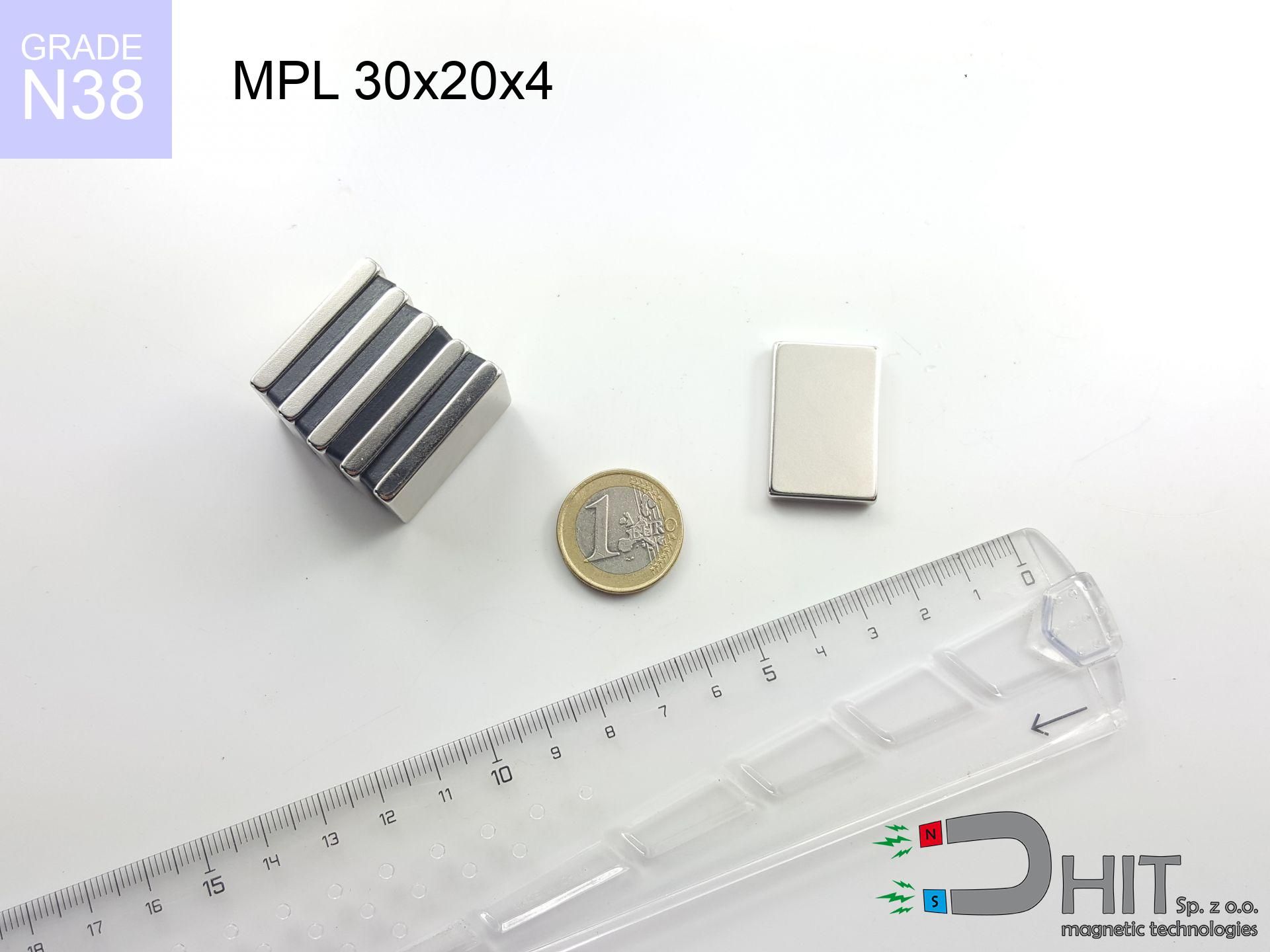

MPL 30x20x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020286

GTIN/EAN: 5906301811848

length

30 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

18 g

Magnetization Direction

↑ axial

Load capacity

6.30 kg / 61.84 N

Magnetic Induction

180.57 mT / 1806 Gs

Coating

[NiCuNi] Nickel

10.23 ZŁ with VAT / pcs + price for transport

8.32 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise drop us a message by means of

inquiry form

the contact form page.

Strength and appearance of neodymium magnets can be tested with our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MPL 30x20x4 / N38 - lamellar magnet

Specification / characteristics - MPL 30x20x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020286 |

| GTIN/EAN | 5906301811848 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 18 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.30 kg / 61.84 N |

| Magnetic Induction ~ ? | 180.57 mT / 1806 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - report

Presented data are the outcome of a physical simulation. Values are based on algorithms for the material Nd2Fe14B. Operational performance may differ. Use these data as a reference point when designing systems.

Table 1: Static pull force (force vs gap) - interaction chart

MPL 30x20x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1805 Gs

180.5 mT

|

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

warning |

| 1 mm |

1728 Gs

172.8 mT

|

5.77 kg / 12.72 lbs

5771.5 g / 56.6 N

|

warning |

| 2 mm |

1628 Gs

162.8 mT

|

5.13 kg / 11.30 lbs

5125.7 g / 50.3 N

|

warning |

| 3 mm |

1515 Gs

151.5 mT

|

4.43 kg / 9.78 lbs

4434.6 g / 43.5 N

|

warning |

| 5 mm |

1271 Gs

127.1 mT

|

3.12 kg / 6.89 lbs

3124.3 g / 30.6 N

|

warning |

| 10 mm |

751 Gs

75.1 mT

|

1.09 kg / 2.40 lbs

1088.7 g / 10.7 N

|

safe |

| 15 mm |

435 Gs

43.5 mT

|

0.37 kg / 0.81 lbs

366.3 g / 3.6 N

|

safe |

| 20 mm |

262 Gs

26.2 mT

|

0.13 kg / 0.29 lbs

132.6 g / 1.3 N

|

safe |

| 30 mm |

110 Gs

11.0 mT

|

0.02 kg / 0.05 lbs

23.2 g / 0.2 N

|

safe |

| 50 mm |

30 Gs

3.0 mT

|

0.00 kg / 0.00 lbs

1.8 g / 0.0 N

|

safe |

Table 2: Vertical capacity (vertical surface)

MPL 30x20x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.26 kg / 2.78 lbs

1260.0 g / 12.4 N

|

| 1 mm | Stal (~0.2) |

1.15 kg / 2.54 lbs

1154.0 g / 11.3 N

|

| 2 mm | Stal (~0.2) |

1.03 kg / 2.26 lbs

1026.0 g / 10.1 N

|

| 3 mm | Stal (~0.2) |

0.89 kg / 1.95 lbs

886.0 g / 8.7 N

|

| 5 mm | Stal (~0.2) |

0.62 kg / 1.38 lbs

624.0 g / 6.1 N

|

| 10 mm | Stal (~0.2) |

0.22 kg / 0.48 lbs

218.0 g / 2.1 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

74.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

26.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 30x20x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.89 kg / 4.17 lbs

1890.0 g / 18.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.26 kg / 2.78 lbs

1260.0 g / 12.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.63 kg / 1.39 lbs

630.0 g / 6.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.15 kg / 6.94 lbs

3150.0 g / 30.9 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 30x20x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.63 kg / 1.39 lbs

630.0 g / 6.2 N

|

| 1 mm |

|

1.58 kg / 3.47 lbs

1575.0 g / 15.5 N

|

| 2 mm |

|

3.15 kg / 6.94 lbs

3150.0 g / 30.9 N

|

| 3 mm |

|

4.73 kg / 10.42 lbs

4725.0 g / 46.4 N

|

| 5 mm |

|

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

| 10 mm |

|

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

| 11 mm |

|

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

| 12 mm |

|

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 30x20x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.30 kg / 13.89 lbs

6300.0 g / 61.8 N

|

OK |

| 40 °C | -2.2% |

6.16 kg / 13.58 lbs

6161.4 g / 60.4 N

|

OK |

| 60 °C | -4.4% |

6.02 kg / 13.28 lbs

6022.8 g / 59.1 N

|

|

| 80 °C | -6.6% |

5.88 kg / 12.97 lbs

5884.2 g / 57.7 N

|

|

| 100 °C | -28.8% |

4.49 kg / 9.89 lbs

4485.6 g / 44.0 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 30x20x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.06 kg / 26.58 lbs

3 198 Gs

|

1.81 kg / 3.99 lbs

1809 g / 17.7 N

|

N/A |

| 1 mm |

11.59 kg / 25.55 lbs

3 540 Gs

|

1.74 kg / 3.83 lbs

1739 g / 17.1 N

|

10.43 kg / 23.00 lbs

~0 Gs

|

| 2 mm |

11.05 kg / 24.35 lbs

3 456 Gs

|

1.66 kg / 3.65 lbs

1657 g / 16.3 N

|

9.94 kg / 21.92 lbs

~0 Gs

|

| 3 mm |

10.45 kg / 23.03 lbs

3 361 Gs

|

1.57 kg / 3.45 lbs

1567 g / 15.4 N

|

9.40 kg / 20.73 lbs

~0 Gs

|

| 5 mm |

9.15 kg / 20.18 lbs

3 146 Gs

|

1.37 kg / 3.03 lbs

1373 g / 13.5 N

|

8.24 kg / 18.16 lbs

~0 Gs

|

| 10 mm |

5.98 kg / 13.18 lbs

2 543 Gs

|

0.90 kg / 1.98 lbs

897 g / 8.8 N

|

5.38 kg / 11.86 lbs

~0 Gs

|

| 20 mm |

2.08 kg / 4.59 lbs

1 501 Gs

|

0.31 kg / 0.69 lbs

313 g / 3.1 N

|

1.88 kg / 4.13 lbs

~0 Gs

|

| 50 mm |

0.10 kg / 0.22 lbs

331 Gs

|

0.02 kg / 0.03 lbs

15 g / 0.1 N

|

0.09 kg / 0.20 lbs

~0 Gs

|

| 60 mm |

0.04 kg / 0.10 lbs

219 Gs

|

0.01 kg / 0.01 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 70 mm |

0.02 kg / 0.05 lbs

151 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

| 80 mm |

0.01 kg / 0.02 lbs

108 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.01 lbs

80 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 lbs

60 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MPL 30x20x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.5 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 30x20x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.81 km/h

(5.78 m/s)

|

0.30 J | |

| 30 mm |

32.75 km/h

(9.10 m/s)

|

0.75 J | |

| 50 mm |

42.20 km/h

(11.72 m/s)

|

1.24 J | |

| 100 mm |

59.66 km/h

(16.57 m/s)

|

2.47 J |

Table 9: Surface protection spec

MPL 30x20x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 30x20x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 12 775 Mx | 127.8 µWb |

| Pc Coefficient | 0.22 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 30x20x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.30 kg | Standard |

| Water (riverbed) |

7.21 kg

(+0.91 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains just ~20% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.22

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more offers

Advantages and disadvantages of rare earth magnets.

Advantages

- Their magnetic field remains stable, and after approximately ten years it decreases only by ~1% (theoretically),

- They do not lose their magnetic properties even under strong external field,

- A magnet with a shiny gold surface has an effective appearance,

- Neodymium magnets create maximum magnetic induction on a small surface, which allows for strong attraction,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- In view of the potential of precise shaping and customization to unique solutions, NdFeB magnets can be produced in a wide range of geometric configurations, which amplifies use scope,

- Universal use in advanced technology sectors – they find application in data components, electric motors, advanced medical instruments, and modern systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which makes them useful in miniature devices

Weaknesses

- At strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited ability of making threads in the magnet and complex shapes - recommended is casing - magnetic holder.

- Health risk to health – tiny shards of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. Furthermore, small components of these devices can complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Detachment force of the magnet in optimal conditions – what affects it?

- with the application of a yoke made of special test steel, ensuring maximum field concentration

- with a cross-section no less than 10 mm

- with an polished contact surface

- under conditions of gap-free contact (metal-to-metal)

- for force applied at a right angle (in the magnet axis)

- at temperature approx. 20 degrees Celsius

Practical lifting capacity: influencing factors

- Air gap (between the magnet and the metal), as even a microscopic distance (e.g. 0.5 mm) results in a drastic drop in force by up to 50% (this also applies to paint, rust or dirt).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of converting into lifting capacity.

- Steel grade – the best choice is high-permeability steel. Stainless steels may have worse magnetic properties.

- Smoothness – ideal contact is possible only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was determined by applying a polished steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under attempts to slide the magnet the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate lowers the holding force.

Warnings

Compass and GPS

A powerful magnetic field interferes with the functioning of compasses in phones and GPS navigation. Do not bring magnets close to a smartphone to avoid breaking the sensors.

Power loss in heat

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will destroy its properties and strength.

Keep away from computers

Do not bring magnets near a wallet, computer, or TV. The magnetism can irreversibly ruin these devices and wipe information from cards.

Dust explosion hazard

Powder created during machining of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Bodily injuries

Mind your fingers. Two large magnets will snap together immediately with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Warning for heart patients

Health Alert: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Warning for allergy sufferers

A percentage of the population have a contact allergy to nickel, which is the standard coating for NdFeB magnets. Prolonged contact might lead to skin redness. We strongly advise use protective gloves.

Shattering risk

Despite metallic appearance, neodymium is delicate and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Swallowing risk

Absolutely store magnets away from children. Choking hazard is high, and the consequences of magnets clamping inside the body are life-threatening.

Do not underestimate power

Before use, read the rules. Sudden snapping can break the magnet or injure your hand. Be predictive.

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)

![UMH 20x7x35 [M4] / N38 - magnetic holder with hook UMH 20x7x35 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-20x7x35-m4-hiz.jpg)