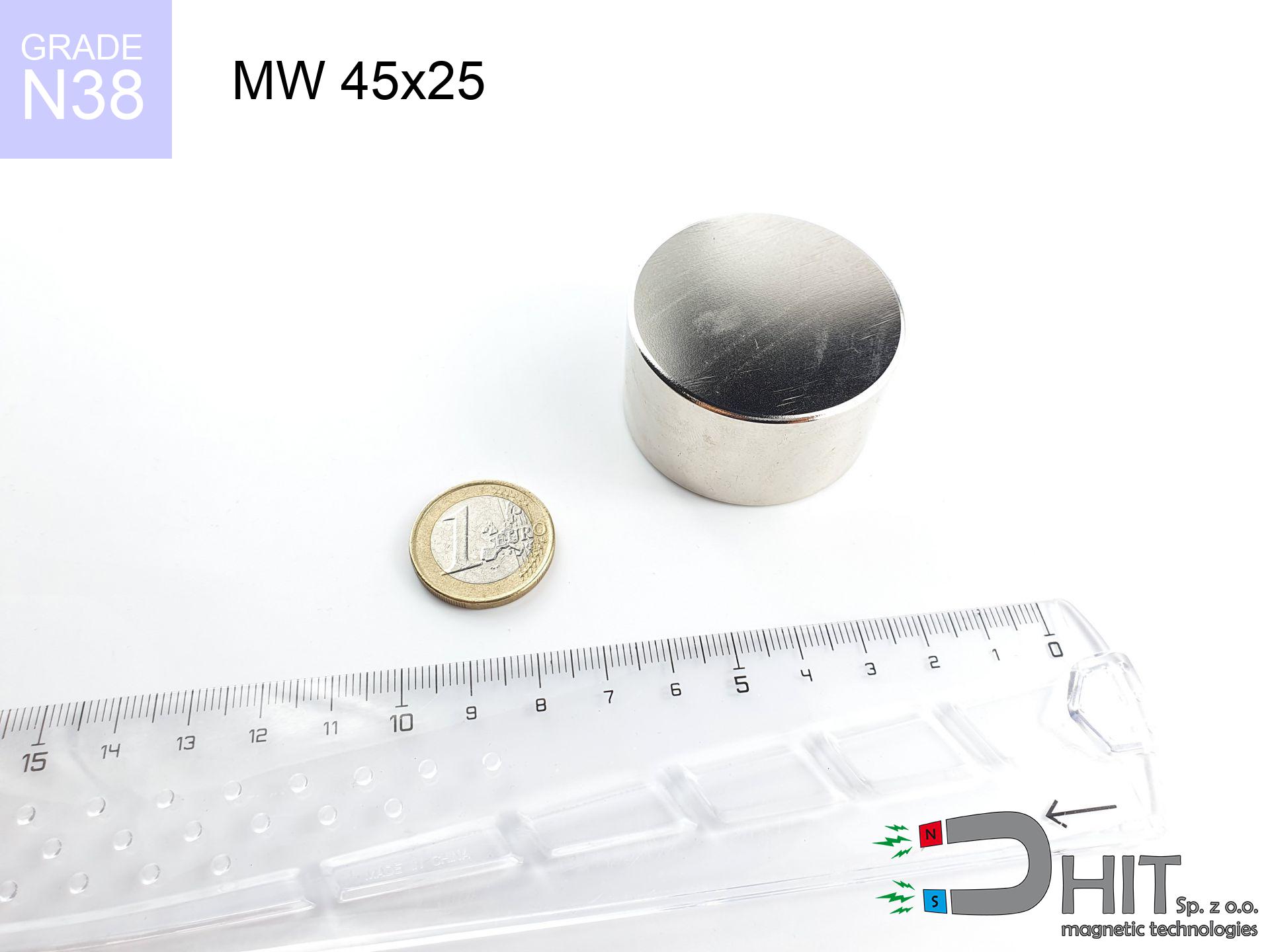

MW 45x25 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010072

GTIN/EAN: 5906301810711

Diameter Ø

45 mm [±0,1 mm]

Height

25 mm [±0,1 mm]

Weight

298.21 g

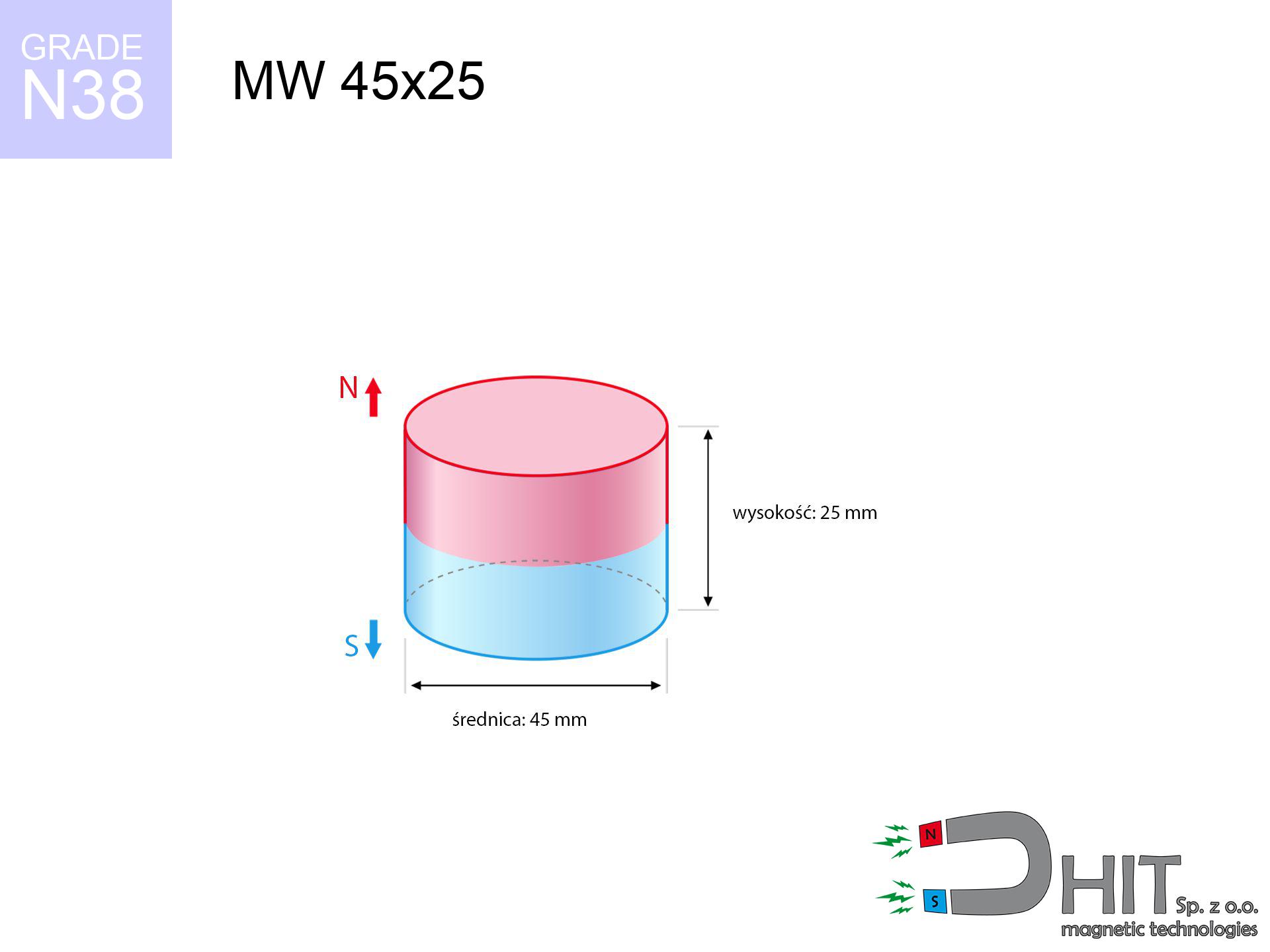

Magnetization Direction

↑ axial

Load capacity

67.33 kg / 660.51 N

Magnetic Induction

460.72 mT / 4607 Gs

Coating

[NiCuNi] Nickel

101.55 ZŁ with VAT / pcs + price for transport

82.56 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or send us a note through

form

through our site.

Lifting power as well as structure of magnets can be reviewed using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical details - MW 45x25 / N38 - cylindrical magnet

Specification / characteristics - MW 45x25 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010072 |

| GTIN/EAN | 5906301810711 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 45 mm [±0,1 mm] |

| Height | 25 mm [±0,1 mm] |

| Weight | 298.21 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 67.33 kg / 660.51 N |

| Magnetic Induction ~ ? | 460.72 mT / 4607 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

Presented data are the direct effect of a engineering calculation. Results were calculated on models for the class Nd2Fe14B. Actual parameters might slightly differ. Treat these data as a supplementary guide for designers.

Table 1: Static pull force (force vs gap) - power drop

MW 45x25 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4606 Gs

460.6 mT

|

67.33 kg / 148.44 LBS

67330.0 g / 660.5 N

|

crushing |

| 1 mm |

4413 Gs

441.3 mT

|

61.79 kg / 136.23 LBS

61791.4 g / 606.2 N

|

crushing |

| 2 mm |

4214 Gs

421.4 mT

|

56.35 kg / 124.22 LBS

56345.9 g / 552.8 N

|

crushing |

| 3 mm |

4014 Gs

401.4 mT

|

51.11 kg / 112.68 LBS

51112.0 g / 501.4 N

|

crushing |

| 5 mm |

3615 Gs

361.5 mT

|

41.47 kg / 91.42 LBS

41466.0 g / 406.8 N

|

crushing |

| 10 mm |

2697 Gs

269.7 mT

|

23.08 kg / 50.89 LBS

23083.9 g / 226.5 N

|

crushing |

| 15 mm |

1965 Gs

196.5 mT

|

12.25 kg / 27.00 LBS

12247.0 g / 120.1 N

|

crushing |

| 20 mm |

1426 Gs

142.6 mT

|

6.46 kg / 14.23 LBS

6455.7 g / 63.3 N

|

medium risk |

| 30 mm |

778 Gs

77.8 mT

|

1.92 kg / 4.24 LBS

1922.5 g / 18.9 N

|

weak grip |

| 50 mm |

285 Gs

28.5 mT

|

0.26 kg / 0.57 LBS

257.0 g / 2.5 N

|

weak grip |

Table 2: Shear force (wall)

MW 45x25 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

13.47 kg / 29.69 LBS

13466.0 g / 132.1 N

|

| 1 mm | Stal (~0.2) |

12.36 kg / 27.24 LBS

12358.0 g / 121.2 N

|

| 2 mm | Stal (~0.2) |

11.27 kg / 24.85 LBS

11270.0 g / 110.6 N

|

| 3 mm | Stal (~0.2) |

10.22 kg / 22.54 LBS

10222.0 g / 100.3 N

|

| 5 mm | Stal (~0.2) |

8.29 kg / 18.29 LBS

8294.0 g / 81.4 N

|

| 10 mm | Stal (~0.2) |

4.62 kg / 10.18 LBS

4616.0 g / 45.3 N

|

| 15 mm | Stal (~0.2) |

2.45 kg / 5.40 LBS

2450.0 g / 24.0 N

|

| 20 mm | Stal (~0.2) |

1.29 kg / 2.85 LBS

1292.0 g / 12.7 N

|

| 30 mm | Stal (~0.2) |

0.38 kg / 0.85 LBS

384.0 g / 3.8 N

|

| 50 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

52.0 g / 0.5 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 45x25 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

20.20 kg / 44.53 LBS

20199.0 g / 198.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

13.47 kg / 29.69 LBS

13466.0 g / 132.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

6.73 kg / 14.84 LBS

6733.0 g / 66.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

33.67 kg / 74.22 LBS

33665.0 g / 330.3 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 45x25 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.24 kg / 4.95 LBS

2244.3 g / 22.0 N

|

| 1 mm |

|

5.61 kg / 12.37 LBS

5610.8 g / 55.0 N

|

| 2 mm |

|

11.22 kg / 24.74 LBS

11221.7 g / 110.1 N

|

| 3 mm |

|

16.83 kg / 37.11 LBS

16832.5 g / 165.1 N

|

| 5 mm |

|

28.05 kg / 61.85 LBS

28054.2 g / 275.2 N

|

| 10 mm |

|

56.11 kg / 123.70 LBS

56108.3 g / 550.4 N

|

| 11 mm |

|

61.72 kg / 136.07 LBS

61719.2 g / 605.5 N

|

| 12 mm |

|

67.33 kg / 148.44 LBS

67330.0 g / 660.5 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MW 45x25 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

67.33 kg / 148.44 LBS

67330.0 g / 660.5 N

|

OK |

| 40 °C | -2.2% |

65.85 kg / 145.17 LBS

65848.7 g / 646.0 N

|

OK |

| 60 °C | -4.4% |

64.37 kg / 141.91 LBS

64367.5 g / 631.4 N

|

OK |

| 80 °C | -6.6% |

62.89 kg / 138.64 LBS

62886.2 g / 616.9 N

|

|

| 100 °C | -28.8% |

47.94 kg / 105.69 LBS

47939.0 g / 470.3 N

|

Table 6: Two magnets (attraction) - field range

MW 45x25 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

208.06 kg / 458.70 LBS

5 651 Gs

|

31.21 kg / 68.80 LBS

31209 g / 306.2 N

|

N/A |

| 1 mm |

199.55 kg / 439.92 LBS

9 023 Gs

|

29.93 kg / 65.99 LBS

29932 g / 293.6 N

|

179.59 kg / 395.93 LBS

~0 Gs

|

| 2 mm |

190.95 kg / 420.96 LBS

8 826 Gs

|

28.64 kg / 63.14 LBS

28642 g / 281.0 N

|

171.85 kg / 378.87 LBS

~0 Gs

|

| 3 mm |

182.46 kg / 402.26 LBS

8 628 Gs

|

27.37 kg / 60.34 LBS

27369 g / 268.5 N

|

164.22 kg / 362.03 LBS

~0 Gs

|

| 5 mm |

165.94 kg / 365.83 LBS

8 228 Gs

|

24.89 kg / 54.87 LBS

24891 g / 244.2 N

|

149.35 kg / 329.25 LBS

~0 Gs

|

| 10 mm |

128.14 kg / 282.49 LBS

7 230 Gs

|

19.22 kg / 42.37 LBS

19221 g / 188.6 N

|

115.32 kg / 254.24 LBS

~0 Gs

|

| 20 mm |

71.33 kg / 157.26 LBS

5 394 Gs

|

10.70 kg / 23.59 LBS

10700 g / 105.0 N

|

64.20 kg / 141.54 LBS

~0 Gs

|

| 50 mm |

10.72 kg / 23.63 LBS

2 091 Gs

|

1.61 kg / 3.54 LBS

1608 g / 15.8 N

|

9.65 kg / 21.26 LBS

~0 Gs

|

| 60 mm |

5.94 kg / 13.10 LBS

1 557 Gs

|

0.89 kg / 1.96 LBS

891 g / 8.7 N

|

5.35 kg / 11.79 LBS

~0 Gs

|

| 70 mm |

3.41 kg / 7.52 LBS

1 180 Gs

|

0.51 kg / 1.13 LBS

512 g / 5.0 N

|

3.07 kg / 6.77 LBS

~0 Gs

|

| 80 mm |

2.03 kg / 4.48 LBS

910 Gs

|

0.30 kg / 0.67 LBS

305 g / 3.0 N

|

1.83 kg / 4.03 LBS

~0 Gs

|

| 90 mm |

1.25 kg / 2.76 LBS

714 Gs

|

0.19 kg / 0.41 LBS

188 g / 1.8 N

|

1.13 kg / 2.48 LBS

~0 Gs

|

| 100 mm |

0.79 kg / 1.75 LBS

569 Gs

|

0.12 kg / 0.26 LBS

119 g / 1.2 N

|

0.71 kg / 1.58 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 45x25 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 24.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 19.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 14.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 11.5 cm |

| Car key | 50 Gs (5.0 mT) | 10.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 45x25 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.11 km/h

(5.03 m/s)

|

3.77 J | |

| 30 mm |

26.71 km/h

(7.42 m/s)

|

8.21 J | |

| 50 mm |

33.97 km/h

(9.43 m/s)

|

13.27 J | |

| 100 mm |

47.92 km/h

(13.31 m/s)

|

26.42 J |

Table 9: Surface protection spec

MW 45x25 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 45x25 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 73 928 Mx | 739.3 µWb |

| Pc Coefficient | 0.63 | High (Stable) |

Table 11: Submerged application

MW 45x25 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 67.33 kg | Standard |

| Water (riverbed) |

77.09 kg

(+9.76 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet retains just approx. 20-30% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) drastically limits the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.63

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more deals

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They have unchanged lifting capacity, and over nearly 10 years their performance decreases symbolically – ~1% (in testing),

- They do not lose their magnetic properties even under strong external field,

- In other words, due to the metallic finish of nickel, the element gains visual value,

- Magnets possess exceptionally strong magnetic induction on the outer side,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of precise machining as well as adjusting to specific requirements,

- Wide application in electronics industry – they are commonly used in computer drives, brushless drives, medical equipment, as well as other advanced devices.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Weaknesses

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- We suggest casing - magnetic holder, due to difficulties in producing nuts inside the magnet and complicated shapes.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child safety. It is also worth noting that small elements of these products are able to complicate diagnosis medical in case of swallowing.

- With mass production the cost of neodymium magnets can be a barrier,

Pull force analysis

Magnetic strength at its maximum – what affects it?

- using a plate made of high-permeability steel, serving as a ideal flux conductor

- with a cross-section no less than 10 mm

- characterized by even structure

- with direct contact (no impurities)

- under perpendicular application of breakaway force (90-degree angle)

- in temp. approx. 20°C

Impact of factors on magnetic holding capacity in practice

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys attracts identically. Alloy additives weaken the interaction with the magnet.

- Smoothness – full contact is possible only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Heat – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity was assessed by applying a polished steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, whereas under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Precautions when working with neodymium magnets

Medical implants

Life threat: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have electronic implants.

Choking Hazard

Product intended for adults. Small elements pose a choking risk, causing severe trauma. Keep away from kids and pets.

Mechanical processing

Dust produced during machining of magnets is flammable. Avoid drilling into magnets unless you are an expert.

Crushing force

Protect your hands. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Magnetic media

Equipment safety: Strong magnets can damage data carriers and sensitive devices (heart implants, medical aids, timepieces).

Heat warning

Regular neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

GPS and phone interference

A strong magnetic field interferes with the functioning of compasses in phones and GPS navigation. Maintain magnets close to a device to prevent damaging the sensors.

Magnet fragility

NdFeB magnets are ceramic materials, meaning they are very brittle. Impact of two magnets leads to them breaking into shards.

Nickel allergy

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If an allergic reaction happens, cease handling magnets and use protective gear.

Caution required

Before use, read the rules. Sudden snapping can break the magnet or injure your hand. Be predictive.

![BM 320x180x70 [4x M8] - magnetic beam BM 320x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-320x180x70-4x-m8-rar.jpg)

![MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl40x10x4x27-3.5-suw.jpg)

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)