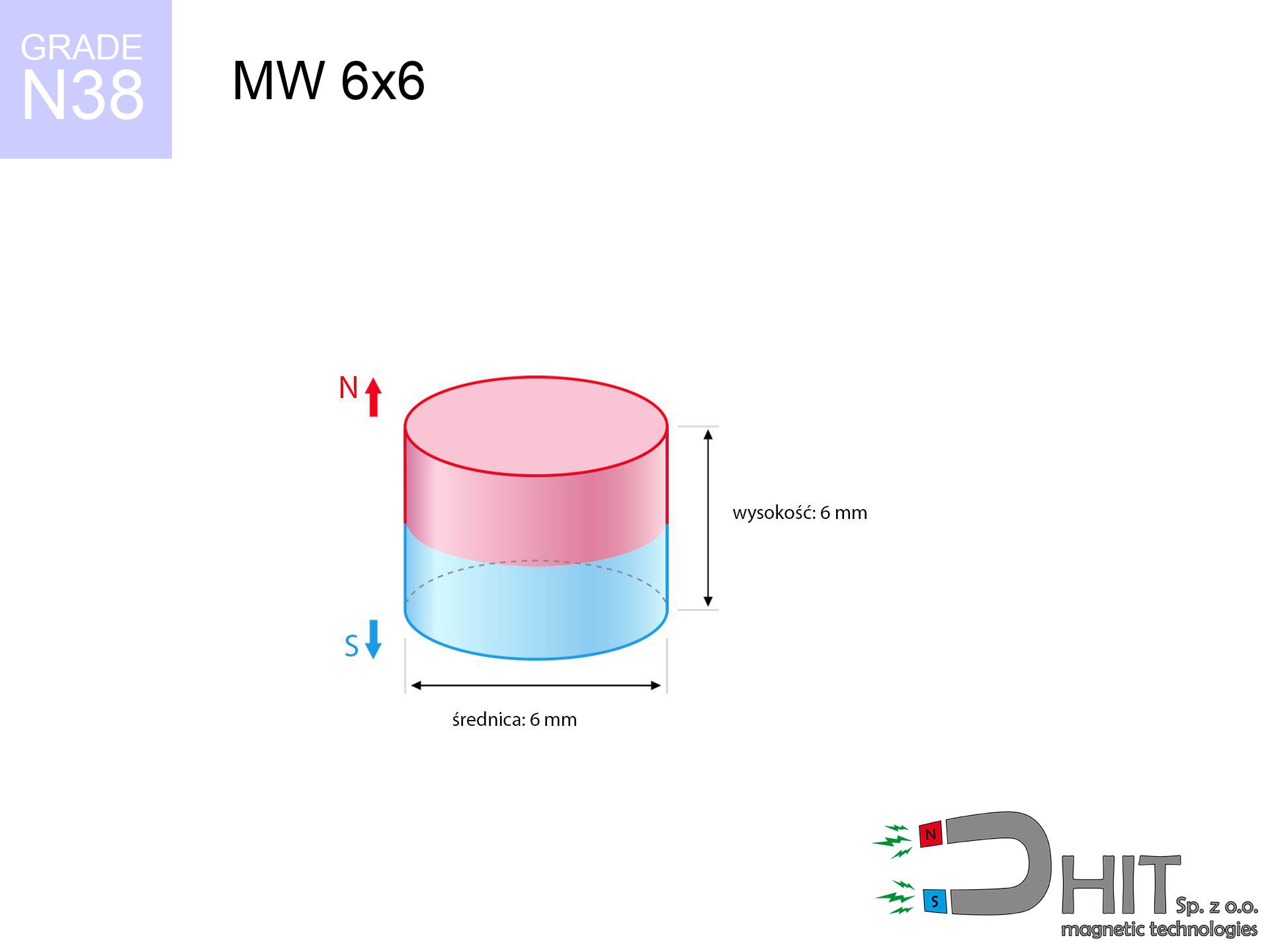

MW 6x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010094

GTIN/EAN: 5906301810933

Diameter Ø

6 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

1.27 g

Magnetization Direction

↑ axial

Load capacity

1.14 kg / 11.18 N

Magnetic Induction

553.38 mT / 5534 Gs

Coating

[NiCuNi] Nickel

0.677 ZŁ with VAT / pcs + price for transport

0.550 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise contact us using

request form

the contact form page.

Lifting power and appearance of a magnet can be calculated on our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Technical - MW 6x6 / N38 - cylindrical magnet

Specification / characteristics - MW 6x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010094 |

| GTIN/EAN | 5906301810933 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 6 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 1.27 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.14 kg / 11.18 N |

| Magnetic Induction ~ ? | 553.38 mT / 5534 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - technical parameters

The following data constitute the result of a engineering simulation. Results were calculated on algorithms for the class Nd2Fe14B. Operational parameters may differ. Use these calculations as a reference point for designers.

Table 1: Static force (pull vs distance) - interaction chart

MW 6x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5527 Gs

552.7 mT

|

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

low risk |

| 1 mm |

3738 Gs

373.8 mT

|

0.52 kg / 1.15 LBS

521.5 g / 5.1 N

|

low risk |

| 2 mm |

2366 Gs

236.6 mT

|

0.21 kg / 0.46 LBS

209.0 g / 2.0 N

|

low risk |

| 3 mm |

1498 Gs

149.8 mT

|

0.08 kg / 0.18 LBS

83.7 g / 0.8 N

|

low risk |

| 5 mm |

665 Gs

66.5 mT

|

0.02 kg / 0.04 LBS

16.5 g / 0.2 N

|

low risk |

| 10 mm |

155 Gs

15.5 mT

|

0.00 kg / 0.00 LBS

0.9 g / 0.0 N

|

low risk |

| 15 mm |

58 Gs

5.8 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 20 mm |

28 Gs

2.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical hold (wall)

MW 6x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.23 kg / 0.50 LBS

228.0 g / 2.2 N

|

| 1 mm | Stal (~0.2) |

0.10 kg / 0.23 LBS

104.0 g / 1.0 N

|

| 2 mm | Stal (~0.2) |

0.04 kg / 0.09 LBS

42.0 g / 0.4 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

16.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 6x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.34 kg / 0.75 LBS

342.0 g / 3.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.23 kg / 0.50 LBS

228.0 g / 2.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.11 kg / 0.25 LBS

114.0 g / 1.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.57 kg / 1.26 LBS

570.0 g / 5.6 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 6x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.11 kg / 0.25 LBS

114.0 g / 1.1 N

|

| 1 mm |

|

0.29 kg / 0.63 LBS

285.0 g / 2.8 N

|

| 2 mm |

|

0.57 kg / 1.26 LBS

570.0 g / 5.6 N

|

| 3 mm |

|

0.86 kg / 1.88 LBS

855.0 g / 8.4 N

|

| 5 mm |

|

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

| 10 mm |

|

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

| 11 mm |

|

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

| 12 mm |

|

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 6x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.14 kg / 2.51 LBS

1140.0 g / 11.2 N

|

OK |

| 40 °C | -2.2% |

1.11 kg / 2.46 LBS

1114.9 g / 10.9 N

|

OK |

| 60 °C | -4.4% |

1.09 kg / 2.40 LBS

1089.8 g / 10.7 N

|

OK |

| 80 °C | -6.6% |

1.06 kg / 2.35 LBS

1064.8 g / 10.4 N

|

|

| 100 °C | -28.8% |

0.81 kg / 1.79 LBS

811.7 g / 8.0 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 6x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.32 kg / 11.74 LBS

5 995 Gs

|

0.80 kg / 1.76 LBS

799 g / 7.8 N

|

N/A |

| 1 mm |

3.70 kg / 8.17 LBS

9 220 Gs

|

0.56 kg / 1.23 LBS

556 g / 5.5 N

|

3.33 kg / 7.35 LBS

~0 Gs

|

| 2 mm |

2.44 kg / 5.37 LBS

7 476 Gs

|

0.37 kg / 0.81 LBS

365 g / 3.6 N

|

2.19 kg / 4.83 LBS

~0 Gs

|

| 3 mm |

1.55 kg / 3.42 LBS

5 968 Gs

|

0.23 kg / 0.51 LBS

233 g / 2.3 N

|

1.40 kg / 3.08 LBS

~0 Gs

|

| 5 mm |

0.61 kg / 1.35 LBS

3 755 Gs

|

0.09 kg / 0.20 LBS

92 g / 0.9 N

|

0.55 kg / 1.22 LBS

~0 Gs

|

| 10 mm |

0.08 kg / 0.17 LBS

1 330 Gs

|

0.01 kg / 0.03 LBS

12 g / 0.1 N

|

0.07 kg / 0.15 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 LBS

311 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

31 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

19 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 6x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 6x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

30.23 km/h

(8.40 m/s)

|

0.04 J | |

| 30 mm |

52.34 km/h

(14.54 m/s)

|

0.13 J | |

| 50 mm |

67.56 km/h

(18.77 m/s)

|

0.22 J | |

| 100 mm |

95.55 km/h

(26.54 m/s)

|

0.45 J |

Table 9: Anti-corrosion coating durability

MW 6x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 6x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 613 Mx | 16.1 µWb |

| Pc Coefficient | 0.89 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 6x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.14 kg | Standard |

| Water (riverbed) |

1.31 kg

(+0.17 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical surface, the magnet retains only ~20% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.89

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Strengths as well as weaknesses of neodymium magnets.

Advantages

- They do not lose magnetism, even after approximately ten years – the drop in power is only ~1% (theoretically),

- They are resistant to demagnetization induced by external field influence,

- By covering with a decorative layer of silver, the element has an professional look,

- Neodymium magnets achieve maximum magnetic induction on a small surface, which allows for strong attraction,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures approaching 230°C and above...

- Thanks to modularity in constructing and the ability to modify to individual projects,

- Fundamental importance in modern technologies – they are used in computer drives, motor assemblies, diagnostic systems, and technologically advanced constructions.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Limitations

- At very strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited possibility of creating nuts in the magnet and complicated forms - recommended is cover - mounting mechanism.

- Health risk related to microscopic parts of magnets can be dangerous, if swallowed, which gains importance in the context of child safety. Additionally, small elements of these products can complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a plate made of mild steel, acting as a magnetic yoke

- with a cross-section no less than 10 mm

- with a plane cleaned and smooth

- without the slightest air gap between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at room temperature

Lifting capacity in practice – influencing factors

- Distance (betwixt the magnet and the metal), since even a very small clearance (e.g. 0.5 mm) results in a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Metal type – not every steel reacts the same. Alloy additives worsen the attraction effect.

- Smoothness – ideal contact is obtained only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Warnings

Fire warning

Fire hazard: Rare earth powder is highly flammable. Do not process magnets in home conditions as this may cause fire.

Safe operation

Handle magnets consciously. Their immense force can surprise even professionals. Plan your moves and do not underestimate their force.

Medical interference

Patients with a ICD should keep an absolute distance from magnets. The magnetism can interfere with the operation of the life-saving device.

Avoid contact if allergic

Nickel alert: The nickel-copper-nickel coating contains nickel. If an allergic reaction happens, cease handling magnets and use protective gear.

Electronic hazard

Data protection: Strong magnets can ruin data carriers and delicate electronics (pacemakers, medical aids, timepieces).

Phone sensors

Be aware: rare earth magnets produce a field that confuses sensitive sensors. Keep a separation from your phone, tablet, and GPS.

Magnets are brittle

Despite metallic appearance, neodymium is delicate and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Adults only

These products are not toys. Eating multiple magnets may result in them attracting across intestines, which constitutes a direct threat to life and requires immediate surgery.

Physical harm

Big blocks can break fingers in a fraction of a second. Do not put your hand between two attracting surfaces.

Operating temperature

Monitor thermal conditions. Heating the magnet to high heat will ruin its magnetic structure and pulling force.

![SM 32x150 [2xM8] / N42 - magnetic separator SM 32x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xus.jpg)