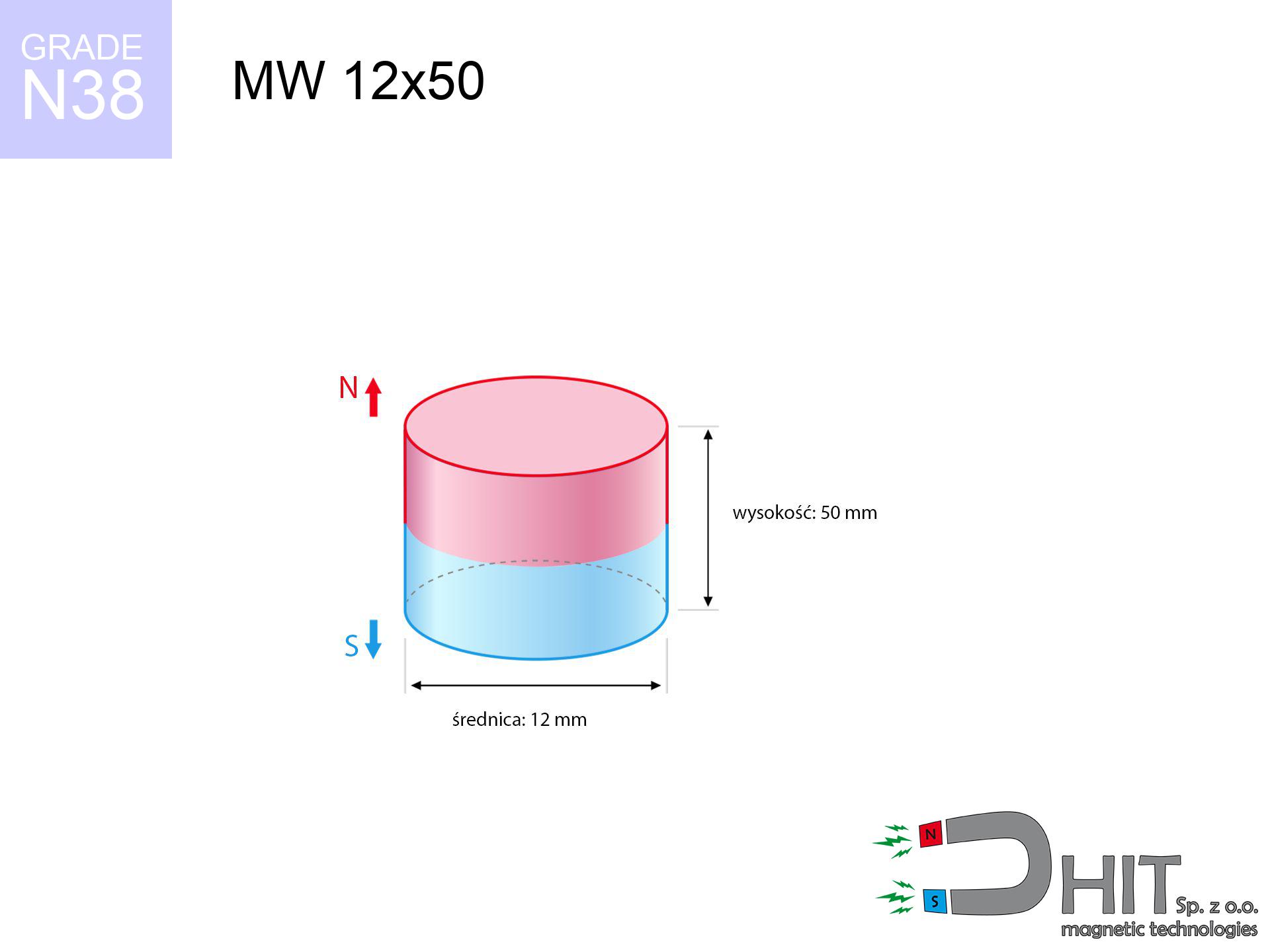

MW 12x50 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010020

GTIN/EAN: 5906301810193

Diameter Ø

12 mm [±0,1 mm]

Height

50 mm [±0,1 mm]

Weight

42.41 g

Magnetization Direction

↑ axial

Load capacity

2.62 kg / 25.73 N

Magnetic Induction

614.94 mT / 6149 Gs

Coating

[NiCuNi] Nickel

28.29 ZŁ with VAT / pcs + price for transport

23.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or let us know by means of

inquiry form

through our site.

Weight along with structure of a magnet can be calculated with our

power calculator.

Same-day shipping for orders placed before 14:00.

Technical parameters of the product - MW 12x50 / N38 - cylindrical magnet

Specification / characteristics - MW 12x50 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010020 |

| GTIN/EAN | 5906301810193 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 50 mm [±0,1 mm] |

| Weight | 42.41 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.62 kg / 25.73 N |

| Magnetic Induction ~ ? | 614.94 mT / 6149 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - technical parameters

Presented data are the direct effect of a physical simulation. Values are based on algorithms for the material Nd2Fe14B. Real-world parameters may differ. Please consider these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (force vs distance) - characteristics

MW 12x50 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6146 Gs

614.6 mT

|

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

strong |

| 1 mm |

5138 Gs

513.8 mT

|

1.83 kg / 4.04 lbs

1831.5 g / 18.0 N

|

safe |

| 2 mm |

4199 Gs

419.9 mT

|

1.22 kg / 2.70 lbs

1222.9 g / 12.0 N

|

safe |

| 3 mm |

3388 Gs

338.8 mT

|

0.80 kg / 1.76 lbs

796.3 g / 7.8 N

|

safe |

| 5 mm |

2194 Gs

219.4 mT

|

0.33 kg / 0.74 lbs

334.0 g / 3.3 N

|

safe |

| 10 mm |

853 Gs

85.3 mT

|

0.05 kg / 0.11 lbs

50.4 g / 0.5 N

|

safe |

| 15 mm |

417 Gs

41.7 mT

|

0.01 kg / 0.03 lbs

12.1 g / 0.1 N

|

safe |

| 20 mm |

239 Gs

23.9 mT

|

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

safe |

| 30 mm |

103 Gs

10.3 mT

|

0.00 kg / 0.00 lbs

0.7 g / 0.0 N

|

safe |

| 50 mm |

33 Gs

3.3 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

Table 2: Shear load (vertical surface)

MW 12x50 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.52 kg / 1.16 lbs

524.0 g / 5.1 N

|

| 1 mm | Stal (~0.2) |

0.37 kg / 0.81 lbs

366.0 g / 3.6 N

|

| 2 mm | Stal (~0.2) |

0.24 kg / 0.54 lbs

244.0 g / 2.4 N

|

| 3 mm | Stal (~0.2) |

0.16 kg / 0.35 lbs

160.0 g / 1.6 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

66.0 g / 0.6 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 12x50 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.79 kg / 1.73 lbs

786.0 g / 7.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.52 kg / 1.16 lbs

524.0 g / 5.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.26 kg / 0.58 lbs

262.0 g / 2.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.31 kg / 2.89 lbs

1310.0 g / 12.9 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 12x50 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.26 kg / 0.58 lbs

262.0 g / 2.6 N

|

| 1 mm |

|

0.66 kg / 1.44 lbs

655.0 g / 6.4 N

|

| 2 mm |

|

1.31 kg / 2.89 lbs

1310.0 g / 12.9 N

|

| 3 mm |

|

1.97 kg / 4.33 lbs

1965.0 g / 19.3 N

|

| 5 mm |

|

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

| 10 mm |

|

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

| 11 mm |

|

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

| 12 mm |

|

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

Table 5: Thermal resistance (stability) - thermal limit

MW 12x50 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.62 kg / 5.78 lbs

2620.0 g / 25.7 N

|

OK |

| 40 °C | -2.2% |

2.56 kg / 5.65 lbs

2562.4 g / 25.1 N

|

OK |

| 60 °C | -4.4% |

2.50 kg / 5.52 lbs

2504.7 g / 24.6 N

|

OK |

| 80 °C | -6.6% |

2.45 kg / 5.39 lbs

2447.1 g / 24.0 N

|

|

| 100 °C | -28.8% |

1.87 kg / 4.11 lbs

1865.4 g / 18.3 N

|

Table 6: Two magnets (repulsion) - field range

MW 12x50 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

26.33 kg / 58.05 lbs

6 179 Gs

|

3.95 kg / 8.71 lbs

3950 g / 38.7 N

|

N/A |

| 1 mm |

22.19 kg / 48.93 lbs

11 284 Gs

|

3.33 kg / 7.34 lbs

3329 g / 32.7 N

|

19.97 kg / 44.04 lbs

~0 Gs

|

| 2 mm |

18.41 kg / 40.58 lbs

10 277 Gs

|

2.76 kg / 6.09 lbs

2761 g / 27.1 N

|

16.57 kg / 36.53 lbs

~0 Gs

|

| 3 mm |

15.11 kg / 33.30 lbs

9 309 Gs

|

2.27 kg / 5.00 lbs

2266 g / 22.2 N

|

13.60 kg / 29.97 lbs

~0 Gs

|

| 5 mm |

9.94 kg / 21.91 lbs

7 551 Gs

|

1.49 kg / 3.29 lbs

1491 g / 14.6 N

|

8.94 kg / 19.72 lbs

~0 Gs

|

| 10 mm |

3.36 kg / 7.40 lbs

4 389 Gs

|

0.50 kg / 1.11 lbs

504 g / 4.9 N

|

3.02 kg / 6.66 lbs

~0 Gs

|

| 20 mm |

0.51 kg / 1.12 lbs

1 706 Gs

|

0.08 kg / 0.17 lbs

76 g / 0.7 N

|

0.46 kg / 1.01 lbs

~0 Gs

|

| 50 mm |

0.02 kg / 0.04 lbs

303 Gs

|

0.00 kg / 0.01 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.02 lbs

206 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 lbs

148 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

110 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

84 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

66 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 12x50 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 12x50 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

8.02 km/h

(2.23 m/s)

|

0.11 J | |

| 30 mm |

13.73 km/h

(3.81 m/s)

|

0.31 J | |

| 50 mm |

17.73 km/h

(4.92 m/s)

|

0.51 J | |

| 100 mm |

25.07 km/h

(6.96 m/s)

|

1.03 J |

Table 9: Corrosion resistance

MW 12x50 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 12x50 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 230 Mx | 82.3 µWb |

| Pc Coefficient | 1.49 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 12x50 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.62 kg | Standard |

| Water (riverbed) |

3.00 kg

(+0.38 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet retains merely ~20% of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.49

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages and disadvantages of neodymium magnets.

Pros

- They retain magnetic properties for nearly 10 years – the loss is just ~1% (according to analyses),

- They have excellent resistance to magnetism drop when exposed to external magnetic sources,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to present itself better,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures reaching 230°C and above...

- Possibility of detailed shaping as well as adapting to specific conditions,

- Huge importance in high-tech industry – they serve a role in magnetic memories, brushless drives, advanced medical instruments, also multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which allows their use in miniature devices

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Limited ability of creating threads in the magnet and complex forms - preferred is casing - magnetic holder.

- Potential hazard to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which gains importance in the context of child safety. Additionally, small elements of these magnets can complicate diagnosis medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Detachment force of the magnet in optimal conditions – what contributes to it?

- using a sheet made of high-permeability steel, serving as a circuit closing element

- with a cross-section of at least 10 mm

- with an ground touching surface

- under conditions of no distance (surface-to-surface)

- under vertical force vector (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Practical aspects of lifting capacity – factors

- Clearance – existence of any layer (paint, tape, air) interrupts the magnetic circuit, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Base massiveness – too thin sheet does not close the flux, causing part of the flux to be escaped into the air.

- Material composition – different alloys attracts identically. Alloy additives weaken the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Rough surfaces reduce efficiency.

- Temperature – heating the magnet results in weakening of induction. Check the thermal limit for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the load capacity is reduced by as much as 75%. Additionally, even a small distance between the magnet’s surface and the plate lowers the lifting capacity.

Precautions when working with NdFeB magnets

Beware of splinters

Despite the nickel coating, neodymium is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into hazardous fragments.

Nickel coating and allergies

Some people experience a hypersensitivity to Ni, which is the typical protective layer for NdFeB magnets. Extended handling might lead to a rash. We recommend wear protective gloves.

Bodily injuries

Mind your fingers. Two powerful magnets will join immediately with a force of massive weight, crushing anything in their path. Be careful!

Thermal limits

Standard neodymium magnets (grade N) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Fire warning

Combustion risk: Neodymium dust is explosive. Do not process magnets without safety gear as this risks ignition.

Handling rules

Before starting, read the rules. Sudden snapping can break the magnet or injure your hand. Think ahead.

Electronic hazard

Avoid bringing magnets close to a purse, computer, or TV. The magnetism can irreversibly ruin these devices and erase data from cards.

Impact on smartphones

Navigation devices and mobile phones are extremely sensitive to magnetic fields. Close proximity with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Product not for children

Strictly store magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are very dangerous.

Warning for heart patients

For implant holders: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or request help to handle the magnets.

![UMGW 36x18x8 [M8] GW / N38 - magnetic holder internal thread UMGW 36x18x8 [M8] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-36x18x8-m8-gw-foj.jpg)