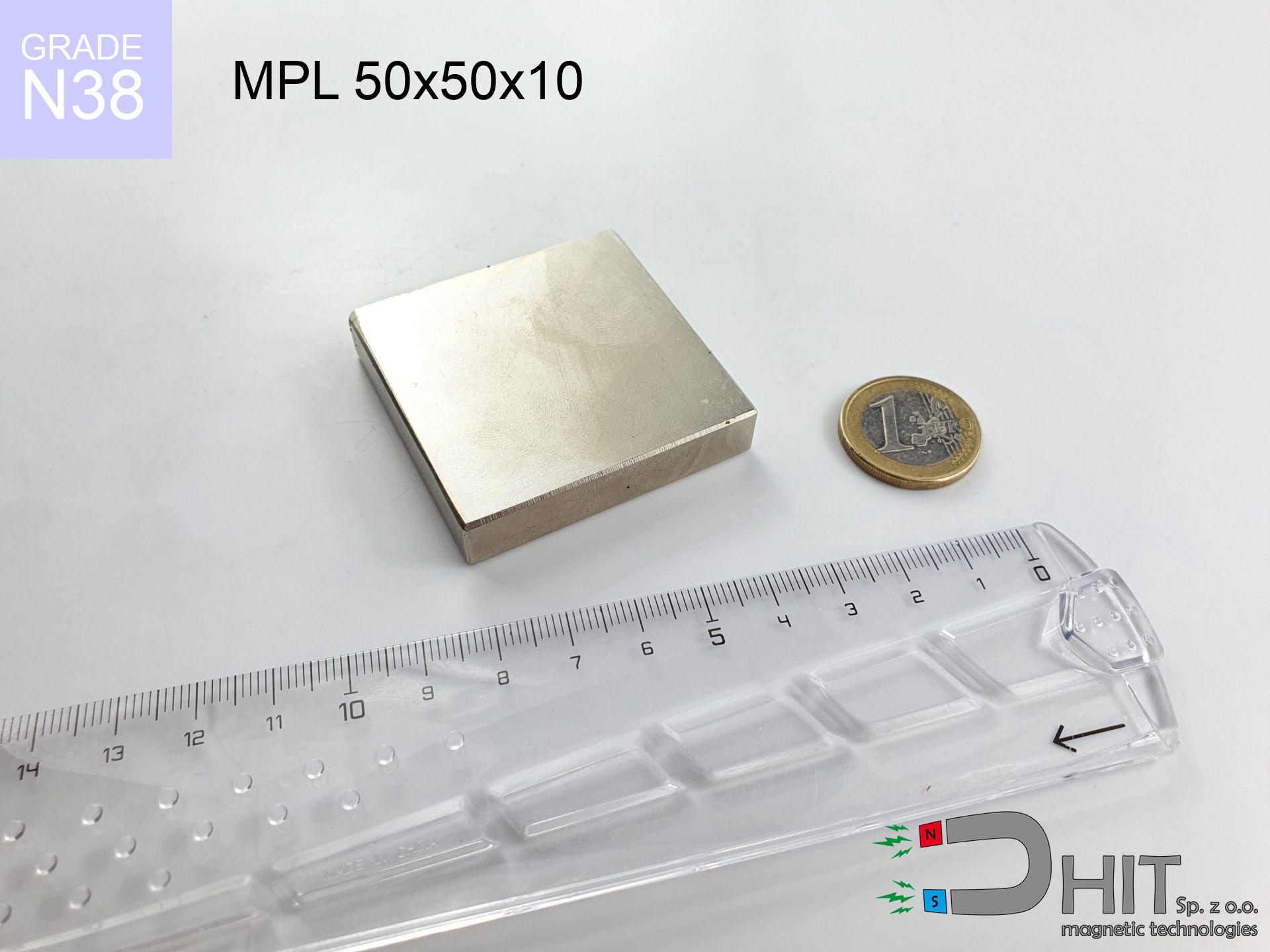

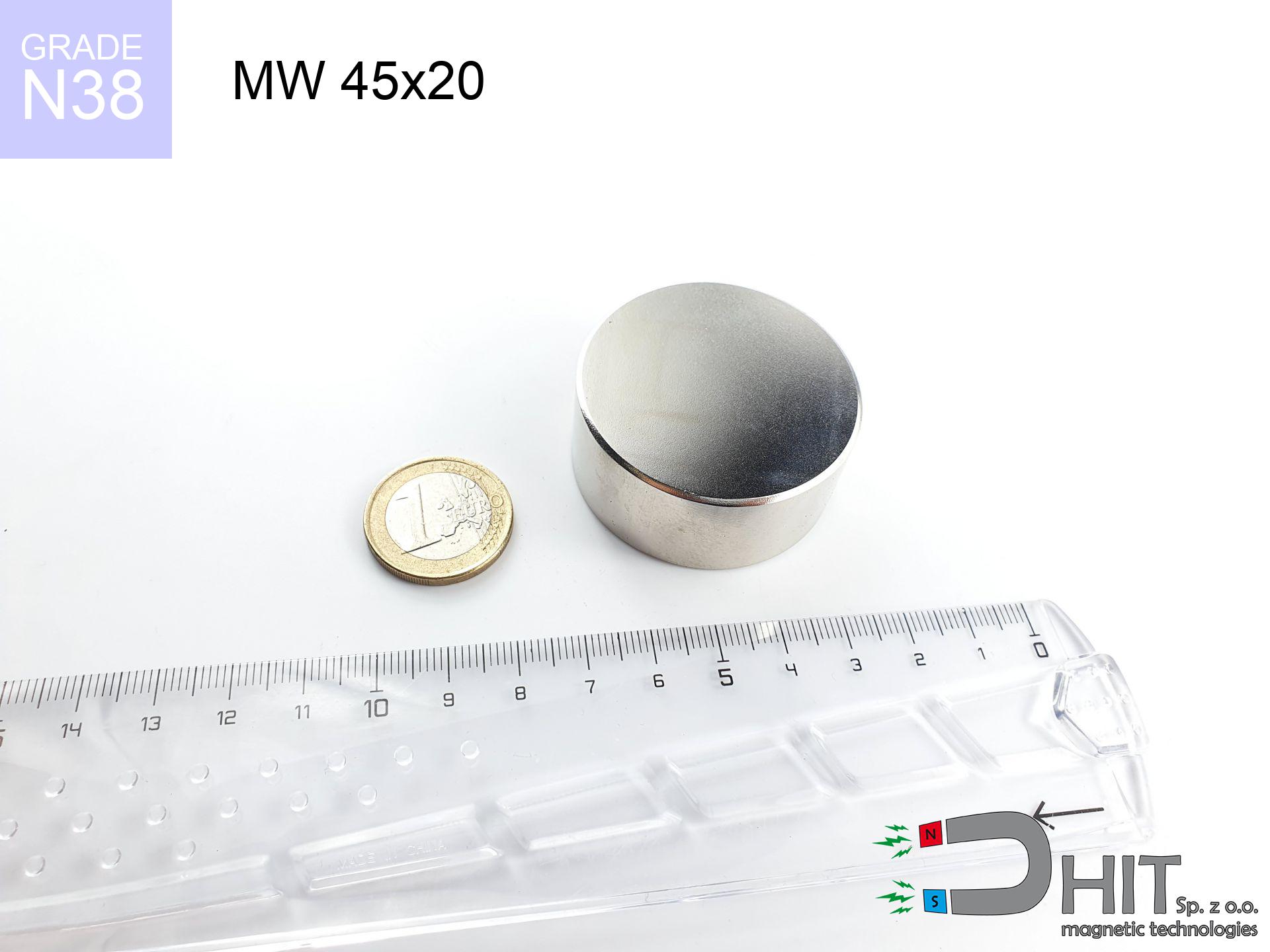

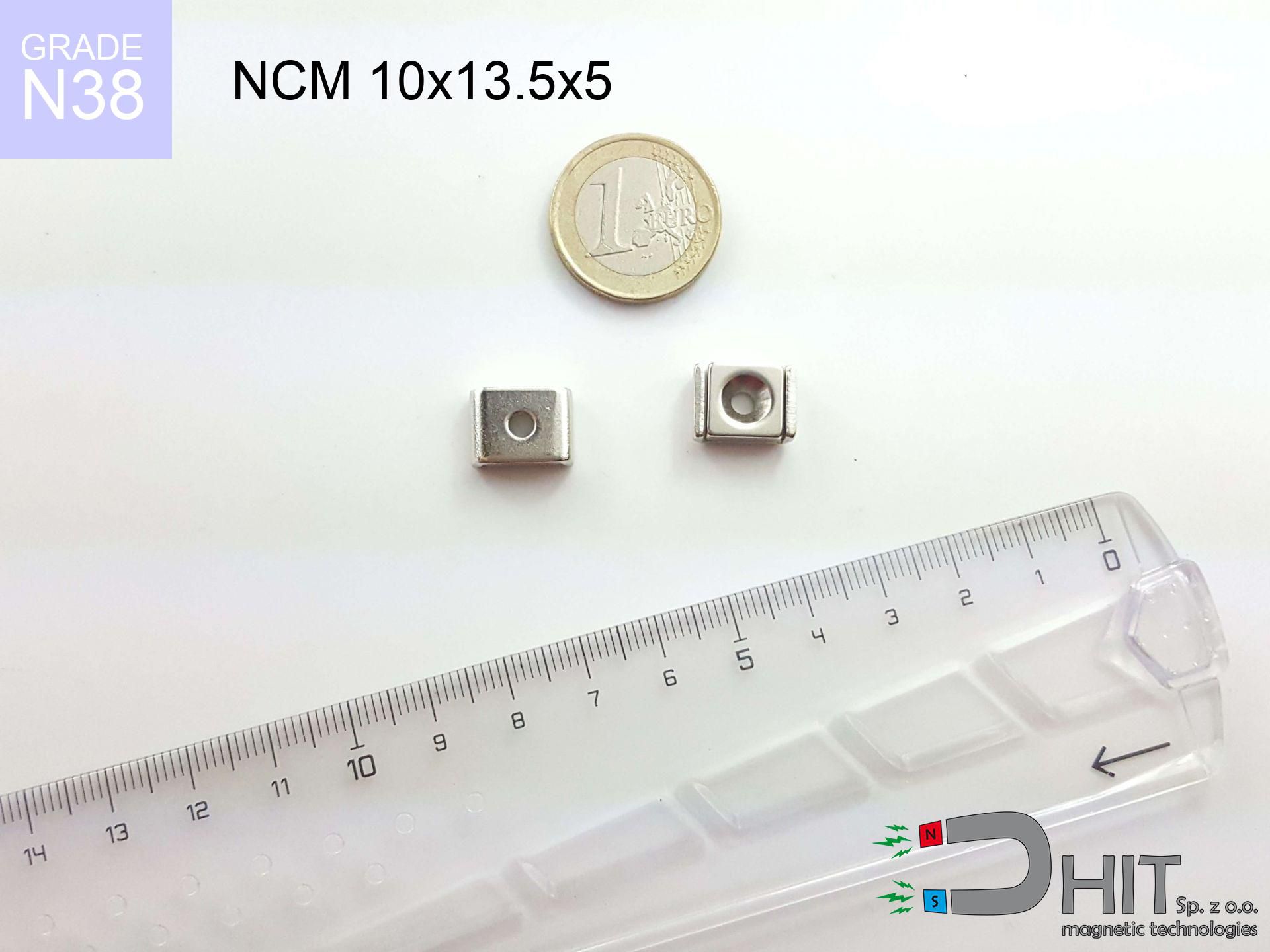

HH 42x8.8 [M6] / N38 - through hole magnetic holder

through hole magnetic holder

Catalog no 370484

GTIN/EAN: 5906301814948

Diameter Ø

42 mm [±1 mm]

Height

8.8 mm [±1 mm]

Weight

75.2 g

Magnetization Direction

↑ axial

Load capacity

55.00 kg / 539.37 N

Coating

[NiCuNi] Nickel

29.89 ZŁ with VAT / pcs + price for transport

24.30 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively send us a note by means of

request form

the contact page.

Strength and appearance of a neodymium magnet can be reviewed using our

force calculator.

Same-day shipping for orders placed before 14:00.

Technical data of the product - HH 42x8.8 [M6] / N38 - through hole magnetic holder

Specification / characteristics - HH 42x8.8 [M6] / N38 - through hole magnetic holder

| properties | values |

|---|---|

| Cat. no. | 370484 |

| GTIN/EAN | 5906301814948 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 42 mm [±1 mm] |

| Height | 8.8 mm [±1 mm] |

| Weight | 75.2 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 55.00 kg / 539.37 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more deals

Advantages and disadvantages of neodymium magnets.

Pros

- Their magnetic field is durable, and after approximately 10 years it drops only by ~1% (theoretically),

- Magnets perfectly defend themselves against loss of magnetization caused by external fields,

- The use of an elegant coating of noble metals (nickel, gold, silver) causes the element to look better,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to versatility in constructing and the ability to adapt to client solutions,

- Fundamental importance in innovative solutions – they serve a role in HDD drives, drive modules, precision medical tools, and other advanced devices.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in creating nuts and complicated shapes in magnets, we propose using a housing - magnetic holder.

- Health risk related to microscopic parts of magnets pose a threat, if swallowed, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these devices can be problematic in diagnostics medical after entering the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Detachment force of the magnet in optimal conditions – what contributes to it?

- with the contact of a yoke made of special test steel, guaranteeing maximum field concentration

- with a cross-section minimum 10 mm

- characterized by lack of roughness

- without any clearance between the magnet and steel

- under vertical force direction (90-degree angle)

- at room temperature

Impact of factors on magnetic holding capacity in practice

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – highest force is obtained only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is typically several times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of converting into lifting capacity.

- Plate material – low-carbon steel attracts best. Higher carbon content reduce magnetic properties and holding force.

- Smoothness – ideal contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature influence – high temperature reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the holding force is lower. Moreover, even a slight gap between the magnet and the plate decreases the holding force.

Safe handling of neodymium magnets

Precision electronics

Navigation devices and mobile phones are highly sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Beware of splinters

Neodymium magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets will cause them shattering into small pieces.

Crushing force

Large magnets can smash fingers instantly. Never put your hand betwixt two strong magnets.

This is not a toy

NdFeB magnets are not toys. Swallowing a few magnets can lead to them attracting across intestines, which constitutes a direct threat to life and necessitates immediate surgery.

Electronic devices

Intense magnetic fields can erase data on credit cards, HDDs, and storage devices. Maintain a gap of min. 10 cm.

Machining danger

Dust produced during grinding of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Heat sensitivity

Avoid heat. Neodymium magnets are sensitive to heat. If you need resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Warning for heart patients

Individuals with a ICD must maintain an large gap from magnets. The magnetic field can interfere with the operation of the implant.

Nickel allergy

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If skin irritation appears, immediately stop handling magnets and wear gloves.

Handling guide

Handle magnets consciously. Their powerful strength can shock even experienced users. Be vigilant and do not underestimate their power.

![Through-hole magnetic holder HH 42x8.8 [M6] / N38 Through-hole magnetic holder HH 42x8.8 [M6] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)

![BM 320x180x70 [4x M8] - magnetic beam BM 320x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-320x180x70-4x-m8-rar.jpg)