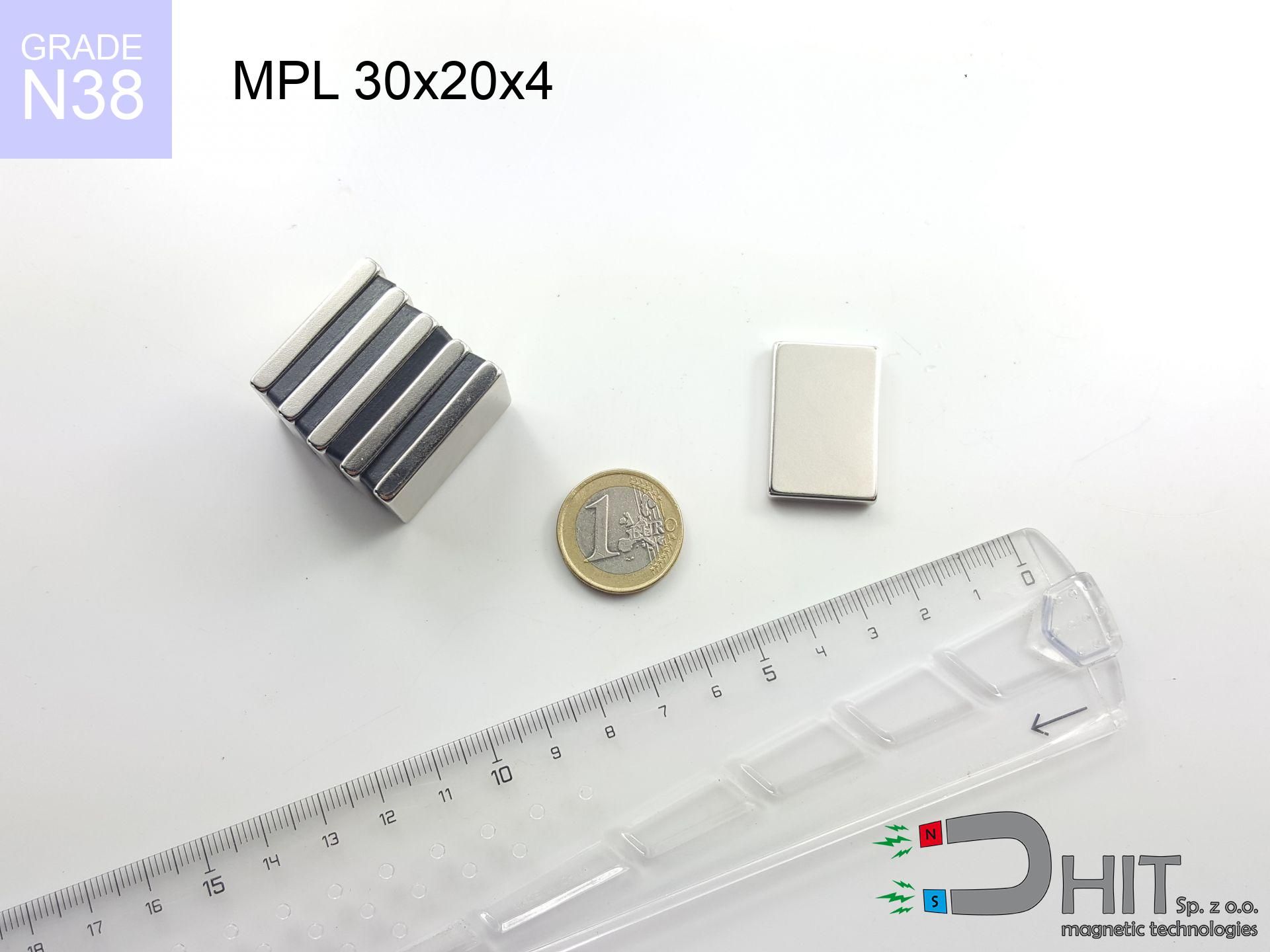

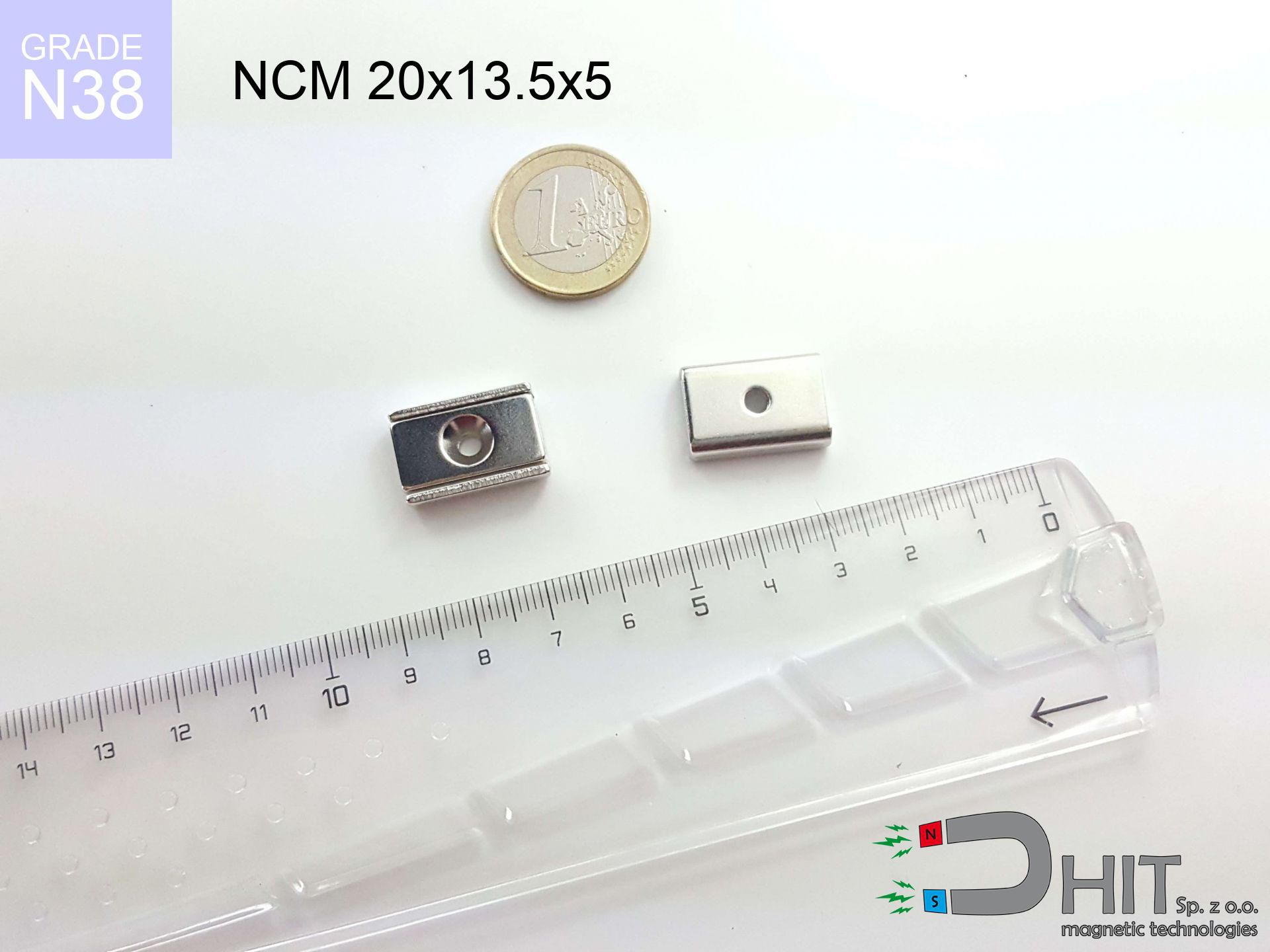

NCM 20x13.5x5 / N38 - channel magnetic holder

channel magnetic holder

Catalog no 360487

GTIN/EAN: 5906301814863

Diameter Ø

20 mm [±1 mm]

Height

13.5 mm [±1 mm]

Weight

9.2 g

Magnetization Direction

↑ axial

Load capacity

8.00 kg / 78.45 N

Coating

[NiCuNi] Nickel

7.29 ZŁ with VAT / pcs + price for transport

5.93 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer let us know through

form

the contact form page.

Specifications and shape of neodymium magnets can be estimated using our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Product card - NCM 20x13.5x5 / N38 - channel magnetic holder

Specification / characteristics - NCM 20x13.5x5 / N38 - channel magnetic holder

| properties | values |

|---|---|

| Cat. no. | 360487 |

| GTIN/EAN | 5906301814863 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±1 mm] |

| Height | 13.5 mm [±1 mm] |

| Weight | 9.2 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 8.00 kg / 78.45 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of Nd2Fe14B magnets.

Strengths

- Their magnetic field is durable, and after around 10 years it decreases only by ~1% (according to research),

- Magnets very well defend themselves against demagnetization caused by ambient magnetic noise,

- The use of an aesthetic layer of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- The surface of neodymium magnets generates a concentrated magnetic field – this is one of their assets,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to modularity in forming and the ability to customize to specific needs,

- Significant place in modern technologies – they find application in computer drives, drive modules, medical equipment, as well as technologically advanced constructions.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Limitations

- To avoid cracks under impact, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of producing threads in the magnet and complex forms - preferred is casing - mounting mechanism.

- Potential hazard to health – tiny shards of magnets can be dangerous, if swallowed, which is particularly important in the context of child health protection. Additionally, small elements of these devices are able to be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which can limit application in large quantities

Pull force analysis

Magnetic strength at its maximum – what it depends on?

- with the application of a sheet made of special test steel, guaranteeing full magnetic saturation

- with a cross-section no less than 10 mm

- characterized by lack of roughness

- without the slightest air gap between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- at ambient temperature room level

Practical lifting capacity: influencing factors

- Distance (betwixt the magnet and the plate), as even a very small clearance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Base massiveness – too thin plate causes magnetic saturation, causing part of the flux to be wasted to the other side.

- Material type – ideal substrate is high-permeability steel. Cast iron may generate lower lifting capacity.

- Smoothness – ideal contact is obtained only on smooth steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

Precautions when working with NdFeB magnets

Bone fractures

Pinching hazard: The pulling power is so great that it can cause blood blisters, pinching, and broken bones. Protective gloves are recommended.

Nickel coating and allergies

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation appears, cease handling magnets and use protective gear.

Life threat

People with a ICD must keep an absolute distance from magnets. The magnetism can interfere with the functioning of the implant.

GPS and phone interference

A powerful magnetic field negatively affects the functioning of magnetometers in smartphones and navigation systems. Do not bring magnets close to a smartphone to avoid breaking the sensors.

Magnets are brittle

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets will cause them cracking into shards.

Fire warning

Fire hazard: Neodymium dust is explosive. Do not process magnets in home conditions as this risks ignition.

Conscious usage

Exercise caution. Rare earth magnets attract from a long distance and connect with huge force, often quicker than you can react.

This is not a toy

Strictly store magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are life-threatening.

Maximum temperature

Regular neodymium magnets (N-type) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Magnetic media

Data protection: Strong magnets can ruin data carriers and delicate electronics (heart implants, hearing aids, timepieces).

![SM 32x375 [2xM8] / N42 - magnetic separator SM 32x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-nif.jpg)

![MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x15x5x27-3.5-cas.jpg)