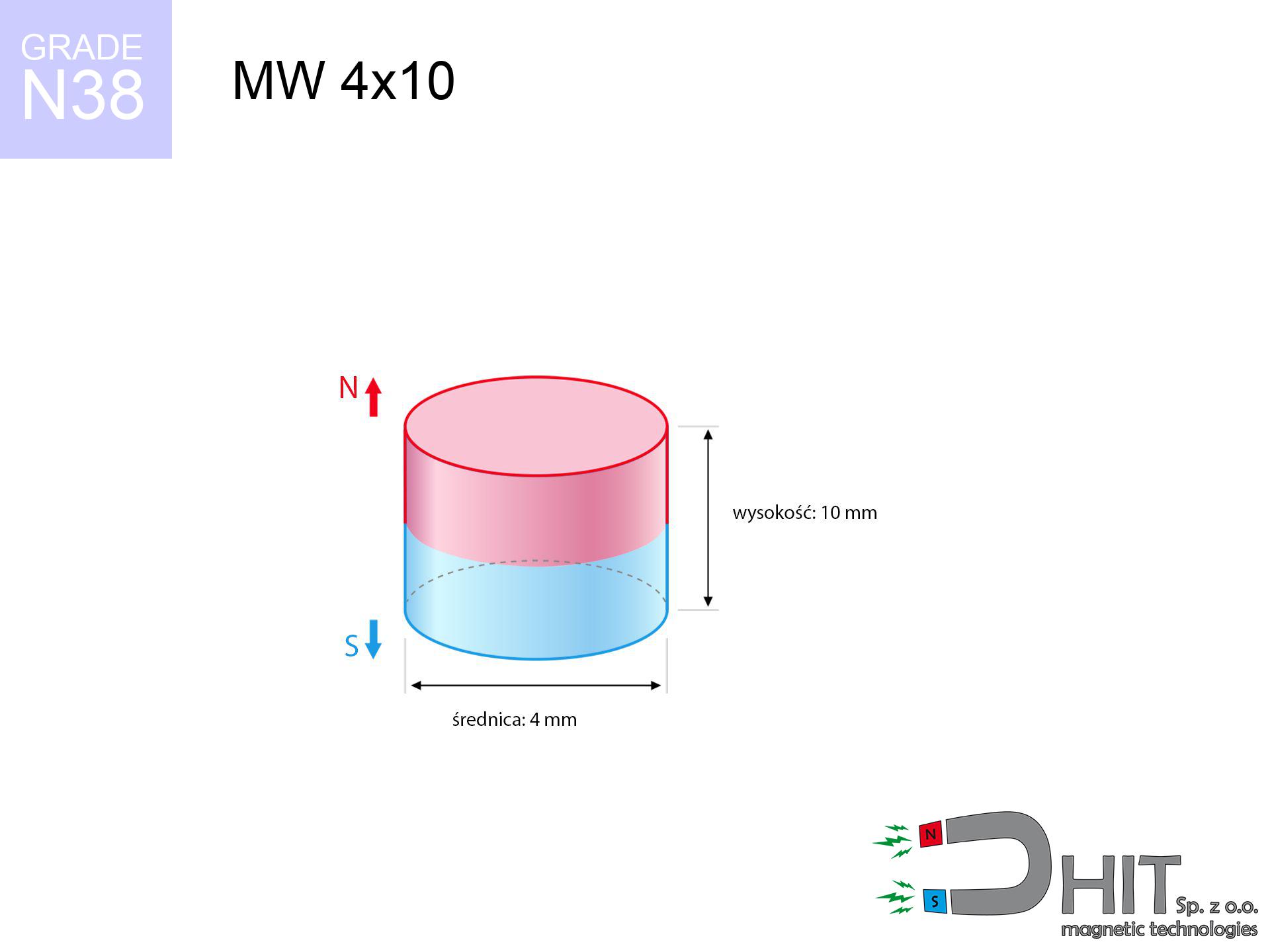

MW 4x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010075

GTIN/EAN: 5906301810742

Diameter Ø

4 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

0.94 g

Magnetization Direction

↑ axial

Load capacity

0.32 kg / 3.16 N

Magnetic Induction

606.05 mT / 6061 Gs

Coating

[NiCuNi] Nickel

0.800 ZŁ with VAT / pcs + price for transport

0.650 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

or get in touch using

inquiry form

our website.

Force along with form of neodymium magnets can be calculated using our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters of the product - MW 4x10 / N38 - cylindrical magnet

Specification / characteristics - MW 4x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010075 |

| GTIN/EAN | 5906301810742 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 4 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 0.94 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.32 kg / 3.16 N |

| Magnetic Induction ~ ? | 606.05 mT / 6061 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - data

The following information represent the outcome of a physical simulation. Values were calculated on algorithms for the material Nd2Fe14B. Real-world parameters might slightly differ. Please consider these calculations as a reference point during assembly planning.

Table 1: Static force (pull vs distance) - interaction chart

MW 4x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6049 Gs

604.9 mT

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

low risk |

| 1 mm |

3327 Gs

332.7 mT

|

0.10 kg / 0.21 pounds

96.8 g / 0.9 N

|

low risk |

| 2 mm |

1732 Gs

173.2 mT

|

0.03 kg / 0.06 pounds

26.2 g / 0.3 N

|

low risk |

| 3 mm |

969 Gs

96.9 mT

|

0.01 kg / 0.02 pounds

8.2 g / 0.1 N

|

low risk |

| 5 mm |

389 Gs

38.9 mT

|

0.00 kg / 0.00 pounds

1.3 g / 0.0 N

|

low risk |

| 10 mm |

90 Gs

9.0 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

low risk |

| 15 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 20 mm |

17 Gs

1.7 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 30 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Shear capacity (vertical surface)

MW 4x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.06 kg / 0.14 pounds

64.0 g / 0.6 N

|

| 1 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

20.0 g / 0.2 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 4x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.10 kg / 0.21 pounds

96.0 g / 0.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.06 kg / 0.14 pounds

64.0 g / 0.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.16 kg / 0.35 pounds

160.0 g / 1.6 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 4x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| 1 mm |

|

0.08 kg / 0.18 pounds

80.0 g / 0.8 N

|

| 2 mm |

|

0.16 kg / 0.35 pounds

160.0 g / 1.6 N

|

| 3 mm |

|

0.24 kg / 0.53 pounds

240.0 g / 2.4 N

|

| 5 mm |

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| 10 mm |

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| 11 mm |

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| 12 mm |

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

Table 5: Thermal stability (material behavior) - power drop

MW 4x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

OK |

| 40 °C | -2.2% |

0.31 kg / 0.69 pounds

313.0 g / 3.1 N

|

OK |

| 60 °C | -4.4% |

0.31 kg / 0.67 pounds

305.9 g / 3.0 N

|

OK |

| 80 °C | -6.6% |

0.30 kg / 0.66 pounds

298.9 g / 2.9 N

|

|

| 100 °C | -28.8% |

0.23 kg / 0.50 pounds

227.8 g / 2.2 N

|

Table 6: Two magnets (repulsion) - field range

MW 4x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.83 kg / 6.25 pounds

6 138 Gs

|

0.43 kg / 0.94 pounds

425 g / 4.2 N

|

N/A |

| 1 mm |

1.63 kg / 3.59 pounds

9 174 Gs

|

0.24 kg / 0.54 pounds

244 g / 2.4 N

|

1.47 kg / 3.23 pounds

~0 Gs

|

| 2 mm |

0.86 kg / 1.89 pounds

6 655 Gs

|

0.13 kg / 0.28 pounds

129 g / 1.3 N

|

0.77 kg / 1.70 pounds

~0 Gs

|

| 3 mm |

0.44 kg / 0.97 pounds

4 777 Gs

|

0.07 kg / 0.15 pounds

66 g / 0.7 N

|

0.40 kg / 0.88 pounds

~0 Gs

|

| 5 mm |

0.13 kg / 0.28 pounds

2 561 Gs

|

0.02 kg / 0.04 pounds

19 g / 0.2 N

|

0.11 kg / 0.25 pounds

~0 Gs

|

| 10 mm |

0.01 kg / 0.03 pounds

778 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.02 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

179 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

19 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

12 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

6 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 4x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 4x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.61 km/h

(5.17 m/s)

|

0.01 J | |

| 30 mm |

32.23 km/h

(8.95 m/s)

|

0.04 J | |

| 50 mm |

41.61 km/h

(11.56 m/s)

|

0.06 J | |

| 100 mm |

58.84 km/h

(16.35 m/s)

|

0.13 J |

Table 9: Anti-corrosion coating durability

MW 4x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 4x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 864 Mx | 8.6 µWb |

| Pc Coefficient | 1.31 | High (Stable) |

Table 11: Physics of underwater searching

MW 4x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.32 kg | Standard |

| Water (riverbed) |

0.37 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely a fraction of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. computer case) severely weakens the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.31

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths and weaknesses of rare earth magnets.

Advantages

- They retain full power for nearly ten years – the drop is just ~1% (according to analyses),

- They retain their magnetic properties even under strong external field,

- By using a shiny coating of gold, the element gains an elegant look,

- Neodymium magnets create maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- In view of the option of flexible molding and adaptation to unique solutions, NdFeB magnets can be produced in a variety of geometric configurations, which amplifies use scope,

- Huge importance in modern industrial fields – they find application in magnetic memories, electromotive mechanisms, diagnostic systems, as well as other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages

- At strong impacts they can break, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Limited possibility of producing nuts in the magnet and complex shapes - preferred is a housing - magnetic holder.

- Health risk resulting from small fragments of magnets can be dangerous, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small elements of these devices are able to complicate diagnosis medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum lifting capacity of the magnet – what it depends on?

- on a block made of structural steel, perfectly concentrating the magnetic flux

- possessing a massiveness of minimum 10 mm to avoid saturation

- with a plane cleaned and smooth

- without any insulating layer between the magnet and steel

- under perpendicular force vector (90-degree angle)

- at temperature approx. 20 degrees Celsius

Determinants of practical lifting force of a magnet

- Space between surfaces – every millimeter of separation (caused e.g. by veneer or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Angle of force application – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is typically many times lower (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be adequately massive. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Plate material – mild steel gives the best results. Alloy admixtures reduce magnetic permeability and lifting capacity.

- Surface structure – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Roughness creates an air distance.

- Temperature – heating the magnet causes a temporary drop of force. Check the maximum operating temperature for a given model.

Lifting capacity was measured by applying a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, however under shearing force the lifting capacity is smaller. Moreover, even a small distance between the magnet’s surface and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Risk of cracking

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Product not for children

Always keep magnets away from children. Risk of swallowing is high, and the consequences of magnets connecting inside the body are very dangerous.

Operating temperature

Regular neodymium magnets (N-type) lose magnetization when the temperature surpasses 80°C. Damage is permanent.

Data carriers

Intense magnetic fields can erase data on payment cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Threat to navigation

An intense magnetic field negatively affects the operation of magnetometers in phones and GPS navigation. Do not bring magnets close to a device to prevent breaking the sensors.

Machining danger

Machining of NdFeB material carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Bone fractures

Mind your fingers. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Powerful field

Be careful. Neodymium magnets act from a distance and snap with huge force, often quicker than you can react.

Allergic reactions

Medical facts indicate that the nickel plating (standard magnet coating) is a strong allergen. If your skin reacts to metals, avoid touching magnets with bare hands and select versions in plastic housing.

Life threat

Patients with a heart stimulator have to keep an large gap from magnets. The magnetism can interfere with the functioning of the implant.

![SM 18x275 [2xM5] / N42 - magnetic separator SM 18x275 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x275-2xm5-zep.jpg)

![SM 18x150 [2xM5] / N42 - magnetic separator SM 18x150 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x150-2xm5-pec.jpg)