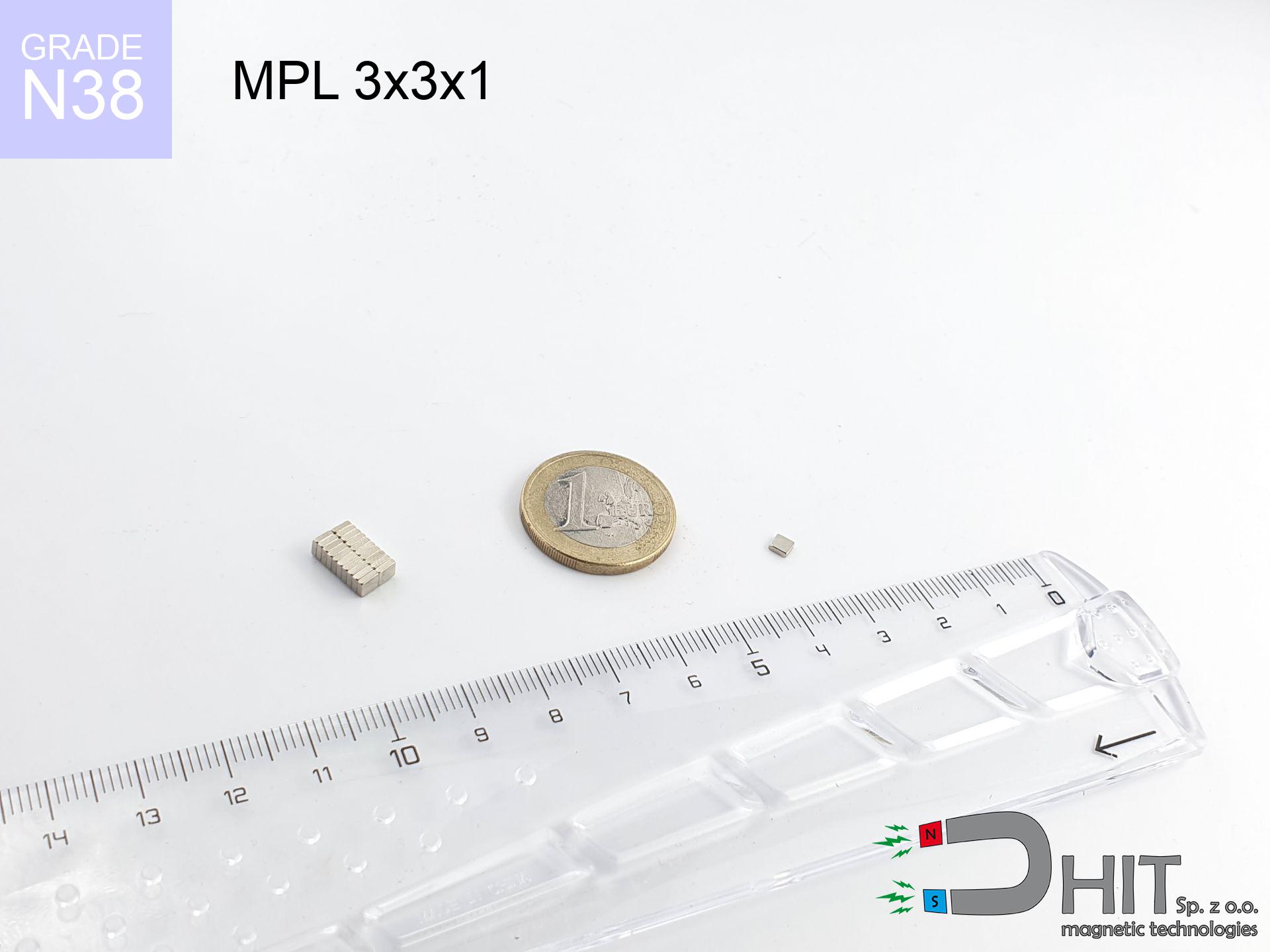

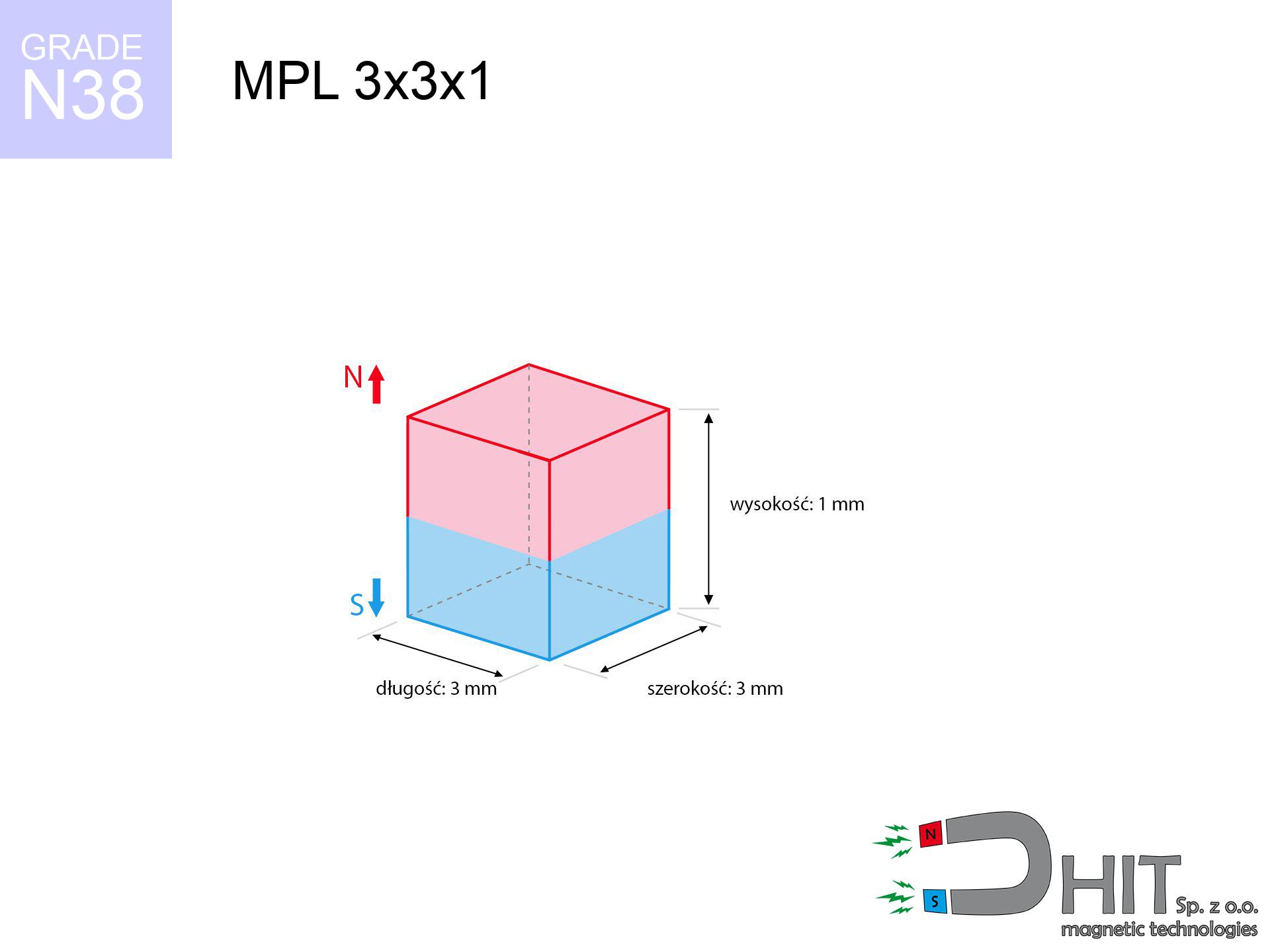

MPL 3x3x1 / N38 - lamellar magnet

lamellar magnet

Catalog no 020146

GTIN/EAN: 5906301811527

length

3 mm [±0,1 mm]

Width

3 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

0.07 g

Magnetization Direction

↑ axial

Load capacity

0.23 kg / 2.29 N

Magnetic Induction

317.31 mT / 3173 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise let us know using

inquiry form

the contact section.

Strength and form of a neodymium magnet can be tested using our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical - MPL 3x3x1 / N38 - lamellar magnet

Specification / characteristics - MPL 3x3x1 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020146 |

| GTIN/EAN | 5906301811527 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 3 mm [±0,1 mm] |

| Width | 3 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 0.07 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.23 kg / 2.29 N |

| Magnetic Induction ~ ? | 317.31 mT / 3173 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - technical parameters

These data are the outcome of a engineering calculation. Results were calculated on models for the class Nd2Fe14B. Actual parameters might slightly differ. Treat these data as a reference point for designers.

Table 1: Static force (force vs gap) - interaction chart

MPL 3x3x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3168 Gs

316.8 mT

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

low risk |

| 1 mm |

1565 Gs

156.5 mT

|

0.06 kg / 0.12 LBS

56.1 g / 0.6 N

|

low risk |

| 2 mm |

659 Gs

65.9 mT

|

0.01 kg / 0.02 LBS

9.9 g / 0.1 N

|

low risk |

| 3 mm |

307 Gs

30.7 mT

|

0.00 kg / 0.00 LBS

2.2 g / 0.0 N

|

low risk |

| 5 mm |

94 Gs

9.4 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 10 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 15 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 20 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage load (wall)

MPL 3x3x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.05 kg / 0.10 LBS

46.0 g / 0.5 N

|

| 1 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 3x3x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.07 kg / 0.15 LBS

69.0 g / 0.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.05 kg / 0.10 LBS

46.0 g / 0.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.02 kg / 0.05 LBS

23.0 g / 0.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.12 kg / 0.25 LBS

115.0 g / 1.1 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 3x3x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.02 kg / 0.05 LBS

23.0 g / 0.2 N

|

| 1 mm |

|

0.06 kg / 0.13 LBS

57.5 g / 0.6 N

|

| 2 mm |

|

0.12 kg / 0.25 LBS

115.0 g / 1.1 N

|

| 3 mm |

|

0.17 kg / 0.38 LBS

172.5 g / 1.7 N

|

| 5 mm |

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

| 10 mm |

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

| 11 mm |

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

| 12 mm |

|

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

Table 5: Thermal stability (material behavior) - power drop

MPL 3x3x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.23 kg / 0.51 LBS

230.0 g / 2.3 N

|

OK |

| 40 °C | -2.2% |

0.22 kg / 0.50 LBS

224.9 g / 2.2 N

|

OK |

| 60 °C | -4.4% |

0.22 kg / 0.48 LBS

219.9 g / 2.2 N

|

|

| 80 °C | -6.6% |

0.21 kg / 0.47 LBS

214.8 g / 2.1 N

|

|

| 100 °C | -28.8% |

0.16 kg / 0.36 LBS

163.8 g / 1.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 3x3x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.56 kg / 1.23 LBS

4 719 Gs

|

0.08 kg / 0.18 LBS

84 g / 0.8 N

|

N/A |

| 1 mm |

0.31 kg / 0.68 LBS

4 706 Gs

|

0.05 kg / 0.10 LBS

46 g / 0.5 N

|

0.28 kg / 0.61 LBS

~0 Gs

|

| 2 mm |

0.14 kg / 0.30 LBS

3 129 Gs

|

0.02 kg / 0.04 LBS

20 g / 0.2 N

|

0.12 kg / 0.27 LBS

~0 Gs

|

| 3 mm |

0.06 kg / 0.12 LBS

2 019 Gs

|

0.01 kg / 0.02 LBS

8 g / 0.1 N

|

0.05 kg / 0.11 LBS

~0 Gs

|

| 5 mm |

0.01 kg / 0.02 LBS

885 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 LBS

188 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

30 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

0 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

0 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 3x3x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 1.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 1.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.0 cm |

| Remote | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 3x3x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

57.81 km/h

(16.06 m/s)

|

0.01 J | |

| 30 mm |

100.13 km/h

(27.81 m/s)

|

0.03 J | |

| 50 mm |

129.27 km/h

(35.91 m/s)

|

0.05 J | |

| 100 mm |

182.81 km/h

(50.78 m/s)

|

0.09 J |

Table 9: Corrosion resistance

MPL 3x3x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 3x3x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 306 Mx | 3.1 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Submerged application

MPL 3x3x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.23 kg | Standard |

| Water (riverbed) |

0.26 kg

(+0.03 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet holds only a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also offers

Pros and cons of rare earth magnets.

Pros

- They retain full power for almost ten years – the drop is just ~1% (in theory),

- They feature excellent resistance to magnetic field loss when exposed to external fields,

- By covering with a smooth coating of silver, the element gains an professional look,

- They feature high magnetic induction at the operating surface, which increases their power,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to flexibility in constructing and the capacity to modify to unusual requirements,

- Fundamental importance in modern industrial fields – they find application in data components, drive modules, advanced medical instruments, also multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, with minimal size,

Weaknesses

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- Limited possibility of producing nuts in the magnet and complex shapes - preferred is a housing - magnet mounting.

- Potential hazard resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these devices can be problematic in diagnostics medical in case of swallowing.

- With budget limitations the cost of neodymium magnets can be a barrier,

Pull force analysis

Maximum holding power of the magnet – what it depends on?

- on a base made of mild steel, perfectly concentrating the magnetic flux

- with a thickness minimum 10 mm

- characterized by lack of roughness

- with total lack of distance (no coatings)

- during pulling in a direction vertical to the plane

- in stable room temperature

Practical lifting capacity: influencing factors

- Gap (between the magnet and the plate), because even a tiny distance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to paint, corrosion or debris).

- Angle of force application – maximum parameter is available only during pulling at a 90° angle. The force required to slide of the magnet along the surface is standardly several times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be wasted to the other side.

- Steel grade – ideal substrate is pure iron steel. Cast iron may generate lower lifting capacity.

- Base smoothness – the smoother and more polished the plate, the better the adhesion and stronger the hold. Roughness acts like micro-gaps.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under a perpendicular pulling force, however under parallel forces the load capacity is reduced by as much as 75%. Moreover, even a minimal clearance between the magnet’s surface and the plate decreases the lifting capacity.

Precautions when working with neodymium magnets

Medical interference

Patients with a ICD must keep an safe separation from magnets. The magnetic field can disrupt the operation of the life-saving device.

Caution required

Exercise caution. Rare earth magnets attract from a distance and connect with huge force, often faster than you can react.

Allergic reactions

Some people suffer from a contact allergy to Ni, which is the common plating for NdFeB magnets. Extended handling might lead to dermatitis. We recommend wear protective gloves.

This is not a toy

Absolutely keep magnets away from children. Ingestion danger is significant, and the effects of magnets clamping inside the body are very dangerous.

GPS Danger

Navigation devices and smartphones are extremely sensitive to magnetic fields. Close proximity with a strong magnet can decalibrate the internal compass in your phone.

Cards and drives

Equipment safety: Strong magnets can ruin data carriers and delicate electronics (pacemakers, medical aids, mechanical watches).

Magnet fragility

Despite metallic appearance, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Pinching danger

Watch your fingers. Two powerful magnets will join instantly with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Maximum temperature

Watch the temperature. Heating the magnet to high heat will destroy its properties and pulling force.

Dust explosion hazard

Combustion risk: Neodymium dust is explosive. Avoid machining magnets in home conditions as this risks ignition.

![AM ucho [M8] - magnetic accessories AM ucho [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m8-lib.jpg)