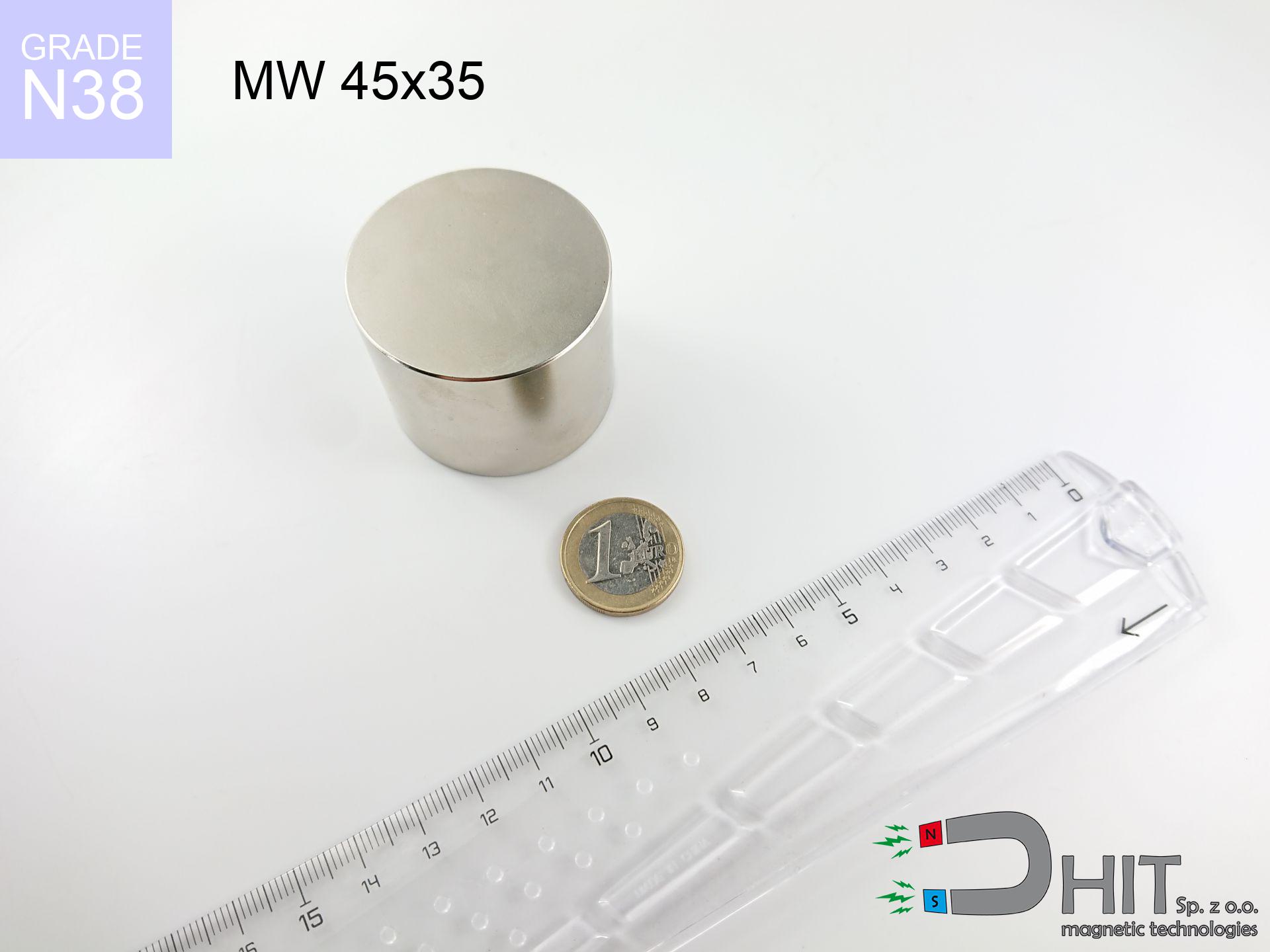

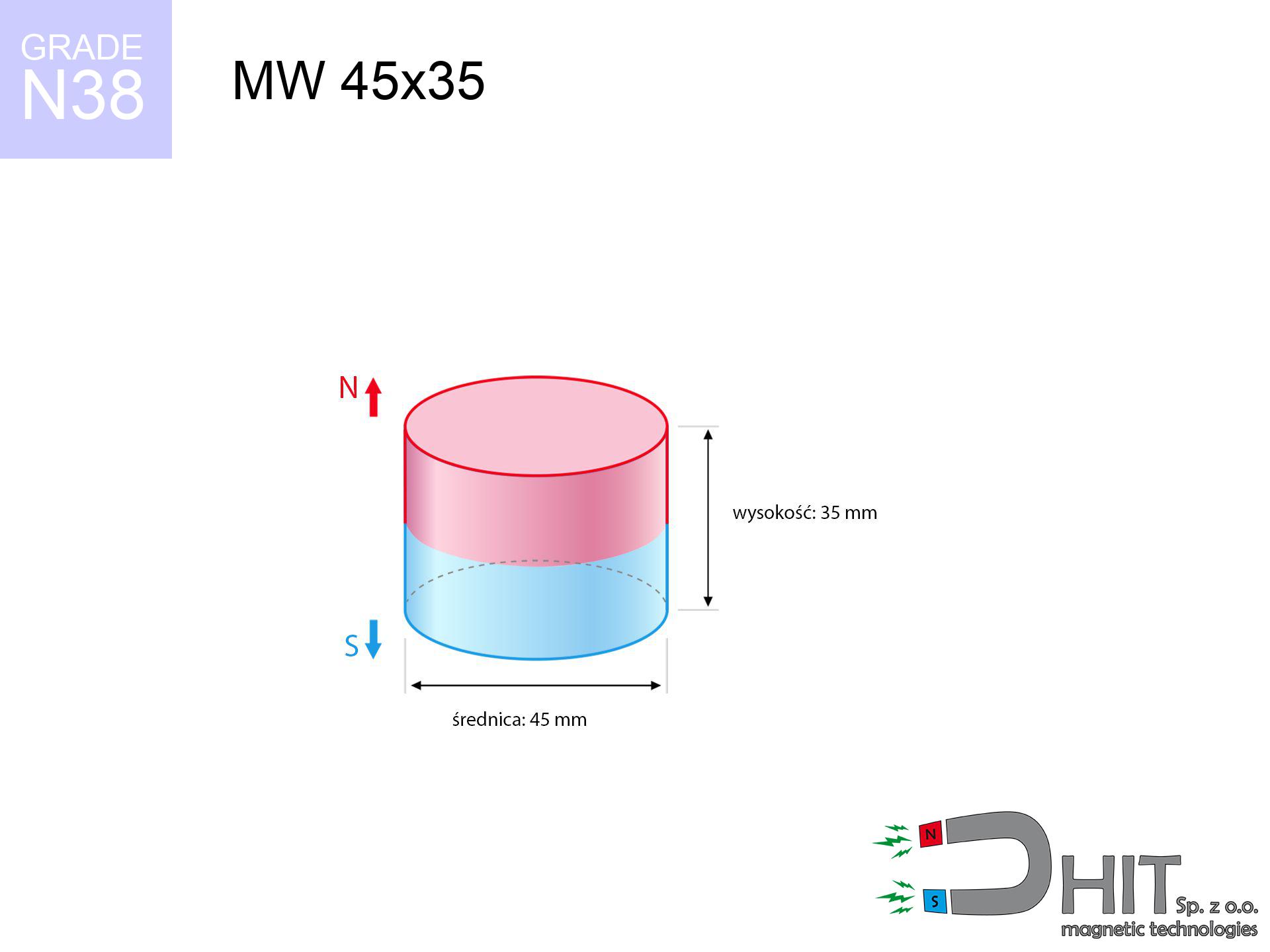

MW 45x35 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010074

GTIN/EAN: 5906301810735

Diameter Ø

45 mm [±0,1 mm]

Height

35 mm [±0,1 mm]

Weight

417.49 g

Magnetization Direction

↑ axial

Load capacity

68.98 kg / 676.73 N

Magnetic Induction

521.39 mT / 5214 Gs

Coating

[NiCuNi] Nickel

180.10 ZŁ with VAT / pcs + price for transport

146.42 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer drop us a message by means of

contact form

the contact page.

Lifting power and appearance of magnetic components can be analyzed on our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical - MW 45x35 / N38 - cylindrical magnet

Specification / characteristics - MW 45x35 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010074 |

| GTIN/EAN | 5906301810735 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 45 mm [±0,1 mm] |

| Height | 35 mm [±0,1 mm] |

| Weight | 417.49 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 68.98 kg / 676.73 N |

| Magnetic Induction ~ ? | 521.39 mT / 5214 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - report

Presented information constitute the outcome of a mathematical simulation. Results rely on models for the class Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Please consider these calculations as a reference point during assembly planning.

Table 1: Static pull force (force vs gap) - characteristics

MW 45x35 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5213 Gs

521.3 mT

|

68.98 kg / 152.07 pounds

68980.0 g / 676.7 N

|

critical level |

| 1 mm |

4982 Gs

498.2 mT

|

63.01 kg / 138.91 pounds

63010.2 g / 618.1 N

|

critical level |

| 2 mm |

4748 Gs

474.8 mT

|

57.23 kg / 126.18 pounds

57234.3 g / 561.5 N

|

critical level |

| 3 mm |

4516 Gs

451.6 mT

|

51.76 kg / 114.10 pounds

51756.9 g / 507.7 N

|

critical level |

| 5 mm |

4059 Gs

405.9 mT

|

41.82 kg / 92.19 pounds

41816.3 g / 410.2 N

|

critical level |

| 10 mm |

3027 Gs

302.7 mT

|

23.26 kg / 51.29 pounds

23264.1 g / 228.2 N

|

critical level |

| 15 mm |

2215 Gs

221.5 mT

|

12.45 kg / 27.45 pounds

12451.1 g / 122.1 N

|

critical level |

| 20 mm |

1619 Gs

161.9 mT

|

6.66 kg / 14.67 pounds

6656.2 g / 65.3 N

|

strong |

| 30 mm |

899 Gs

89.9 mT

|

2.05 kg / 4.52 pounds

2051.1 g / 20.1 N

|

strong |

| 50 mm |

340 Gs

34.0 mT

|

0.29 kg / 0.65 pounds

292.8 g / 2.9 N

|

low risk |

Table 2: Vertical force (vertical surface)

MW 45x35 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

13.80 kg / 30.41 pounds

13796.0 g / 135.3 N

|

| 1 mm | Stal (~0.2) |

12.60 kg / 27.78 pounds

12602.0 g / 123.6 N

|

| 2 mm | Stal (~0.2) |

11.45 kg / 25.23 pounds

11446.0 g / 112.3 N

|

| 3 mm | Stal (~0.2) |

10.35 kg / 22.82 pounds

10352.0 g / 101.6 N

|

| 5 mm | Stal (~0.2) |

8.36 kg / 18.44 pounds

8364.0 g / 82.1 N

|

| 10 mm | Stal (~0.2) |

4.65 kg / 10.26 pounds

4652.0 g / 45.6 N

|

| 15 mm | Stal (~0.2) |

2.49 kg / 5.49 pounds

2490.0 g / 24.4 N

|

| 20 mm | Stal (~0.2) |

1.33 kg / 2.94 pounds

1332.0 g / 13.1 N

|

| 30 mm | Stal (~0.2) |

0.41 kg / 0.90 pounds

410.0 g / 4.0 N

|

| 50 mm | Stal (~0.2) |

0.06 kg / 0.13 pounds

58.0 g / 0.6 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 45x35 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

20.69 kg / 45.62 pounds

20694.0 g / 203.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

13.80 kg / 30.41 pounds

13796.0 g / 135.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

6.90 kg / 15.21 pounds

6898.0 g / 67.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

34.49 kg / 76.04 pounds

34490.0 g / 338.3 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 45x35 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.30 kg / 5.07 pounds

2299.3 g / 22.6 N

|

| 1 mm |

|

5.75 kg / 12.67 pounds

5748.3 g / 56.4 N

|

| 2 mm |

|

11.50 kg / 25.35 pounds

11496.7 g / 112.8 N

|

| 3 mm |

|

17.25 kg / 38.02 pounds

17245.0 g / 169.2 N

|

| 5 mm |

|

28.74 kg / 63.36 pounds

28741.7 g / 282.0 N

|

| 10 mm |

|

57.48 kg / 126.73 pounds

57483.3 g / 563.9 N

|

| 11 mm |

|

63.23 kg / 139.40 pounds

63231.7 g / 620.3 N

|

| 12 mm |

|

68.98 kg / 152.07 pounds

68980.0 g / 676.7 N

|

Table 5: Working in heat (stability) - resistance threshold

MW 45x35 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

68.98 kg / 152.07 pounds

68980.0 g / 676.7 N

|

OK |

| 40 °C | -2.2% |

67.46 kg / 148.73 pounds

67462.4 g / 661.8 N

|

OK |

| 60 °C | -4.4% |

65.94 kg / 145.38 pounds

65944.9 g / 646.9 N

|

OK |

| 80 °C | -6.6% |

64.43 kg / 142.04 pounds

64427.3 g / 632.0 N

|

|

| 100 °C | -28.8% |

49.11 kg / 108.28 pounds

49113.8 g / 481.8 N

|

Table 6: Two magnets (repulsion) - field collision

MW 45x35 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

266.45 kg / 587.43 pounds

5 900 Gs

|

39.97 kg / 88.11 pounds

39968 g / 392.1 N

|

N/A |

| 1 mm |

254.93 kg / 562.03 pounds

10 198 Gs

|

38.24 kg / 84.30 pounds

38240 g / 375.1 N

|

229.44 kg / 505.82 pounds

~0 Gs

|

| 2 mm |

243.39 kg / 536.59 pounds

9 965 Gs

|

36.51 kg / 80.49 pounds

36509 g / 358.2 N

|

219.05 kg / 482.93 pounds

~0 Gs

|

| 3 mm |

232.10 kg / 511.70 pounds

9 731 Gs

|

34.82 kg / 76.76 pounds

34816 g / 341.5 N

|

208.89 kg / 460.53 pounds

~0 Gs

|

| 5 mm |

210.35 kg / 463.75 pounds

9 264 Gs

|

31.55 kg / 69.56 pounds

31553 g / 309.5 N

|

189.32 kg / 417.37 pounds

~0 Gs

|

| 10 mm |

161.53 kg / 356.11 pounds

8 118 Gs

|

24.23 kg / 53.42 pounds

24229 g / 237.7 N

|

145.37 kg / 320.49 pounds

~0 Gs

|

| 20 mm |

89.86 kg / 198.12 pounds

6 055 Gs

|

13.48 kg / 29.72 pounds

13480 g / 132.2 N

|

80.88 kg / 178.30 pounds

~0 Gs

|

| 50 mm |

14.04 kg / 30.96 pounds

2 394 Gs

|

2.11 kg / 4.64 pounds

2107 g / 20.7 N

|

12.64 kg / 27.87 pounds

~0 Gs

|

| 60 mm |

7.92 kg / 17.47 pounds

1 798 Gs

|

1.19 kg / 2.62 pounds

1188 g / 11.7 N

|

7.13 kg / 15.72 pounds

~0 Gs

|

| 70 mm |

4.63 kg / 10.21 pounds

1 375 Gs

|

0.69 kg / 1.53 pounds

695 g / 6.8 N

|

4.17 kg / 9.19 pounds

~0 Gs

|

| 80 mm |

2.80 kg / 6.18 pounds

1 070 Gs

|

0.42 kg / 0.93 pounds

421 g / 4.1 N

|

2.52 kg / 5.56 pounds

~0 Gs

|

| 90 mm |

1.75 kg / 3.87 pounds

846 Gs

|

0.26 kg / 0.58 pounds

263 g / 2.6 N

|

1.58 kg / 3.48 pounds

~0 Gs

|

| 100 mm |

1.13 kg / 2.49 pounds

679 Gs

|

0.17 kg / 0.37 pounds

170 g / 1.7 N

|

1.02 kg / 2.24 pounds

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 45x35 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 26.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 20.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 16.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 12.5 cm |

| Remote | 50 Gs (5.0 mT) | 11.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 45x35 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.46 km/h

(4.29 m/s)

|

3.85 J | |

| 30 mm |

22.87 km/h

(6.35 m/s)

|

8.42 J | |

| 50 mm |

29.06 km/h

(8.07 m/s)

|

13.61 J | |

| 100 mm |

41.00 km/h

(11.39 m/s)

|

27.07 J |

Table 9: Coating parameters (durability)

MW 45x35 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 45x35 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 83 921 Mx | 839.2 µWb |

| Pc Coefficient | 0.78 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 45x35 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 68.98 kg | Standard |

| Water (riverbed) |

78.98 kg

(+10.00 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet holds just ~20% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.78

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of neodymium magnets.

Pros

- Their magnetic field is maintained, and after around 10 years it decreases only by ~1% (according to research),

- Neodymium magnets are characterized by exceptionally resistant to demagnetization caused by magnetic disturbances,

- By applying a lustrous layer of gold, the element acquires an aesthetic look,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to modularity in shaping and the capacity to customize to unusual requirements,

- Huge importance in future technologies – they are commonly used in mass storage devices, electric drive systems, diagnostic systems, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which allows their use in miniature devices

Weaknesses

- At very strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- We recommend cover - magnetic holder, due to difficulties in creating nuts inside the magnet and complicated forms.

- Health risk related to microscopic parts of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. Additionally, small components of these products are able to be problematic in diagnostics medical in case of swallowing.

- With mass production the cost of neodymium magnets can be a barrier,

Lifting parameters

Highest magnetic holding force – what affects it?

- using a sheet made of mild steel, acting as a ideal flux conductor

- whose transverse dimension is min. 10 mm

- characterized by smoothness

- under conditions of no distance (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at room temperature

Determinants of lifting force in real conditions

- Air gap (between the magnet and the metal), because even a microscopic clearance (e.g. 0.5 mm) can cause a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or dirt).

- Loading method – catalog parameter refers to detachment vertically. When applying parallel force, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys reacts the same. High carbon content weaken the attraction effect.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Temperature influence – high temperature reduces magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity was assessed using a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet and the plate reduces the lifting capacity.

Warnings

Magnetic interference

GPS units and smartphones are extremely sensitive to magnetism. Close proximity with a powerful NdFeB magnet can ruin the sensors in your phone.

Heat sensitivity

Regular neodymium magnets (grade N) lose power when the temperature exceeds 80°C. Damage is permanent.

Cards and drives

Avoid bringing magnets near a wallet, computer, or screen. The magnetism can permanently damage these devices and wipe information from cards.

Material brittleness

Neodymium magnets are ceramic materials, which means they are fragile like glass. Clashing of two magnets leads to them breaking into shards.

Product not for children

Product intended for adults. Small elements pose a choking risk, leading to intestinal necrosis. Keep away from kids and pets.

Fire risk

Dust generated during machining of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Conscious usage

Handle magnets with awareness. Their powerful strength can shock even professionals. Plan your moves and do not underestimate their force.

Serious injuries

Mind your fingers. Two large magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Exercise extreme caution!

Implant safety

Health Alert: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Metal Allergy

Certain individuals have a sensitization to nickel, which is the typical protective layer for NdFeB magnets. Extended handling may cause dermatitis. We suggest use safety gloves.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)