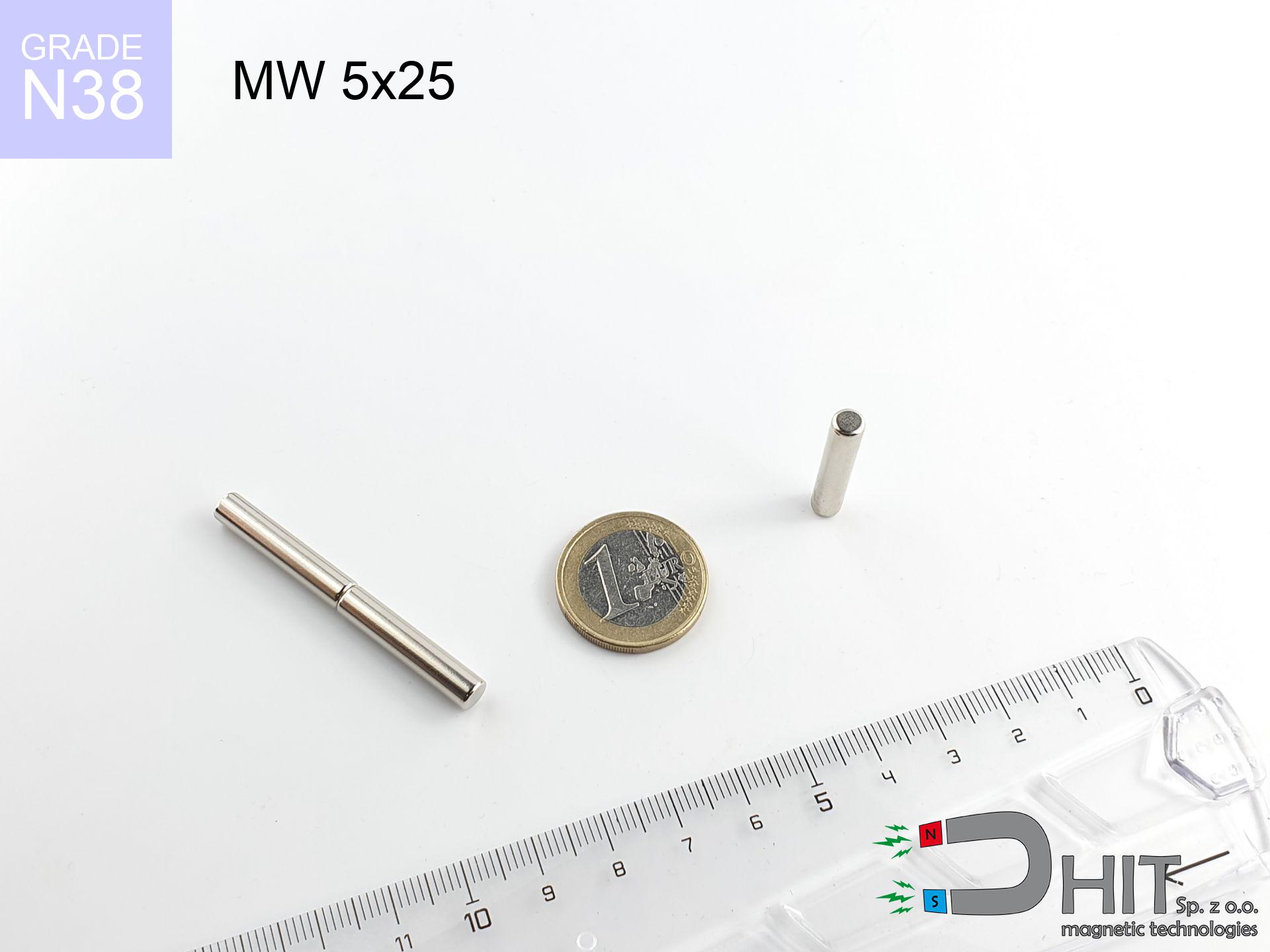

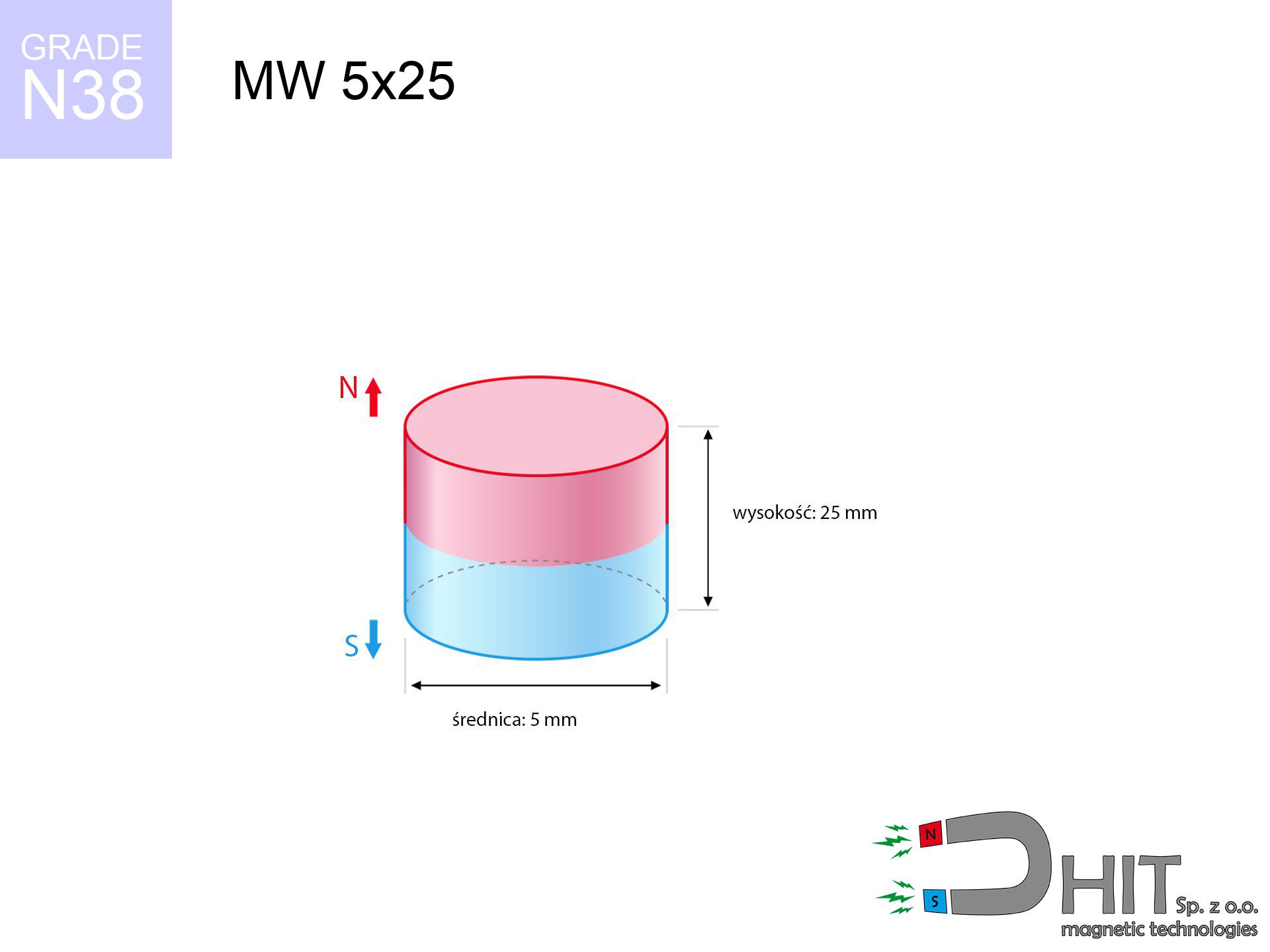

MW 5x25 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010086

GTIN/EAN: 5906301810858

Diameter Ø

5 mm [±0,1 mm]

Height

25 mm [±0,1 mm]

Weight

3.68 g

Magnetization Direction

↑ axial

Load capacity

0.45 kg / 4.41 N

Magnetic Induction

615.39 mT / 6154 Gs

Coating

[NiCuNi] Nickel

2.31 ZŁ with VAT / pcs + price for transport

1.880 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer contact us using

request form

through our site.

Force and form of magnetic components can be tested with our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data - MW 5x25 / N38 - cylindrical magnet

Specification / characteristics - MW 5x25 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010086 |

| GTIN/EAN | 5906301810858 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 25 mm [±0,1 mm] |

| Weight | 3.68 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.45 kg / 4.41 N |

| Magnetic Induction ~ ? | 615.39 mT / 6154 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - data

The following information constitute the outcome of a engineering analysis. Values were calculated on models for the class Nd2Fe14B. Real-world performance might slightly deviate from the simulation results. Use these data as a preliminary roadmap for designers.

Table 1: Static pull force (force vs gap) - power drop

MW 5x25 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6144 Gs

614.4 mT

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

weak grip |

| 1 mm |

3869 Gs

386.9 mT

|

0.18 kg / 0.39 LBS

178.4 g / 1.8 N

|

weak grip |

| 2 mm |

2300 Gs

230.0 mT

|

0.06 kg / 0.14 LBS

63.1 g / 0.6 N

|

weak grip |

| 3 mm |

1412 Gs

141.2 mT

|

0.02 kg / 0.05 LBS

23.8 g / 0.2 N

|

weak grip |

| 5 mm |

633 Gs

63.3 mT

|

0.00 kg / 0.01 LBS

4.8 g / 0.0 N

|

weak grip |

| 10 mm |

169 Gs

16.9 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

weak grip |

| 15 mm |

72 Gs

7.2 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 20 mm |

38 Gs

3.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Vertical force (wall)

MW 5x25 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| 1 mm | Stal (~0.2) |

0.04 kg / 0.08 LBS

36.0 g / 0.4 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 5x25 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.14 kg / 0.30 LBS

135.0 g / 1.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.05 kg / 0.10 LBS

45.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.23 kg / 0.50 LBS

225.0 g / 2.2 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 5x25 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.05 kg / 0.10 LBS

45.0 g / 0.4 N

|

| 1 mm |

|

0.11 kg / 0.25 LBS

112.5 g / 1.1 N

|

| 2 mm |

|

0.23 kg / 0.50 LBS

225.0 g / 2.2 N

|

| 3 mm |

|

0.34 kg / 0.74 LBS

337.5 g / 3.3 N

|

| 5 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 10 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 11 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 12 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

Table 5: Thermal stability (stability) - power drop

MW 5x25 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

OK |

| 40 °C | -2.2% |

0.44 kg / 0.97 LBS

440.1 g / 4.3 N

|

OK |

| 60 °C | -4.4% |

0.43 kg / 0.95 LBS

430.2 g / 4.2 N

|

OK |

| 80 °C | -6.6% |

0.42 kg / 0.93 LBS

420.3 g / 4.1 N

|

|

| 100 °C | -28.8% |

0.32 kg / 0.71 LBS

320.4 g / 3.1 N

|

Table 6: Two magnets (attraction) - field range

MW 5x25 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.57 kg / 10.08 LBS

6 167 Gs

|

0.69 kg / 1.51 LBS

686 g / 6.7 N

|

N/A |

| 1 mm |

2.97 kg / 6.55 LBS

9 909 Gs

|

0.45 kg / 0.98 LBS

446 g / 4.4 N

|

2.67 kg / 5.90 LBS

~0 Gs

|

| 2 mm |

1.81 kg / 3.99 LBS

7 738 Gs

|

0.27 kg / 0.60 LBS

272 g / 2.7 N

|

1.63 kg / 3.60 LBS

~0 Gs

|

| 3 mm |

1.08 kg / 2.37 LBS

5 965 Gs

|

0.16 kg / 0.36 LBS

162 g / 1.6 N

|

0.97 kg / 2.14 LBS

~0 Gs

|

| 5 mm |

0.39 kg / 0.86 LBS

3 581 Gs

|

0.06 kg / 0.13 LBS

58 g / 0.6 N

|

0.35 kg / 0.77 LBS

~0 Gs

|

| 10 mm |

0.05 kg / 0.11 LBS

1 266 Gs

|

0.01 kg / 0.02 LBS

7 g / 0.1 N

|

0.04 kg / 0.10 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 LBS

339 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

46 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

30 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

21 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

15 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 5x25 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - warning

MW 5x25 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

11.16 km/h

(3.10 m/s)

|

0.02 J | |

| 30 mm |

19.32 km/h

(5.37 m/s)

|

0.05 J | |

| 50 mm |

24.94 km/h

(6.93 m/s)

|

0.09 J | |

| 100 mm |

35.27 km/h

(9.80 m/s)

|

0.18 J |

Table 9: Surface protection spec

MW 5x25 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 5x25 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 450 Mx | 14.5 µWb |

| Pc Coefficient | 1.55 | High (Stable) |

Table 11: Submerged application

MW 5x25 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.45 kg | Standard |

| Water (riverbed) |

0.52 kg

(+0.07 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds only a fraction of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.55

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Advantages

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (in laboratory conditions),

- They have excellent resistance to weakening of magnetic properties when exposed to external fields,

- By covering with a shiny layer of gold, the element presents an elegant look,

- Neodymium magnets achieve maximum magnetic induction on a their surface, which increases force concentration,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of custom shaping as well as modifying to defined needs,

- Key role in high-tech industry – they are commonly used in magnetic memories, electric motors, medical equipment, as well as industrial machines.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Weaknesses

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a special holder, which not only protects them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- We recommend cover - magnetic mechanism, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Possible danger resulting from small fragments of magnets are risky, in case of ingestion, which becomes key in the context of child safety. Furthermore, small elements of these magnets can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Maximum lifting capacity of the magnet – what it depends on?

- using a base made of high-permeability steel, acting as a ideal flux conductor

- whose thickness equals approx. 10 mm

- characterized by lack of roughness

- with total lack of distance (without impurities)

- for force applied at a right angle (in the magnet axis)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Gap between surfaces – every millimeter of distance (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of generating force.

- Material type – the best choice is high-permeability steel. Cast iron may attract less.

- Surface condition – ground elements guarantee perfect abutment, which increases field saturation. Uneven metal reduce efficiency.

- Thermal factor – hot environment reduces magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under shearing force the load capacity is reduced by as much as 5 times. In addition, even a small distance between the magnet and the plate lowers the lifting capacity.

Safety rules for work with NdFeB magnets

Danger to the youngest

Neodymium magnets are not toys. Accidental ingestion of several magnets can lead to them pinching intestinal walls, which poses a critical condition and requires urgent medical intervention.

Threat to navigation

Note: neodymium magnets generate a field that confuses precision electronics. Keep a safe distance from your phone, device, and navigation systems.

ICD Warning

People with a pacemaker have to keep an large gap from magnets. The magnetic field can stop the operation of the implant.

Dust is flammable

Combustion risk: Rare earth powder is explosive. Avoid machining magnets in home conditions as this risks ignition.

Bone fractures

Watch your fingers. Two powerful magnets will snap together immediately with a force of massive weight, destroying anything in their path. Be careful!

Permanent damage

Standard neodymium magnets (N-type) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Eye protection

Watch out for shards. Magnets can fracture upon violent connection, launching sharp fragments into the air. Eye protection is mandatory.

Keep away from computers

Powerful magnetic fields can erase data on payment cards, HDDs, and other magnetic media. Keep a distance of at least 10 cm.

Warning for allergy sufferers

It is widely known that the nickel plating (the usual finish) is a potent allergen. If your skin reacts to metals, avoid touching magnets with bare hands or opt for encased magnets.

Handling rules

Be careful. Neodymium magnets act from a long distance and snap with massive power, often faster than you can move away.

![SM 32x175 [2xM8] / N42 - magnetic separator SM 32x175 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-tej.jpg)

![AM ucho [M10] - magnetic accessories AM ucho [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m10-tij.jpg)