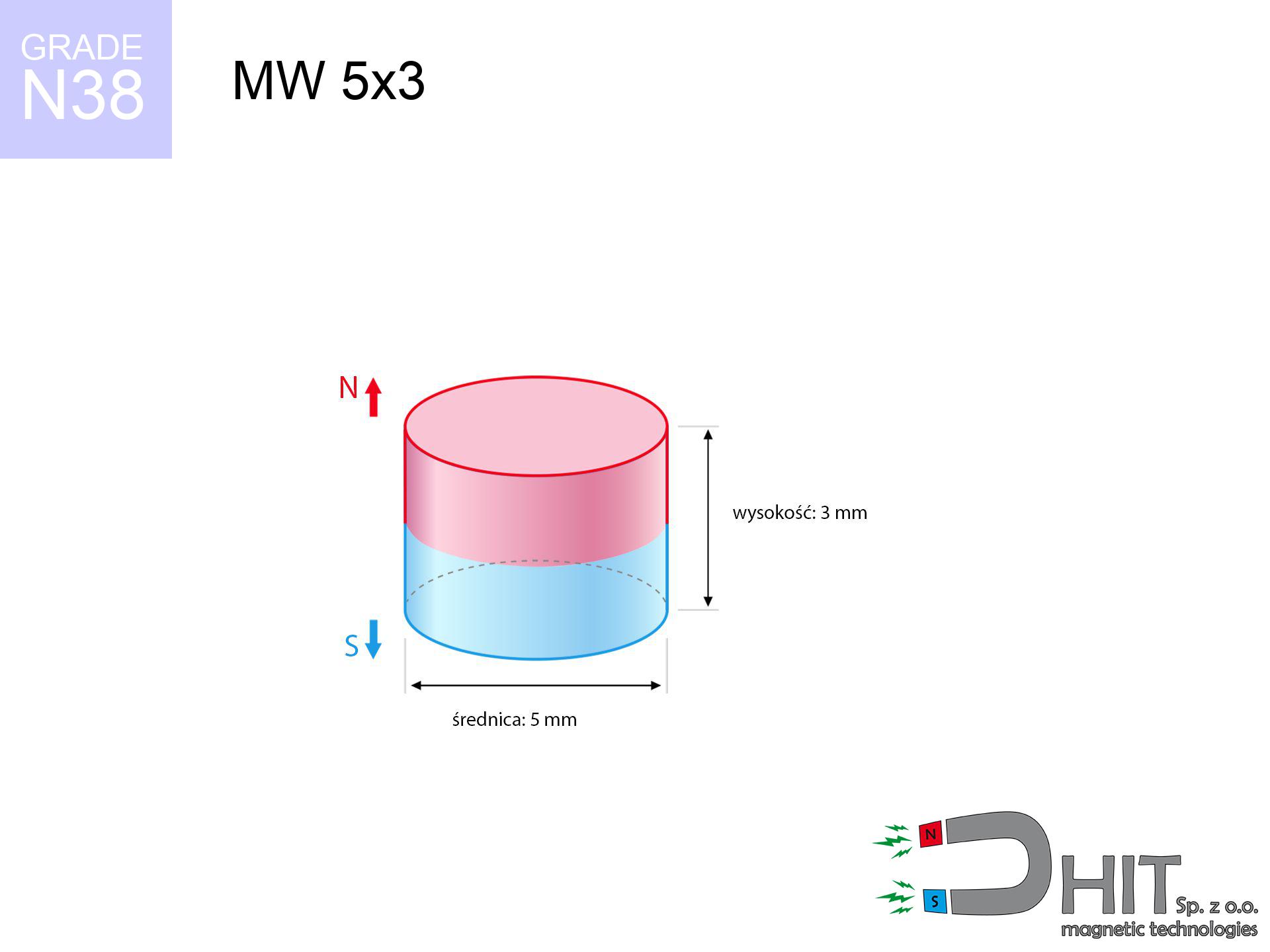

MW 5x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010087

GTIN/EAN: 5906301810865

Diameter Ø

5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

0.44 g

Magnetization Direction

↑ axial

Load capacity

0.84 kg / 8.25 N

Magnetic Induction

475.16 mT / 4752 Gs

Coating

[NiCuNi] Nickel

0.283 ZŁ with VAT / pcs + price for transport

0.230 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise drop us a message through

form

our website.

Force as well as appearance of magnetic components can be tested on our

online calculation tool.

Same-day processing for orders placed before 14:00.

Technical of the product - MW 5x3 / N38 - cylindrical magnet

Specification / characteristics - MW 5x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010087 |

| GTIN/EAN | 5906301810865 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 0.44 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.84 kg / 8.25 N |

| Magnetic Induction ~ ? | 475.16 mT / 4752 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - data

The following values are the outcome of a engineering calculation. Values were calculated on models for the material Nd2Fe14B. Operational performance may differ from theoretical values. Please consider these calculations as a reference point for designers.

Table 1: Static force (force vs gap) - power drop

MW 5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4745 Gs

474.5 mT

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

low risk |

| 1 mm |

2955 Gs

295.5 mT

|

0.33 kg / 0.72 LBS

325.8 g / 3.2 N

|

low risk |

| 2 mm |

1672 Gs

167.2 mT

|

0.10 kg / 0.23 LBS

104.4 g / 1.0 N

|

low risk |

| 3 mm |

960 Gs

96.0 mT

|

0.03 kg / 0.08 LBS

34.4 g / 0.3 N

|

low risk |

| 5 mm |

372 Gs

37.2 mT

|

0.01 kg / 0.01 LBS

5.2 g / 0.1 N

|

low risk |

| 10 mm |

74 Gs

7.4 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 15 mm |

25 Gs

2.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 20 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding force (vertical surface)

MW 5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

168.0 g / 1.6 N

|

| 1 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

66.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

20.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.25 kg / 0.56 LBS

252.0 g / 2.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.17 kg / 0.37 LBS

168.0 g / 1.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.19 LBS

84.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.42 kg / 0.93 LBS

420.0 g / 4.1 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.19 LBS

84.0 g / 0.8 N

|

| 1 mm |

|

0.21 kg / 0.46 LBS

210.0 g / 2.1 N

|

| 2 mm |

|

0.42 kg / 0.93 LBS

420.0 g / 4.1 N

|

| 3 mm |

|

0.63 kg / 1.39 LBS

630.0 g / 6.2 N

|

| 5 mm |

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

| 10 mm |

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

| 11 mm |

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

| 12 mm |

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MW 5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

OK |

| 40 °C | -2.2% |

0.82 kg / 1.81 LBS

821.5 g / 8.1 N

|

OK |

| 60 °C | -4.4% |

0.80 kg / 1.77 LBS

803.0 g / 7.9 N

|

OK |

| 80 °C | -6.6% |

0.78 kg / 1.73 LBS

784.6 g / 7.7 N

|

|

| 100 °C | -28.8% |

0.60 kg / 1.32 LBS

598.1 g / 5.9 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.73 kg / 6.01 LBS

5 700 Gs

|

0.41 kg / 0.90 LBS

409 g / 4.0 N

|

N/A |

| 1 mm |

1.77 kg / 3.91 LBS

7 658 Gs

|

0.27 kg / 0.59 LBS

266 g / 2.6 N

|

1.60 kg / 3.52 LBS

~0 Gs

|

| 2 mm |

1.06 kg / 2.33 LBS

5 910 Gs

|

0.16 kg / 0.35 LBS

159 g / 1.6 N

|

0.95 kg / 2.10 LBS

~0 Gs

|

| 3 mm |

0.60 kg / 1.33 LBS

4 460 Gs

|

0.09 kg / 0.20 LBS

90 g / 0.9 N

|

0.54 kg / 1.19 LBS

~0 Gs

|

| 5 mm |

0.19 kg / 0.42 LBS

2 520 Gs

|

0.03 kg / 0.06 LBS

29 g / 0.3 N

|

0.17 kg / 0.38 LBS

~0 Gs

|

| 10 mm |

0.02 kg / 0.04 LBS

745 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.03 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

147 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

44.07 km/h

(12.24 m/s)

|

0.03 J | |

| 30 mm |

76.32 km/h

(21.20 m/s)

|

0.10 J | |

| 50 mm |

98.53 km/h

(27.37 m/s)

|

0.16 J | |

| 100 mm |

139.35 km/h

(38.71 m/s)

|

0.33 J |

Table 9: Surface protection spec

MW 5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 942 Mx | 9.4 µWb |

| Pc Coefficient | 0.66 | High (Stable) |

Table 11: Physics of underwater searching

MW 5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.84 kg | Standard |

| Water (riverbed) |

0.96 kg

(+0.12 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds only ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely limits the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.66

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- They retain attractive force for nearly ten years – the drop is just ~1% (in theory),

- They maintain their magnetic properties even under close interference source,

- The use of an elegant layer of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, enabling action at temperatures approaching 230°C and above...

- Possibility of individual forming and adapting to defined requirements,

- Versatile presence in innovative solutions – they find application in HDD drives, brushless drives, medical equipment, and other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in compact constructions

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Due to limitations in producing nuts and complex shapes in magnets, we propose using cover - magnetic holder.

- Health risk resulting from small fragments of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, small elements of these products are able to complicate diagnosis medical in case of swallowing.

- Due to neodymium price, their price exceeds standard values,

Pull force analysis

Maximum lifting force for a neodymium magnet – what affects it?

- using a base made of low-carbon steel, acting as a circuit closing element

- possessing a massiveness of at least 10 mm to avoid saturation

- with a plane free of scratches

- without the slightest air gap between the magnet and steel

- under axial application of breakaway force (90-degree angle)

- at ambient temperature room level

Determinants of lifting force in real conditions

- Distance – the presence of any layer (rust, dirt, air) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Material type – the best choice is high-permeability steel. Stainless steels may attract less.

- Surface quality – the more even the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under parallel forces the holding force is lower. Additionally, even a small distance between the magnet’s surface and the plate lowers the holding force.

Safe handling of neodymium magnets

Metal Allergy

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation occurs, immediately stop handling magnets and wear gloves.

Swallowing risk

Adult use only. Small elements pose a choking risk, leading to intestinal necrosis. Keep out of reach of kids and pets.

GPS and phone interference

GPS units and mobile phones are highly sensitive to magnetic fields. Close proximity with a strong magnet can decalibrate the sensors in your phone.

Bone fractures

Large magnets can break fingers instantly. Never place your hand between two attracting surfaces.

Eye protection

Neodymium magnets are ceramic materials, which means they are very brittle. Collision of two magnets will cause them cracking into shards.

Safe distance

Very strong magnetic fields can erase data on credit cards, HDDs, and other magnetic media. Keep a distance of min. 10 cm.

Health Danger

For implant holders: Strong magnetic fields affect electronics. Keep minimum 30 cm distance or ask another person to handle the magnets.

Fire risk

Combustion risk: Rare earth powder is explosive. Avoid machining magnets without safety gear as this may cause fire.

Handling guide

Be careful. Rare earth magnets attract from a distance and snap with massive power, often faster than you can move away.

Permanent damage

Avoid heat. NdFeB magnets are susceptible to heat. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

![SM 32x275 [2xM8] / N52 - magnetic separator SM 32x275 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x275-2xm8-get.jpg)

![SM 32x325 [2xM8] / N42 - magnetic separator SM 32x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-fog.jpg)

![UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-platinium-lina-wiz.jpg)