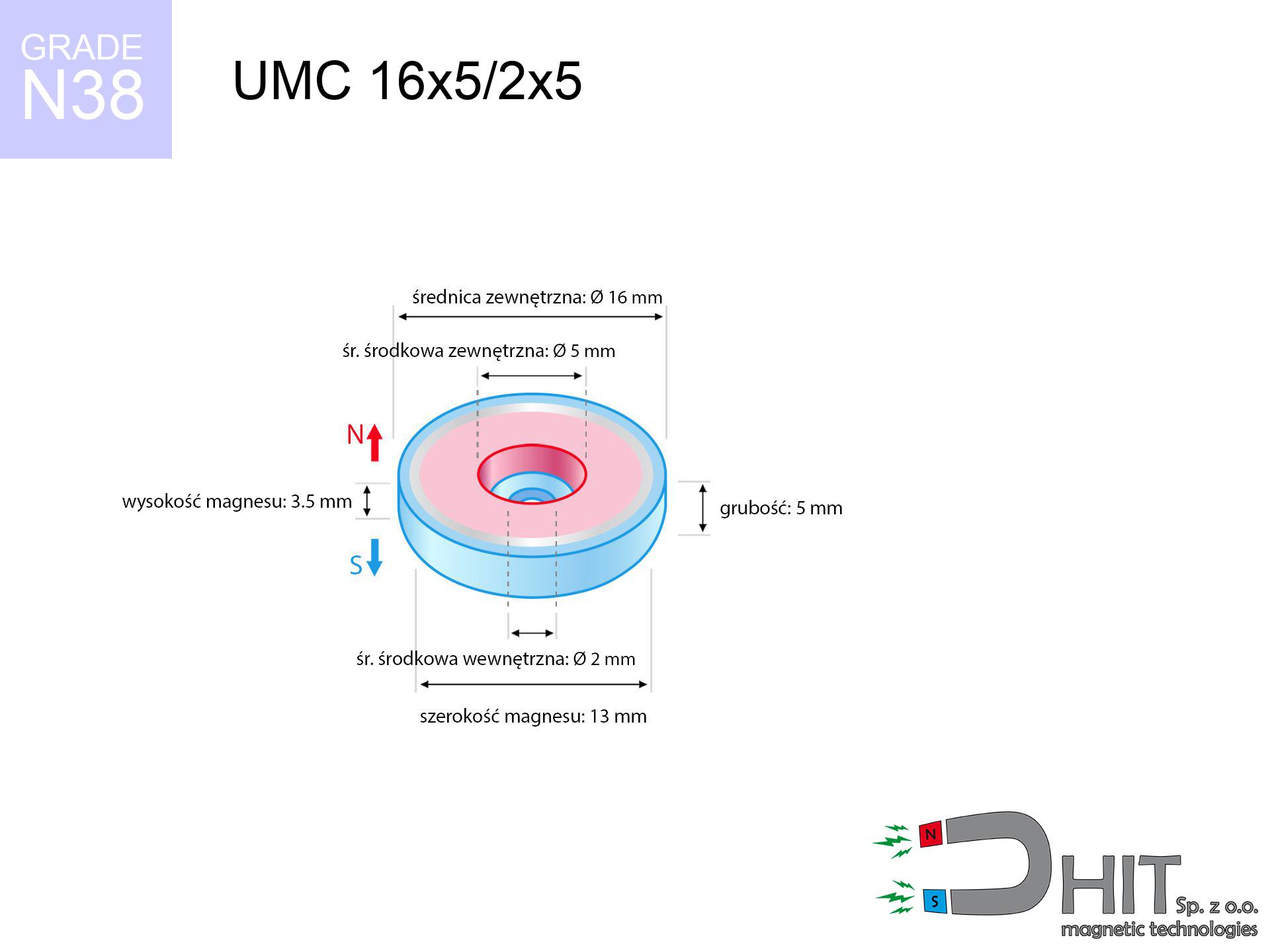

UMC 16x5/2x5 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320406

GTIN/EAN: 5906301814627

Diameter

16 mm [±1 mm]

internal diameter Ø

5/2 mm [±1 mm]

Height

5 mm [±1 mm]

Weight

5.5 g

Load capacity

4.00 kg / 39.23 N

Coating

[NiCuNi] Nickel

3.33 ZŁ with VAT / pcs + price for transport

2.71 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or let us know via

form

the contact section.

Specifications and form of magnets can be calculated with our

modular calculator.

Order by 14:00 and we’ll ship today!

Product card - UMC 16x5/2x5 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 16x5/2x5 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320406 |

| GTIN/EAN | 5906301814627 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 16 mm [±1 mm] |

| internal diameter Ø | 5/2 mm [±1 mm] |

| Height | 5 mm [±1 mm] |

| Weight | 5.5 g |

| Load capacity ~ ? | 4.00 kg / 39.23 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of rare earth magnets.

Benefits

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (in laboratory conditions),

- They show high resistance to demagnetization induced by external magnetic fields,

- Thanks to the reflective finish, the coating of Ni-Cu-Ni, gold-plated, or silver gives an aesthetic appearance,

- Neodymium magnets ensure maximum magnetic induction on a small area, which ensures high operational effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to modularity in forming and the ability to modify to unusual requirements,

- Key role in modern industrial fields – they are utilized in mass storage devices, motor assemblies, precision medical tools, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which allows their use in compact constructions

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in realizing threads and complicated shapes in magnets, we propose using cover - magnetic mount.

- Health risk related to microscopic parts of magnets can be dangerous, if swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, tiny parts of these magnets are able to complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting capacity of the magnet – what contributes to it?

- using a plate made of low-carbon steel, serving as a circuit closing element

- with a cross-section no less than 10 mm

- characterized by even structure

- under conditions of no distance (metal-to-metal)

- during pulling in a direction vertical to the plane

- at ambient temperature room level

Lifting capacity in real conditions – factors

- Clearance – the presence of any layer (paint, dirt, gap) acts as an insulator, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Angle of force application – highest force is obtained only during perpendicular pulling. The force required to slide of the magnet along the plate is typically many times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Material type – the best choice is pure iron steel. Hardened steels may generate lower lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which increases field saturation. Uneven metal weaken the grip.

- Operating temperature – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the holding force is lower. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

H&S for magnets

Sensitization to coating

Studies show that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, refrain from direct skin contact and choose encased magnets.

Handling rules

Be careful. Neodymium magnets act from a distance and snap with massive power, often faster than you can move away.

Finger safety

Large magnets can smash fingers in a fraction of a second. Under no circumstances put your hand betwixt two attracting surfaces.

Magnet fragility

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

Permanent damage

Standard neodymium magnets (N-type) undergo demagnetization when the temperature goes above 80°C. Damage is permanent.

Medical implants

Life threat: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Impact on smartphones

A powerful magnetic field negatively affects the functioning of compasses in smartphones and navigation systems. Keep magnets near a device to prevent damaging the sensors.

Machining danger

Fire hazard: Neodymium dust is explosive. Avoid machining magnets in home conditions as this may cause fire.

Threat to electronics

Powerful magnetic fields can destroy records on credit cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

Choking Hazard

These products are not suitable for play. Accidental ingestion of several magnets may result in them connecting inside the digestive tract, which poses a severe health hazard and necessitates urgent medical intervention.

![UMH 36x8x46 [M6] / N38 - magnetic holder with hook UMH 36x8x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-36x8x46-m6-wim.jpg)