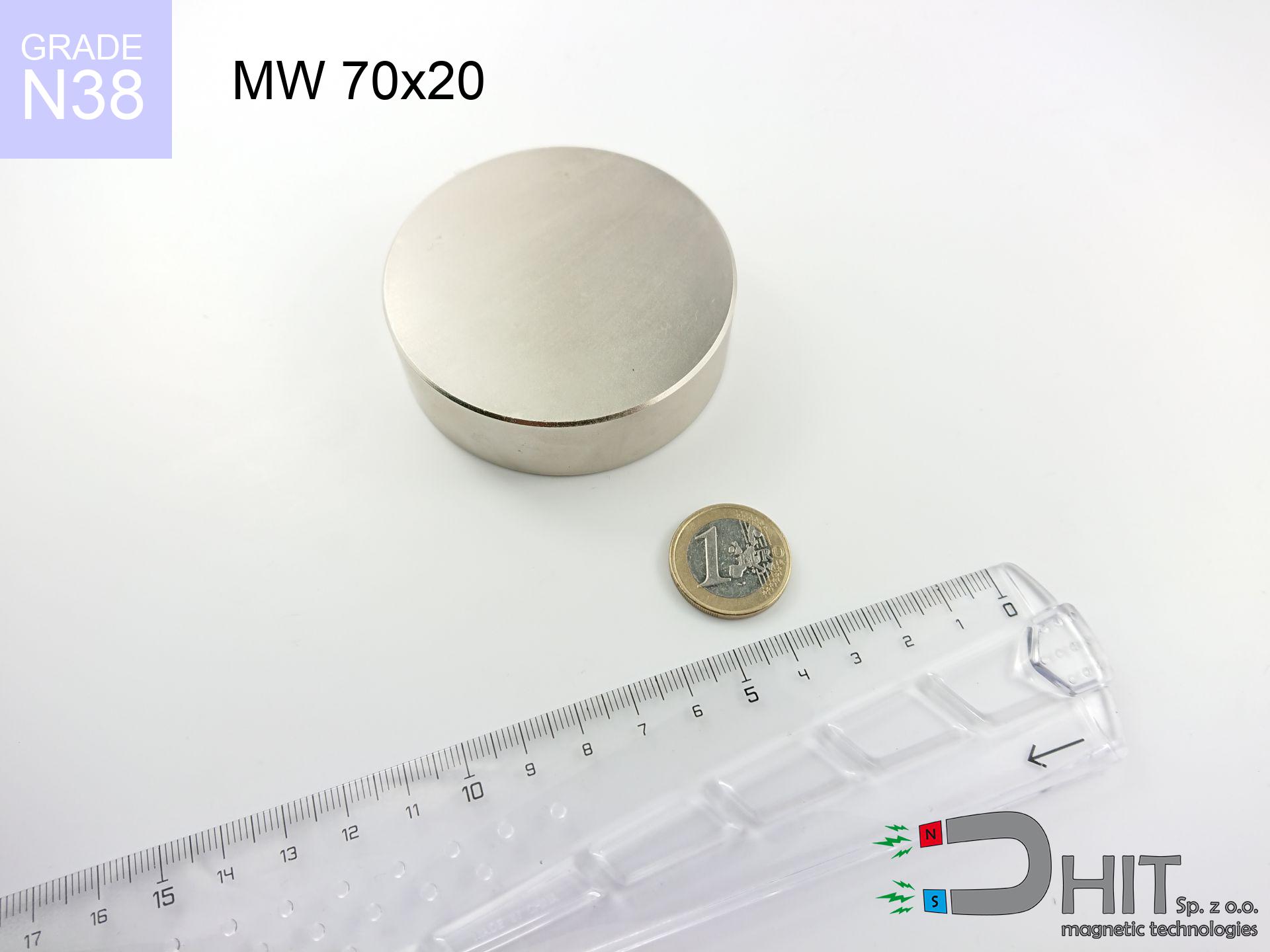

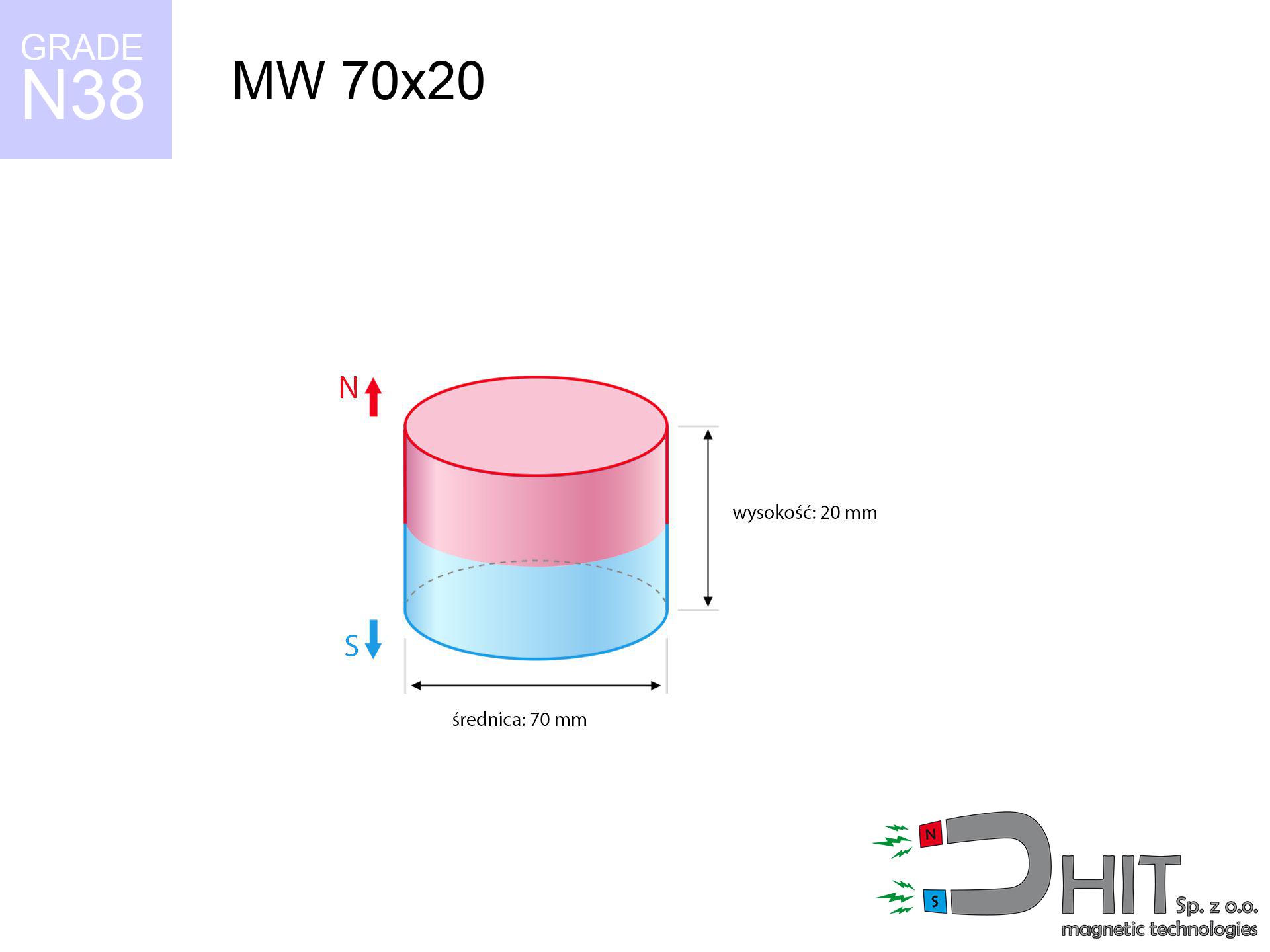

MW 70x20 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010095

GTIN/EAN: 5906301810940

Diameter Ø

70 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

577.27 g

Magnetization Direction

↑ axial

Load capacity

99.83 kg / 979.31 N

Magnetic Induction

307.57 mT / 3076 Gs

Coating

[NiCuNi] Nickel

239.85 ZŁ with VAT / pcs + price for transport

195.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

otherwise contact us using

inquiry form

the contact page.

Weight along with shape of a neodymium magnet can be checked using our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Physical properties - MW 70x20 / N38 - cylindrical magnet

Specification / characteristics - MW 70x20 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010095 |

| GTIN/EAN | 5906301810940 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 70 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 577.27 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 99.83 kg / 979.31 N |

| Magnetic Induction ~ ? | 307.57 mT / 3076 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - data

Presented information constitute the outcome of a physical calculation. Results rely on algorithms for the material Nd2Fe14B. Real-world conditions may deviate from the simulation results. Please consider these calculations as a preliminary roadmap for designers.

Table 1: Static force (pull vs distance) - characteristics

MW 70x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3075 Gs

307.5 mT

|

99.83 kg / 220.09 LBS

99830.0 g / 979.3 N

|

crushing |

| 1 mm |

3013 Gs

301.3 mT

|

95.80 kg / 211.21 LBS

95804.4 g / 939.8 N

|

crushing |

| 2 mm |

2946 Gs

294.6 mT

|

91.59 kg / 201.92 LBS

91587.7 g / 898.5 N

|

crushing |

| 3 mm |

2875 Gs

287.5 mT

|

87.27 kg / 192.39 LBS

87266.0 g / 856.1 N

|

crushing |

| 5 mm |

2727 Gs

272.7 mT

|

78.48 kg / 173.02 LBS

78482.2 g / 769.9 N

|

crushing |

| 10 mm |

2332 Gs

233.2 mT

|

57.38 kg / 126.50 LBS

57380.6 g / 562.9 N

|

crushing |

| 15 mm |

1942 Gs

194.2 mT

|

39.80 kg / 87.73 LBS

39795.7 g / 390.4 N

|

crushing |

| 20 mm |

1590 Gs

159.0 mT

|

26.68 kg / 58.82 LBS

26680.3 g / 261.7 N

|

crushing |

| 30 mm |

1044 Gs

104.4 mT

|

11.51 kg / 25.38 LBS

11511.2 g / 112.9 N

|

crushing |

| 50 mm |

466 Gs

46.6 mT

|

2.29 kg / 5.06 LBS

2294.1 g / 22.5 N

|

strong |

Table 2: Shear force (wall)

MW 70x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

19.97 kg / 44.02 LBS

19966.0 g / 195.9 N

|

| 1 mm | Stal (~0.2) |

19.16 kg / 42.24 LBS

19160.0 g / 188.0 N

|

| 2 mm | Stal (~0.2) |

18.32 kg / 40.38 LBS

18318.0 g / 179.7 N

|

| 3 mm | Stal (~0.2) |

17.45 kg / 38.48 LBS

17454.0 g / 171.2 N

|

| 5 mm | Stal (~0.2) |

15.70 kg / 34.60 LBS

15696.0 g / 154.0 N

|

| 10 mm | Stal (~0.2) |

11.48 kg / 25.30 LBS

11476.0 g / 112.6 N

|

| 15 mm | Stal (~0.2) |

7.96 kg / 17.55 LBS

7960.0 g / 78.1 N

|

| 20 mm | Stal (~0.2) |

5.34 kg / 11.76 LBS

5336.0 g / 52.3 N

|

| 30 mm | Stal (~0.2) |

2.30 kg / 5.08 LBS

2302.0 g / 22.6 N

|

| 50 mm | Stal (~0.2) |

0.46 kg / 1.01 LBS

458.0 g / 4.5 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 70x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

29.95 kg / 66.03 LBS

29949.0 g / 293.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

19.97 kg / 44.02 LBS

19966.0 g / 195.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

9.98 kg / 22.01 LBS

9983.0 g / 97.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

49.92 kg / 110.04 LBS

49915.0 g / 489.7 N

|

Table 4: Material efficiency (saturation) - power losses

MW 70x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

3.33 kg / 7.34 LBS

3327.7 g / 32.6 N

|

| 1 mm |

|

8.32 kg / 18.34 LBS

8319.2 g / 81.6 N

|

| 2 mm |

|

16.64 kg / 36.68 LBS

16638.3 g / 163.2 N

|

| 3 mm |

|

24.96 kg / 55.02 LBS

24957.5 g / 244.8 N

|

| 5 mm |

|

41.60 kg / 91.70 LBS

41595.8 g / 408.1 N

|

| 10 mm |

|

83.19 kg / 183.41 LBS

83191.7 g / 816.1 N

|

| 11 mm |

|

91.51 kg / 201.75 LBS

91510.8 g / 897.7 N

|

| 12 mm |

|

99.83 kg / 220.09 LBS

99830.0 g / 979.3 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 70x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

99.83 kg / 220.09 LBS

99830.0 g / 979.3 N

|

OK |

| 40 °C | -2.2% |

97.63 kg / 215.25 LBS

97633.7 g / 957.8 N

|

OK |

| 60 °C | -4.4% |

95.44 kg / 210.40 LBS

95437.5 g / 936.2 N

|

|

| 80 °C | -6.6% |

93.24 kg / 205.56 LBS

93241.2 g / 914.7 N

|

|

| 100 °C | -28.8% |

71.08 kg / 156.70 LBS

71079.0 g / 697.3 N

|

Table 6: Two magnets (attraction) - field range

MW 70x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

224.41 kg / 494.73 LBS

4 665 Gs

|

33.66 kg / 74.21 LBS

33661 g / 330.2 N

|

N/A |

| 1 mm |

219.98 kg / 484.97 LBS

6 090 Gs

|

33.00 kg / 72.74 LBS

32997 g / 323.7 N

|

197.98 kg / 436.47 LBS

~0 Gs

|

| 2 mm |

215.36 kg / 474.78 LBS

6 026 Gs

|

32.30 kg / 71.22 LBS

32304 g / 316.9 N

|

193.82 kg / 427.31 LBS

~0 Gs

|

| 3 mm |

210.66 kg / 464.41 LBS

5 959 Gs

|

31.60 kg / 69.66 LBS

31598 g / 310.0 N

|

189.59 kg / 417.97 LBS

~0 Gs

|

| 5 mm |

201.05 kg / 443.23 LBS

5 822 Gs

|

30.16 kg / 66.48 LBS

30157 g / 295.8 N

|

180.94 kg / 398.91 LBS

~0 Gs

|

| 10 mm |

176.42 kg / 388.94 LBS

5 454 Gs

|

26.46 kg / 58.34 LBS

26463 g / 259.6 N

|

158.78 kg / 350.05 LBS

~0 Gs

|

| 20 mm |

128.99 kg / 284.36 LBS

4 663 Gs

|

19.35 kg / 42.65 LBS

19348 g / 189.8 N

|

116.09 kg / 255.93 LBS

~0 Gs

|

| 50 mm |

39.50 kg / 87.08 LBS

2 581 Gs

|

5.93 kg / 13.06 LBS

5925 g / 58.1 N

|

35.55 kg / 78.38 LBS

~0 Gs

|

| 60 mm |

25.88 kg / 57.05 LBS

2 089 Gs

|

3.88 kg / 8.56 LBS

3881 g / 38.1 N

|

23.29 kg / 51.34 LBS

~0 Gs

|

| 70 mm |

17.01 kg / 37.49 LBS

1 693 Gs

|

2.55 kg / 5.62 LBS

2551 g / 25.0 N

|

15.31 kg / 33.74 LBS

~0 Gs

|

| 80 mm |

11.28 kg / 24.86 LBS

1 379 Gs

|

1.69 kg / 3.73 LBS

1692 g / 16.6 N

|

10.15 kg / 22.38 LBS

~0 Gs

|

| 90 mm |

7.57 kg / 16.69 LBS

1 130 Gs

|

1.14 kg / 2.50 LBS

1136 g / 11.1 N

|

6.81 kg / 15.02 LBS

~0 Gs

|

| 100 mm |

5.16 kg / 11.37 LBS

932 Gs

|

0.77 kg / 1.71 LBS

774 g / 7.6 N

|

4.64 kg / 10.23 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 70x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 30.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 24.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 18.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 14.5 cm |

| Car key | 50 Gs (5.0 mT) | 13.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 70x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.39 km/h

(4.83 m/s)

|

6.73 J | |

| 30 mm |

24.57 km/h

(6.83 m/s)

|

13.45 J | |

| 50 mm |

30.08 km/h

(8.36 m/s)

|

20.15 J | |

| 100 mm |

41.97 km/h

(11.66 m/s)

|

39.23 J |

Table 9: Surface protection spec

MW 70x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 70x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 128 363 Mx | 1283.6 µWb |

| Pc Coefficient | 0.39 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 70x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 99.83 kg | Standard |

| Water (riverbed) |

114.31 kg

(+14.48 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds only a fraction of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.39

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Strengths and weaknesses of neodymium magnets.

Advantages

- They have constant strength, and over around ten years their performance decreases symbolically – ~1% (according to theory),

- They possess excellent resistance to weakening of magnetic properties when exposed to external magnetic sources,

- Thanks to the reflective finish, the surface of Ni-Cu-Ni, gold, or silver gives an modern appearance,

- Magnetic induction on the surface of the magnet is maximum,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to freedom in forming and the ability to adapt to complex applications,

- Fundamental importance in modern industrial fields – they are utilized in HDD drives, electric motors, advanced medical instruments, also industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- We recommend cover - magnetic mount, due to difficulties in realizing threads inside the magnet and complex shapes.

- Health risk related to microscopic parts of magnets pose a threat, in case of ingestion, which becomes key in the context of child safety. Furthermore, tiny parts of these magnets are able to be problematic in diagnostics medical after entering the body.

- With large orders the cost of neodymium magnets is a challenge,

Lifting parameters

Detachment force of the magnet in optimal conditions – what contributes to it?

- on a base made of structural steel, optimally conducting the magnetic flux

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ground touching surface

- under conditions of ideal adhesion (metal-to-metal)

- under perpendicular force vector (90-degree angle)

- at conditions approx. 20°C

Practical lifting capacity: influencing factors

- Distance (betwixt the magnet and the metal), as even a very small clearance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Load vector – highest force is reached only during pulling at a 90° angle. The force required to slide of the magnet along the plate is typically several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick plate does not close the flux, causing part of the power to be lost into the air.

- Material type – the best choice is high-permeability steel. Hardened steels may have worse magnetic properties.

- Base smoothness – the more even the plate, the larger the contact zone and stronger the hold. Roughness acts like micro-gaps.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and in frost gain strength (up to a certain limit).

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the load capacity is reduced by as much as 75%. In addition, even a small distance between the magnet’s surface and the plate reduces the holding force.

H&S for magnets

Nickel allergy

A percentage of the population have a contact allergy to nickel, which is the standard coating for NdFeB magnets. Frequent touching may cause an allergic reaction. We recommend wear safety gloves.

Permanent damage

Monitor thermal conditions. Exposing the magnet to high heat will destroy its properties and strength.

Do not give to children

Product intended for adults. Small elements can be swallowed, causing intestinal necrosis. Keep out of reach of kids and pets.

Conscious usage

Before starting, read the rules. Sudden snapping can break the magnet or hurt your hand. Be predictive.

Phone sensors

Be aware: neodymium magnets produce a field that confuses precision electronics. Keep a separation from your phone, device, and navigation systems.

Dust is flammable

Machining of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Safe distance

Device Safety: Strong magnets can ruin data carriers and delicate electronics (heart implants, medical aids, mechanical watches).

Material brittleness

Despite metallic appearance, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Physical harm

Large magnets can crush fingers in a fraction of a second. Under no circumstances put your hand between two attracting surfaces.

Warning for heart patients

Individuals with a pacemaker should maintain an large gap from magnets. The magnetism can interfere with the operation of the life-saving device.

![UMGW 75x33x18 [M10] GW / N38 - magnetic holder internal thread UMGW 75x33x18 [M10] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/umgw-75x33x18-m10-gw-cak.jpg)

![SM 32x325 [2xM8] / N52 - magnetic separator SM 32x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-xec.jpg)