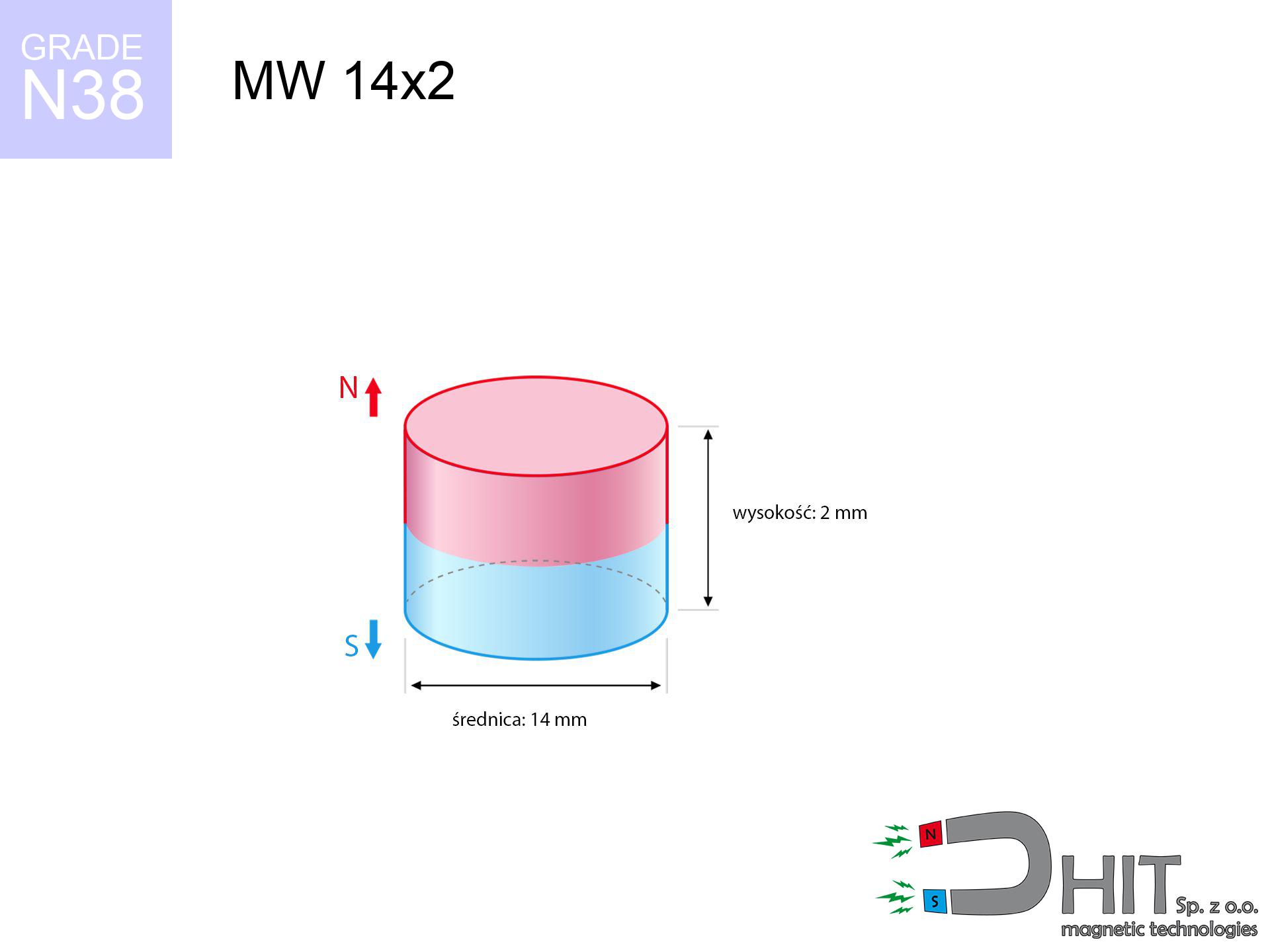

MW 14x2 / N38 - cylindrical magnet

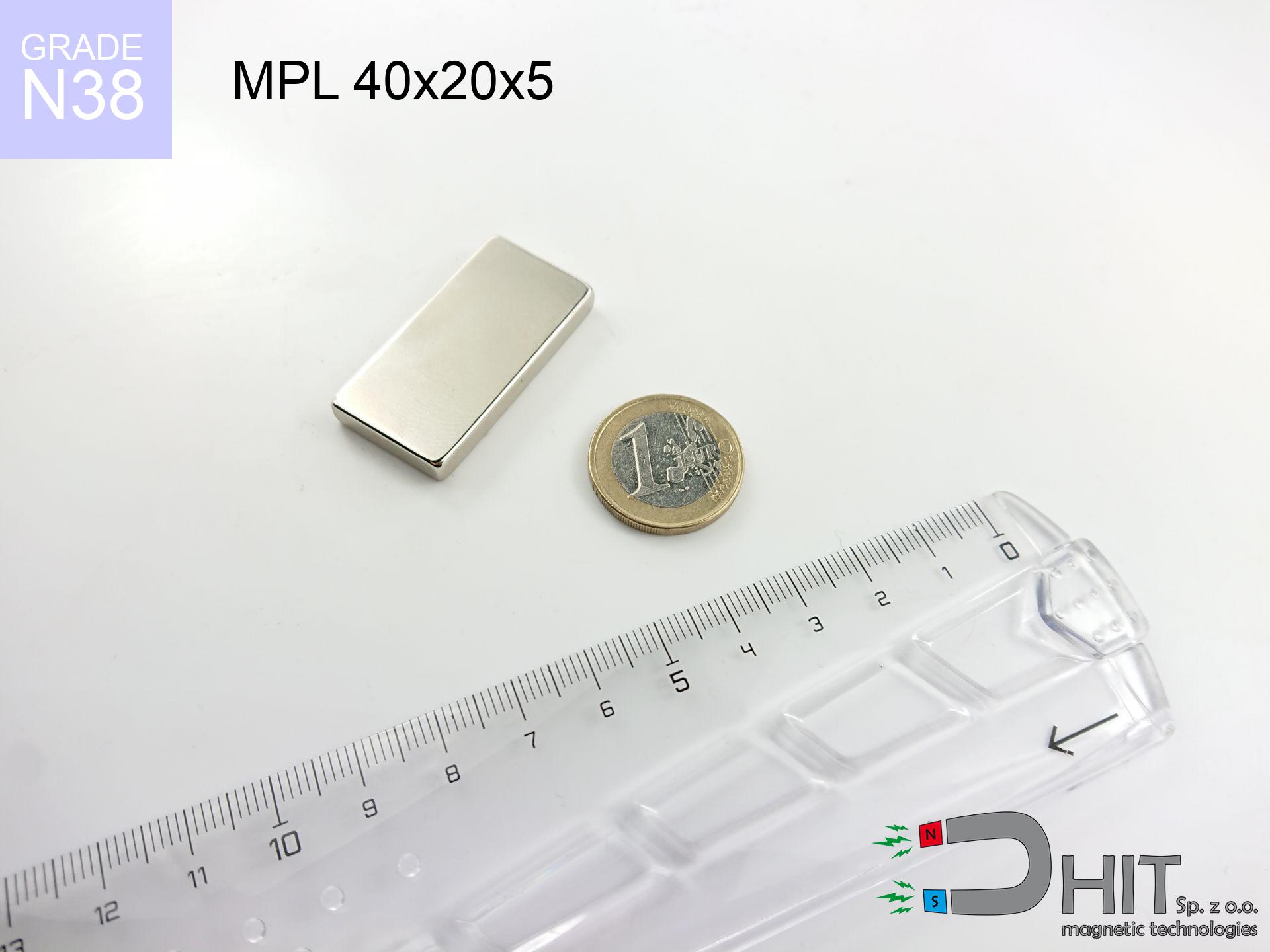

cylindrical magnet

Catalog no 010024

GTIN/EAN: 5906301810230

Diameter Ø

14 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

2.31 g

Magnetization Direction

↑ axial

Load capacity

1.48 kg / 14.51 N

Magnetic Induction

170.27 mT / 1703 Gs

Coating

[NiCuNi] Nickel

0.898 ZŁ with VAT / pcs + price for transport

0.730 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or let us know using

contact form

through our site.

Parameters as well as form of a neodymium magnet can be estimated with our

modular calculator.

Same-day shipping for orders placed before 14:00.

Technical - MW 14x2 / N38 - cylindrical magnet

Specification / characteristics - MW 14x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010024 |

| GTIN/EAN | 5906301810230 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 14 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 2.31 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.48 kg / 14.51 N |

| Magnetic Induction ~ ? | 170.27 mT / 1703 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the assembly - report

The following information are the outcome of a physical simulation. Values were calculated on models for the class Nd2Fe14B. Real-world parameters might slightly differ. Treat these calculations as a reference point during assembly planning.

Table 1: Static pull force (force vs distance) - characteristics

MW 14x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1702 Gs

170.2 mT

|

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

weak grip |

| 1 mm |

1565 Gs

156.5 mT

|

1.25 kg / 2.76 lbs

1251.7 g / 12.3 N

|

weak grip |

| 2 mm |

1373 Gs

137.3 mT

|

0.96 kg / 2.12 lbs

962.5 g / 9.4 N

|

weak grip |

| 3 mm |

1161 Gs

116.1 mT

|

0.69 kg / 1.52 lbs

688.9 g / 6.8 N

|

weak grip |

| 5 mm |

780 Gs

78.0 mT

|

0.31 kg / 0.69 lbs

311.0 g / 3.1 N

|

weak grip |

| 10 mm |

276 Gs

27.6 mT

|

0.04 kg / 0.09 lbs

39.0 g / 0.4 N

|

weak grip |

| 15 mm |

115 Gs

11.5 mT

|

0.01 kg / 0.01 lbs

6.7 g / 0.1 N

|

weak grip |

| 20 mm |

56 Gs

5.6 mT

|

0.00 kg / 0.00 lbs

1.6 g / 0.0 N

|

weak grip |

| 30 mm |

19 Gs

1.9 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

weak grip |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear hold (wall)

MW 14x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.30 kg / 0.65 lbs

296.0 g / 2.9 N

|

| 1 mm | Stal (~0.2) |

0.25 kg / 0.55 lbs

250.0 g / 2.5 N

|

| 2 mm | Stal (~0.2) |

0.19 kg / 0.42 lbs

192.0 g / 1.9 N

|

| 3 mm | Stal (~0.2) |

0.14 kg / 0.30 lbs

138.0 g / 1.4 N

|

| 5 mm | Stal (~0.2) |

0.06 kg / 0.14 lbs

62.0 g / 0.6 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 14x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.44 kg / 0.98 lbs

444.0 g / 4.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.30 kg / 0.65 lbs

296.0 g / 2.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.15 kg / 0.33 lbs

148.0 g / 1.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.74 kg / 1.63 lbs

740.0 g / 7.3 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 14x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.15 kg / 0.33 lbs

148.0 g / 1.5 N

|

| 1 mm |

|

0.37 kg / 0.82 lbs

370.0 g / 3.6 N

|

| 2 mm |

|

0.74 kg / 1.63 lbs

740.0 g / 7.3 N

|

| 3 mm |

|

1.11 kg / 2.45 lbs

1110.0 g / 10.9 N

|

| 5 mm |

|

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

| 10 mm |

|

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

| 11 mm |

|

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

| 12 mm |

|

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MW 14x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.48 kg / 3.26 lbs

1480.0 g / 14.5 N

|

OK |

| 40 °C | -2.2% |

1.45 kg / 3.19 lbs

1447.4 g / 14.2 N

|

OK |

| 60 °C | -4.4% |

1.41 kg / 3.12 lbs

1414.9 g / 13.9 N

|

|

| 80 °C | -6.6% |

1.38 kg / 3.05 lbs

1382.3 g / 13.6 N

|

|

| 100 °C | -28.8% |

1.05 kg / 2.32 lbs

1053.8 g / 10.3 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 14x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.75 kg / 6.06 lbs

3 073 Gs

|

0.41 kg / 0.91 lbs

413 g / 4.0 N

|

N/A |

| 1 mm |

2.56 kg / 5.65 lbs

3 287 Gs

|

0.38 kg / 0.85 lbs

385 g / 3.8 N

|

2.31 kg / 5.09 lbs

~0 Gs

|

| 2 mm |

2.33 kg / 5.13 lbs

3 131 Gs

|

0.35 kg / 0.77 lbs

349 g / 3.4 N

|

2.09 kg / 4.61 lbs

~0 Gs

|

| 3 mm |

2.06 kg / 4.54 lbs

2 947 Gs

|

0.31 kg / 0.68 lbs

309 g / 3.0 N

|

1.85 kg / 4.09 lbs

~0 Gs

|

| 5 mm |

1.52 kg / 3.36 lbs

2 535 Gs

|

0.23 kg / 0.50 lbs

229 g / 2.2 N

|

1.37 kg / 3.02 lbs

~0 Gs

|

| 10 mm |

0.58 kg / 1.27 lbs

1 561 Gs

|

0.09 kg / 0.19 lbs

87 g / 0.9 N

|

0.52 kg / 1.15 lbs

~0 Gs

|

| 20 mm |

0.07 kg / 0.16 lbs

552 Gs

|

0.01 kg / 0.02 lbs

11 g / 0.1 N

|

0.07 kg / 0.14 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

62 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

38 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

25 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

17 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

12 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

9 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 14x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 14x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.94 km/h

(7.21 m/s)

|

0.06 J | |

| 30 mm |

44.22 km/h

(12.28 m/s)

|

0.17 J | |

| 50 mm |

57.08 km/h

(15.86 m/s)

|

0.29 J | |

| 100 mm |

80.72 km/h

(22.42 m/s)

|

0.58 J |

Table 9: Anti-corrosion coating durability

MW 14x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 14x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 247 Mx | 32.5 µWb |

| Pc Coefficient | 0.22 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 14x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.48 kg | Standard |

| Water (riverbed) |

1.69 kg

(+0.21 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical surface, the magnet retains only ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.22

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (in laboratory conditions),

- Magnets perfectly protect themselves against demagnetization caused by ambient magnetic noise,

- In other words, due to the shiny surface of silver, the element gains a professional look,

- They are known for high magnetic induction at the operating surface, which increases their power,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Due to the option of free shaping and adaptation to custom projects, magnetic components can be created in a wide range of forms and dimensions, which amplifies use scope,

- Key role in modern technologies – they are used in hard drives, electromotive mechanisms, diagnostic systems, and multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They rust in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing nuts and complicated shapes in magnets, we recommend using a housing - magnetic holder.

- Potential hazard related to microscopic parts of magnets are risky, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that tiny parts of these devices are able to disrupt the diagnostic process medical after entering the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum lifting force for a neodymium magnet – what it depends on?

- on a block made of mild steel, perfectly concentrating the magnetic field

- with a cross-section of at least 10 mm

- with a surface cleaned and smooth

- under conditions of gap-free contact (metal-to-metal)

- during detachment in a direction vertical to the plane

- at ambient temperature room level

Practical lifting capacity: influencing factors

- Gap (between the magnet and the plate), since even a tiny distance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to paint, rust or dirt).

- Loading method – catalog parameter refers to detachment vertically. When applying parallel force, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Plate thickness – too thin plate does not close the flux, causing part of the power to be lost to the other side.

- Material composition – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves field saturation. Uneven metal weaken the grip.

- Temperature – temperature increase results in weakening of force. Check the maximum operating temperature for a given model.

Lifting capacity was measured using a smooth steel plate of suitable thickness (min. 20 mm), under vertically applied force, in contrast under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a small distance between the magnet’s surface and the plate lowers the lifting capacity.

Safety rules for work with neodymium magnets

Physical harm

Pinching hazard: The pulling power is so great that it can result in blood blisters, pinching, and broken bones. Protective gloves are recommended.

Warning for allergy sufferers

It is widely known that nickel (standard magnet coating) is a strong allergen. If your skin reacts to metals, prevent touching magnets with bare hands and choose coated magnets.

Fragile material

Protect your eyes. Magnets can explode upon uncontrolled impact, ejecting sharp fragments into the air. We recommend safety glasses.

Protect data

Data protection: Strong magnets can ruin data carriers and sensitive devices (pacemakers, medical aids, timepieces).

Compass and GPS

A powerful magnetic field disrupts the operation of compasses in smartphones and navigation systems. Do not bring magnets close to a device to avoid breaking the sensors.

Powerful field

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or hurt your hand. Be predictive.

Do not overheat magnets

Keep cool. Neodymium magnets are sensitive to heat. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Flammability

Fire hazard: Neodymium dust is highly flammable. Avoid machining magnets without safety gear as this risks ignition.

Medical interference

For implant holders: Powerful magnets disrupt medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Choking Hazard

Neodymium magnets are not toys. Eating several magnets may result in them pinching intestinal walls, which constitutes a critical condition and necessitates immediate surgery.

![SM 18x250 [2xM5] / N42 - magnetic separator SM 18x250 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x250-2xm5-raz.jpg)

![UMGGZ 43x6 [M6] GZ / N38 - rubber magnetic holder external thread UMGGZ 43x6 [M6] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-43x6-m6-gz-miw.jpg)