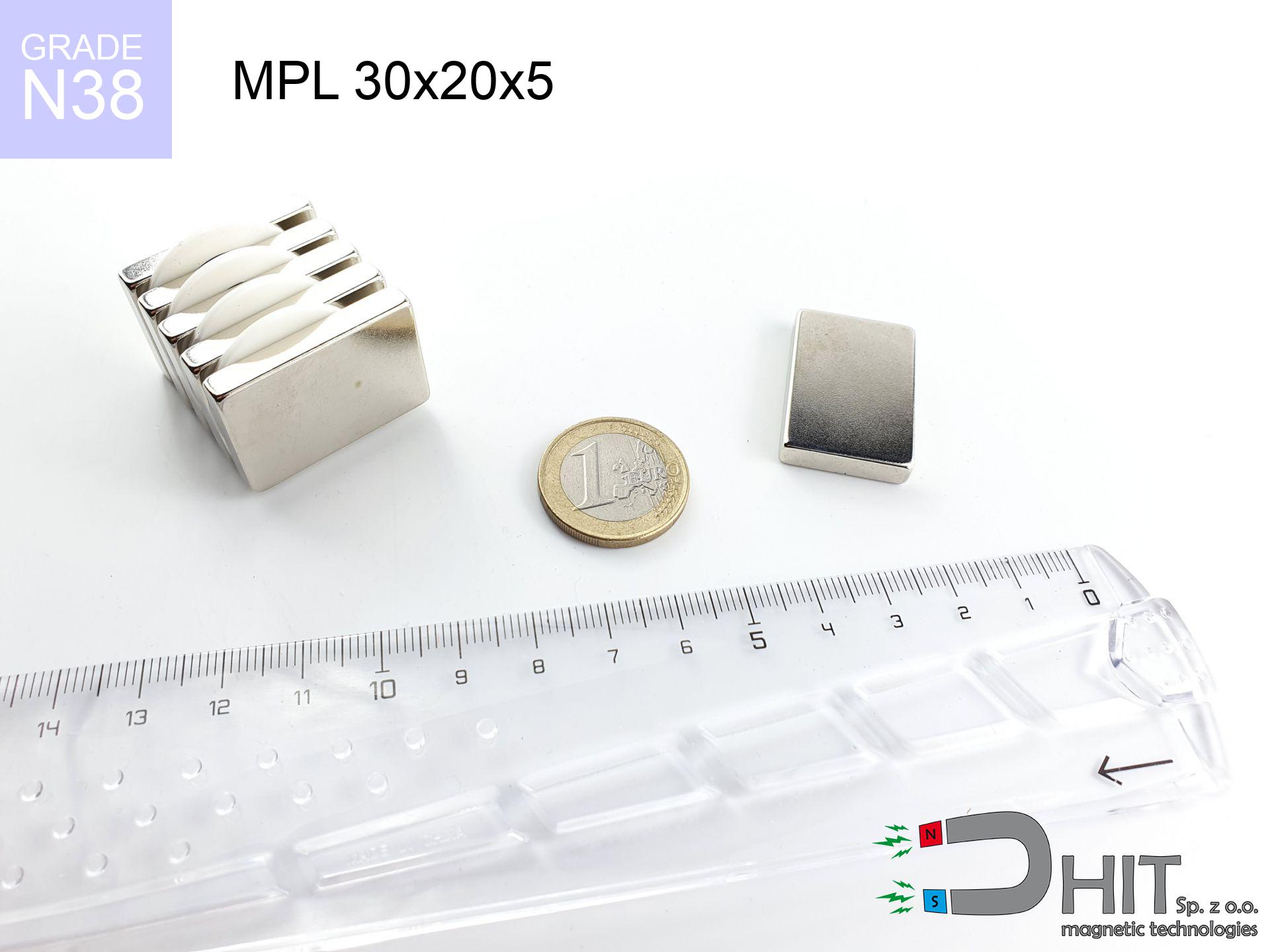

MPL 30x20x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020143

GTIN/EAN: 5906301811497

length

30 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

22.5 g

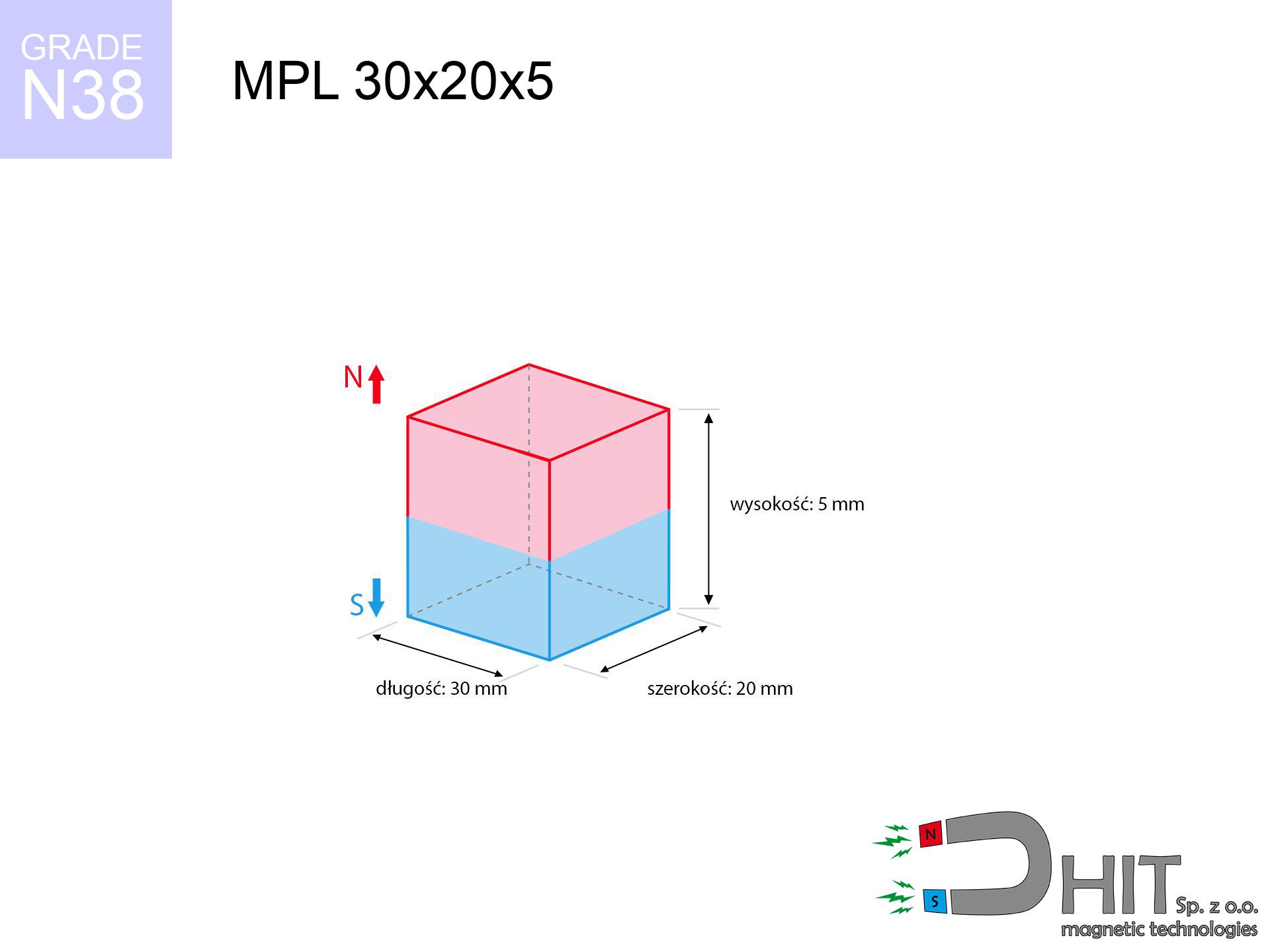

Magnetization Direction

↑ axial

Load capacity

8.86 kg / 86.90 N

Magnetic Induction

220.03 mT / 2200 Gs

Coating

[NiCuNi] Nickel

9.10 ZŁ with VAT / pcs + price for transport

7.40 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise let us know through

contact form

through our site.

Lifting power along with shape of a neodymium magnet can be reviewed using our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Detailed specification - MPL 30x20x5 / N38 - lamellar magnet

Specification / characteristics - MPL 30x20x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020143 |

| GTIN/EAN | 5906301811497 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 22.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 8.86 kg / 86.90 N |

| Magnetic Induction ~ ? | 220.03 mT / 2200 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - data

Presented information constitute the outcome of a mathematical analysis. Values are based on models for the class Nd2Fe14B. Real-world parameters might slightly differ from theoretical values. Treat these data as a preliminary roadmap for designers.

Table 1: Static force (pull vs distance) - power drop

MPL 30x20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2200 Gs

220.0 mT

|

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

strong |

| 1 mm |

2092 Gs

209.2 mT

|

8.01 kg / 17.67 lbs

8013.9 g / 78.6 N

|

strong |

| 2 mm |

1961 Gs

196.1 mT

|

7.04 kg / 15.53 lbs

7042.1 g / 69.1 N

|

strong |

| 3 mm |

1817 Gs

181.7 mT

|

6.04 kg / 13.32 lbs

6041.8 g / 59.3 N

|

strong |

| 5 mm |

1516 Gs

151.6 mT

|

4.21 kg / 9.28 lbs

4209.6 g / 41.3 N

|

strong |

| 10 mm |

892 Gs

89.2 mT

|

1.46 kg / 3.21 lbs

1456.2 g / 14.3 N

|

low risk |

| 15 mm |

519 Gs

51.9 mT

|

0.49 kg / 1.09 lbs

492.4 g / 4.8 N

|

low risk |

| 20 mm |

313 Gs

31.3 mT

|

0.18 kg / 0.40 lbs

179.8 g / 1.8 N

|

low risk |

| 30 mm |

132 Gs

13.2 mT

|

0.03 kg / 0.07 lbs

31.9 g / 0.3 N

|

low risk |

| 50 mm |

37 Gs

3.7 mT

|

0.00 kg / 0.01 lbs

2.5 g / 0.0 N

|

low risk |

Table 2: Vertical force (wall)

MPL 30x20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.77 kg / 3.91 lbs

1772.0 g / 17.4 N

|

| 1 mm | Stal (~0.2) |

1.60 kg / 3.53 lbs

1602.0 g / 15.7 N

|

| 2 mm | Stal (~0.2) |

1.41 kg / 3.10 lbs

1408.0 g / 13.8 N

|

| 3 mm | Stal (~0.2) |

1.21 kg / 2.66 lbs

1208.0 g / 11.9 N

|

| 5 mm | Stal (~0.2) |

0.84 kg / 1.86 lbs

842.0 g / 8.3 N

|

| 10 mm | Stal (~0.2) |

0.29 kg / 0.64 lbs

292.0 g / 2.9 N

|

| 15 mm | Stal (~0.2) |

0.10 kg / 0.22 lbs

98.0 g / 1.0 N

|

| 20 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

36.0 g / 0.4 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 30x20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.66 kg / 5.86 lbs

2658.0 g / 26.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.77 kg / 3.91 lbs

1772.0 g / 17.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.89 kg / 1.95 lbs

886.0 g / 8.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 30x20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.89 kg / 1.95 lbs

886.0 g / 8.7 N

|

| 1 mm |

|

2.22 kg / 4.88 lbs

2215.0 g / 21.7 N

|

| 2 mm |

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

| 3 mm |

|

6.65 kg / 14.65 lbs

6645.0 g / 65.2 N

|

| 5 mm |

|

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

| 10 mm |

|

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

| 11 mm |

|

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

| 12 mm |

|

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MPL 30x20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

8.86 kg / 19.53 lbs

8860.0 g / 86.9 N

|

OK |

| 40 °C | -2.2% |

8.67 kg / 19.10 lbs

8665.1 g / 85.0 N

|

OK |

| 60 °C | -4.4% |

8.47 kg / 18.67 lbs

8470.2 g / 83.1 N

|

|

| 80 °C | -6.6% |

8.28 kg / 18.24 lbs

8275.2 g / 81.2 N

|

|

| 100 °C | -28.8% |

6.31 kg / 13.91 lbs

6308.3 g / 61.9 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 30x20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.90 kg / 39.47 lbs

3 715 Gs

|

2.69 kg / 5.92 lbs

2685 g / 26.3 N

|

N/A |

| 1 mm |

17.10 kg / 37.69 lbs

4 300 Gs

|

2.56 kg / 5.65 lbs

2565 g / 25.2 N

|

15.39 kg / 33.92 lbs

~0 Gs

|

| 2 mm |

16.19 kg / 35.70 lbs

4 184 Gs

|

2.43 kg / 5.35 lbs

2429 g / 23.8 N

|

14.57 kg / 32.13 lbs

~0 Gs

|

| 3 mm |

15.23 kg / 33.57 lbs

4 058 Gs

|

2.28 kg / 5.04 lbs

2284 g / 22.4 N

|

13.71 kg / 30.22 lbs

~0 Gs

|

| 5 mm |

13.22 kg / 29.14 lbs

3 780 Gs

|

1.98 kg / 4.37 lbs

1982 g / 19.4 N

|

11.89 kg / 26.22 lbs

~0 Gs

|

| 10 mm |

8.51 kg / 18.75 lbs

3 033 Gs

|

1.28 kg / 2.81 lbs

1276 g / 12.5 N

|

7.66 kg / 16.88 lbs

~0 Gs

|

| 20 mm |

2.94 kg / 6.49 lbs

1 784 Gs

|

0.44 kg / 0.97 lbs

441 g / 4.3 N

|

2.65 kg / 5.84 lbs

~0 Gs

|

| 50 mm |

0.15 kg / 0.32 lbs

398 Gs

|

0.02 kg / 0.05 lbs

22 g / 0.2 N

|

0.13 kg / 0.29 lbs

~0 Gs

|

| 60 mm |

0.06 kg / 0.14 lbs

264 Gs

|

0.01 kg / 0.02 lbs

10 g / 0.1 N

|

0.06 kg / 0.13 lbs

~0 Gs

|

| 70 mm |

0.03 kg / 0.07 lbs

183 Gs

|

0.00 kg / 0.01 lbs

5 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 80 mm |

0.02 kg / 0.04 lbs

131 Gs

|

0.00 kg / 0.01 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.02 lbs

97 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 lbs

73 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 30x20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 6.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 30x20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.97 km/h

(6.10 m/s)

|

0.42 J | |

| 30 mm |

34.74 km/h

(9.65 m/s)

|

1.05 J | |

| 50 mm |

44.76 km/h

(12.43 m/s)

|

1.74 J | |

| 100 mm |

63.29 km/h

(17.58 m/s)

|

3.48 J |

Table 9: Coating parameters (durability)

MPL 30x20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 30x20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 14 969 Mx | 149.7 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 30x20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 8.86 kg | Standard |

| Water (riverbed) |

10.14 kg

(+1.28 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet retains merely ~20% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) drastically limits the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Advantages and disadvantages of Nd2Fe14B magnets.

Pros

- They have stable power, and over nearly ten years their performance decreases symbolically – ~1% (in testing),

- They are resistant to demagnetization induced by external magnetic fields,

- Thanks to the glossy finish, the surface of nickel, gold, or silver-plated gives an modern appearance,

- Magnetic induction on the working part of the magnet turns out to be exceptional,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, enabling functioning at temperatures reaching 230°C and above...

- Thanks to the ability of precise shaping and adaptation to unique solutions, NdFeB magnets can be modeled in a wide range of forms and dimensions, which increases their versatility,

- Fundamental importance in modern technologies – they find application in computer drives, drive modules, advanced medical instruments, also multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Weaknesses

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in creating threads and complex shapes in magnets, we recommend using cover - magnetic holder.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the context of child health protection. It is also worth noting that small components of these devices can disrupt the diagnostic process medical when they are in the body.

- Due to complex production process, their price is higher than average,

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what it depends on?

- using a plate made of high-permeability steel, serving as a circuit closing element

- with a thickness of at least 10 mm

- characterized by lack of roughness

- without the slightest insulating layer between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- in stable room temperature

Key elements affecting lifting force

- Space between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Base massiveness – too thin plate does not accept the full field, causing part of the flux to be escaped to the other side.

- Material type – the best choice is high-permeability steel. Stainless steels may have worse magnetic properties.

- Surface structure – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Unevenness creates an air distance.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Allergic reactions

A percentage of the population experience a hypersensitivity to Ni, which is the common plating for neodymium magnets. Frequent touching might lead to an allergic reaction. We suggest use safety gloves.

Data carriers

Avoid bringing magnets close to a wallet, laptop, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Health Danger

People with a pacemaker must maintain an large gap from magnets. The magnetism can disrupt the functioning of the life-saving device.

Pinching danger

Protect your hands. Two powerful magnets will snap together immediately with a force of massive weight, destroying anything in their path. Be careful!

Choking Hazard

Strictly store magnets out of reach of children. Risk of swallowing is high, and the effects of magnets connecting inside the body are life-threatening.

Caution required

Before starting, check safety instructions. Uncontrolled attraction can break the magnet or hurt your hand. Be predictive.

Eye protection

Neodymium magnets are ceramic materials, meaning they are fragile like glass. Clashing of two magnets leads to them breaking into small pieces.

Mechanical processing

Machining of NdFeB material carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Heat sensitivity

Control the heat. Exposing the magnet to high heat will permanently weaken its properties and pulling force.

GPS Danger

A powerful magnetic field disrupts the operation of magnetometers in smartphones and navigation systems. Maintain magnets near a smartphone to prevent breaking the sensors.

![SM 32x100 [2xM8] / N42 - magnetic separator SM 32x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x100-2xm8-cox.jpg)

![HH 16x5.3 [M3] / N38 - through hole magnetic holder HH 16x5.3 [M3] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-16x5.3-m3-sud.jpg)