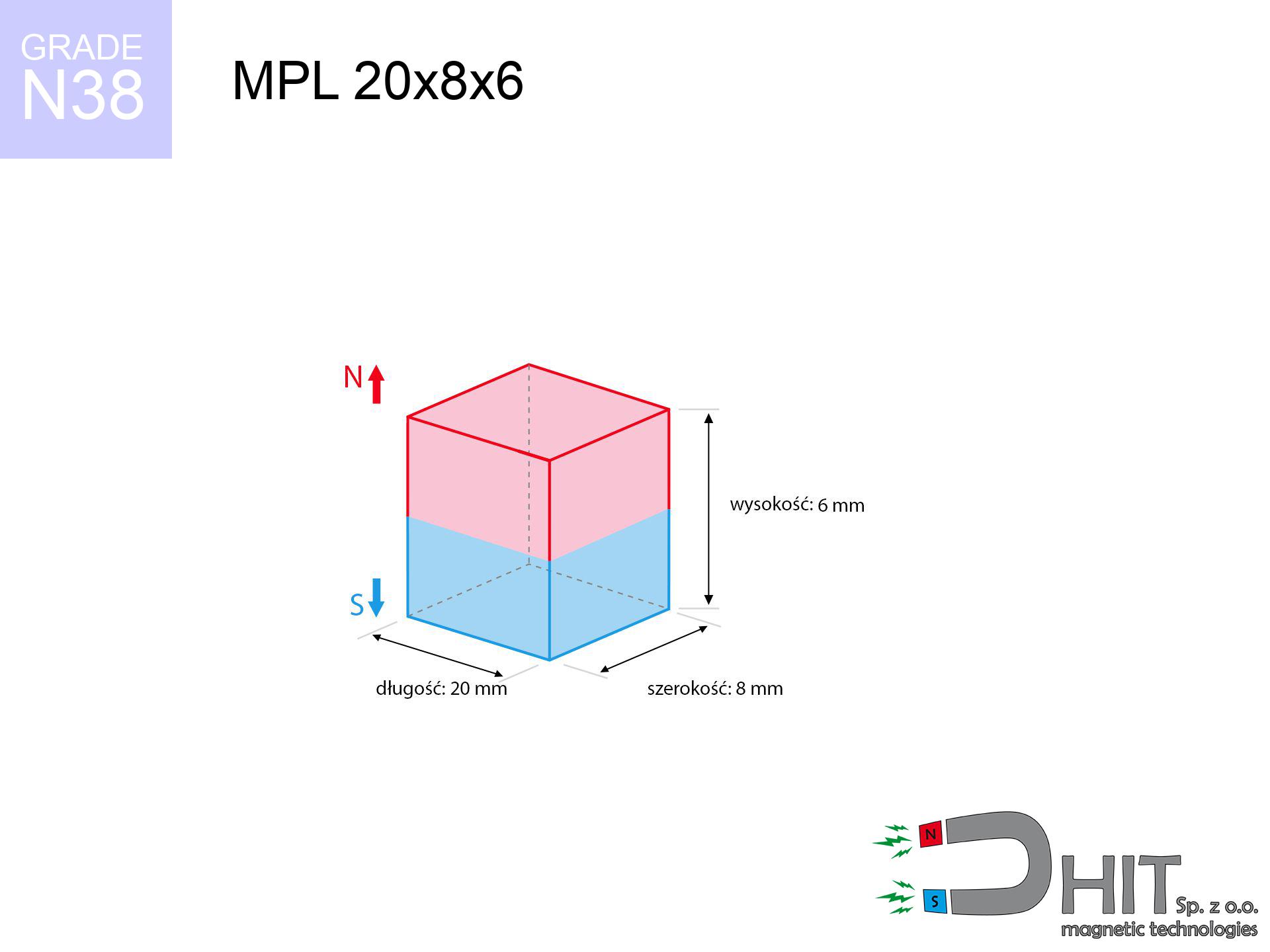

MPL 20x8x6 / N38 - lamellar magnet

lamellar magnet

Catalog no 020134

GTIN/EAN: 5906301811404

length

20 mm [±0,1 mm]

Width

8 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

7.2 g

Magnetization Direction

↑ axial

Load capacity

6.27 kg / 61.50 N

Magnetic Induction

423.90 mT / 4239 Gs

Coating

[NiCuNi] Nickel

5.17 ZŁ with VAT / pcs + price for transport

4.20 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or let us know by means of

our online form

the contact form page.

Force as well as shape of a neodymium magnet can be tested with our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Detailed specification - MPL 20x8x6 / N38 - lamellar magnet

Specification / characteristics - MPL 20x8x6 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020134 |

| GTIN/EAN | 5906301811404 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 8 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 7.2 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.27 kg / 61.50 N |

| Magnetic Induction ~ ? | 423.90 mT / 4239 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - data

The following data represent the outcome of a physical analysis. Results were calculated on models for the material Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static force (force vs distance) - power drop

MPL 20x8x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4236 Gs

423.6 mT

|

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

medium risk |

| 1 mm |

3505 Gs

350.5 mT

|

4.29 kg / 9.47 pounds

4293.5 g / 42.1 N

|

medium risk |

| 2 mm |

2814 Gs

281.4 mT

|

2.77 kg / 6.10 pounds

2766.9 g / 27.1 N

|

medium risk |

| 3 mm |

2235 Gs

223.5 mT

|

1.75 kg / 3.85 pounds

1745.9 g / 17.1 N

|

weak grip |

| 5 mm |

1425 Gs

142.5 mT

|

0.71 kg / 1.56 pounds

709.0 g / 7.0 N

|

weak grip |

| 10 mm |

540 Gs

54.0 mT

|

0.10 kg / 0.22 pounds

101.9 g / 1.0 N

|

weak grip |

| 15 mm |

248 Gs

24.8 mT

|

0.02 kg / 0.05 pounds

21.5 g / 0.2 N

|

weak grip |

| 20 mm |

131 Gs

13.1 mT

|

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

weak grip |

| 30 mm |

48 Gs

4.8 mT

|

0.00 kg / 0.00 pounds

0.8 g / 0.0 N

|

weak grip |

| 50 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

weak grip |

Table 2: Shear load (vertical surface)

MPL 20x8x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.25 kg / 2.76 pounds

1254.0 g / 12.3 N

|

| 1 mm | Stal (~0.2) |

0.86 kg / 1.89 pounds

858.0 g / 8.4 N

|

| 2 mm | Stal (~0.2) |

0.55 kg / 1.22 pounds

554.0 g / 5.4 N

|

| 3 mm | Stal (~0.2) |

0.35 kg / 0.77 pounds

350.0 g / 3.4 N

|

| 5 mm | Stal (~0.2) |

0.14 kg / 0.31 pounds

142.0 g / 1.4 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

20.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 20x8x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.88 kg / 4.15 pounds

1881.0 g / 18.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.25 kg / 2.76 pounds

1254.0 g / 12.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.63 kg / 1.38 pounds

627.0 g / 6.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.14 kg / 6.91 pounds

3135.0 g / 30.8 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 20x8x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.63 kg / 1.38 pounds

627.0 g / 6.2 N

|

| 1 mm |

|

1.57 kg / 3.46 pounds

1567.5 g / 15.4 N

|

| 2 mm |

|

3.14 kg / 6.91 pounds

3135.0 g / 30.8 N

|

| 3 mm |

|

4.70 kg / 10.37 pounds

4702.5 g / 46.1 N

|

| 5 mm |

|

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

| 10 mm |

|

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

| 11 mm |

|

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

| 12 mm |

|

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 20x8x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.27 kg / 13.82 pounds

6270.0 g / 61.5 N

|

OK |

| 40 °C | -2.2% |

6.13 kg / 13.52 pounds

6132.1 g / 60.2 N

|

OK |

| 60 °C | -4.4% |

5.99 kg / 13.21 pounds

5994.1 g / 58.8 N

|

|

| 80 °C | -6.6% |

5.86 kg / 12.91 pounds

5856.2 g / 57.4 N

|

|

| 100 °C | -28.8% |

4.46 kg / 9.84 pounds

4464.2 g / 43.8 N

|

Table 6: Two magnets (attraction) - field range

MPL 20x8x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.70 kg / 39.02 pounds

5 386 Gs

|

2.66 kg / 5.85 pounds

2655 g / 26.0 N

|

N/A |

| 1 mm |

14.82 kg / 32.66 pounds

7 751 Gs

|

2.22 kg / 4.90 pounds

2222 g / 21.8 N

|

13.33 kg / 29.40 pounds

~0 Gs

|

| 2 mm |

12.12 kg / 26.72 pounds

7 011 Gs

|

1.82 kg / 4.01 pounds

1818 g / 17.8 N

|

10.91 kg / 24.05 pounds

~0 Gs

|

| 3 mm |

9.78 kg / 21.55 pounds

6 296 Gs

|

1.47 kg / 3.23 pounds

1466 g / 14.4 N

|

8.80 kg / 19.40 pounds

~0 Gs

|

| 5 mm |

6.21 kg / 13.69 pounds

5 018 Gs

|

0.93 kg / 2.05 pounds

932 g / 9.1 N

|

5.59 kg / 12.32 pounds

~0 Gs

|

| 10 mm |

2.00 kg / 4.41 pounds

2 849 Gs

|

0.30 kg / 0.66 pounds

300 g / 2.9 N

|

1.80 kg / 3.97 pounds

~0 Gs

|

| 20 mm |

0.29 kg / 0.63 pounds

1 080 Gs

|

0.04 kg / 0.10 pounds

43 g / 0.4 N

|

0.26 kg / 0.57 pounds

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 pounds

153 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 pounds

97 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

65 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

45 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

33 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

25 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 20x8x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MPL 20x8x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

30.06 km/h

(8.35 m/s)

|

0.25 J | |

| 30 mm |

51.55 km/h

(14.32 m/s)

|

0.74 J | |

| 50 mm |

66.55 km/h

(18.49 m/s)

|

1.23 J | |

| 100 mm |

94.11 km/h

(26.14 m/s)

|

2.46 J |

Table 9: Surface protection spec

MPL 20x8x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 20x8x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 558 Mx | 65.6 µWb |

| Pc Coefficient | 0.52 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 20x8x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.27 kg | Standard |

| Water (riverbed) |

7.18 kg

(+0.91 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds only ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) severely reduces the holding force.

3. Heat tolerance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.52

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- They do not lose power, even after approximately ten years – the decrease in strength is only ~1% (based on measurements),

- Neodymium magnets prove to be highly resistant to loss of magnetic properties caused by external field sources,

- The use of an aesthetic coating of noble metals (nickel, gold, silver) causes the element to look better,

- They are known for high magnetic induction at the operating surface, which affects their effectiveness,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for operation at temperatures approaching 230°C and above...

- In view of the possibility of precise forming and customization to specialized solutions, neodymium magnets can be modeled in a variety of geometric configurations, which increases their versatility,

- Universal use in future technologies – they find application in computer drives, electric drive systems, diagnostic systems, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They oxidize in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- We suggest casing - magnetic holder, due to difficulties in creating threads inside the magnet and complex forms.

- Potential hazard resulting from small fragments of magnets are risky, in case of ingestion, which gains importance in the context of child health protection. Additionally, tiny parts of these magnets are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Magnetic strength at its maximum – what affects it?

- using a plate made of high-permeability steel, acting as a magnetic yoke

- whose thickness equals approx. 10 mm

- characterized by even structure

- without the slightest air gap between the magnet and steel

- under axial force vector (90-degree angle)

- at temperature room level

Lifting capacity in real conditions – factors

- Clearance – existence of foreign body (rust, tape, gap) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of converting into lifting capacity.

- Material composition – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Uneven metal reduce efficiency.

- Thermal environment – heating the magnet causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under shearing force the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

H&S for magnets

Caution required

Before use, read the rules. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Do not overheat magnets

Do not overheat. Neodymium magnets are sensitive to heat. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

Shattering risk

NdFeB magnets are ceramic materials, which means they are prone to chipping. Collision of two magnets will cause them breaking into small pieces.

This is not a toy

Absolutely store magnets out of reach of children. Ingestion danger is high, and the effects of magnets clamping inside the body are fatal.

Precision electronics

A powerful magnetic field disrupts the functioning of magnetometers in phones and navigation systems. Maintain magnets close to a device to avoid damaging the sensors.

Hand protection

Large magnets can smash fingers instantly. Do not put your hand between two strong magnets.

Life threat

Warning for patients: Strong magnetic fields affect medical devices. Keep at least 30 cm distance or request help to handle the magnets.

Do not drill into magnets

Mechanical processing of NdFeB material poses a fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Threat to electronics

Intense magnetic fields can corrupt files on credit cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

Nickel coating and allergies

A percentage of the population suffer from a sensitization to nickel, which is the common plating for NdFeB magnets. Frequent touching can result in dermatitis. We strongly advise use safety gloves.

![UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-29x8-m4-gw-duf.jpg)