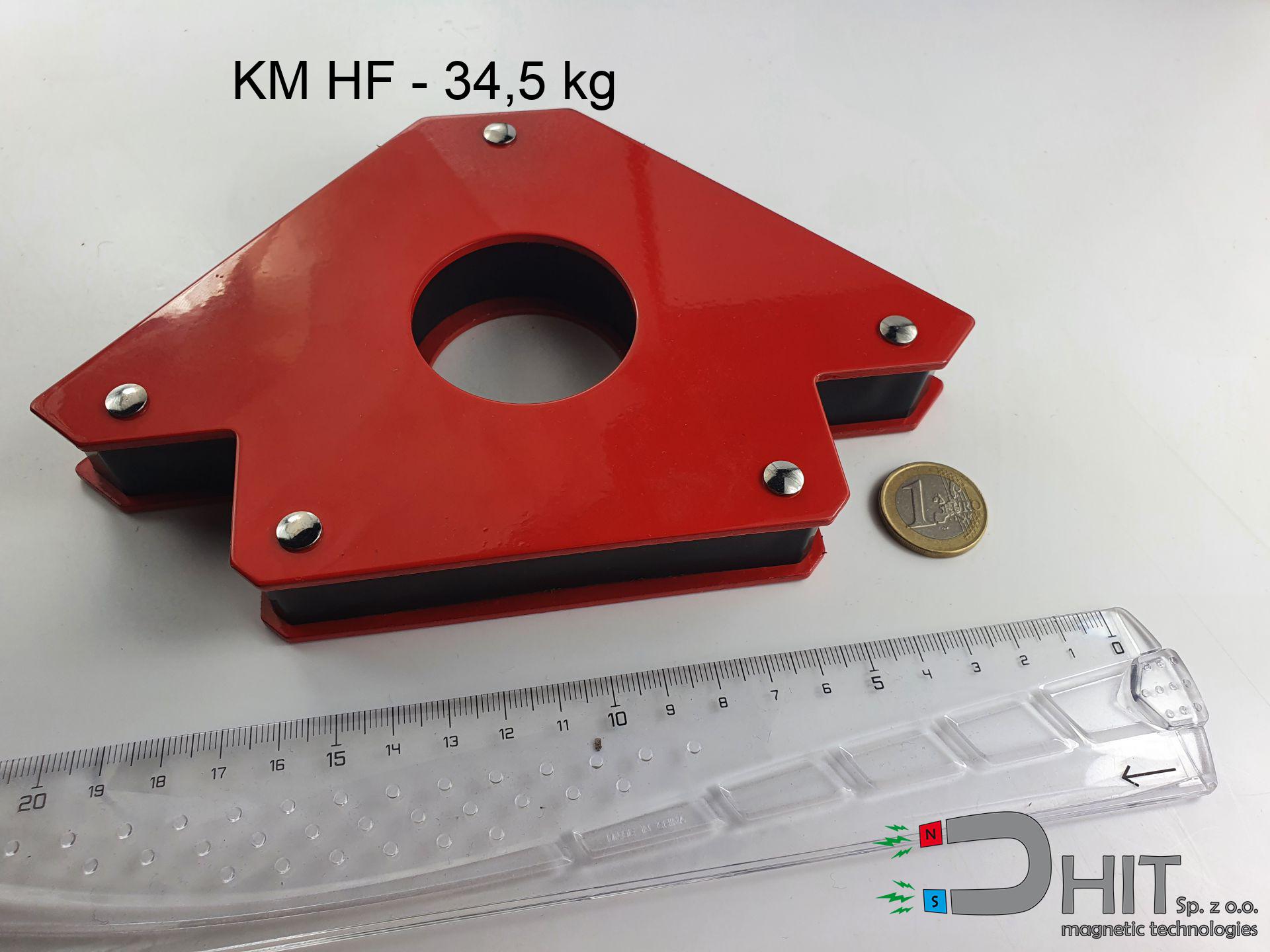

KM HF - 34,5 kg - magnetic bracket

magnetic bracket

Catalog no 170258

GTIN/EAN: 5906301813705

Weight

1040 g

Load capacity

34.50 kg / 338.33 N

34.44 ZŁ with VAT / pcs + price for transport

28.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively contact us using

request form

the contact form page.

Force and structure of neodymium magnets can be estimated with our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data - KM HF - 34,5 kg - magnetic bracket

Specification / characteristics - KM HF - 34,5 kg - magnetic bracket

| properties | values |

|---|---|

| Cat. no. | 170258 |

| GTIN/EAN | 5906301813705 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 1040 g |

| Load capacity ~ ? | 34.50 kg / 338.33 N |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Strengths

- They have unchanged lifting capacity, and over nearly 10 years their attraction force decreases symbolically – ~1% (according to theory),

- Neodymium magnets are characterized by remarkably resistant to magnetic field loss caused by external field sources,

- Thanks to the smooth finish, the surface of Ni-Cu-Ni, gold-plated, or silver gives an professional appearance,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to modularity in forming and the ability to customize to unusual requirements,

- Huge importance in modern technologies – they are utilized in data components, electromotive mechanisms, diagnostic systems, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which enables their usage in small systems

Limitations

- At strong impacts they can break, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- We suggest casing - magnetic mount, due to difficulties in producing nuts inside the magnet and complicated forms.

- Health risk to health – tiny shards of magnets pose a threat, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Additionally, tiny parts of these devices can disrupt the diagnostic process medical after entering the body.

- Due to neodymium price, their price is relatively high,

Lifting parameters

Best holding force of the magnet in ideal parameters – what affects it?

- using a plate made of high-permeability steel, acting as a ideal flux conductor

- possessing a massiveness of minimum 10 mm to avoid saturation

- with an polished contact surface

- without the slightest clearance between the magnet and steel

- under vertical force direction (90-degree angle)

- at temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

- Clearance – existence of foreign body (paint, dirt, gap) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Load vector – maximum parameter is available only during perpendicular pulling. The shear force of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – low-carbon steel attracts best. Alloy admixtures decrease magnetic properties and holding force.

- Plate texture – ground elements ensure maximum contact, which improves field saturation. Rough surfaces weaken the grip.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they lose power, and in frost they can be stronger (up to a certain limit).

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the holding force is lower. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

Safety rules for work with NdFeB magnets

Skin irritation risks

Studies show that nickel (the usual finish) is a strong allergen. For allergy sufferers, avoid touching magnets with bare hands or select coated magnets.

Serious injuries

Pinching hazard: The attraction force is so immense that it can result in hematomas, crushing, and broken bones. Use thick gloves.

Magnetic interference

An intense magnetic field interferes with the functioning of magnetometers in smartphones and GPS navigation. Keep magnets near a smartphone to avoid breaking the sensors.

Permanent damage

Standard neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. The loss of strength is permanent.

Material brittleness

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Medical implants

Life threat: Neodymium magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Dust explosion hazard

Fire warning: Rare earth powder is explosive. Avoid machining magnets without safety gear as this risks ignition.

Electronic devices

Powerful magnetic fields can erase data on credit cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Conscious usage

Before use, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Think ahead.

Swallowing risk

Absolutely keep magnets out of reach of children. Choking hazard is high, and the effects of magnets connecting inside the body are life-threatening.

![UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump135x40-m10+m12-gw-f-600-kg-luz.jpg)

![SM 32x200 [2xM8] / N52 - magnetic separator SM 32x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-tus.jpg)