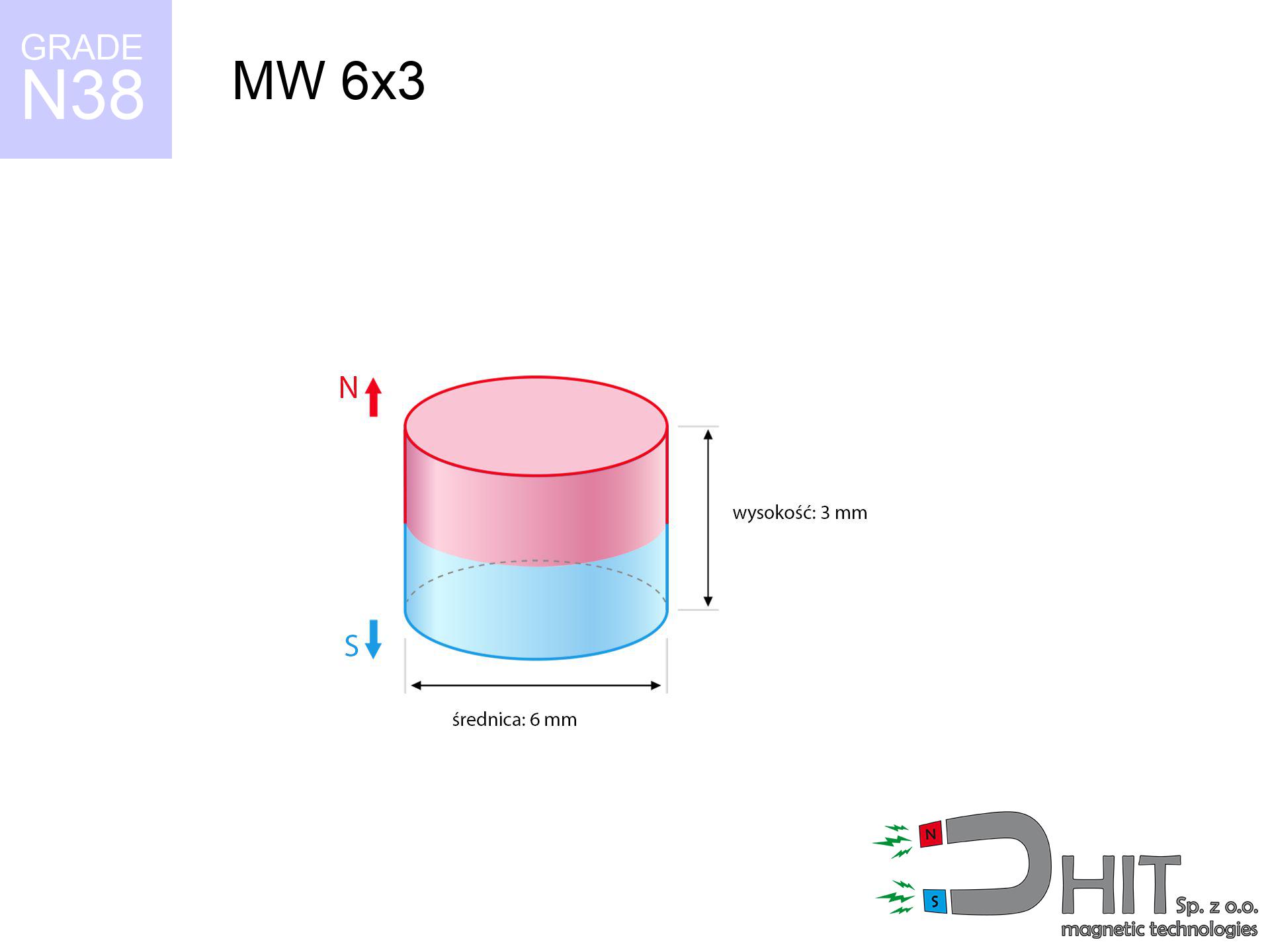

MW 6x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010093

GTIN/EAN: 5906301810926

Diameter Ø

6 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

0.64 g

Magnetization Direction

↑ axial

Load capacity

1.15 kg / 11.23 N

Magnetic Induction

437.58 mT / 4376 Gs

Coating

[NiCuNi] Nickel

0.381 ZŁ with VAT / pcs + price for transport

0.310 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise contact us through

our online form

through our site.

Parameters and structure of a magnet can be reviewed with our

online calculation tool.

Same-day processing for orders placed before 14:00.

Detailed specification - MW 6x3 / N38 - cylindrical magnet

Specification / characteristics - MW 6x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010093 |

| GTIN/EAN | 5906301810926 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 6 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 0.64 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.15 kg / 11.23 N |

| Magnetic Induction ~ ? | 437.58 mT / 4376 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - technical parameters

Presented values represent the direct effect of a mathematical calculation. Values rely on models for the material Nd2Fe14B. Actual performance may differ from theoretical values. Use these data as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs gap) - characteristics

MW 6x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4371 Gs

437.1 mT

|

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

low risk |

| 1 mm |

2999 Gs

299.9 mT

|

0.54 kg / 1.19 LBS

541.6 g / 5.3 N

|

low risk |

| 2 mm |

1877 Gs

187.7 mT

|

0.21 kg / 0.47 LBS

212.2 g / 2.1 N

|

low risk |

| 3 mm |

1161 Gs

116.1 mT

|

0.08 kg / 0.18 LBS

81.2 g / 0.8 N

|

low risk |

| 5 mm |

489 Gs

48.9 mT

|

0.01 kg / 0.03 LBS

14.4 g / 0.1 N

|

low risk |

| 10 mm |

103 Gs

10.3 mT

|

0.00 kg / 0.00 LBS

0.6 g / 0.0 N

|

low risk |

| 15 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 20 mm |

17 Gs

1.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical load (wall)

MW 6x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

| 1 mm | Stal (~0.2) |

0.11 kg / 0.24 LBS

108.0 g / 1.1 N

|

| 2 mm | Stal (~0.2) |

0.04 kg / 0.09 LBS

42.0 g / 0.4 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

16.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 6x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.35 kg / 0.76 LBS

345.0 g / 3.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.11 kg / 0.25 LBS

115.0 g / 1.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.58 kg / 1.27 LBS

575.0 g / 5.6 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 6x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.11 kg / 0.25 LBS

115.0 g / 1.1 N

|

| 1 mm |

|

0.29 kg / 0.63 LBS

287.5 g / 2.8 N

|

| 2 mm |

|

0.58 kg / 1.27 LBS

575.0 g / 5.6 N

|

| 3 mm |

|

0.86 kg / 1.90 LBS

862.5 g / 8.5 N

|

| 5 mm |

|

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

| 10 mm |

|

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

| 11 mm |

|

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

| 12 mm |

|

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MW 6x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.15 kg / 2.54 LBS

1150.0 g / 11.3 N

|

OK |

| 40 °C | -2.2% |

1.12 kg / 2.48 LBS

1124.7 g / 11.0 N

|

OK |

| 60 °C | -4.4% |

1.10 kg / 2.42 LBS

1099.4 g / 10.8 N

|

|

| 80 °C | -6.6% |

1.07 kg / 2.37 LBS

1074.1 g / 10.5 N

|

|

| 100 °C | -28.8% |

0.82 kg / 1.81 LBS

818.8 g / 8.0 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 6x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.33 kg / 7.34 LBS

5 527 Gs

|

0.50 kg / 1.10 LBS

499 g / 4.9 N

|

N/A |

| 1 mm |

2.37 kg / 5.23 LBS

7 376 Gs

|

0.36 kg / 0.78 LBS

356 g / 3.5 N

|

2.13 kg / 4.70 LBS

~0 Gs

|

| 2 mm |

1.57 kg / 3.46 LBS

5 999 Gs

|

0.24 kg / 0.52 LBS

235 g / 2.3 N

|

1.41 kg / 3.11 LBS

~0 Gs

|

| 3 mm |

0.99 kg / 2.19 LBS

4 772 Gs

|

0.15 kg / 0.33 LBS

149 g / 1.5 N

|

0.89 kg / 1.97 LBS

~0 Gs

|

| 5 mm |

0.38 kg / 0.83 LBS

2 948 Gs

|

0.06 kg / 0.13 LBS

57 g / 0.6 N

|

0.34 kg / 0.75 LBS

~0 Gs

|

| 10 mm |

0.04 kg / 0.09 LBS

978 Gs

|

0.01 kg / 0.01 LBS

6 g / 0.1 N

|

0.04 kg / 0.08 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

205 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

18 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 6x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 6x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

42.77 km/h

(11.88 m/s)

|

0.05 J | |

| 30 mm |

74.05 km/h

(20.57 m/s)

|

0.14 J | |

| 50 mm |

95.59 km/h

(26.55 m/s)

|

0.23 J | |

| 100 mm |

135.19 km/h

(37.55 m/s)

|

0.45 J |

Table 9: Corrosion resistance

MW 6x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 6x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 256 Mx | 12.6 µWb |

| Pc Coefficient | 0.59 | Low (Flat) |

Table 11: Submerged application

MW 6x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.15 kg | Standard |

| Water (riverbed) |

1.32 kg

(+0.17 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains just ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.59

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also offers

Pros and cons of Nd2Fe14B magnets.

Pros

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (according to literature),

- They possess excellent resistance to magnetic field loss when exposed to opposing magnetic fields,

- By covering with a smooth layer of gold, the element gains an modern look,

- The surface of neodymium magnets generates a maximum magnetic field – this is one of their assets,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to freedom in designing and the ability to customize to complex applications,

- Versatile presence in high-tech industry – they are commonly used in HDD drives, drive modules, advanced medical instruments, and multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture

- We suggest casing - magnetic mechanism, due to difficulties in realizing threads inside the magnet and complicated shapes.

- Potential hazard to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. It is also worth noting that small components of these magnets are able to be problematic in diagnostics medical in case of swallowing.

- Due to neodymium price, their price is relatively high,

Holding force characteristics

Highest magnetic holding force – what affects it?

- on a base made of mild steel, perfectly concentrating the magnetic field

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an polished touching surface

- without any insulating layer between the magnet and steel

- during detachment in a direction vertical to the plane

- at standard ambient temperature

Practical aspects of lifting capacity – factors

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Plate thickness – insufficiently thick plate does not close the flux, causing part of the power to be escaped to the other side.

- Chemical composition of the base – mild steel attracts best. Higher carbon content decrease magnetic permeability and holding force.

- Smoothness – full contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Thermal conditions – NdFeB sinters have a negative temperature coefficient. At higher temperatures they lose power, and in frost gain strength (up to a certain limit).

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under perpendicular forces, whereas under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Additionally, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

H&S for magnets

Fire risk

Machining of NdFeB material carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Bodily injuries

Risk of injury: The attraction force is so immense that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Heat sensitivity

Control the heat. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Keep away from children

NdFeB magnets are not toys. Accidental ingestion of several magnets may result in them attracting across intestines, which constitutes a direct threat to life and requires immediate surgery.

Keep away from electronics

A powerful magnetic field negatively affects the operation of magnetometers in phones and GPS navigation. Do not bring magnets close to a device to avoid damaging the sensors.

Threat to electronics

Device Safety: Neodymium magnets can damage data carriers and sensitive devices (pacemakers, hearing aids, mechanical watches).

Implant safety

People with a pacemaker must keep an safe separation from magnets. The magnetism can stop the functioning of the life-saving device.

Handling guide

Handle with care. Rare earth magnets act from a distance and connect with huge force, often faster than you can react.

Avoid contact if allergic

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation appears, immediately stop working with magnets and use protective gear.

Protective goggles

Despite the nickel coating, the material is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

![SM 32x500 [2xM8] / N42 - magnetic separator SM 32x500 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x500-2xm8-jan.jpg)

![HH 32x7.8 [M5] / N38 - through hole magnetic holder HH 32x7.8 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-32x7.8-m5-war.jpg)