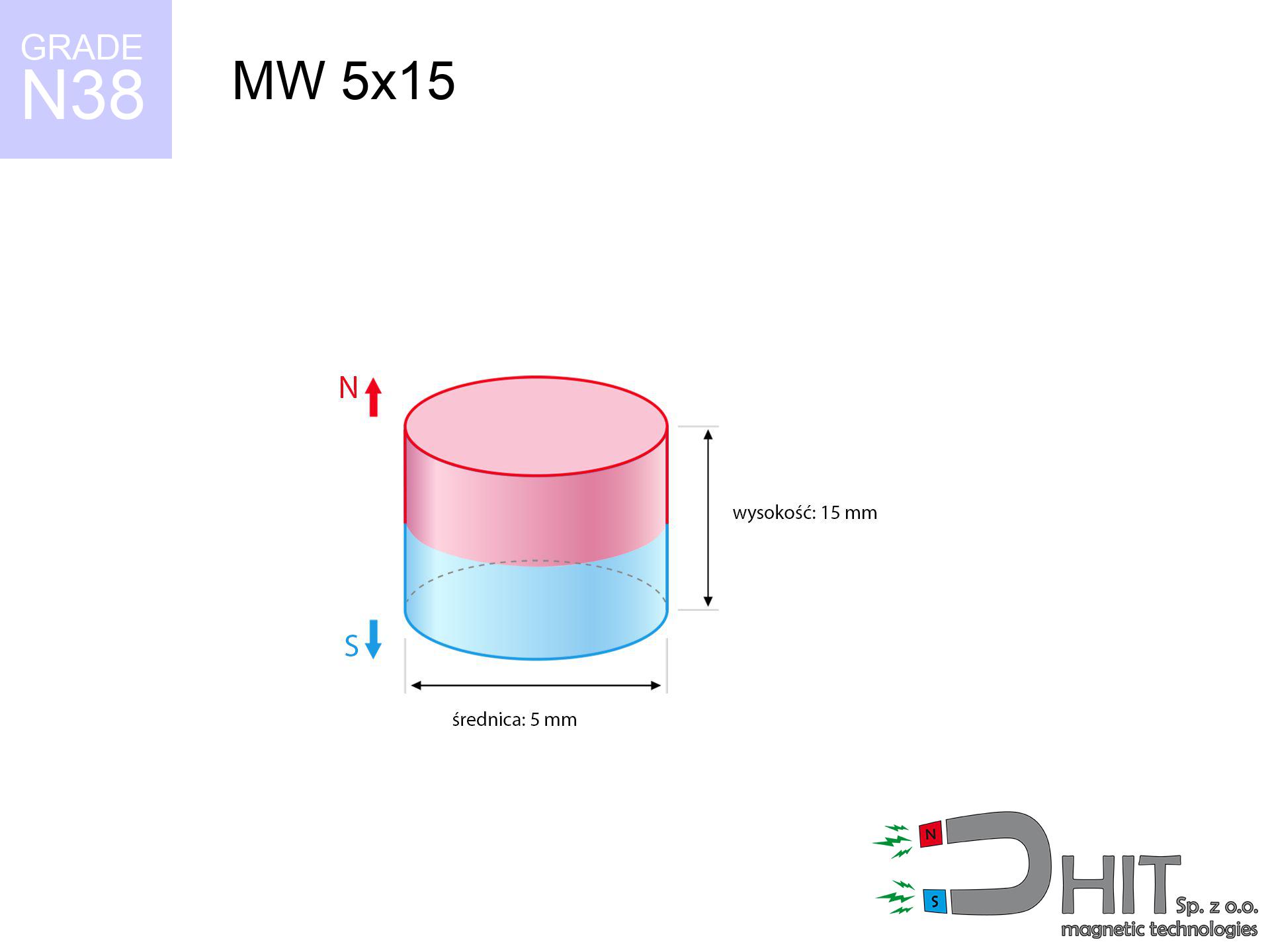

MW 5x15 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010084

GTIN/EAN: 5906301810834

Diameter Ø

5 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

2.21 g

Magnetization Direction

↑ axial

Load capacity

0.48 kg / 4.68 N

Magnetic Induction

610.03 mT / 6100 Gs

Coating

[NiCuNi] Nickel

1.107 ZŁ with VAT / pcs + price for transport

0.900 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or let us know using

form

the contact section.

Weight along with form of neodymium magnets can be reviewed using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters - MW 5x15 / N38 - cylindrical magnet

Specification / characteristics - MW 5x15 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010084 |

| GTIN/EAN | 5906301810834 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 2.21 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.48 kg / 4.68 N |

| Magnetic Induction ~ ? | 610.03 mT / 6100 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the assembly - report

These data constitute the result of a mathematical analysis. Results are based on models for the material Nd2Fe14B. Operational performance might slightly differ. Please consider these data as a reference point during assembly planning.

Table 1: Static force (pull vs distance) - characteristics

MW 5x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6091 Gs

609.1 mT

|

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

low risk |

| 1 mm |

3823 Gs

382.3 mT

|

0.19 kg / 0.42 lbs

189.1 g / 1.9 N

|

low risk |

| 2 mm |

2261 Gs

226.1 mT

|

0.07 kg / 0.15 lbs

66.1 g / 0.6 N

|

low risk |

| 3 mm |

1378 Gs

137.8 mT

|

0.02 kg / 0.05 lbs

24.6 g / 0.2 N

|

low risk |

| 5 mm |

607 Gs

60.7 mT

|

0.00 kg / 0.01 lbs

4.8 g / 0.0 N

|

low risk |

| 10 mm |

154 Gs

15.4 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

low risk |

| 15 mm |

63 Gs

6.3 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

| 20 mm |

32 Gs

3.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage hold (vertical surface)

MW 5x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.10 kg / 0.21 lbs

96.0 g / 0.9 N

|

| 1 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

38.0 g / 0.4 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 5x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.14 kg / 0.32 lbs

144.0 g / 1.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.10 kg / 0.21 lbs

96.0 g / 0.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.05 kg / 0.11 lbs

48.0 g / 0.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.24 kg / 0.53 lbs

240.0 g / 2.4 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 5x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.05 kg / 0.11 lbs

48.0 g / 0.5 N

|

| 1 mm |

|

0.12 kg / 0.26 lbs

120.0 g / 1.2 N

|

| 2 mm |

|

0.24 kg / 0.53 lbs

240.0 g / 2.4 N

|

| 3 mm |

|

0.36 kg / 0.79 lbs

360.0 g / 3.5 N

|

| 5 mm |

|

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

| 10 mm |

|

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

| 11 mm |

|

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

| 12 mm |

|

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

Table 5: Thermal stability (stability) - resistance threshold

MW 5x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.48 kg / 1.06 lbs

480.0 g / 4.7 N

|

OK |

| 40 °C | -2.2% |

0.47 kg / 1.03 lbs

469.4 g / 4.6 N

|

OK |

| 60 °C | -4.4% |

0.46 kg / 1.01 lbs

458.9 g / 4.5 N

|

OK |

| 80 °C | -6.6% |

0.45 kg / 0.99 lbs

448.3 g / 4.4 N

|

|

| 100 °C | -28.8% |

0.34 kg / 0.75 lbs

341.8 g / 3.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 5x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.49 kg / 9.90 lbs

6 154 Gs

|

0.67 kg / 1.49 lbs

674 g / 6.6 N

|

N/A |

| 1 mm |

2.91 kg / 6.42 lbs

9 810 Gs

|

0.44 kg / 0.96 lbs

437 g / 4.3 N

|

2.62 kg / 5.78 lbs

~0 Gs

|

| 2 mm |

1.77 kg / 3.90 lbs

7 646 Gs

|

0.27 kg / 0.59 lbs

265 g / 2.6 N

|

1.59 kg / 3.51 lbs

~0 Gs

|

| 3 mm |

1.05 kg / 2.31 lbs

5 880 Gs

|

0.16 kg / 0.35 lbs

157 g / 1.5 N

|

0.94 kg / 2.08 lbs

~0 Gs

|

| 5 mm |

0.37 kg / 0.82 lbs

3 507 Gs

|

0.06 kg / 0.12 lbs

56 g / 0.5 N

|

0.34 kg / 0.74 lbs

~0 Gs

|

| 10 mm |

0.04 kg / 0.10 lbs

1 213 Gs

|

0.01 kg / 0.01 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 lbs

309 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

37 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

16 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

11 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

8 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

6 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 5x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 5x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

14.87 km/h

(4.13 m/s)

|

0.02 J | |

| 30 mm |

25.74 km/h

(7.15 m/s)

|

0.06 J | |

| 50 mm |

33.23 km/h

(9.23 m/s)

|

0.09 J | |

| 100 mm |

47.00 km/h

(13.06 m/s)

|

0.19 J |

Table 9: Corrosion resistance

MW 5x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 5x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 382 Mx | 13.8 µWb |

| Pc Coefficient | 1.38 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 5x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.48 kg | Standard |

| Water (riverbed) |

0.55 kg

(+0.07 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical wall, the magnet retains just approx. 20-30% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.38

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of neodymium magnets.

Advantages

- They do not lose power, even during nearly ten years – the decrease in power is only ~1% (based on measurements),

- They have excellent resistance to magnetism drop as a result of external fields,

- Thanks to the glossy finish, the surface of Ni-Cu-Ni, gold, or silver-plated gives an modern appearance,

- Neodymium magnets generate maximum magnetic induction on a small surface, which increases force concentration,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of individual shaping and adapting to atypical needs,

- Versatile presence in future technologies – they find application in mass storage devices, electric motors, diagnostic systems, also technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which makes them useful in miniature devices

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a steel housing, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- We suggest cover - magnetic mount, due to difficulties in producing nuts inside the magnet and complex forms.

- Potential hazard related to microscopic parts of magnets are risky, if swallowed, which becomes key in the context of child health protection. Additionally, small elements of these products are able to be problematic in diagnostics medical when they are in the body.

- With mass production the cost of neodymium magnets can be a barrier,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a base made of mild steel, perfectly concentrating the magnetic field

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with a plane perfectly flat

- without the slightest clearance between the magnet and steel

- for force applied at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Determinants of practical lifting force of a magnet

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When applying parallel force, the magnet holds significantly lower power (typically approx. 20-30% of maximum force).

- Steel thickness – insufficiently thick plate causes magnetic saturation, causing part of the power to be escaped to the other side.

- Steel type – mild steel gives the best results. Higher carbon content reduce magnetic properties and lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Rough surfaces weaken the grip.

- Temperature – temperature increase causes a temporary drop of induction. Check the thermal limit for a given model.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under perpendicular forces, in contrast under parallel forces the holding force is lower. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

H&S for magnets

Keep away from children

Always store magnets out of reach of children. Ingestion danger is high, and the consequences of magnets connecting inside the body are very dangerous.

Sensitization to coating

Medical facts indicate that the nickel plating (the usual finish) is a potent allergen. If you have an allergy, refrain from direct skin contact and select coated magnets.

Hand protection

Watch your fingers. Two large magnets will snap together instantly with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

ICD Warning

Warning for patients: Powerful magnets disrupt medical devices. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Precision electronics

GPS units and mobile phones are highly susceptible to magnetic fields. Close proximity with a strong magnet can ruin the sensors in your phone.

Data carriers

Data protection: Neodymium magnets can damage data carriers and sensitive devices (heart implants, hearing aids, mechanical watches).

Caution required

Handle magnets consciously. Their huge power can shock even experienced users. Plan your moves and do not underestimate their force.

Maximum temperature

Regular neodymium magnets (N-type) lose power when the temperature exceeds 80°C. Damage is permanent.

Flammability

Machining of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Fragile material

Despite metallic appearance, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

![UMH 48x11x65 [M6] / N38 - magnetic holder with hook UMH 48x11x65 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-48x11x65-m6-wiw.jpg)

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)