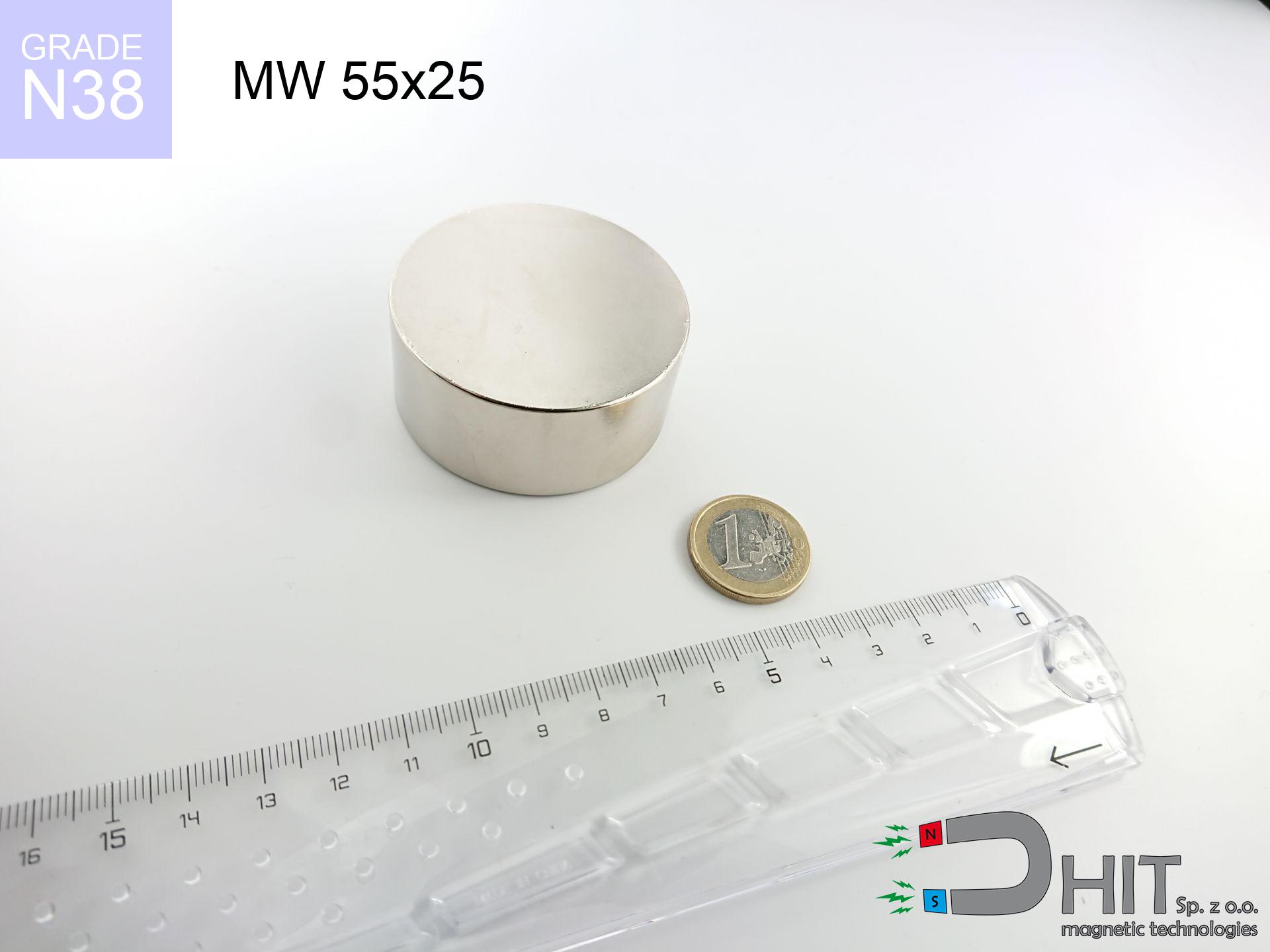

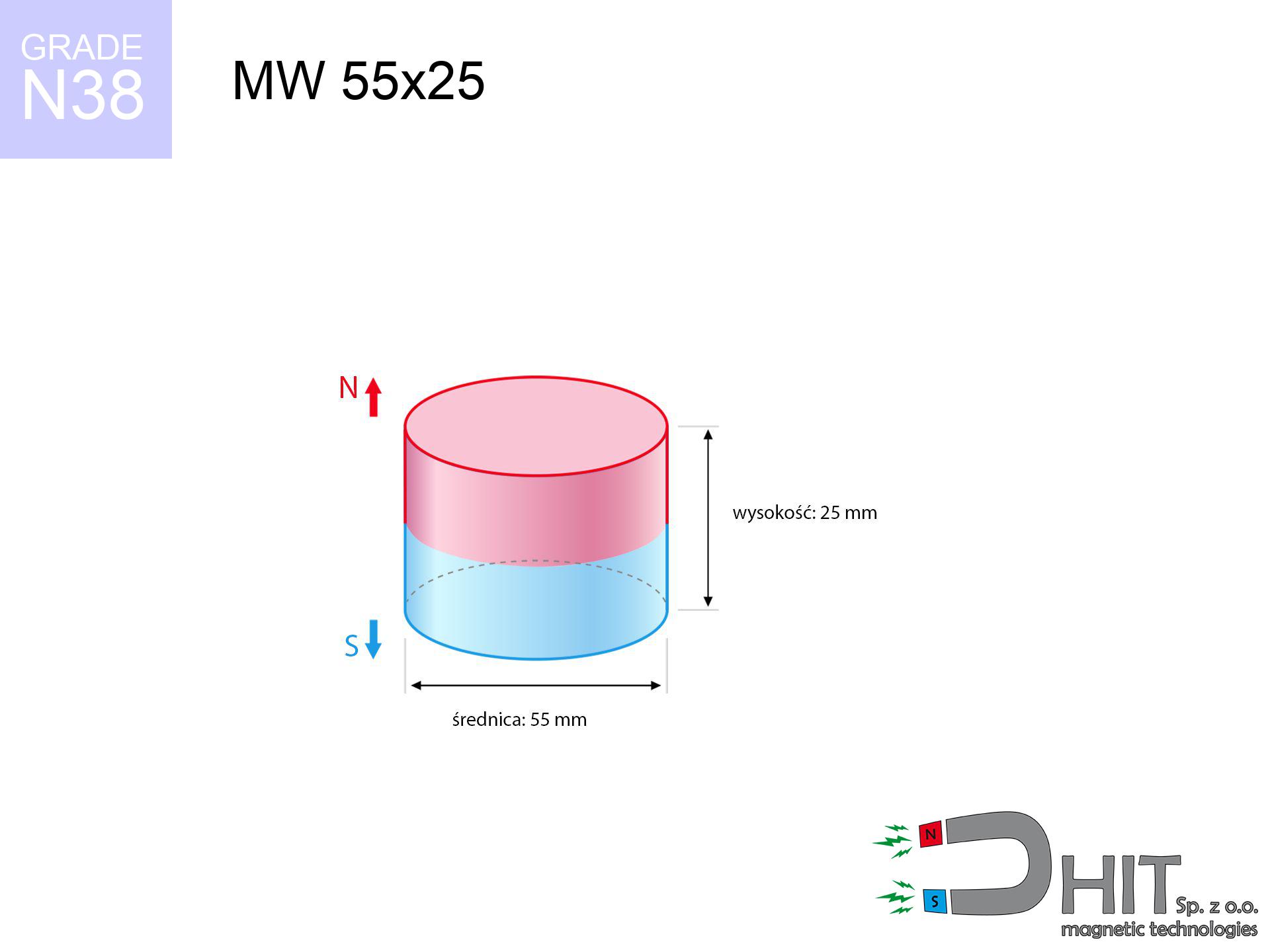

MW 55x25 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010081

GTIN/EAN: 5906301810803

Diameter Ø

55 mm [±0,1 mm]

Height

25 mm [±0,1 mm]

Weight

445.47 g

Magnetization Direction

↑ axial

Load capacity

92.25 kg / 904.94 N

Magnetic Induction

416.97 mT / 4170 Gs

Coating

[NiCuNi] Nickel

154.21 ZŁ with VAT / pcs + price for transport

125.37 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

alternatively send us a note through

inquiry form

the contact form page.

Strength as well as appearance of magnetic components can be checked using our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical specification - MW 55x25 / N38 - cylindrical magnet

Specification / characteristics - MW 55x25 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010081 |

| GTIN/EAN | 5906301810803 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 55 mm [±0,1 mm] |

| Height | 25 mm [±0,1 mm] |

| Weight | 445.47 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 92.25 kg / 904.94 N |

| Magnetic Induction ~ ? | 416.97 mT / 4170 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - data

Presented data constitute the result of a mathematical simulation. Results rely on algorithms for the material Nd2Fe14B. Real-world performance may deviate from the simulation results. Treat these data as a supplementary guide for designers.

Table 1: Static pull force (force vs distance) - interaction chart

MW 55x25 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4169 Gs

416.9 mT

|

92.25 kg / 203.38 pounds

92250.0 g / 905.0 N

|

dangerous! |

| 1 mm |

4034 Gs

403.4 mT

|

86.37 kg / 190.41 pounds

86369.8 g / 847.3 N

|

dangerous! |

| 2 mm |

3894 Gs

389.4 mT

|

80.47 kg / 177.41 pounds

80469.7 g / 789.4 N

|

dangerous! |

| 3 mm |

3751 Gs

375.1 mT

|

74.67 kg / 164.62 pounds

74670.6 g / 732.5 N

|

dangerous! |

| 5 mm |

3461 Gs

346.1 mT

|

63.58 kg / 140.17 pounds

63580.6 g / 623.7 N

|

dangerous! |

| 10 mm |

2756 Gs

275.6 mT

|

40.32 kg / 88.89 pounds

40320.8 g / 395.5 N

|

dangerous! |

| 15 mm |

2140 Gs

214.0 mT

|

24.31 kg / 53.59 pounds

24308.3 g / 238.5 N

|

dangerous! |

| 20 mm |

1644 Gs

164.4 mT

|

14.34 kg / 31.61 pounds

14338.1 g / 140.7 N

|

dangerous! |

| 30 mm |

975 Gs

97.5 mT

|

5.05 kg / 11.12 pounds

5046.0 g / 49.5 N

|

strong |

| 50 mm |

388 Gs

38.8 mT

|

0.80 kg / 1.77 pounds

801.0 g / 7.9 N

|

safe |

Table 2: Shear hold (vertical surface)

MW 55x25 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

18.45 kg / 40.68 pounds

18450.0 g / 181.0 N

|

| 1 mm | Stal (~0.2) |

17.27 kg / 38.08 pounds

17274.0 g / 169.5 N

|

| 2 mm | Stal (~0.2) |

16.09 kg / 35.48 pounds

16094.0 g / 157.9 N

|

| 3 mm | Stal (~0.2) |

14.93 kg / 32.92 pounds

14934.0 g / 146.5 N

|

| 5 mm | Stal (~0.2) |

12.72 kg / 28.03 pounds

12716.0 g / 124.7 N

|

| 10 mm | Stal (~0.2) |

8.06 kg / 17.78 pounds

8064.0 g / 79.1 N

|

| 15 mm | Stal (~0.2) |

4.86 kg / 10.72 pounds

4862.0 g / 47.7 N

|

| 20 mm | Stal (~0.2) |

2.87 kg / 6.32 pounds

2868.0 g / 28.1 N

|

| 30 mm | Stal (~0.2) |

1.01 kg / 2.23 pounds

1010.0 g / 9.9 N

|

| 50 mm | Stal (~0.2) |

0.16 kg / 0.35 pounds

160.0 g / 1.6 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 55x25 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

27.68 kg / 61.01 pounds

27675.0 g / 271.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

18.45 kg / 40.68 pounds

18450.0 g / 181.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

9.23 kg / 20.34 pounds

9225.0 g / 90.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

46.13 kg / 101.69 pounds

46125.0 g / 452.5 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 55x25 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

3.08 kg / 6.78 pounds

3075.0 g / 30.2 N

|

| 1 mm |

|

7.69 kg / 16.95 pounds

7687.5 g / 75.4 N

|

| 2 mm |

|

15.37 kg / 33.90 pounds

15375.0 g / 150.8 N

|

| 3 mm |

|

23.06 kg / 50.84 pounds

23062.5 g / 226.2 N

|

| 5 mm |

|

38.44 kg / 84.74 pounds

38437.5 g / 377.1 N

|

| 10 mm |

|

76.88 kg / 169.48 pounds

76875.0 g / 754.1 N

|

| 11 mm |

|

84.56 kg / 186.43 pounds

84562.5 g / 829.6 N

|

| 12 mm |

|

92.25 kg / 203.38 pounds

92250.0 g / 905.0 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MW 55x25 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

92.25 kg / 203.38 pounds

92250.0 g / 905.0 N

|

OK |

| 40 °C | -2.2% |

90.22 kg / 198.90 pounds

90220.5 g / 885.1 N

|

OK |

| 60 °C | -4.4% |

88.19 kg / 194.43 pounds

88191.0 g / 865.2 N

|

|

| 80 °C | -6.6% |

86.16 kg / 189.95 pounds

86161.5 g / 845.2 N

|

|

| 100 °C | -28.8% |

65.68 kg / 144.80 pounds

65682.0 g / 644.3 N

|

Table 6: Two magnets (attraction) - field collision

MW 55x25 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

254.60 kg / 561.30 pounds

5 431 Gs

|

38.19 kg / 84.20 pounds

38190 g / 374.6 N

|

N/A |

| 1 mm |

246.57 kg / 543.59 pounds

8 206 Gs

|

36.99 kg / 81.54 pounds

36985 g / 362.8 N

|

221.91 kg / 489.23 pounds

~0 Gs

|

| 2 mm |

238.37 kg / 525.52 pounds

8 068 Gs

|

35.76 kg / 78.83 pounds

35756 g / 350.8 N

|

214.54 kg / 472.97 pounds

~0 Gs

|

| 3 mm |

230.21 kg / 507.52 pounds

7 929 Gs

|

34.53 kg / 76.13 pounds

34531 g / 338.7 N

|

207.19 kg / 456.77 pounds

~0 Gs

|

| 5 mm |

214.04 kg / 471.88 pounds

7 645 Gs

|

32.11 kg / 70.78 pounds

32106 g / 315.0 N

|

192.64 kg / 424.69 pounds

~0 Gs

|

| 10 mm |

175.48 kg / 386.86 pounds

6 923 Gs

|

26.32 kg / 58.03 pounds

26322 g / 258.2 N

|

157.93 kg / 348.17 pounds

~0 Gs

|

| 20 mm |

111.28 kg / 245.33 pounds

5 513 Gs

|

16.69 kg / 36.80 pounds

16692 g / 163.8 N

|

100.15 kg / 220.80 pounds

~0 Gs

|

| 50 mm |

23.33 kg / 51.43 pounds

2 524 Gs

|

3.50 kg / 7.71 pounds

3499 g / 34.3 N

|

20.99 kg / 46.28 pounds

~0 Gs

|

| 60 mm |

13.93 kg / 30.70 pounds

1 950 Gs

|

2.09 kg / 4.61 pounds

2089 g / 20.5 N

|

12.53 kg / 27.63 pounds

~0 Gs

|

| 70 mm |

8.48 kg / 18.70 pounds

1 522 Gs

|

1.27 kg / 2.81 pounds

1272 g / 12.5 N

|

7.63 kg / 16.83 pounds

~0 Gs

|

| 80 mm |

5.29 kg / 11.66 pounds

1 202 Gs

|

0.79 kg / 1.75 pounds

793 g / 7.8 N

|

4.76 kg / 10.50 pounds

~0 Gs

|

| 90 mm |

3.38 kg / 7.45 pounds

961 Gs

|

0.51 kg / 1.12 pounds

507 g / 5.0 N

|

3.04 kg / 6.70 pounds

~0 Gs

|

| 100 mm |

2.21 kg / 4.87 pounds

777 Gs

|

0.33 kg / 0.73 pounds

332 g / 3.3 N

|

1.99 kg / 4.39 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 55x25 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 27.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 21.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 17.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 13.0 cm |

| Remote | 50 Gs (5.0 mT) | 12.0 cm |

| Payment card | 400 Gs (40.0 mT) | 5.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 55x25 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.05 km/h

(5.01 m/s)

|

5.60 J | |

| 30 mm |

25.98 km/h

(7.22 m/s)

|

11.60 J | |

| 50 mm |

32.63 km/h

(9.06 m/s)

|

18.30 J | |

| 100 mm |

45.90 km/h

(12.75 m/s)

|

36.21 J |

Table 9: Coating parameters (durability)

MW 55x25 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 55x25 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 101 075 Mx | 1010.7 µWb |

| Pc Coefficient | 0.55 | Low (Flat) |

Table 11: Submerged application

MW 55x25 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 92.25 kg | Standard |

| Water (riverbed) |

105.63 kg

(+13.38 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds merely approx. 20-30% of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Heat tolerance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.55

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Strengths and weaknesses of rare earth magnets.

Advantages

- They retain full power for around ten years – the drop is just ~1% (in theory),

- Neodymium magnets are characterized by remarkably resistant to magnetic field loss caused by external magnetic fields,

- Thanks to the metallic finish, the surface of Ni-Cu-Ni, gold-plated, or silver gives an visually attractive appearance,

- Magnets are characterized by very high magnetic induction on the outer layer,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling action at temperatures approaching 230°C and above...

- Thanks to freedom in shaping and the ability to modify to complex applications,

- Key role in innovative solutions – they are used in magnetic memories, electromotive mechanisms, precision medical tools, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which allows their use in miniature devices

Weaknesses

- Brittleness is one of their disadvantages. Upon strong impact they can break. We advise keeping them in a special holder, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation and corrosion.

- We recommend a housing - magnetic mount, due to difficulties in realizing threads inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the context of child safety. Additionally, tiny parts of these devices are able to disrupt the diagnostic process medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum lifting capacity of the magnet – what it depends on?

- on a block made of structural steel, optimally conducting the magnetic field

- with a thickness no less than 10 mm

- with an polished touching surface

- without any clearance between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- at room temperature

Key elements affecting lifting force

- Distance – existence of any layer (rust, tape, gap) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Material composition – different alloys attracts identically. High carbon content worsen the interaction with the magnet.

- Smoothness – full contact is possible only on smooth steel. Any scratches and bumps create air cushions, reducing force.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. Additionally, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Warnings

Metal Allergy

Certain individuals have a contact allergy to Ni, which is the standard coating for NdFeB magnets. Extended handling might lead to an allergic reaction. We recommend wear protective gloves.

Impact on smartphones

GPS units and smartphones are highly susceptible to magnetic fields. Direct contact with a strong magnet can permanently damage the sensors in your phone.

Serious injuries

Big blocks can break fingers instantly. Do not place your hand between two strong magnets.

ICD Warning

Life threat: Strong magnets can deactivate pacemakers and defibrillators. Do not approach if you have electronic implants.

Eye protection

Neodymium magnets are sintered ceramics, which means they are very brittle. Impact of two magnets will cause them cracking into small pieces.

Danger to the youngest

Strictly store magnets away from children. Ingestion danger is high, and the consequences of magnets connecting inside the body are very dangerous.

Handling guide

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Magnetic media

Data protection: Neodymium magnets can ruin payment cards and delicate electronics (pacemakers, medical aids, timepieces).

Flammability

Mechanical processing of neodymium magnets poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Heat warning

Control the heat. Exposing the magnet above 80 degrees Celsius will ruin its properties and strength.

![SM 25x375 [2xM8] / N42 - magnetic separator SM 25x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-feg.jpg)

![SM 32x125 [2xM8] / N52 - magnetic separator SM 32x125 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-moj.jpg)