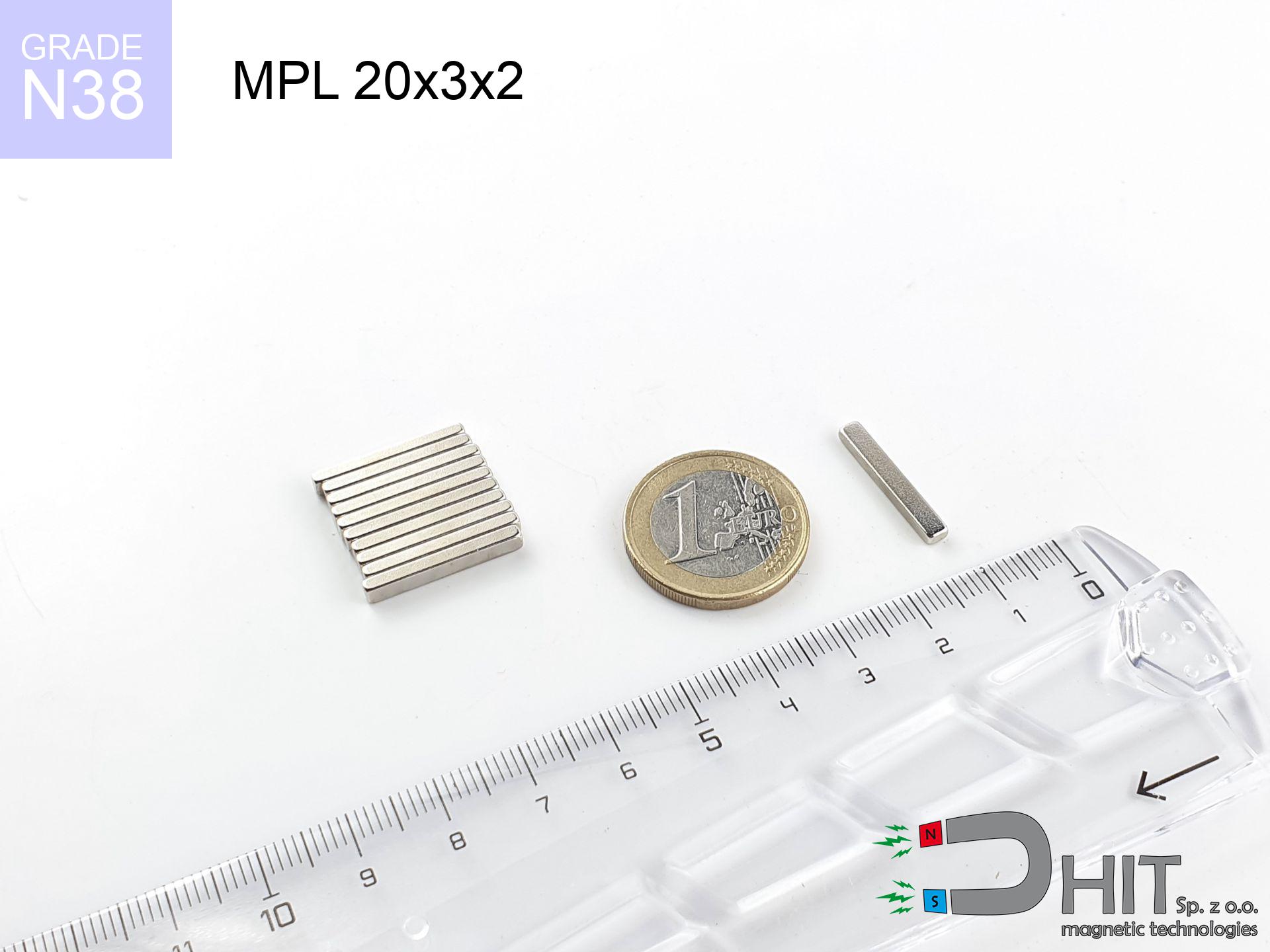

MPL 20x3x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020130

GTIN/EAN: 5906301811367

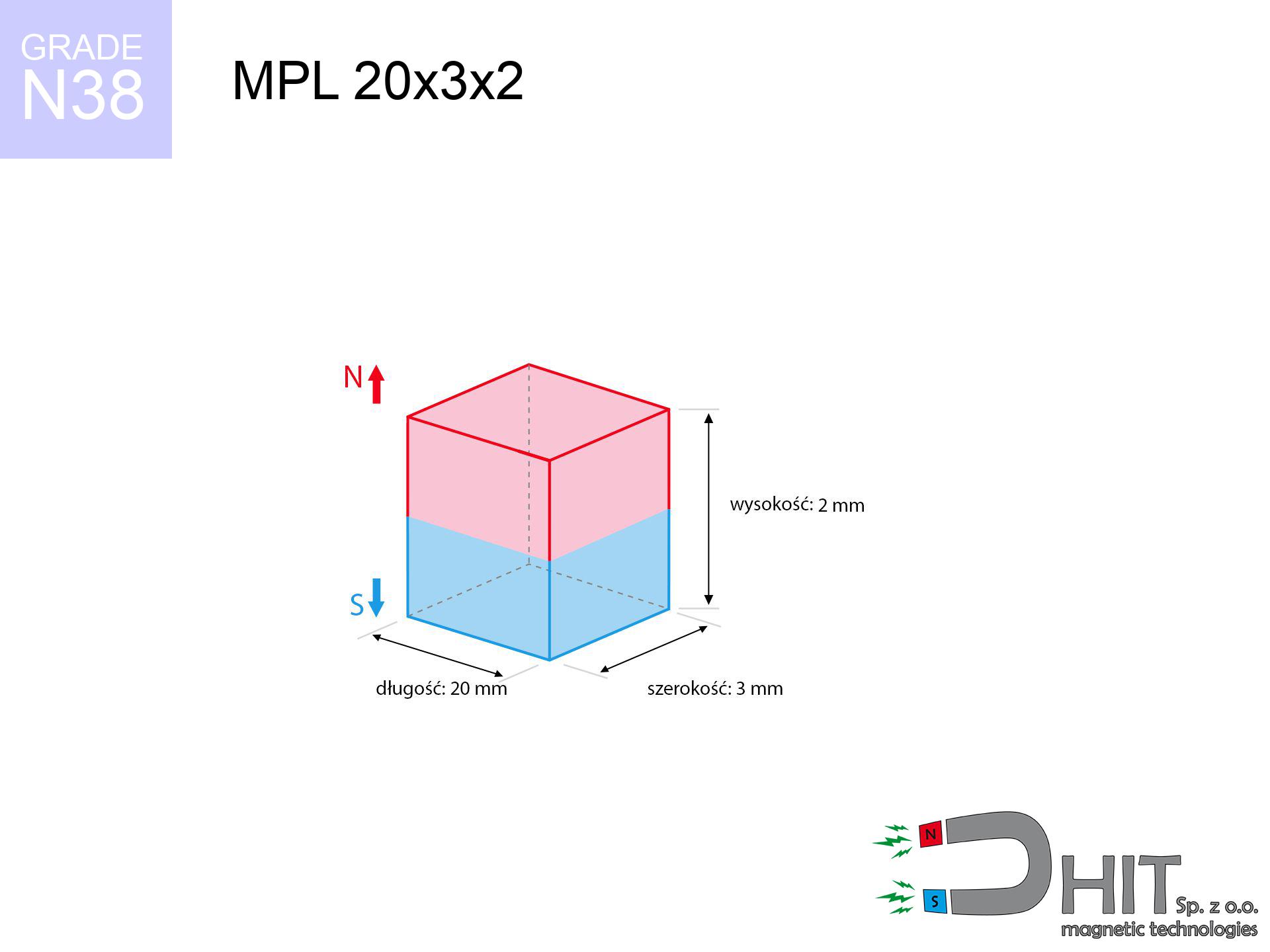

length

20 mm [±0,1 mm]

Width

3 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.9 g

Magnetization Direction

↑ axial

Load capacity

2.33 kg / 22.90 N

Magnetic Induction

370.68 mT / 3707 Gs

Coating

[NiCuNi] Nickel

0.394 ZŁ with VAT / pcs + price for transport

0.320 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise send us a note by means of

form

the contact section.

Strength as well as shape of a magnet can be tested on our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical details - MPL 20x3x2 / N38 - lamellar magnet

Specification / characteristics - MPL 20x3x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020130 |

| GTIN/EAN | 5906301811367 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 3 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.9 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.33 kg / 22.90 N |

| Magnetic Induction ~ ? | 370.68 mT / 3707 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - technical parameters

Presented values constitute the result of a physical analysis. Results were calculated on models for the class Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Use these data as a reference point when designing systems.

Table 1: Static force (pull vs gap) - characteristics

MPL 20x3x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3700 Gs

370.0 mT

|

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

warning |

| 1 mm |

2103 Gs

210.3 mT

|

0.75 kg / 1.66 pounds

752.3 g / 7.4 N

|

weak grip |

| 2 mm |

1172 Gs

117.2 mT

|

0.23 kg / 0.52 pounds

233.7 g / 2.3 N

|

weak grip |

| 3 mm |

721 Gs

72.1 mT

|

0.09 kg / 0.20 pounds

88.5 g / 0.9 N

|

weak grip |

| 5 mm |

345 Gs

34.5 mT

|

0.02 kg / 0.04 pounds

20.3 g / 0.2 N

|

weak grip |

| 10 mm |

101 Gs

10.1 mT

|

0.00 kg / 0.00 pounds

1.7 g / 0.0 N

|

weak grip |

| 15 mm |

42 Gs

4.2 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

weak grip |

| 20 mm |

21 Gs

2.1 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

weak grip |

| 30 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

Table 2: Slippage load (wall)

MPL 20x3x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.47 kg / 1.03 pounds

466.0 g / 4.6 N

|

| 1 mm | Stal (~0.2) |

0.15 kg / 0.33 pounds

150.0 g / 1.5 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.10 pounds

46.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

18.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 20x3x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.70 kg / 1.54 pounds

699.0 g / 6.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.47 kg / 1.03 pounds

466.0 g / 4.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.23 kg / 0.51 pounds

233.0 g / 2.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.17 kg / 2.57 pounds

1165.0 g / 11.4 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 20x3x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.23 kg / 0.51 pounds

233.0 g / 2.3 N

|

| 1 mm |

|

0.58 kg / 1.28 pounds

582.5 g / 5.7 N

|

| 2 mm |

|

1.17 kg / 2.57 pounds

1165.0 g / 11.4 N

|

| 3 mm |

|

1.75 kg / 3.85 pounds

1747.5 g / 17.1 N

|

| 5 mm |

|

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

| 10 mm |

|

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

| 11 mm |

|

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

| 12 mm |

|

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

Table 5: Thermal stability (stability) - resistance threshold

MPL 20x3x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.33 kg / 5.14 pounds

2330.0 g / 22.9 N

|

OK |

| 40 °C | -2.2% |

2.28 kg / 5.02 pounds

2278.7 g / 22.4 N

|

OK |

| 60 °C | -4.4% |

2.23 kg / 4.91 pounds

2227.5 g / 21.9 N

|

|

| 80 °C | -6.6% |

2.18 kg / 4.80 pounds

2176.2 g / 21.3 N

|

|

| 100 °C | -28.8% |

1.66 kg / 3.66 pounds

1659.0 g / 16.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 20x3x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.06 kg / 11.17 pounds

4 866 Gs

|

0.76 kg / 1.67 pounds

760 g / 7.5 N

|

N/A |

| 1 mm |

3.01 kg / 6.64 pounds

5 705 Gs

|

0.45 kg / 1.00 pounds

452 g / 4.4 N

|

2.71 kg / 5.97 pounds

~0 Gs

|

| 2 mm |

1.64 kg / 3.61 pounds

4 205 Gs

|

0.25 kg / 0.54 pounds

245 g / 2.4 N

|

1.47 kg / 3.24 pounds

~0 Gs

|

| 3 mm |

0.89 kg / 1.97 pounds

3 106 Gs

|

0.13 kg / 0.29 pounds

134 g / 1.3 N

|

0.80 kg / 1.77 pounds

~0 Gs

|

| 5 mm |

0.31 kg / 0.67 pounds

1 816 Gs

|

0.05 kg / 0.10 pounds

46 g / 0.4 N

|

0.27 kg / 0.61 pounds

~0 Gs

|

| 10 mm |

0.04 kg / 0.10 pounds

690 Gs

|

0.01 kg / 0.01 pounds

7 g / 0.1 N

|

0.04 kg / 0.09 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 pounds

202 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

24 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

14 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

9 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

6 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MPL 20x3x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 20x3x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

51.34 km/h

(14.26 m/s)

|

0.09 J | |

| 30 mm |

88.88 km/h

(24.69 m/s)

|

0.27 J | |

| 50 mm |

114.74 km/h

(31.87 m/s)

|

0.46 J | |

| 100 mm |

162.27 km/h

(45.08 m/s)

|

0.91 J |

Table 9: Corrosion resistance

MPL 20x3x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 20x3x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 748 Mx | 17.5 µWb |

| Pc Coefficient | 0.32 | Low (Flat) |

Table 11: Submerged application

MPL 20x3x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.33 kg | Standard |

| Water (riverbed) |

2.67 kg

(+0.34 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet holds merely approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) severely weakens the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.32

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Advantages and disadvantages of rare earth magnets.

Advantages

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (according to literature),

- Neodymium magnets are distinguished by highly resistant to loss of magnetic properties caused by external interference,

- By covering with a reflective layer of gold, the element has an modern look,

- Magnetic induction on the top side of the magnet is very high,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in designing and the capacity to customize to client solutions,

- Wide application in high-tech industry – they are utilized in HDD drives, electromotive mechanisms, medical devices, also complex engineering applications.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Disadvantages

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Due to limitations in creating threads and complicated shapes in magnets, we propose using cover - magnetic mechanism.

- Potential hazard to health – tiny shards of magnets are risky, if swallowed, which gains importance in the context of child health protection. It is also worth noting that small elements of these magnets are able to be problematic in diagnostics medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Lifting parameters

Highest magnetic holding force – what contributes to it?

- using a base made of mild steel, functioning as a circuit closing element

- with a thickness minimum 10 mm

- with an ideally smooth touching surface

- with zero gap (without impurities)

- during detachment in a direction perpendicular to the mounting surface

- at standard ambient temperature

Lifting capacity in practice – influencing factors

- Air gap (betwixt the magnet and the plate), because even a tiny distance (e.g. 0.5 mm) results in a reduction in lifting capacity by up to 50% (this also applies to paint, rust or dirt).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Material type – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Smoothness – full contact is possible only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity was assessed by applying a steel plate with a smooth surface of optimal thickness (min. 20 mm), under vertically applied force, however under shearing force the holding force is lower. Moreover, even a small distance between the magnet and the plate lowers the load capacity.

H&S for magnets

Electronic hazard

Device Safety: Neodymium magnets can ruin payment cards and sensitive devices (heart implants, hearing aids, mechanical watches).

Phone sensors

Navigation devices and mobile phones are highly sensitive to magnetic fields. Close proximity with a strong magnet can permanently damage the internal compass in your phone.

Do not drill into magnets

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Operating temperature

Standard neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Serious injuries

Big blocks can break fingers in a fraction of a second. Never put your hand between two attracting surfaces.

Keep away from children

Absolutely store magnets out of reach of children. Ingestion danger is significant, and the consequences of magnets connecting inside the body are very dangerous.

Material brittleness

Despite the nickel coating, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Handling rules

Handle magnets consciously. Their immense force can shock even experienced users. Plan your moves and do not underestimate their power.

Skin irritation risks

Some people suffer from a sensitization to Ni, which is the common plating for NdFeB magnets. Prolonged contact may cause an allergic reaction. We suggest wear protective gloves.

Life threat

Warning for patients: Strong magnetic fields affect electronics. Keep minimum 30 cm distance or request help to work with the magnets.

![UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gz-vaf.jpg)

![UMP 75x25 [M10x3] GW F200 GOLD / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-pag.jpg)