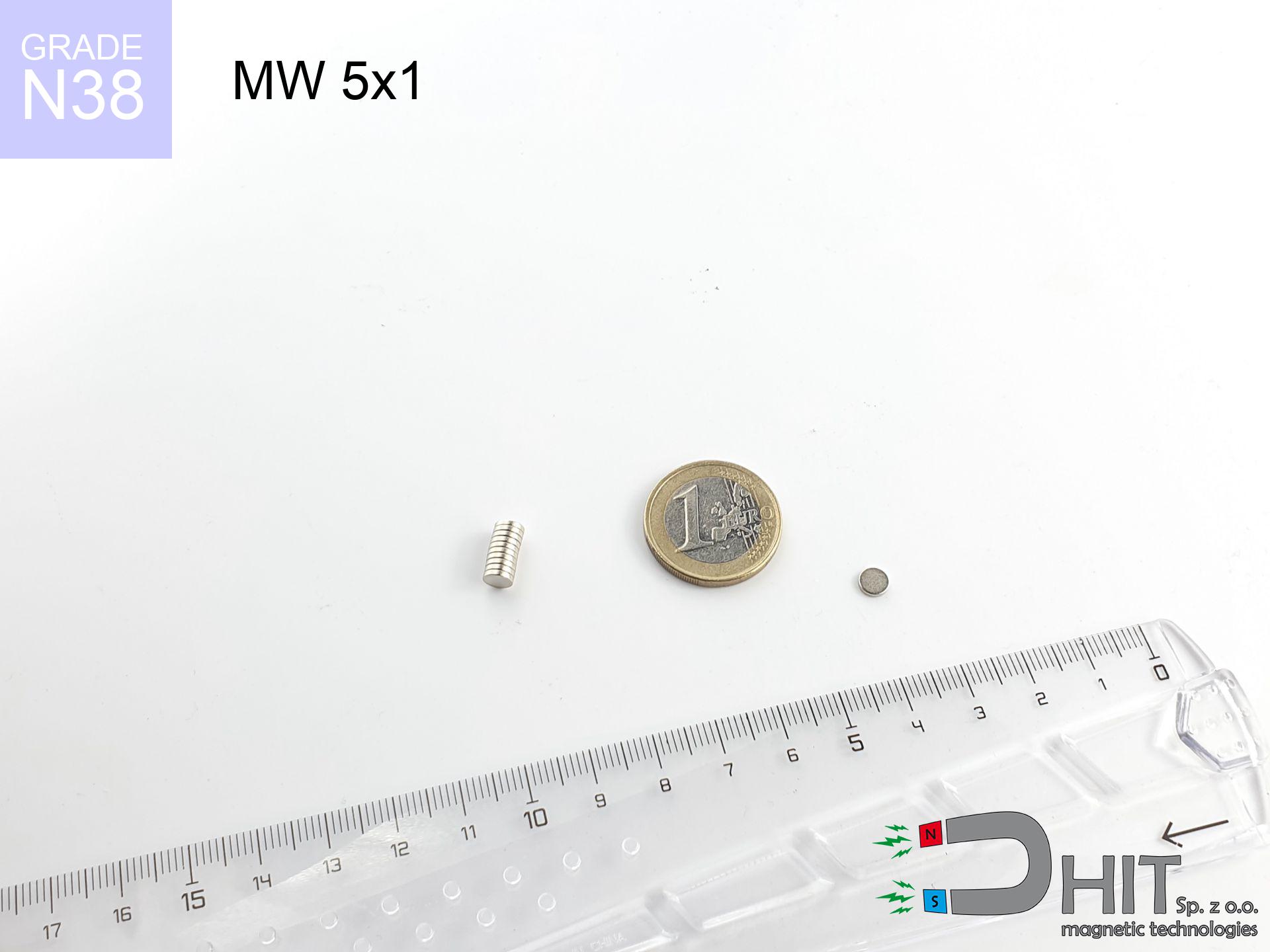

MW 5x1 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010082

GTIN/EAN: 5906301810810

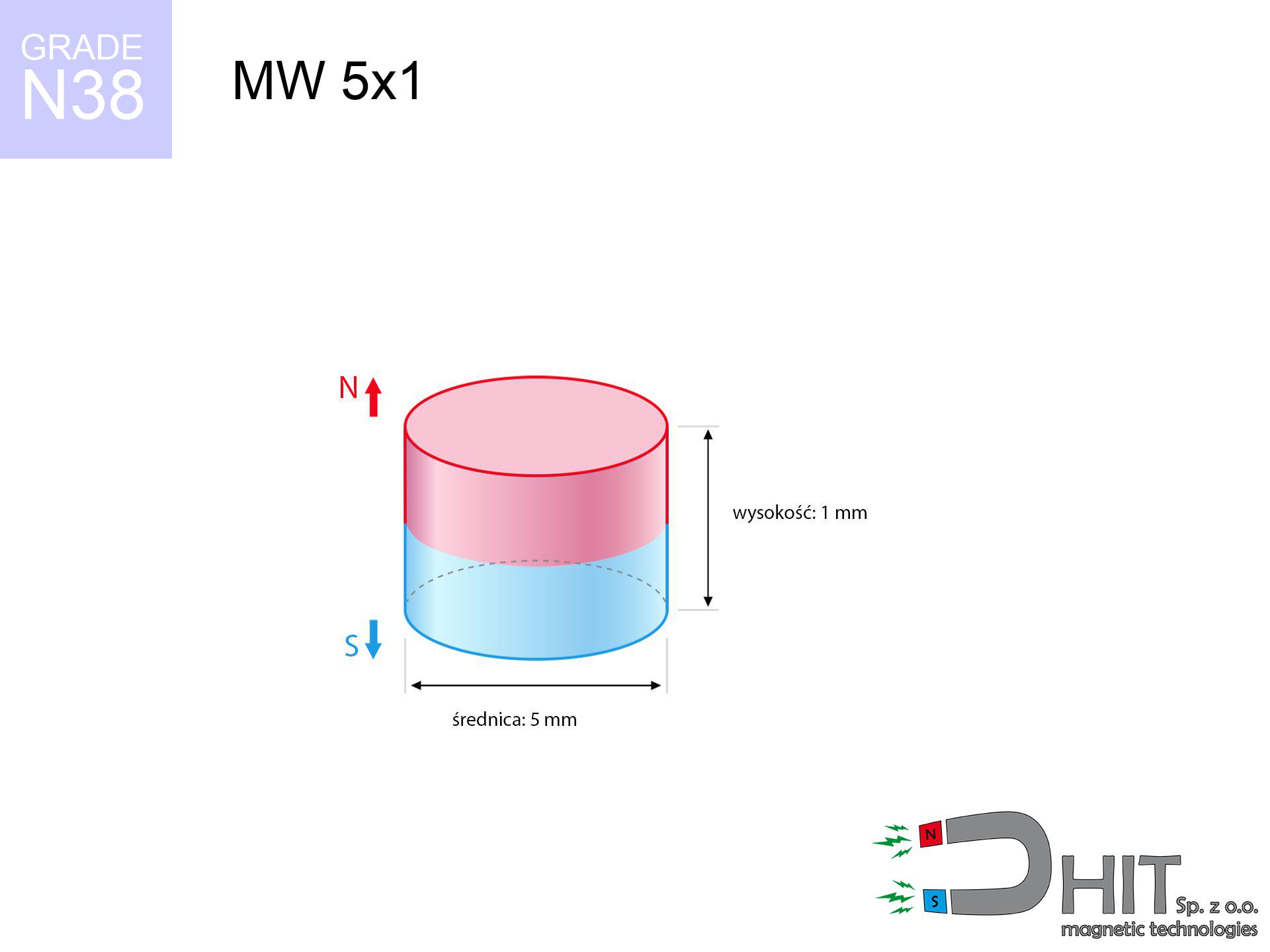

Diameter Ø

5 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

0.15 g

Magnetization Direction

↑ axial

Load capacity

0.32 kg / 3.12 N

Magnetic Induction

229.95 mT / 2300 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or let us know through

form

our website.

Strength and form of a neodymium magnet can be analyzed using our

force calculator.

Order by 14:00 and we’ll ship today!

Technical of the product - MW 5x1 / N38 - cylindrical magnet

Specification / characteristics - MW 5x1 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010082 |

| GTIN/EAN | 5906301810810 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 0.15 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.32 kg / 3.12 N |

| Magnetic Induction ~ ? | 229.95 mT / 2300 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - technical parameters

The following data represent the result of a engineering calculation. Results are based on algorithms for the material Nd2Fe14B. Actual conditions might slightly differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs distance) - characteristics

MW 5x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2298 Gs

229.8 mT

|

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

low risk |

| 1 mm |

1570 Gs

157.0 mT

|

0.15 kg / 0.33 lbs

149.5 g / 1.5 N

|

low risk |

| 2 mm |

890 Gs

89.0 mT

|

0.05 kg / 0.11 lbs

48.0 g / 0.5 N

|

low risk |

| 3 mm |

495 Gs

49.5 mT

|

0.01 kg / 0.03 lbs

14.8 g / 0.1 N

|

low risk |

| 5 mm |

178 Gs

17.8 mT

|

0.00 kg / 0.00 lbs

1.9 g / 0.0 N

|

low risk |

| 10 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

| 15 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 20 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 30 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical load (vertical surface)

MW 5x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.06 kg / 0.14 lbs

64.0 g / 0.6 N

|

| 1 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

30.0 g / 0.3 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 5x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.10 kg / 0.21 lbs

96.0 g / 0.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.06 kg / 0.14 lbs

64.0 g / 0.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.16 kg / 0.35 lbs

160.0 g / 1.6 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 5x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| 1 mm |

|

0.08 kg / 0.18 lbs

80.0 g / 0.8 N

|

| 2 mm |

|

0.16 kg / 0.35 lbs

160.0 g / 1.6 N

|

| 3 mm |

|

0.24 kg / 0.53 lbs

240.0 g / 2.4 N

|

| 5 mm |

|

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

| 10 mm |

|

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

| 11 mm |

|

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

| 12 mm |

|

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 5x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

OK |

| 40 °C | -2.2% |

0.31 kg / 0.69 lbs

313.0 g / 3.1 N

|

OK |

| 60 °C | -4.4% |

0.31 kg / 0.67 lbs

305.9 g / 3.0 N

|

|

| 80 °C | -6.6% |

0.30 kg / 0.66 lbs

298.9 g / 2.9 N

|

|

| 100 °C | -28.8% |

0.23 kg / 0.50 lbs

227.8 g / 2.2 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 5x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.64 kg / 1.41 lbs

3 860 Gs

|

0.10 kg / 0.21 lbs

96 g / 0.9 N

|

N/A |

| 1 mm |

0.47 kg / 1.04 lbs

3 948 Gs

|

0.07 kg / 0.16 lbs

71 g / 0.7 N

|

0.42 kg / 0.94 lbs

~0 Gs

|

| 2 mm |

0.30 kg / 0.66 lbs

3 141 Gs

|

0.04 kg / 0.10 lbs

45 g / 0.4 N

|

0.27 kg / 0.59 lbs

~0 Gs

|

| 3 mm |

0.17 kg / 0.38 lbs

2 388 Gs

|

0.03 kg / 0.06 lbs

26 g / 0.3 N

|

0.16 kg / 0.34 lbs

~0 Gs

|

| 5 mm |

0.05 kg / 0.12 lbs

1 322 Gs

|

0.01 kg / 0.02 lbs

8 g / 0.1 N

|

0.05 kg / 0.10 lbs

~0 Gs

|

| 10 mm |

0.00 kg / 0.01 lbs

355 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

62 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

5 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 5x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 5x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

46.59 km/h

(12.94 m/s)

|

0.01 J | |

| 30 mm |

80.68 km/h

(22.41 m/s)

|

0.04 J | |

| 50 mm |

104.16 km/h

(28.93 m/s)

|

0.06 J | |

| 100 mm |

147.30 km/h

(40.92 m/s)

|

0.13 J |

Table 9: Coating parameters (durability)

MW 5x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 5x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 524 Mx | 5.2 µWb |

| Pc Coefficient | 0.29 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 5x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.32 kg | Standard |

| Water (riverbed) |

0.37 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet holds only ~20% of its max power.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.29

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

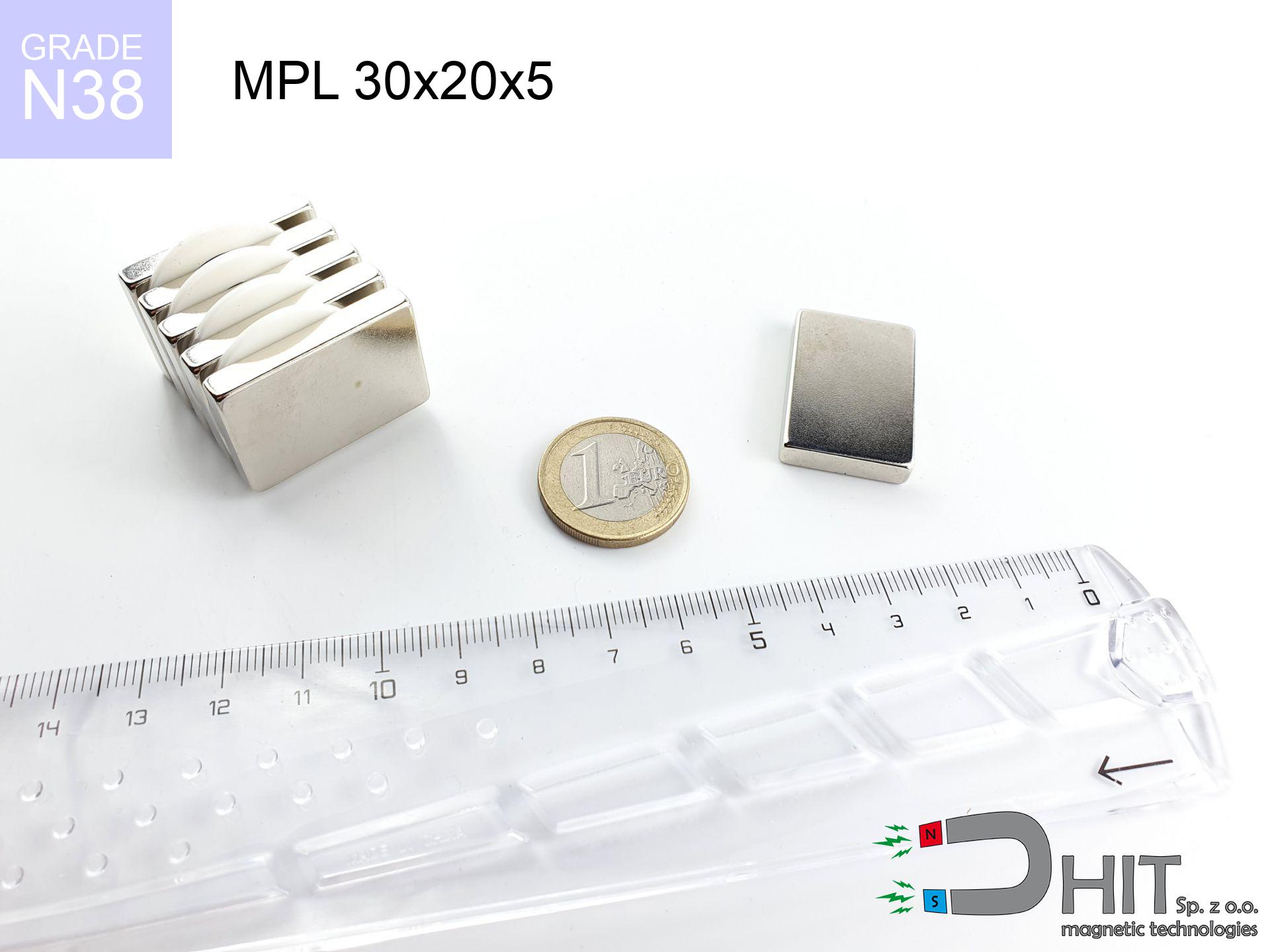

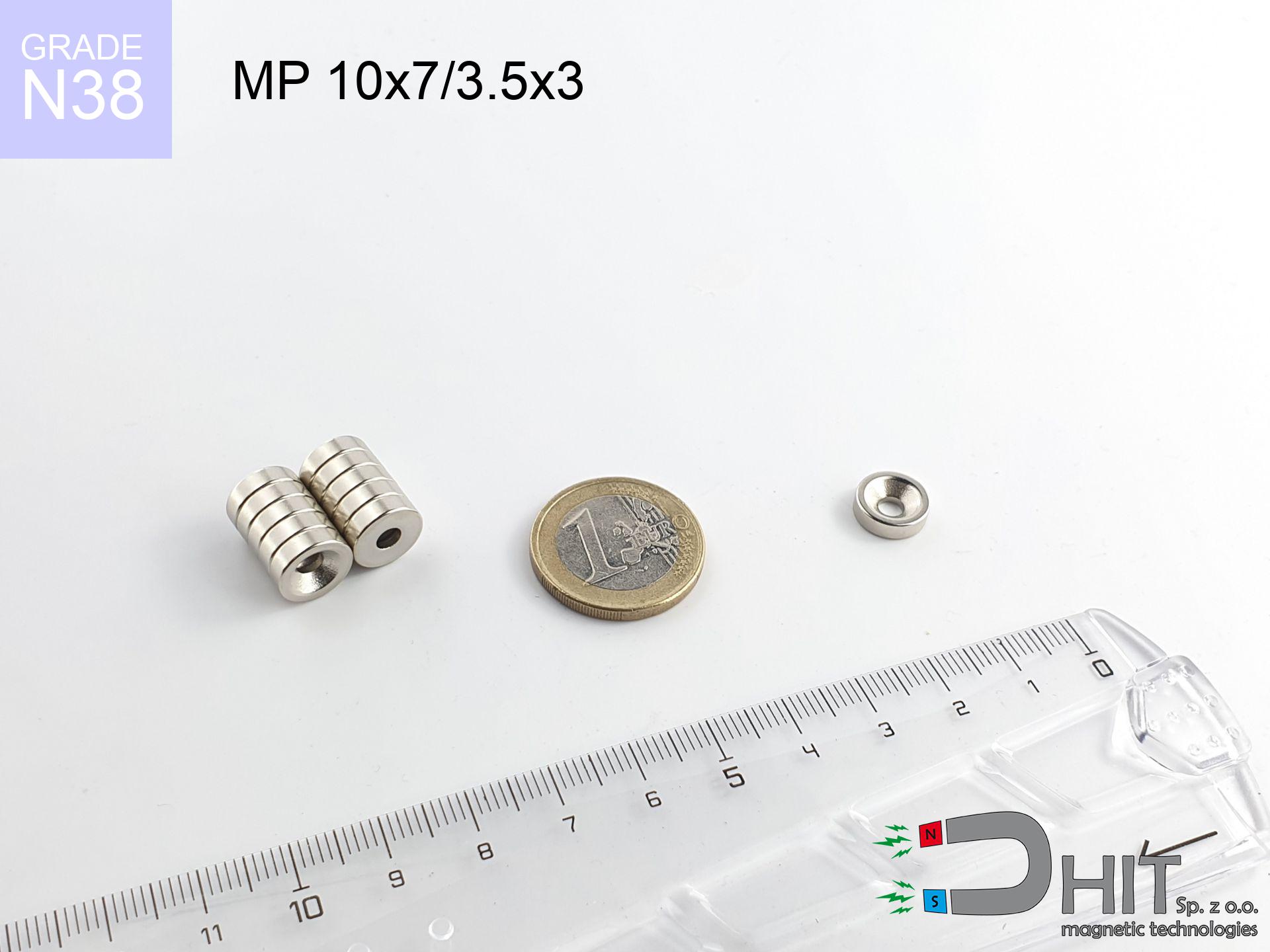

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- Their magnetic field remains stable, and after approximately 10 years it decreases only by ~1% (according to research),

- Neodymium magnets are extremely resistant to loss of magnetic properties caused by external field sources,

- In other words, due to the glossy layer of gold, the element gains a professional look,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Considering the ability of flexible shaping and customization to unique needs, neodymium magnets can be created in a variety of forms and dimensions, which expands the range of possible applications,

- Wide application in innovative solutions – they serve a role in mass storage devices, electric motors, precision medical tools, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which enables their usage in compact constructions

Cons

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in producing nuts and complicated shapes in magnets, we recommend using a housing - magnetic holder.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child safety. Furthermore, small components of these products are able to disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Lifting parameters

Maximum magnetic pulling force – what affects it?

- on a plate made of mild steel, perfectly concentrating the magnetic field

- with a cross-section of at least 10 mm

- characterized by smoothness

- without the slightest air gap between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at standard ambient temperature

Impact of factors on magnetic holding capacity in practice

- Distance – existence of foreign body (rust, dirt, air) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Chemical composition of the base – low-carbon steel attracts best. Alloy admixtures reduce magnetic properties and lifting capacity.

- Plate texture – ground elements ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Operating temperature – neodymium magnets have a sensitivity to temperature. When it is hot they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on a smooth plate of suitable thickness, under a perpendicular pulling force, in contrast under parallel forces the holding force is lower. Moreover, even a slight gap between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Skin irritation risks

A percentage of the population suffer from a hypersensitivity to Ni, which is the common plating for NdFeB magnets. Prolonged contact may cause a rash. It is best to wear safety gloves.

Warning for heart patients

People with a heart stimulator have to keep an absolute distance from magnets. The magnetism can interfere with the functioning of the life-saving device.

Respect the power

Handle magnets consciously. Their immense force can shock even experienced users. Stay alert and respect their power.

Flammability

Fire warning: Neodymium dust is explosive. Do not process magnets in home conditions as this risks ignition.

Shattering risk

Protect your eyes. Magnets can explode upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Impact on smartphones

A powerful magnetic field negatively affects the operation of compasses in smartphones and GPS navigation. Keep magnets near a smartphone to prevent damaging the sensors.

Hand protection

Large magnets can break fingers in a fraction of a second. Do not put your hand between two attracting surfaces.

Swallowing risk

Always keep magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are very dangerous.

Cards and drives

Data protection: Strong magnets can damage data carriers and sensitive devices (heart implants, hearing aids, timepieces).

Demagnetization risk

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).