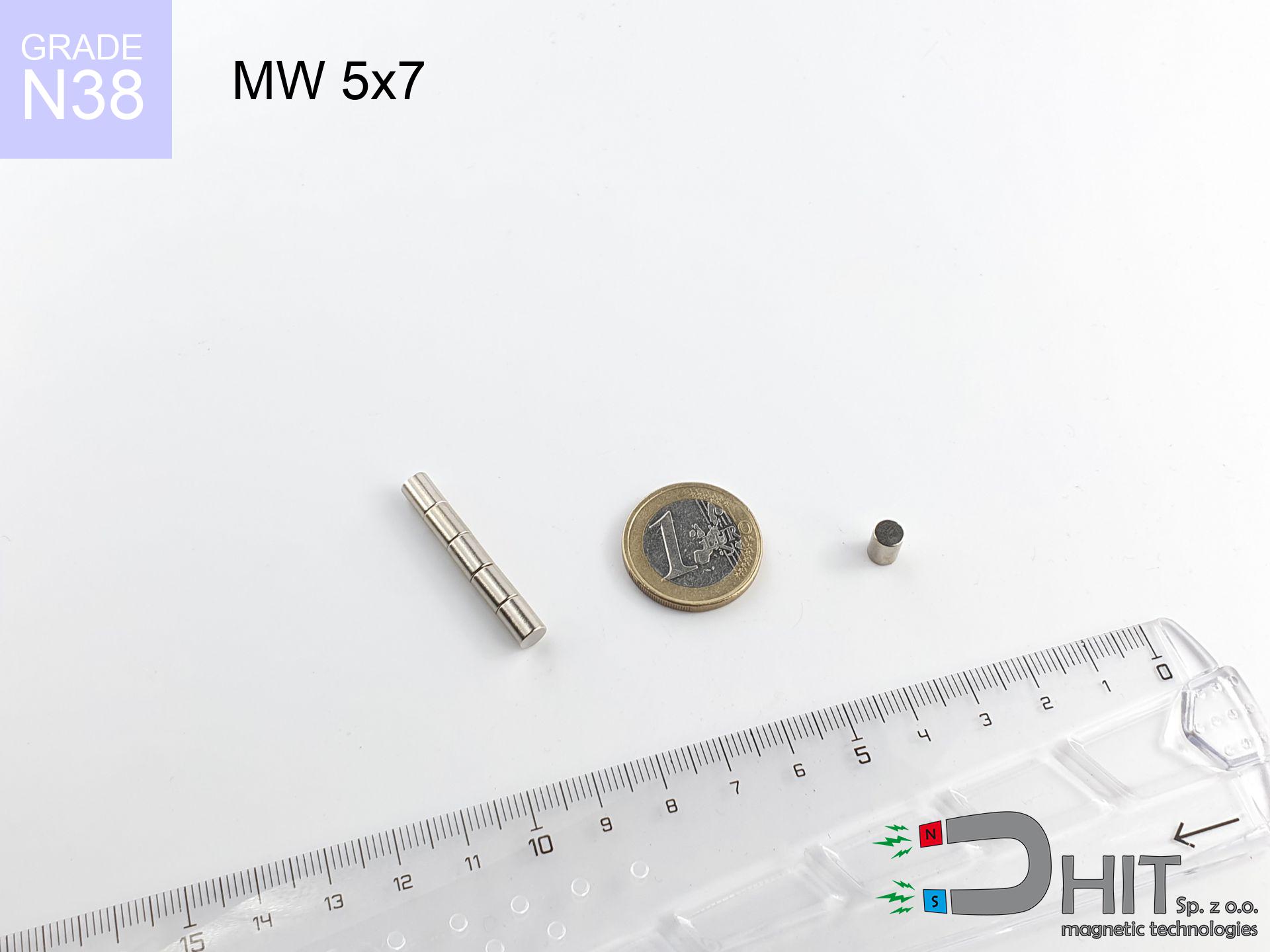

MW 5x7 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010090

GTIN/EAN: 5906301810896

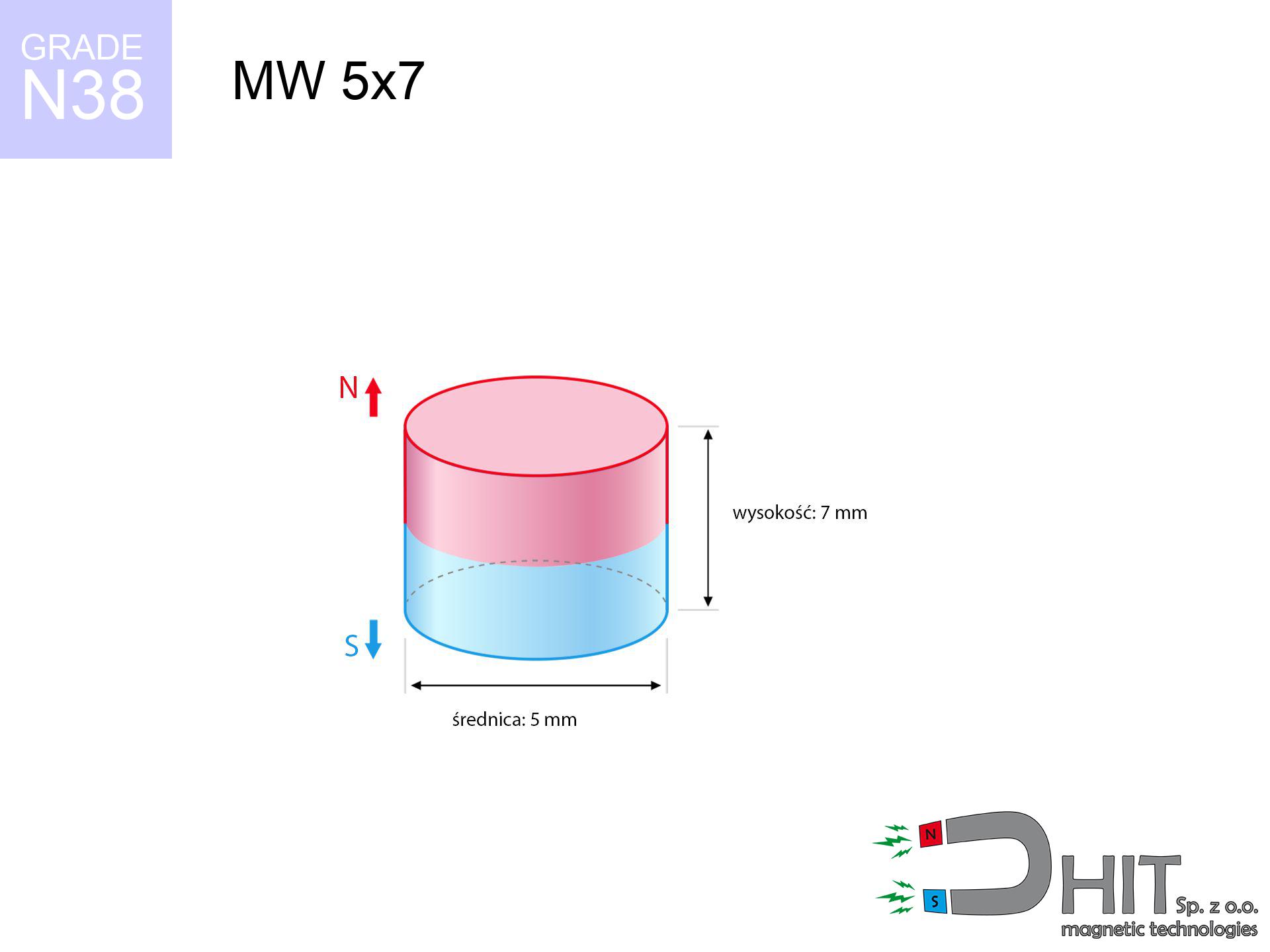

Diameter Ø

5 mm [±0,1 mm]

Height

7 mm [±0,1 mm]

Weight

1.03 g

Magnetization Direction

↑ axial

Load capacity

0.67 kg / 6.60 N

Magnetic Induction

582.40 mT / 5824 Gs

Coating

[NiCuNi] Nickel

0.726 ZŁ with VAT / pcs + price for transport

0.590 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively get in touch through

our online form

the contact form page.

Specifications along with appearance of neodymium magnets can be analyzed using our

power calculator.

Order by 14:00 and we’ll ship today!

Product card - MW 5x7 / N38 - cylindrical magnet

Specification / characteristics - MW 5x7 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010090 |

| GTIN/EAN | 5906301810896 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 7 mm [±0,1 mm] |

| Weight | 1.03 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.67 kg / 6.60 N |

| Magnetic Induction ~ ? | 582.40 mT / 5824 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

Presented data are the direct effect of a physical simulation. Values rely on algorithms for the material Nd2Fe14B. Real-world parameters might slightly differ from theoretical values. Please consider these data as a preliminary roadmap for designers.

Table 1: Static pull force (pull vs distance) - interaction chart

MW 5x7 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5815 Gs

581.5 mT

|

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

weak grip |

| 1 mm |

3615 Gs

361.5 mT

|

0.26 kg / 0.57 pounds

259.0 g / 2.5 N

|

weak grip |

| 2 mm |

2101 Gs

210.1 mT

|

0.09 kg / 0.19 pounds

87.4 g / 0.9 N

|

weak grip |

| 3 mm |

1252 Gs

125.2 mT

|

0.03 kg / 0.07 pounds

31.1 g / 0.3 N

|

weak grip |

| 5 mm |

524 Gs

52.4 mT

|

0.01 kg / 0.01 pounds

5.4 g / 0.1 N

|

weak grip |

| 10 mm |

119 Gs

11.9 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

weak grip |

| 15 mm |

45 Gs

4.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 20 mm |

21 Gs

2.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

Table 2: Vertical force (wall)

MW 5x7 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.13 kg / 0.30 pounds

134.0 g / 1.3 N

|

| 1 mm | Stal (~0.2) |

0.05 kg / 0.11 pounds

52.0 g / 0.5 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

18.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 5x7 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.20 kg / 0.44 pounds

201.0 g / 2.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.13 kg / 0.30 pounds

134.0 g / 1.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.07 kg / 0.15 pounds

67.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.34 kg / 0.74 pounds

335.0 g / 3.3 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 5x7 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.07 kg / 0.15 pounds

67.0 g / 0.7 N

|

| 1 mm |

|

0.17 kg / 0.37 pounds

167.5 g / 1.6 N

|

| 2 mm |

|

0.34 kg / 0.74 pounds

335.0 g / 3.3 N

|

| 3 mm |

|

0.50 kg / 1.11 pounds

502.5 g / 4.9 N

|

| 5 mm |

|

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

| 10 mm |

|

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

| 11 mm |

|

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

| 12 mm |

|

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 5x7 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.67 kg / 1.48 pounds

670.0 g / 6.6 N

|

OK |

| 40 °C | -2.2% |

0.66 kg / 1.44 pounds

655.3 g / 6.4 N

|

OK |

| 60 °C | -4.4% |

0.64 kg / 1.41 pounds

640.5 g / 6.3 N

|

OK |

| 80 °C | -6.6% |

0.63 kg / 1.38 pounds

625.8 g / 6.1 N

|

|

| 100 °C | -28.8% |

0.48 kg / 1.05 pounds

477.0 g / 4.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 5x7 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.09 kg / 9.02 pounds

6 079 Gs

|

0.61 kg / 1.35 pounds

614 g / 6.0 N

|

N/A |

| 1 mm |

2.64 kg / 5.81 pounds

9 332 Gs

|

0.40 kg / 0.87 pounds

395 g / 3.9 N

|

2.37 kg / 5.23 pounds

~0 Gs

|

| 2 mm |

1.58 kg / 3.49 pounds

7 230 Gs

|

0.24 kg / 0.52 pounds

237 g / 2.3 N

|

1.42 kg / 3.14 pounds

~0 Gs

|

| 3 mm |

0.92 kg / 2.03 pounds

5 516 Gs

|

0.14 kg / 0.30 pounds

138 g / 1.4 N

|

0.83 kg / 1.83 pounds

~0 Gs

|

| 5 mm |

0.31 kg / 0.69 pounds

3 224 Gs

|

0.05 kg / 0.10 pounds

47 g / 0.5 N

|

0.28 kg / 0.62 pounds

~0 Gs

|

| 10 mm |

0.03 kg / 0.07 pounds

1 048 Gs

|

0.00 kg / 0.01 pounds

5 g / 0.0 N

|

0.03 kg / 0.07 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

238 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

24 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

15 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

7 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 5x7 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MW 5x7 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.73 km/h

(7.15 m/s)

|

0.03 J | |

| 30 mm |

44.55 km/h

(12.38 m/s)

|

0.08 J | |

| 50 mm |

57.52 km/h

(15.98 m/s)

|

0.13 J | |

| 100 mm |

81.34 km/h

(22.59 m/s)

|

0.26 J |

Table 9: Coating parameters (durability)

MW 5x7 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 5x7 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 219 Mx | 12.2 µWb |

| Pc Coefficient | 1.05 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 5x7 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.67 kg | Standard |

| Water (riverbed) |

0.77 kg

(+0.10 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet retains just ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.05

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Advantages as well as disadvantages of Nd2Fe14B magnets.

Strengths

- They do not lose magnetism, even after approximately 10 years – the decrease in power is only ~1% (based on measurements),

- Magnets very well protect themselves against demagnetization caused by external fields,

- Thanks to the shiny finish, the layer of nickel, gold-plated, or silver gives an elegant appearance,

- Neodymium magnets generate maximum magnetic induction on a small surface, which increases force concentration,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of detailed modeling as well as optimizing to atypical conditions,

- Key role in modern technologies – they serve a role in mass storage devices, electric motors, medical equipment, and other advanced devices.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Weaknesses

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a steel housing, which not only secures them against impacts but also increases their durability

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- We suggest a housing - magnetic mount, due to difficulties in producing nuts inside the magnet and complex shapes.

- Possible danger related to microscopic parts of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child health protection. Furthermore, small elements of these products are able to be problematic in diagnostics medical in case of swallowing.

- With mass production the cost of neodymium magnets is economically unviable,

Lifting parameters

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- on a plate made of mild steel, effectively closing the magnetic flux

- possessing a thickness of at least 10 mm to avoid saturation

- with an polished touching surface

- under conditions of no distance (surface-to-surface)

- during pulling in a direction vertical to the mounting surface

- at temperature approx. 20 degrees Celsius

Impact of factors on magnetic holding capacity in practice

- Clearance – the presence of any layer (paint, tape, air) interrupts the magnetic circuit, which lowers capacity steeply (even by 50% at 0.5 mm).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Plate thickness – insufficiently thick plate does not accept the full field, causing part of the flux to be escaped into the air.

- Metal type – not every steel reacts the same. High carbon content worsen the interaction with the magnet.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Roughness acts like micro-gaps.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

Precautions when working with neodymium magnets

Heat warning

Do not overheat. NdFeB magnets are sensitive to heat. If you require operation above 80°C, look for HT versions (H, SH, UH).

Conscious usage

Before use, check safety instructions. Sudden snapping can destroy the magnet or hurt your hand. Think ahead.

Data carriers

Powerful magnetic fields can destroy records on credit cards, hard drives, and storage devices. Stay away of min. 10 cm.

Danger to pacemakers

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Magnets are brittle

Beware of splinters. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.

Sensitization to coating

Studies show that nickel (the usual finish) is a strong allergen. For allergy sufferers, avoid direct skin contact or select versions in plastic housing.

No play value

Always keep magnets out of reach of children. Choking hazard is high, and the effects of magnets clamping inside the body are very dangerous.

Finger safety

Watch your fingers. Two large magnets will snap together instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Threat to navigation

GPS units and smartphones are highly sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the internal compass in your phone.

Machining danger

Drilling and cutting of NdFeB material poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

![UMGW 60x30x15 [M10] GW / N38 - magnetic holder internal thread UMGW 60x30x15 [M10] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gw-cug.jpg)