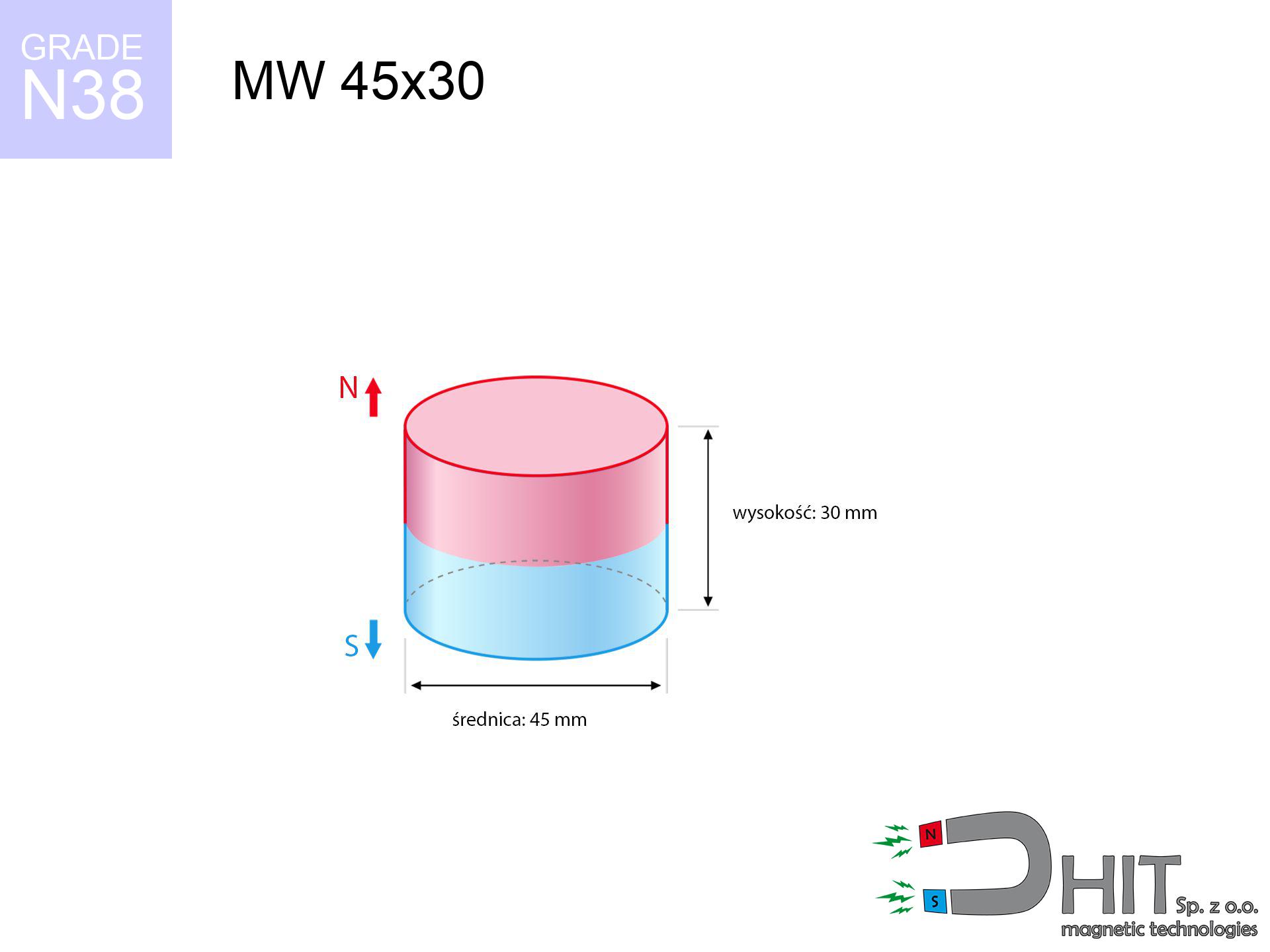

MW 45x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010073

GTIN/EAN: 5906301810728

Diameter Ø

45 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

357.85 g

Magnetization Direction

↑ axial

Load capacity

69.46 kg / 681.39 N

Magnetic Induction

495.87 mT / 4959 Gs

Coating

[NiCuNi] Nickel

136.80 ZŁ with VAT / pcs + price for transport

111.22 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise drop us a message via

form

the contact section.

Force and shape of a neodymium magnet can be checked with our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical data - MW 45x30 / N38 - cylindrical magnet

Specification / characteristics - MW 45x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010073 |

| GTIN/EAN | 5906301810728 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 45 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 357.85 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 69.46 kg / 681.39 N |

| Magnetic Induction ~ ? | 495.87 mT / 4959 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - data

Presented values represent the outcome of a mathematical calculation. Values rely on algorithms for the material Nd2Fe14B. Operational parameters may deviate from the simulation results. Use these data as a supplementary guide during assembly planning.

Table 1: Static pull force (force vs gap) - interaction chart

MW 45x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4958 Gs

495.8 mT

|

69.46 kg / 153.13 lbs

69460.0 g / 681.4 N

|

dangerous! |

| 1 mm |

4742 Gs

474.2 mT

|

63.55 kg / 140.11 lbs

63553.9 g / 623.5 N

|

dangerous! |

| 2 mm |

4523 Gs

452.3 mT

|

57.81 kg / 127.44 lbs

57805.8 g / 567.1 N

|

dangerous! |

| 3 mm |

4303 Gs

430.3 mT

|

52.33 kg / 115.36 lbs

52327.7 g / 513.3 N

|

dangerous! |

| 5 mm |

3870 Gs

387.0 mT

|

42.33 kg / 93.32 lbs

42329.9 g / 415.3 N

|

dangerous! |

| 10 mm |

2886 Gs

288.6 mT

|

23.53 kg / 51.88 lbs

23531.8 g / 230.8 N

|

dangerous! |

| 15 mm |

2106 Gs

210.6 mT

|

12.54 kg / 27.64 lbs

12537.0 g / 123.0 N

|

dangerous! |

| 20 mm |

1535 Gs

153.5 mT

|

6.66 kg / 14.68 lbs

6657.1 g / 65.3 N

|

warning |

| 30 mm |

845 Gs

84.5 mT

|

2.02 kg / 4.45 lbs

2018.9 g / 19.8 N

|

warning |

| 50 mm |

315 Gs

31.5 mT

|

0.28 kg / 0.62 lbs

279.5 g / 2.7 N

|

safe |

Table 2: Vertical hold (wall)

MW 45x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

13.89 kg / 30.63 lbs

13892.0 g / 136.3 N

|

| 1 mm | Stal (~0.2) |

12.71 kg / 28.02 lbs

12710.0 g / 124.7 N

|

| 2 mm | Stal (~0.2) |

11.56 kg / 25.49 lbs

11562.0 g / 113.4 N

|

| 3 mm | Stal (~0.2) |

10.47 kg / 23.07 lbs

10466.0 g / 102.7 N

|

| 5 mm | Stal (~0.2) |

8.47 kg / 18.66 lbs

8466.0 g / 83.1 N

|

| 10 mm | Stal (~0.2) |

4.71 kg / 10.37 lbs

4706.0 g / 46.2 N

|

| 15 mm | Stal (~0.2) |

2.51 kg / 5.53 lbs

2508.0 g / 24.6 N

|

| 20 mm | Stal (~0.2) |

1.33 kg / 2.94 lbs

1332.0 g / 13.1 N

|

| 30 mm | Stal (~0.2) |

0.40 kg / 0.89 lbs

404.0 g / 4.0 N

|

| 50 mm | Stal (~0.2) |

0.06 kg / 0.12 lbs

56.0 g / 0.5 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 45x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

20.84 kg / 45.94 lbs

20838.0 g / 204.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

13.89 kg / 30.63 lbs

13892.0 g / 136.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

6.95 kg / 15.31 lbs

6946.0 g / 68.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

34.73 kg / 76.57 lbs

34730.0 g / 340.7 N

|

Table 4: Material efficiency (saturation) - power losses

MW 45x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.32 kg / 5.10 lbs

2315.3 g / 22.7 N

|

| 1 mm |

|

5.79 kg / 12.76 lbs

5788.3 g / 56.8 N

|

| 2 mm |

|

11.58 kg / 25.52 lbs

11576.7 g / 113.6 N

|

| 3 mm |

|

17.37 kg / 38.28 lbs

17365.0 g / 170.4 N

|

| 5 mm |

|

28.94 kg / 63.81 lbs

28941.7 g / 283.9 N

|

| 10 mm |

|

57.88 kg / 127.61 lbs

57883.3 g / 567.8 N

|

| 11 mm |

|

63.67 kg / 140.37 lbs

63671.7 g / 624.6 N

|

| 12 mm |

|

69.46 kg / 153.13 lbs

69460.0 g / 681.4 N

|

Table 5: Working in heat (stability) - power drop

MW 45x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

69.46 kg / 153.13 lbs

69460.0 g / 681.4 N

|

OK |

| 40 °C | -2.2% |

67.93 kg / 149.76 lbs

67931.9 g / 666.4 N

|

OK |

| 60 °C | -4.4% |

66.40 kg / 146.40 lbs

66403.8 g / 651.4 N

|

OK |

| 80 °C | -6.6% |

64.88 kg / 143.03 lbs

64875.6 g / 636.4 N

|

|

| 100 °C | -28.8% |

49.46 kg / 109.03 lbs

49455.5 g / 485.2 N

|

Table 6: Two magnets (repulsion) - field collision

MW 45x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

241.01 kg / 531.33 lbs

5 803 Gs

|

36.15 kg / 79.70 lbs

36151 g / 354.6 N

|

N/A |

| 1 mm |

230.79 kg / 508.80 lbs

9 703 Gs

|

34.62 kg / 76.32 lbs

34618 g / 339.6 N

|

207.71 kg / 457.92 lbs

~0 Gs

|

| 2 mm |

220.52 kg / 486.16 lbs

9 485 Gs

|

33.08 kg / 72.92 lbs

33078 g / 324.5 N

|

198.47 kg / 437.54 lbs

~0 Gs

|

| 3 mm |

210.44 kg / 463.94 lbs

9 265 Gs

|

31.57 kg / 69.59 lbs

31566 g / 309.7 N

|

189.39 kg / 417.54 lbs

~0 Gs

|

| 5 mm |

190.94 kg / 420.95 lbs

8 826 Gs

|

28.64 kg / 63.14 lbs

28641 g / 281.0 N

|

171.85 kg / 378.86 lbs

~0 Gs

|

| 10 mm |

146.87 kg / 323.80 lbs

7 741 Gs

|

22.03 kg / 48.57 lbs

22031 g / 216.1 N

|

132.19 kg / 291.42 lbs

~0 Gs

|

| 20 mm |

81.65 kg / 180.01 lbs

5 771 Gs

|

12.25 kg / 27.00 lbs

12247 g / 120.1 N

|

73.48 kg / 162.01 lbs

~0 Gs

|

| 50 mm |

12.52 kg / 27.60 lbs

2 260 Gs

|

1.88 kg / 4.14 lbs

1878 g / 18.4 N

|

11.27 kg / 24.84 lbs

~0 Gs

|

| 60 mm |

7.01 kg / 15.44 lbs

1 690 Gs

|

1.05 kg / 2.32 lbs

1051 g / 10.3 N

|

6.30 kg / 13.90 lbs

~0 Gs

|

| 70 mm |

4.06 kg / 8.95 lbs

1 287 Gs

|

0.61 kg / 1.34 lbs

609 g / 6.0 N

|

3.66 kg / 8.06 lbs

~0 Gs

|

| 80 mm |

2.44 kg / 5.38 lbs

998 Gs

|

0.37 kg / 0.81 lbs

366 g / 3.6 N

|

2.20 kg / 4.84 lbs

~0 Gs

|

| 90 mm |

1.51 kg / 3.34 lbs

786 Gs

|

0.23 kg / 0.50 lbs

227 g / 2.2 N

|

1.36 kg / 3.01 lbs

~0 Gs

|

| 100 mm |

0.97 kg / 2.14 lbs

629 Gs

|

0.15 kg / 0.32 lbs

145 g / 1.4 N

|

0.87 kg / 1.92 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 45x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 25.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 20.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 15.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 12.0 cm |

| Remote | 50 Gs (5.0 mT) | 11.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 45x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.76 km/h

(4.66 m/s)

|

3.88 J | |

| 30 mm |

24.77 km/h

(6.88 m/s)

|

8.47 J | |

| 50 mm |

31.50 km/h

(8.75 m/s)

|

13.70 J | |

| 100 mm |

44.44 km/h

(12.34 m/s)

|

27.26 J |

Table 9: Corrosion resistance

MW 45x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 45x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 79 446 Mx | 794.5 µWb |

| Pc Coefficient | 0.71 | High (Stable) |

Table 11: Physics of underwater searching

MW 45x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 69.46 kg | Standard |

| Water (riverbed) |

79.53 kg

(+10.07 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.71

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of neodymium magnets.

Pros

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (in laboratory conditions),

- Magnets perfectly resist against demagnetization caused by foreign field sources,

- By using a shiny coating of silver, the element acquires an aesthetic look,

- Magnetic induction on the working part of the magnet is maximum,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, enabling action at temperatures approaching 230°C and above...

- Thanks to freedom in forming and the capacity to adapt to individual projects,

- Fundamental importance in innovative solutions – they find application in magnetic memories, electric motors, advanced medical instruments, also other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Limitations

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- We recommend a housing - magnetic holder, due to difficulties in creating nuts inside the magnet and complex shapes.

- Health risk resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small components of these magnets can be problematic in diagnostics medical after entering the body.

- With mass production the cost of neodymium magnets can be a barrier,

Pull force analysis

Maximum lifting capacity of the magnet – what affects it?

- on a base made of mild steel, perfectly concentrating the magnetic field

- with a thickness minimum 10 mm

- with a plane cleaned and smooth

- with zero gap (without impurities)

- during pulling in a direction perpendicular to the plane

- in neutral thermal conditions

Lifting capacity in practice – influencing factors

- Air gap (between the magnet and the plate), as even a microscopic distance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to varnish, rust or dirt).

- Angle of force application – highest force is available only during perpendicular pulling. The resistance to sliding of the magnet along the plate is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin sheet does not close the flux, causing part of the power to be escaped to the other side.

- Steel grade – ideal substrate is pure iron steel. Cast iron may attract less.

- Surface quality – the smoother and more polished the surface, the larger the contact zone and higher the lifting capacity. Unevenness creates an air distance.

- Heat – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under shearing force the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate lowers the load capacity.

Warnings

Pacemakers

Health Alert: Strong magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

Protective goggles

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Mechanical processing

Combustion risk: Rare earth powder is highly flammable. Do not process magnets without safety gear as this risks ignition.

Do not underestimate power

Handle with care. Rare earth magnets act from a distance and connect with massive power, often faster than you can react.

Hand protection

Watch your fingers. Two large magnets will join instantly with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

Choking Hazard

Always store magnets away from children. Ingestion danger is high, and the effects of magnets connecting inside the body are very dangerous.

Permanent damage

Standard neodymium magnets (grade N) lose magnetization when the temperature exceeds 80°C. This process is irreversible.

Protect data

Device Safety: Strong magnets can damage payment cards and delicate electronics (heart implants, hearing aids, timepieces).

Metal Allergy

A percentage of the population experience a contact allergy to nickel, which is the common plating for NdFeB magnets. Extended handling might lead to skin redness. We recommend use safety gloves.

Phone sensors

Note: neodymium magnets produce a field that disrupts precision electronics. Keep a safe distance from your phone, device, and GPS.

![SM 25x150 [2xM8] / N52 - magnetic separator SM 25x150 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x150-2xm8-sux.jpg)

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)