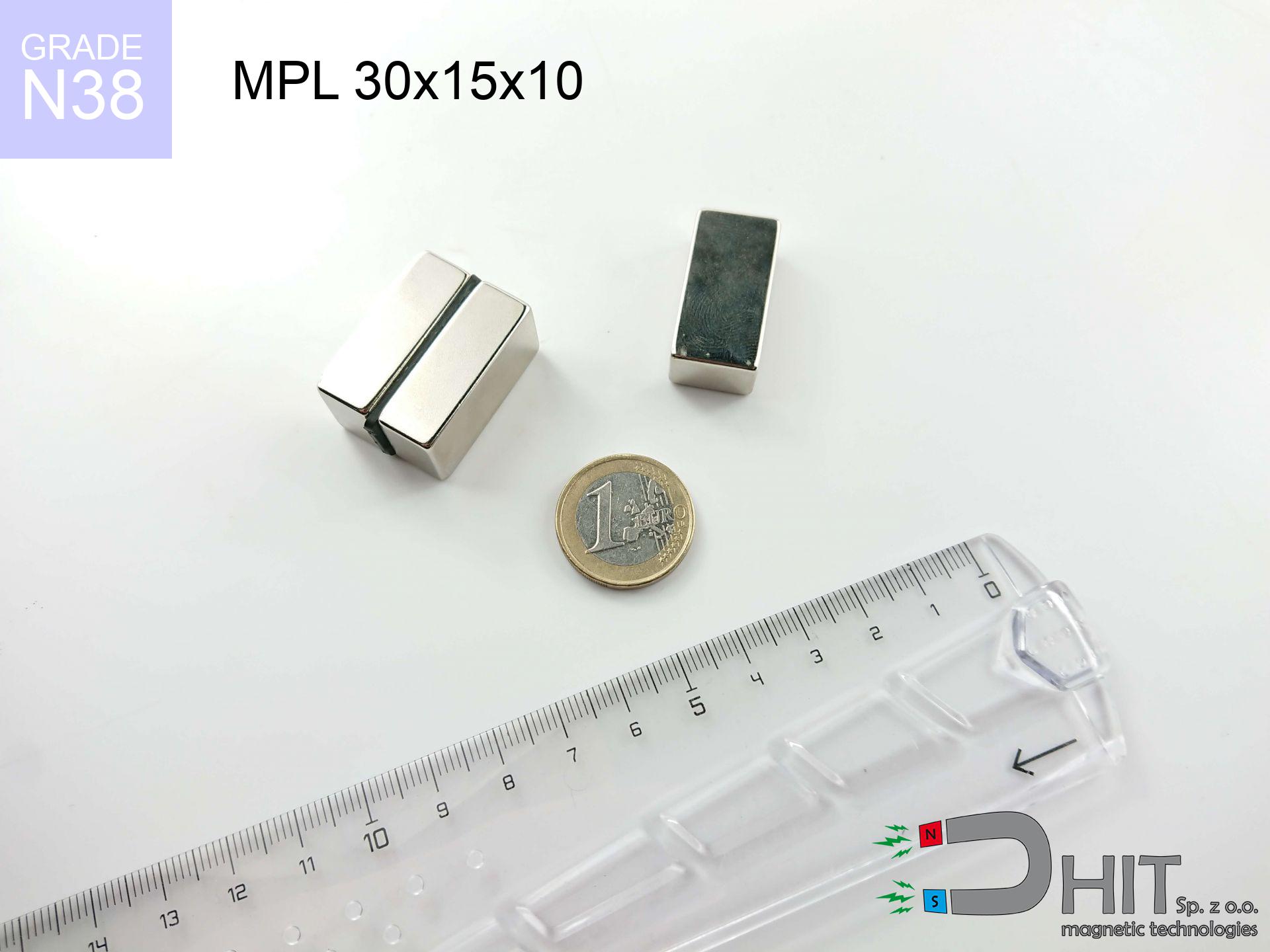

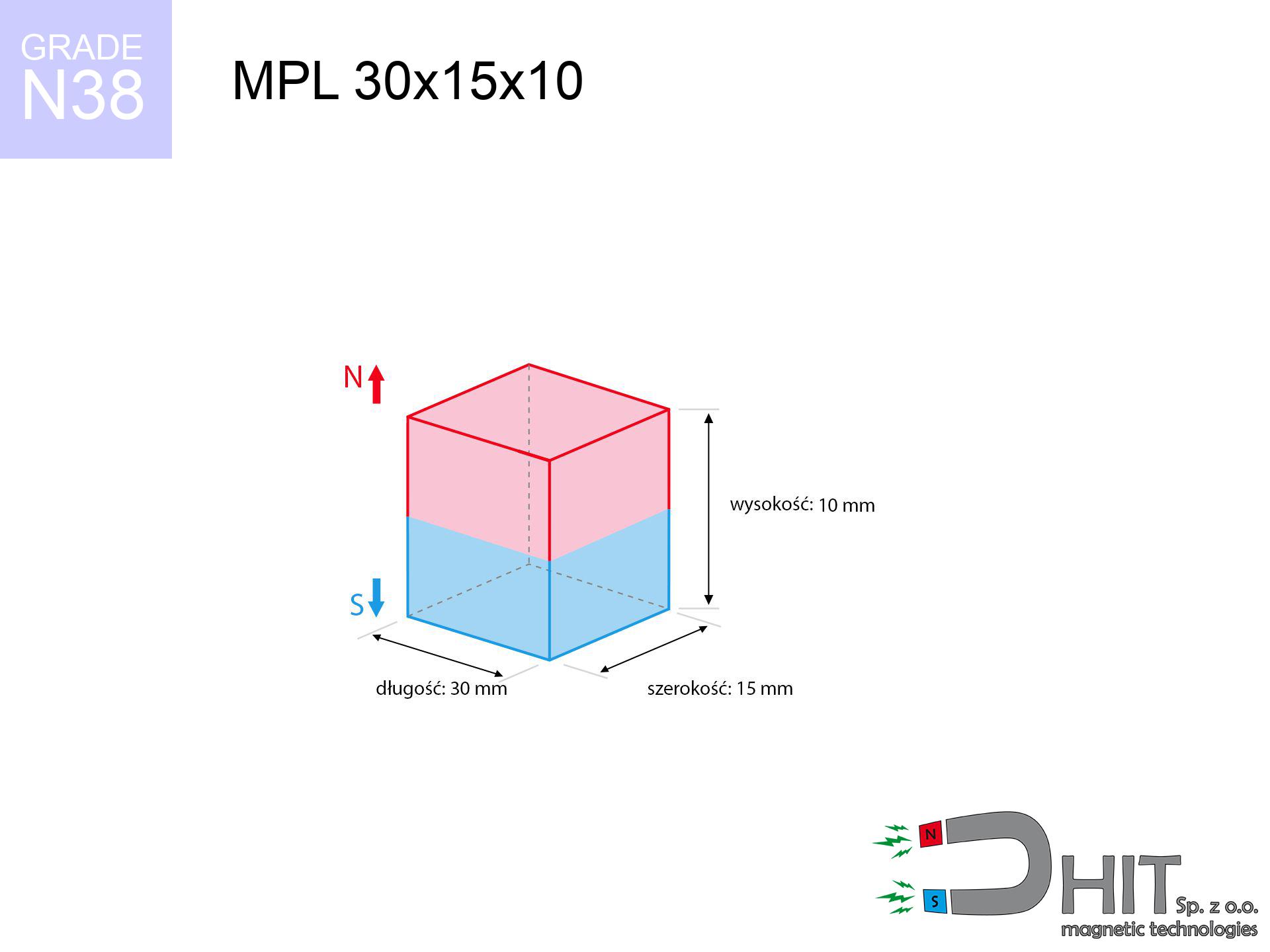

MPL 30x15x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020389

GTIN/EAN: 5906301811886

length

30 mm [±0,1 mm]

Width

15 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

33.75 g

Magnetization Direction

↑ axial

Load capacity

16.84 kg / 165.22 N

Magnetic Induction

413.45 mT / 4135 Gs

Coating

[NiCuNi] Nickel

24.48 ZŁ with VAT / pcs + price for transport

19.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or drop us a message using

contact form

the contact section.

Weight along with form of magnetic components can be verified using our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical of the product - MPL 30x15x10 / N38 - lamellar magnet

Specification / characteristics - MPL 30x15x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020389 |

| GTIN/EAN | 5906301811886 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 15 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 33.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 16.84 kg / 165.22 N |

| Magnetic Induction ~ ? | 413.45 mT / 4135 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - data

Presented values are the direct effect of a physical analysis. Results are based on algorithms for the class Nd2Fe14B. Operational performance may differ from theoretical values. Use these data as a preliminary roadmap for designers.

Table 1: Static pull force (force vs gap) - power drop

MPL 30x15x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4133 Gs

413.3 mT

|

16.84 kg / 37.13 pounds

16840.0 g / 165.2 N

|

critical level |

| 1 mm |

3754 Gs

375.4 mT

|

13.89 kg / 30.62 pounds

13889.5 g / 136.3 N

|

critical level |

| 2 mm |

3365 Gs

336.5 mT

|

11.16 kg / 24.60 pounds

11159.2 g / 109.5 N

|

critical level |

| 3 mm |

2988 Gs

298.8 mT

|

8.80 kg / 19.41 pounds

8803.6 g / 86.4 N

|

warning |

| 5 mm |

2321 Gs

232.1 mT

|

5.31 kg / 11.71 pounds

5309.9 g / 52.1 N

|

warning |

| 10 mm |

1225 Gs

122.5 mT

|

1.48 kg / 3.26 pounds

1480.1 g / 14.5 N

|

safe |

| 15 mm |

684 Gs

68.4 mT

|

0.46 kg / 1.02 pounds

461.6 g / 4.5 N

|

safe |

| 20 mm |

409 Gs

40.9 mT

|

0.16 kg / 0.36 pounds

164.8 g / 1.6 N

|

safe |

| 30 mm |

173 Gs

17.3 mT

|

0.03 kg / 0.07 pounds

29.6 g / 0.3 N

|

safe |

| 50 mm |

50 Gs

5.0 mT

|

0.00 kg / 0.01 pounds

2.4 g / 0.0 N

|

safe |

Table 2: Sliding capacity (wall)

MPL 30x15x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.37 kg / 7.43 pounds

3368.0 g / 33.0 N

|

| 1 mm | Stal (~0.2) |

2.78 kg / 6.12 pounds

2778.0 g / 27.3 N

|

| 2 mm | Stal (~0.2) |

2.23 kg / 4.92 pounds

2232.0 g / 21.9 N

|

| 3 mm | Stal (~0.2) |

1.76 kg / 3.88 pounds

1760.0 g / 17.3 N

|

| 5 mm | Stal (~0.2) |

1.06 kg / 2.34 pounds

1062.0 g / 10.4 N

|

| 10 mm | Stal (~0.2) |

0.30 kg / 0.65 pounds

296.0 g / 2.9 N

|

| 15 mm | Stal (~0.2) |

0.09 kg / 0.20 pounds

92.0 g / 0.9 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MPL 30x15x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.05 kg / 11.14 pounds

5052.0 g / 49.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.37 kg / 7.43 pounds

3368.0 g / 33.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.68 kg / 3.71 pounds

1684.0 g / 16.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

8.42 kg / 18.56 pounds

8420.0 g / 82.6 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 30x15x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.84 kg / 1.86 pounds

842.0 g / 8.3 N

|

| 1 mm |

|

2.11 kg / 4.64 pounds

2105.0 g / 20.7 N

|

| 2 mm |

|

4.21 kg / 9.28 pounds

4210.0 g / 41.3 N

|

| 3 mm |

|

6.31 kg / 13.92 pounds

6315.0 g / 62.0 N

|

| 5 mm |

|

10.53 kg / 23.20 pounds

10525.0 g / 103.3 N

|

| 10 mm |

|

16.84 kg / 37.13 pounds

16840.0 g / 165.2 N

|

| 11 mm |

|

16.84 kg / 37.13 pounds

16840.0 g / 165.2 N

|

| 12 mm |

|

16.84 kg / 37.13 pounds

16840.0 g / 165.2 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MPL 30x15x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

16.84 kg / 37.13 pounds

16840.0 g / 165.2 N

|

OK |

| 40 °C | -2.2% |

16.47 kg / 36.31 pounds

16469.5 g / 161.6 N

|

OK |

| 60 °C | -4.4% |

16.10 kg / 35.49 pounds

16099.0 g / 157.9 N

|

|

| 80 °C | -6.6% |

15.73 kg / 34.68 pounds

15728.6 g / 154.3 N

|

|

| 100 °C | -28.8% |

11.99 kg / 26.43 pounds

11990.1 g / 117.6 N

|

Table 6: Two magnets (repulsion) - field collision

MPL 30x15x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

47.39 kg / 104.48 pounds

5 357 Gs

|

7.11 kg / 15.67 pounds

7109 g / 69.7 N

|

N/A |

| 1 mm |

43.23 kg / 95.30 pounds

7 895 Gs

|

6.48 kg / 14.29 pounds

6484 g / 63.6 N

|

38.90 kg / 85.77 pounds

~0 Gs

|

| 2 mm |

39.09 kg / 86.17 pounds

7 507 Gs

|

5.86 kg / 12.93 pounds

5863 g / 57.5 N

|

35.18 kg / 77.56 pounds

~0 Gs

|

| 3 mm |

35.13 kg / 77.45 pounds

7 117 Gs

|

5.27 kg / 11.62 pounds

5270 g / 51.7 N

|

31.62 kg / 69.70 pounds

~0 Gs

|

| 5 mm |

27.95 kg / 61.61 pounds

6 348 Gs

|

4.19 kg / 9.24 pounds

4192 g / 41.1 N

|

25.15 kg / 55.45 pounds

~0 Gs

|

| 10 mm |

14.94 kg / 32.94 pounds

4 642 Gs

|

2.24 kg / 4.94 pounds

2242 g / 22.0 N

|

13.45 kg / 29.65 pounds

~0 Gs

|

| 20 mm |

4.17 kg / 9.18 pounds

2 451 Gs

|

0.62 kg / 1.38 pounds

625 g / 6.1 N

|

3.75 kg / 8.26 pounds

~0 Gs

|

| 50 mm |

0.19 kg / 0.41 pounds

519 Gs

|

0.03 kg / 0.06 pounds

28 g / 0.3 N

|

0.17 kg / 0.37 pounds

~0 Gs

|

| 60 mm |

0.08 kg / 0.18 pounds

347 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

| 70 mm |

0.04 kg / 0.09 pounds

242 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.04 kg / 0.08 pounds

~0 Gs

|

| 80 mm |

0.02 kg / 0.05 pounds

175 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.04 pounds

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 pounds

130 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.02 pounds

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 pounds

99 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 30x15x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 12.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 7.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 30x15x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.73 km/h

(6.59 m/s)

|

0.73 J | |

| 30 mm |

39.06 km/h

(10.85 m/s)

|

1.99 J | |

| 50 mm |

50.38 km/h

(13.99 m/s)

|

3.30 J | |

| 100 mm |

71.24 km/h

(19.79 m/s)

|

6.61 J |

Table 9: Surface protection spec

MPL 30x15x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 30x15x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 18 390 Mx | 183.9 µWb |

| Pc Coefficient | 0.52 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 30x15x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 16.84 kg | Standard |

| Water (riverbed) |

19.28 kg

(+2.44 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.52

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

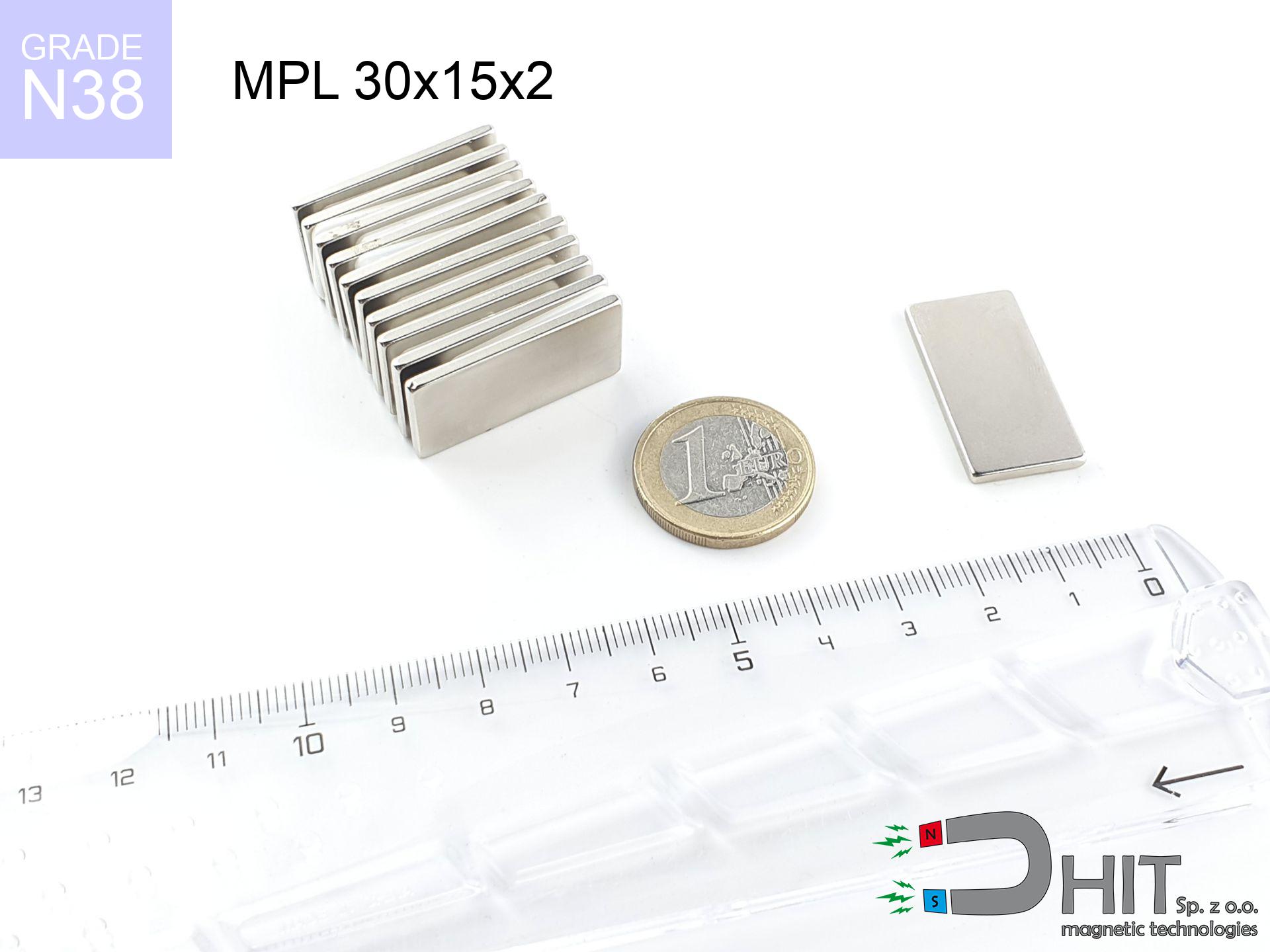

See also offers

Pros as well as cons of neodymium magnets.

Advantages

- They have stable power, and over nearly ten years their attraction force decreases symbolically – ~1% (according to theory),

- They retain their magnetic properties even under close interference source,

- In other words, due to the glossy surface of nickel, the element gains a professional look,

- The surface of neodymium magnets generates a powerful magnetic field – this is one of their assets,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to the option of accurate shaping and adaptation to custom requirements, magnetic components can be modeled in a broad palette of shapes and sizes, which amplifies use scope,

- Huge importance in electronics industry – they are utilized in data components, drive modules, precision medical tools, and modern systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in small dimensions, which allows their use in compact constructions

Cons

- At strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Limited possibility of producing nuts in the magnet and complicated shapes - recommended is a housing - magnetic holder.

- Possible danger to health – tiny shards of magnets pose a threat, in case of ingestion, which is particularly important in the context of child safety. Furthermore, small components of these products are able to be problematic in diagnostics medical after entering the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what affects it?

- on a base made of mild steel, effectively closing the magnetic field

- possessing a thickness of at least 10 mm to avoid saturation

- with a plane free of scratches

- without any air gap between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- at conditions approx. 20°C

Magnet lifting force in use – key factors

- Distance – existence of foreign body (rust, dirt, air) interrupts the magnetic circuit, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Force direction – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Substrate thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Material composition – not every steel attracts identically. High carbon content weaken the interaction with the magnet.

- Surface finish – full contact is obtained only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Temperature – heating the magnet causes a temporary drop of force. Check the maximum operating temperature for a given model.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under shearing force the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the holding force.

Warnings

Precision electronics

Navigation devices and mobile phones are extremely susceptible to magnetism. Close proximity with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Finger safety

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, crushing anything in their path. Be careful!

Fire warning

Fire hazard: Neodymium dust is explosive. Do not process magnets in home conditions as this may cause fire.

Cards and drives

Avoid bringing magnets near a wallet, laptop, or TV. The magnetism can destroy these devices and erase data from cards.

Sensitization to coating

It is widely known that the nickel plating (the usual finish) is a common allergen. If your skin reacts to metals, avoid direct skin contact or opt for coated magnets.

Product not for children

Product intended for adults. Small elements can be swallowed, leading to intestinal necrosis. Store away from children and animals.

Heat sensitivity

Monitor thermal conditions. Heating the magnet above 80 degrees Celsius will destroy its magnetic structure and pulling force.

Medical implants

Medical warning: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Powerful field

Handle with care. Rare earth magnets attract from a distance and connect with huge force, often quicker than you can move away.

Beware of splinters

Protect your eyes. Magnets can explode upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.