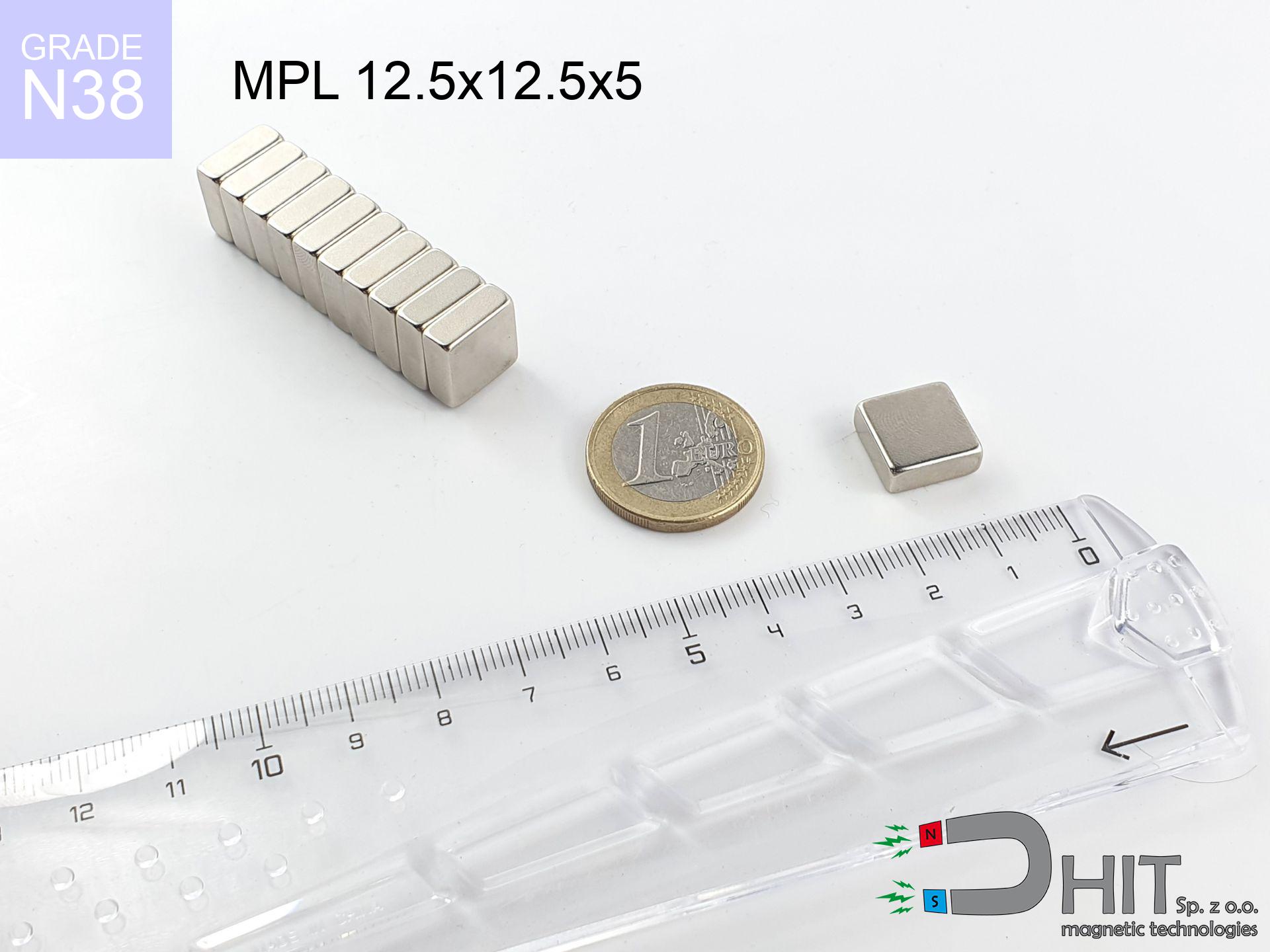

MPL 12.5x12.5x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020117

GTIN/EAN: 5906301811237

length

12.5 mm [±0,1 mm]

Width

12.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

5.86 g

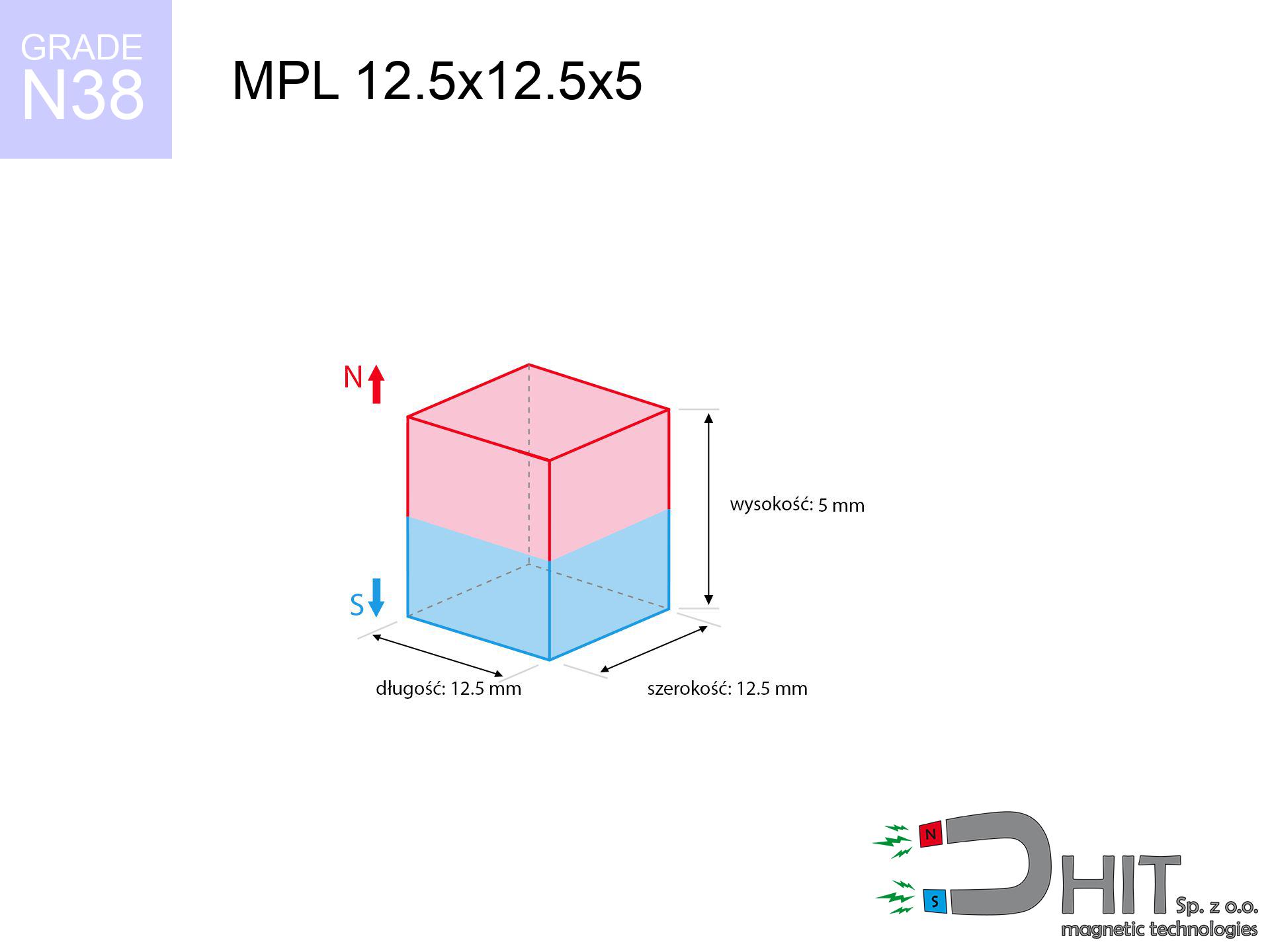

Magnetization Direction

↑ axial

Load capacity

4.84 kg / 47.51 N

Magnetic Induction

360.91 mT / 3609 Gs

Coating

[NiCuNi] Nickel

2.83 ZŁ with VAT / pcs + price for transport

2.30 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or let us know via

inquiry form

our website.

Weight and structure of magnetic components can be estimated on our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical details - MPL 12.5x12.5x5 / N38 - lamellar magnet

Specification / characteristics - MPL 12.5x12.5x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020117 |

| GTIN/EAN | 5906301811237 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 12.5 mm [±0,1 mm] |

| Width | 12.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 5.86 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.84 kg / 47.51 N |

| Magnetic Induction ~ ? | 360.91 mT / 3609 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - technical parameters

These information are the direct effect of a engineering simulation. Results rely on algorithms for the class Nd2Fe14B. Operational parameters may differ. Treat these calculations as a supplementary guide when designing systems.

Table 1: Static pull force (pull vs distance) - power drop

MPL 12.5x12.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3608 Gs

360.8 mT

|

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

medium risk |

| 1 mm |

3156 Gs

315.6 mT

|

3.70 kg / 8.17 LBS

3704.2 g / 36.3 N

|

medium risk |

| 2 mm |

2671 Gs

267.1 mT

|

2.65 kg / 5.85 LBS

2653.8 g / 26.0 N

|

medium risk |

| 3 mm |

2211 Gs

221.1 mT

|

1.82 kg / 4.01 LBS

1817.7 g / 17.8 N

|

weak grip |

| 5 mm |

1464 Gs

146.4 mT

|

0.80 kg / 1.76 LBS

797.6 g / 7.8 N

|

weak grip |

| 10 mm |

538 Gs

53.8 mT

|

0.11 kg / 0.24 LBS

107.6 g / 1.1 N

|

weak grip |

| 15 mm |

234 Gs

23.4 mT

|

0.02 kg / 0.05 LBS

20.4 g / 0.2 N

|

weak grip |

| 20 mm |

119 Gs

11.9 mT

|

0.01 kg / 0.01 LBS

5.3 g / 0.1 N

|

weak grip |

| 30 mm |

42 Gs

4.2 mT

|

0.00 kg / 0.00 LBS

0.7 g / 0.0 N

|

weak grip |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding load (vertical surface)

MPL 12.5x12.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.97 kg / 2.13 LBS

968.0 g / 9.5 N

|

| 1 mm | Stal (~0.2) |

0.74 kg / 1.63 LBS

740.0 g / 7.3 N

|

| 2 mm | Stal (~0.2) |

0.53 kg / 1.17 LBS

530.0 g / 5.2 N

|

| 3 mm | Stal (~0.2) |

0.36 kg / 0.80 LBS

364.0 g / 3.6 N

|

| 5 mm | Stal (~0.2) |

0.16 kg / 0.35 LBS

160.0 g / 1.6 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

22.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 12.5x12.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.45 kg / 3.20 LBS

1452.0 g / 14.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.97 kg / 2.13 LBS

968.0 g / 9.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.48 kg / 1.07 LBS

484.0 g / 4.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.42 kg / 5.34 LBS

2420.0 g / 23.7 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 12.5x12.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.48 kg / 1.07 LBS

484.0 g / 4.7 N

|

| 1 mm |

|

1.21 kg / 2.67 LBS

1210.0 g / 11.9 N

|

| 2 mm |

|

2.42 kg / 5.34 LBS

2420.0 g / 23.7 N

|

| 3 mm |

|

3.63 kg / 8.00 LBS

3630.0 g / 35.6 N

|

| 5 mm |

|

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

| 10 mm |

|

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

| 11 mm |

|

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

| 12 mm |

|

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

Table 5: Thermal stability (stability) - resistance threshold

MPL 12.5x12.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.84 kg / 10.67 LBS

4840.0 g / 47.5 N

|

OK |

| 40 °C | -2.2% |

4.73 kg / 10.44 LBS

4733.5 g / 46.4 N

|

OK |

| 60 °C | -4.4% |

4.63 kg / 10.20 LBS

4627.0 g / 45.4 N

|

|

| 80 °C | -6.6% |

4.52 kg / 9.97 LBS

4520.6 g / 44.3 N

|

|

| 100 °C | -28.8% |

3.45 kg / 7.60 LBS

3446.1 g / 33.8 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 12.5x12.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.54 kg / 27.64 LBS

5 069 Gs

|

1.88 kg / 4.15 LBS

1880 g / 18.4 N

|

N/A |

| 1 mm |

11.08 kg / 24.43 LBS

6 783 Gs

|

1.66 kg / 3.66 LBS

1662 g / 16.3 N

|

9.97 kg / 21.98 LBS

~0 Gs

|

| 2 mm |

9.59 kg / 21.15 LBS

6 312 Gs

|

1.44 kg / 3.17 LBS

1439 g / 14.1 N

|

8.63 kg / 19.04 LBS

~0 Gs

|

| 3 mm |

8.18 kg / 18.03 LBS

5 827 Gs

|

1.23 kg / 2.70 LBS

1226 g / 12.0 N

|

7.36 kg / 16.22 LBS

~0 Gs

|

| 5 mm |

5.71 kg / 12.60 LBS

4 871 Gs

|

0.86 kg / 1.89 LBS

857 g / 8.4 N

|

5.14 kg / 11.34 LBS

~0 Gs

|

| 10 mm |

2.07 kg / 4.55 LBS

2 929 Gs

|

0.31 kg / 0.68 LBS

310 g / 3.0 N

|

1.86 kg / 4.10 LBS

~0 Gs

|

| 20 mm |

0.28 kg / 0.61 LBS

1 076 Gs

|

0.04 kg / 0.09 LBS

42 g / 0.4 N

|

0.25 kg / 0.55 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

136 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

84 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

56 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

39 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

28 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

21 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MPL 12.5x12.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 12.5x12.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.38 km/h

(8.16 m/s)

|

0.20 J | |

| 30 mm |

50.21 km/h

(13.95 m/s)

|

0.57 J | |

| 50 mm |

64.81 km/h

(18.00 m/s)

|

0.95 J | |

| 100 mm |

91.65 km/h

(25.46 m/s)

|

1.90 J |

Table 9: Corrosion resistance

MPL 12.5x12.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 12.5x12.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 874 Mx | 58.7 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 12.5x12.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.84 kg | Standard |

| Water (riverbed) |

5.54 kg

(+0.70 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Advantages as well as disadvantages of neodymium magnets.

Strengths

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (in laboratory conditions),

- They have excellent resistance to weakening of magnetic properties due to opposing magnetic fields,

- Thanks to the shimmering finish, the layer of Ni-Cu-Ni, gold-plated, or silver gives an aesthetic appearance,

- Neodymium magnets achieve maximum magnetic induction on a small area, which ensures high operational effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to versatility in constructing and the capacity to modify to complex applications,

- Key role in electronics industry – they find application in magnetic memories, motor assemblies, advanced medical instruments, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which makes them useful in small systems

Disadvantages

- At very strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We suggest cover - magnetic holder, due to difficulties in realizing nuts inside the magnet and complex shapes.

- Possible danger related to microscopic parts of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Additionally, small elements of these devices can disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum magnetic pulling force – what affects it?

- using a sheet made of high-permeability steel, serving as a magnetic yoke

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- characterized by even structure

- under conditions of ideal adhesion (metal-to-metal)

- for force acting at a right angle (in the magnet axis)

- at temperature approx. 20 degrees Celsius

Practical aspects of lifting capacity – factors

- Distance (betwixt the magnet and the metal), because even a microscopic distance (e.g. 0.5 mm) leads to a decrease in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Angle of force application – maximum parameter is reached only during perpendicular pulling. The shear force of the magnet along the surface is typically several times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Chemical composition of the base – mild steel gives the best results. Higher carbon content lower magnetic properties and lifting capacity.

- Surface finish – full contact is possible only on smooth steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature – temperature increase causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Lifting capacity was assessed by applying a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

Warnings

Protect data

Very strong magnetic fields can destroy records on payment cards, hard drives, and other magnetic media. Stay away of min. 10 cm.

Beware of splinters

Beware of splinters. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. We recommend safety glasses.

GPS Danger

GPS units and smartphones are highly susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can permanently damage the sensors in your phone.

Danger to pacemakers

Individuals with a ICD have to maintain an safe separation from magnets. The magnetic field can interfere with the functioning of the life-saving device.

Machining danger

Dust produced during machining of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

No play value

Only for adults. Tiny parts can be swallowed, leading to severe trauma. Store away from children and animals.

Crushing risk

Large magnets can break fingers in a fraction of a second. Do not put your hand betwixt two attracting surfaces.

Conscious usage

Be careful. Neodymium magnets attract from a distance and connect with huge force, often faster than you can move away.

Allergy Warning

Some people experience a hypersensitivity to nickel, which is the typical protective layer for NdFeB magnets. Prolonged contact may cause skin redness. We suggest wear safety gloves.

Heat sensitivity

Do not overheat. NdFeB magnets are sensitive to heat. If you require operation above 80°C, ask us about special high-temperature series (H, SH, UH).

![UMP 94x28 [3xM10] GW F300 GOLD / N38 - search holder UMP 94x28 [3xM10] GW F300 GOLD / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x28-m10-gw-f300-vux.jpg)