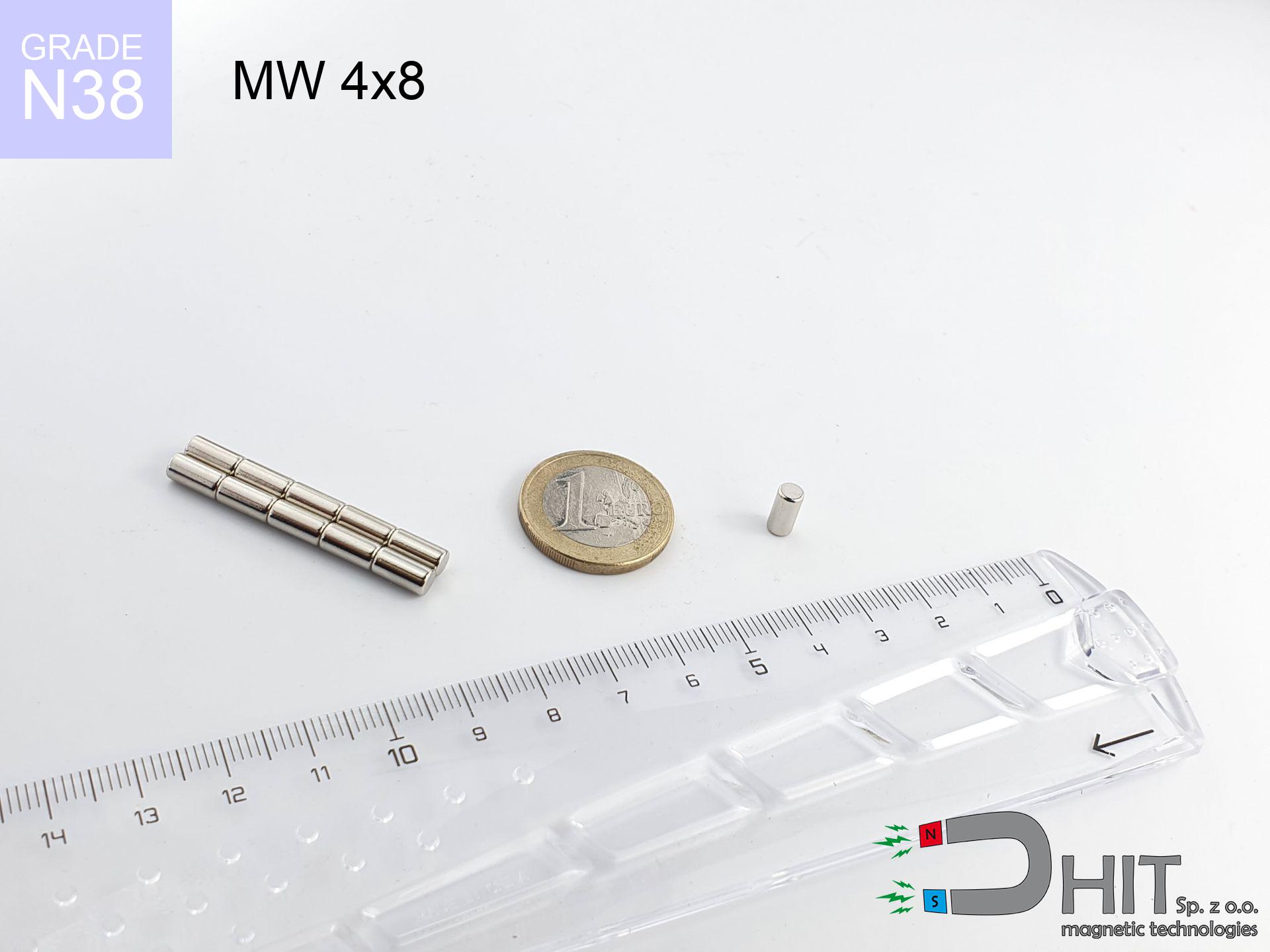

MW 4x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010079

GTIN/EAN: 5906301810780

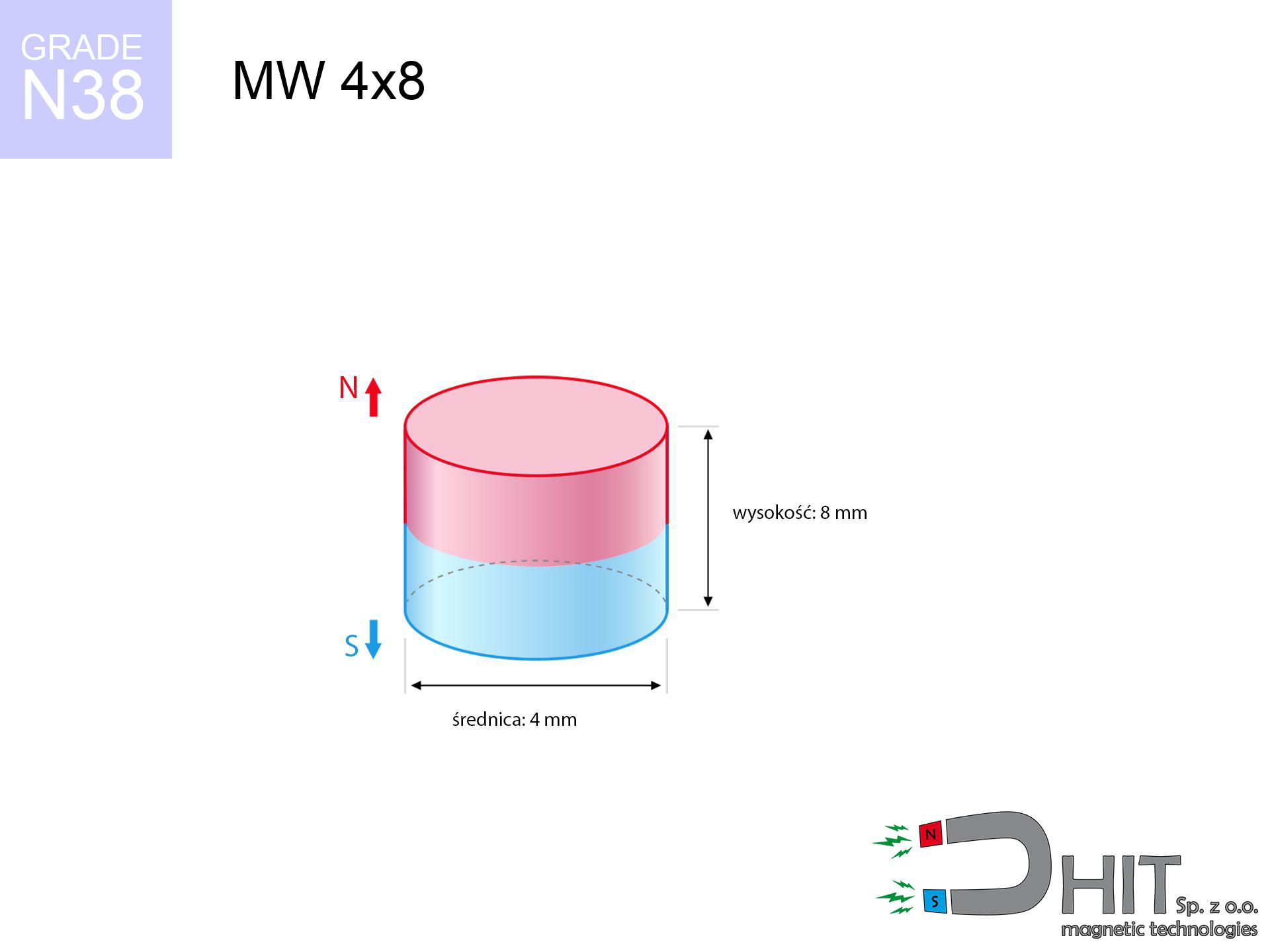

Diameter Ø

4 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

0.75 g

Magnetization Direction

↑ axial

Load capacity

0.35 kg / 3.48 N

Magnetic Induction

599.59 mT / 5996 Gs

Coating

[NiCuNi] Nickel

0.701 ZŁ with VAT / pcs + price for transport

0.570 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively let us know via

our online form

the contact form page.

Force and form of neodymium magnets can be analyzed using our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical - MW 4x8 / N38 - cylindrical magnet

Specification / characteristics - MW 4x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010079 |

| GTIN/EAN | 5906301810780 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 4 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 0.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.35 kg / 3.48 N |

| Magnetic Induction ~ ? | 599.59 mT / 5996 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the magnet - technical parameters

Presented information represent the result of a engineering analysis. Values are based on models for the class Nd2Fe14B. Real-world performance may differ. Use these calculations as a supplementary guide when designing systems.

Table 1: Static pull force (pull vs gap) - characteristics

MW 4x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5984 Gs

598.4 mT

|

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

weak grip |

| 1 mm |

3280 Gs

328.0 mT

|

0.11 kg / 0.23 LBS

105.1 g / 1.0 N

|

weak grip |

| 2 mm |

1696 Gs

169.6 mT

|

0.03 kg / 0.06 LBS

28.1 g / 0.3 N

|

weak grip |

| 3 mm |

941 Gs

94.1 mT

|

0.01 kg / 0.02 LBS

8.7 g / 0.1 N

|

weak grip |

| 5 mm |

371 Gs

37.1 mT

|

0.00 kg / 0.00 LBS

1.3 g / 0.0 N

|

weak grip |

| 10 mm |

82 Gs

8.2 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 15 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 20 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear capacity (vertical surface)

MW 4x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 1 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

22.0 g / 0.2 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 4x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.11 kg / 0.23 LBS

105.0 g / 1.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.08 LBS

35.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.18 kg / 0.39 LBS

175.0 g / 1.7 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 4x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.08 LBS

35.0 g / 0.3 N

|

| 1 mm |

|

0.09 kg / 0.19 LBS

87.5 g / 0.9 N

|

| 2 mm |

|

0.18 kg / 0.39 LBS

175.0 g / 1.7 N

|

| 3 mm |

|

0.26 kg / 0.58 LBS

262.5 g / 2.6 N

|

| 5 mm |

|

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

| 10 mm |

|

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

| 11 mm |

|

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

| 12 mm |

|

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 4x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.35 kg / 0.77 LBS

350.0 g / 3.4 N

|

OK |

| 40 °C | -2.2% |

0.34 kg / 0.75 LBS

342.3 g / 3.4 N

|

OK |

| 60 °C | -4.4% |

0.33 kg / 0.74 LBS

334.6 g / 3.3 N

|

OK |

| 80 °C | -6.6% |

0.33 kg / 0.72 LBS

326.9 g / 3.2 N

|

|

| 100 °C | -28.8% |

0.25 kg / 0.55 LBS

249.2 g / 2.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 4x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.77 kg / 6.12 LBS

6 121 Gs

|

0.42 kg / 0.92 LBS

416 g / 4.1 N

|

N/A |

| 1 mm |

1.59 kg / 3.51 LBS

9 063 Gs

|

0.24 kg / 0.53 LBS

239 g / 2.3 N

|

1.43 kg / 3.16 LBS

~0 Gs

|

| 2 mm |

0.83 kg / 1.84 LBS

6 559 Gs

|

0.12 kg / 0.28 LBS

125 g / 1.2 N

|

0.75 kg / 1.65 LBS

~0 Gs

|

| 3 mm |

0.43 kg / 0.94 LBS

4 694 Gs

|

0.06 kg / 0.14 LBS

64 g / 0.6 N

|

0.38 kg / 0.85 LBS

~0 Gs

|

| 5 mm |

0.12 kg / 0.27 LBS

2 498 Gs

|

0.02 kg / 0.04 LBS

18 g / 0.2 N

|

0.11 kg / 0.24 LBS

~0 Gs

|

| 10 mm |

0.01 kg / 0.02 LBS

743 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

165 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

10 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 4x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 4x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.79 km/h

(6.05 m/s)

|

0.01 J | |

| 30 mm |

37.74 km/h

(10.48 m/s)

|

0.04 J | |

| 50 mm |

48.72 km/h

(13.53 m/s)

|

0.07 J | |

| 100 mm |

68.89 km/h

(19.14 m/s)

|

0.14 J |

Table 9: Coating parameters (durability)

MW 4x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 4x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 836 Mx | 8.4 µWb |

| Pc Coefficient | 1.21 | High (Stable) |

Table 11: Submerged application

MW 4x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.35 kg | Standard |

| Water (riverbed) |

0.40 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet retains merely a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Power loss vs temp

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.21

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Pros and cons of Nd2Fe14B magnets.

Advantages

- They have stable power, and over around ten years their performance decreases symbolically – ~1% (in testing),

- They show high resistance to demagnetization induced by external magnetic fields,

- A magnet with a shiny silver surface is more attractive,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Thanks to resistance to high temperature, they are capable of working (depending on the form) even at temperatures up to 230°C and higher...

- Due to the option of accurate shaping and customization to individualized needs, neodymium magnets can be created in a wide range of forms and dimensions, which amplifies use scope,

- Universal use in future technologies – they find application in data components, electric drive systems, advanced medical instruments, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in miniature devices

Disadvantages

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in realizing threads and complex shapes in magnets, we propose using cover - magnetic holder.

- Possible danger to health – tiny shards of magnets pose a threat, when accidentally swallowed, which is particularly important in the context of child safety. It is also worth noting that small elements of these products are able to disrupt the diagnostic process medical in case of swallowing.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Maximum lifting capacity of the magnet – what affects it?

- using a base made of low-carbon steel, acting as a circuit closing element

- possessing a massiveness of min. 10 mm to avoid saturation

- with a plane cleaned and smooth

- without the slightest insulating layer between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- at temperature room level

Lifting capacity in real conditions – factors

- Air gap (betwixt the magnet and the plate), because even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Loading method – catalog parameter refers to pulling vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Steel grade – the best choice is high-permeability steel. Cast iron may attract less.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Thermal factor – high temperature reduces pulling force. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was determined with the use of a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a slight gap between the magnet and the plate decreases the load capacity.

H&S for magnets

Nickel allergy

Certain individuals have a contact allergy to Ni, which is the typical protective layer for NdFeB magnets. Extended handling might lead to an allergic reaction. It is best to use protective gloves.

Flammability

Combustion risk: Rare earth powder is highly flammable. Avoid machining magnets in home conditions as this may cause fire.

Pacemakers

Life threat: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have electronic implants.

Magnetic interference

Remember: rare earth magnets generate a field that disrupts precision electronics. Maintain a safe distance from your mobile, tablet, and GPS.

Magnetic media

Data protection: Strong magnets can damage data carriers and sensitive devices (heart implants, hearing aids, timepieces).

Bone fractures

Danger of trauma: The pulling power is so immense that it can result in hematomas, crushing, and even bone fractures. Use thick gloves.

Permanent damage

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, look for HT versions (H, SH, UH).

Conscious usage

Handle with care. Neodymium magnets act from a long distance and snap with massive power, often faster than you can move away.

Shattering risk

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Do not give to children

These products are not toys. Eating several magnets may result in them pinching intestinal walls, which poses a critical condition and necessitates immediate surgery.

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)

![SM 32x475 [2xM8] / N52 - magnetic separator SM 32x475 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x475-2xm8-wef.jpg)