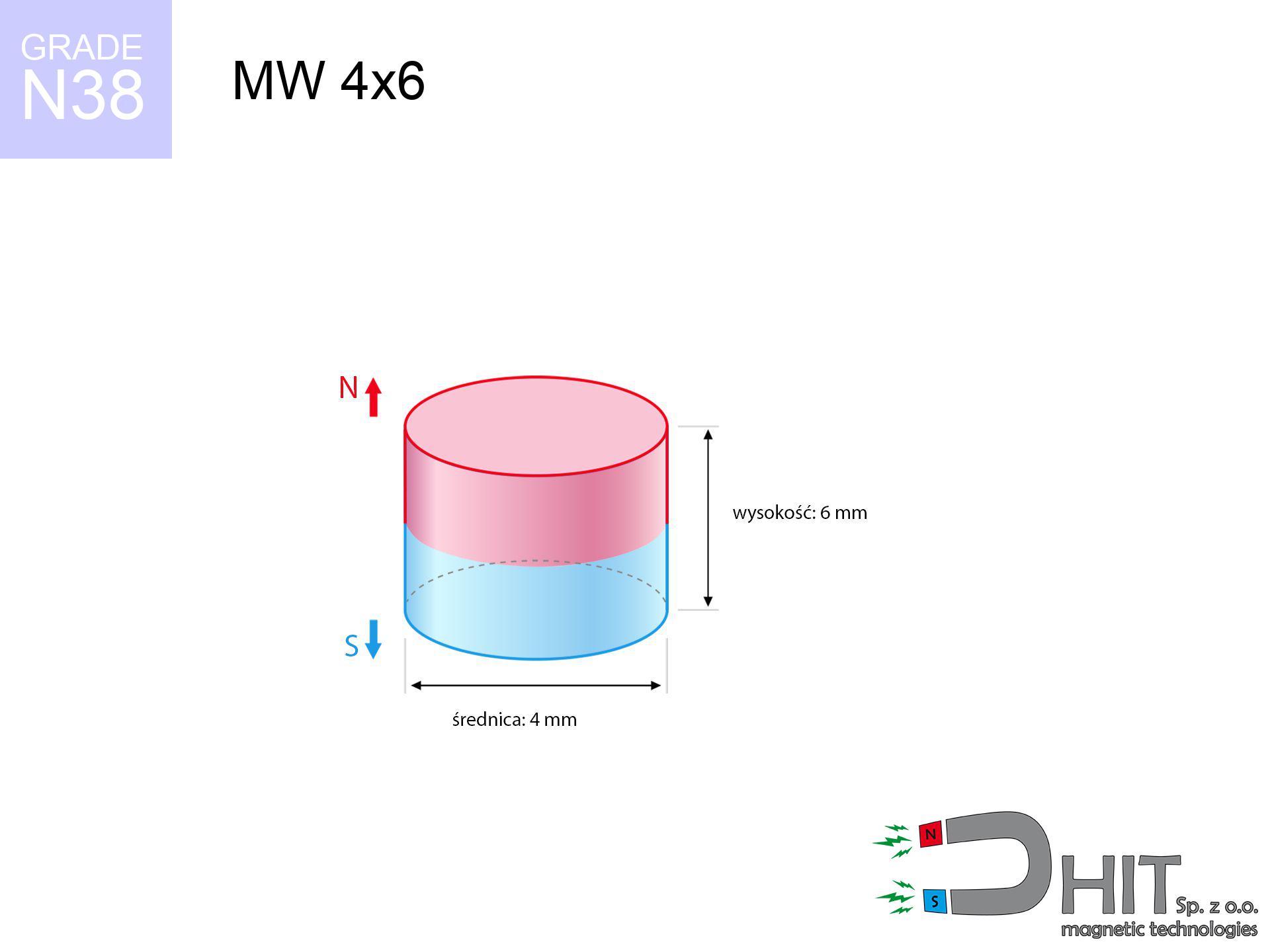

MW 4x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010078

GTIN/EAN: 5906301810773

Diameter Ø

4 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

0.57 g

Magnetization Direction

↑ axial

Load capacity

0.41 kg / 4.06 N

Magnetic Induction

586.32 mT / 5863 Gs

Coating

[NiCuNi] Nickel

0.381 ZŁ with VAT / pcs + price for transport

0.310 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

if you prefer drop us a message through

contact form

through our site.

Strength as well as shape of magnets can be calculated with our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical specification of the product - MW 4x6 / N38 - cylindrical magnet

Specification / characteristics - MW 4x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010078 |

| GTIN/EAN | 5906301810773 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 4 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 0.57 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.41 kg / 4.06 N |

| Magnetic Induction ~ ? | 586.32 mT / 5863 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - data

Presented values represent the result of a physical simulation. Results rely on models for the class Nd2Fe14B. Operational performance may deviate from the simulation results. Please consider these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs distance) - power drop

MW 4x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5852 Gs

585.2 mT

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

safe |

| 1 mm |

3189 Gs

318.9 mT

|

0.12 kg / 0.27 lbs

121.7 g / 1.2 N

|

safe |

| 2 mm |

1631 Gs

163.1 mT

|

0.03 kg / 0.07 lbs

31.8 g / 0.3 N

|

safe |

| 3 mm |

894 Gs

89.4 mT

|

0.01 kg / 0.02 lbs

9.6 g / 0.1 N

|

safe |

| 5 mm |

343 Gs

34.3 mT

|

0.00 kg / 0.00 lbs

1.4 g / 0.0 N

|

safe |

| 10 mm |

73 Gs

7.3 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

| 15 mm |

26 Gs

2.6 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 20 mm |

13 Gs

1.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 30 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Vertical load (wall)

MW 4x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.08 kg / 0.18 lbs

82.0 g / 0.8 N

|

| 1 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 4x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.12 kg / 0.27 lbs

123.0 g / 1.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.08 kg / 0.18 lbs

82.0 g / 0.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.04 kg / 0.09 lbs

41.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.21 kg / 0.45 lbs

205.0 g / 2.0 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 4x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.04 kg / 0.09 lbs

41.0 g / 0.4 N

|

| 1 mm |

|

0.10 kg / 0.23 lbs

102.5 g / 1.0 N

|

| 2 mm |

|

0.21 kg / 0.45 lbs

205.0 g / 2.0 N

|

| 3 mm |

|

0.31 kg / 0.68 lbs

307.5 g / 3.0 N

|

| 5 mm |

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

| 10 mm |

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

| 11 mm |

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

| 12 mm |

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

Table 5: Thermal resistance (stability) - thermal limit

MW 4x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

OK |

| 40 °C | -2.2% |

0.40 kg / 0.88 lbs

401.0 g / 3.9 N

|

OK |

| 60 °C | -4.4% |

0.39 kg / 0.86 lbs

392.0 g / 3.8 N

|

OK |

| 80 °C | -6.6% |

0.38 kg / 0.84 lbs

382.9 g / 3.8 N

|

|

| 100 °C | -28.8% |

0.29 kg / 0.64 lbs

291.9 g / 2.9 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 4x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.65 kg / 5.85 lbs

6 085 Gs

|

0.40 kg / 0.88 lbs

398 g / 3.9 N

|

N/A |

| 1 mm |

1.51 kg / 3.34 lbs

8 844 Gs

|

0.23 kg / 0.50 lbs

227 g / 2.2 N

|

1.36 kg / 3.01 lbs

~0 Gs

|

| 2 mm |

0.79 kg / 1.74 lbs

6 377 Gs

|

0.12 kg / 0.26 lbs

118 g / 1.2 N

|

0.71 kg / 1.56 lbs

~0 Gs

|

| 3 mm |

0.40 kg / 0.88 lbs

4 541 Gs

|

0.06 kg / 0.13 lbs

60 g / 0.6 N

|

0.36 kg / 0.79 lbs

~0 Gs

|

| 5 mm |

0.11 kg / 0.24 lbs

2 388 Gs

|

0.02 kg / 0.04 lbs

17 g / 0.2 N

|

0.10 kg / 0.22 lbs

~0 Gs

|

| 10 mm |

0.01 kg / 0.02 lbs

687 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

145 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

14 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

8 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

5 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

4 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 4x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MW 4x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.05 km/h

(7.51 m/s)

|

0.02 J | |

| 30 mm |

46.85 km/h

(13.01 m/s)

|

0.05 J | |

| 50 mm |

60.48 km/h

(16.80 m/s)

|

0.08 J | |

| 100 mm |

85.53 km/h

(23.76 m/s)

|

0.16 J |

Table 9: Surface protection spec

MW 4x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 4x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 792 Mx | 7.9 µWb |

| Pc Coefficient | 1.09 | High (Stable) |

Table 11: Physics of underwater searching

MW 4x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.41 kg | Standard |

| Water (riverbed) |

0.47 kg

(+0.06 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet retains just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely limits the holding force.

3. Temperature resistance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.09

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Strengths and weaknesses of rare earth magnets.

Advantages

- They do not lose strength, even over approximately 10 years – the decrease in strength is only ~1% (theoretically),

- Magnets very well protect themselves against loss of magnetization caused by foreign field sources,

- A magnet with a metallic nickel surface looks better,

- Magnets are distinguished by maximum magnetic induction on the working surface,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of precise modeling as well as adjusting to atypical needs,

- Huge importance in advanced technology sectors – they serve a role in hard drives, motor assemblies, advanced medical instruments, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which makes them useful in compact constructions

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation and corrosion.

- Limited possibility of producing nuts in the magnet and complex forms - recommended is cover - magnet mounting.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which becomes key in the context of child safety. It is also worth noting that small elements of these magnets are able to complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what affects it?

- with the application of a sheet made of low-carbon steel, ensuring full magnetic saturation

- whose transverse dimension reaches at least 10 mm

- with an ideally smooth touching surface

- without any air gap between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- in temp. approx. 20°C

Lifting capacity in practice – influencing factors

- Distance (betwixt the magnet and the plate), because even a very small clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet holds much less (often approx. 20-30% of maximum force).

- Plate thickness – too thin plate does not accept the full field, causing part of the flux to be escaped into the air.

- Metal type – different alloys attracts identically. Alloy additives weaken the attraction effect.

- Surface quality – the smoother and more polished the surface, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity was assessed using a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular pulling force, in contrast under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

Safety rules for work with NdFeB magnets

Threat to navigation

GPS units and smartphones are highly sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Heat sensitivity

Watch the temperature. Exposing the magnet to high heat will destroy its properties and strength.

Material brittleness

NdFeB magnets are ceramic materials, which means they are fragile like glass. Collision of two magnets leads to them shattering into shards.

No play value

Absolutely store magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are fatal.

Serious injuries

Mind your fingers. Two large magnets will snap together instantly with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Data carriers

Equipment safety: Neodymium magnets can damage data carriers and delicate electronics (heart implants, hearing aids, mechanical watches).

Nickel coating and allergies

Medical facts indicate that nickel (standard magnet coating) is a strong allergen. If you have an allergy, avoid touching magnets with bare hands and choose coated magnets.

Handling rules

Handle magnets with awareness. Their immense force can shock even experienced users. Stay alert and respect their power.

ICD Warning

For implant holders: Strong magnetic fields affect electronics. Maintain at least 30 cm distance or ask another person to handle the magnets.

Fire risk

Dust created during cutting of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.