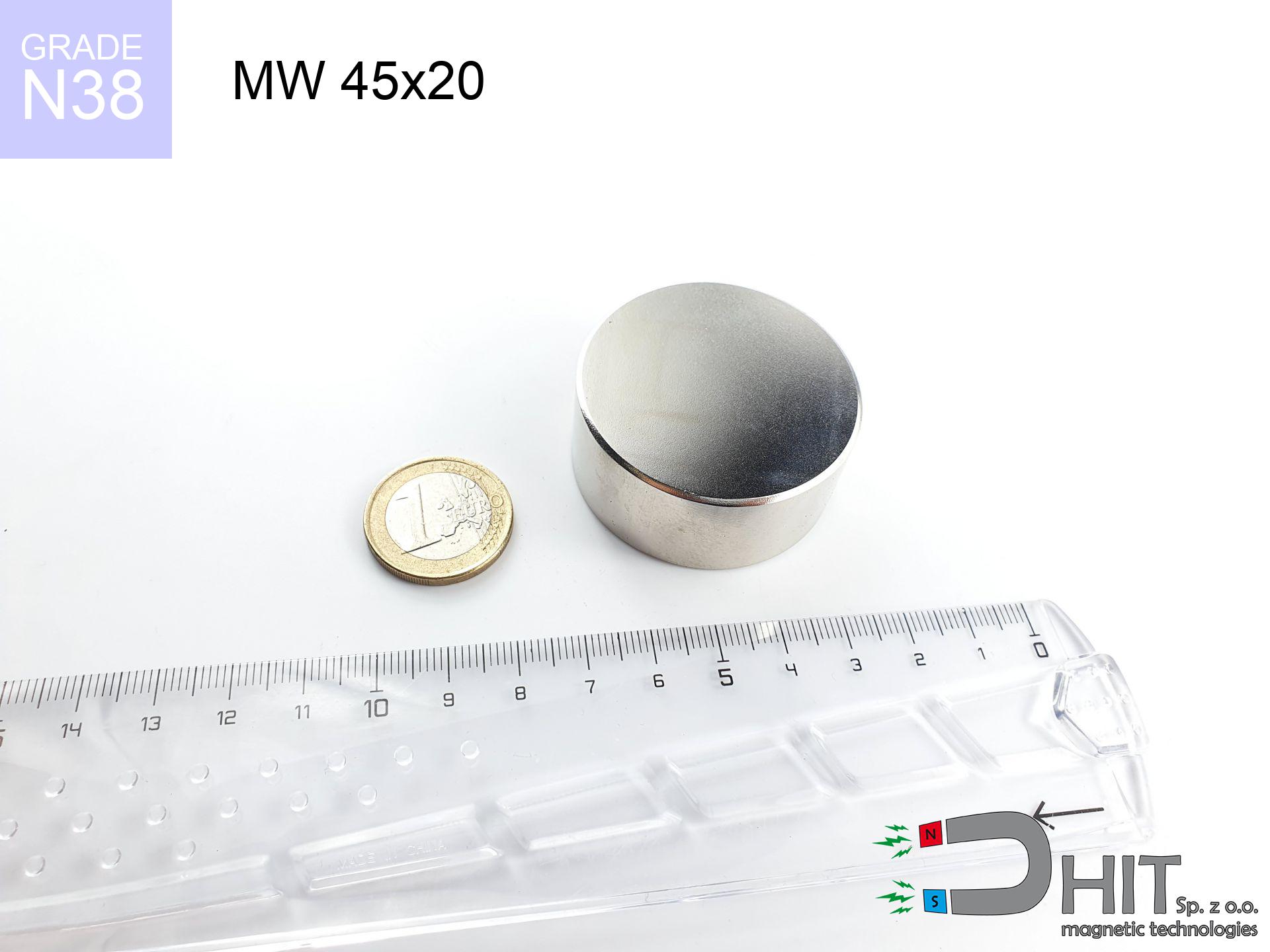

MW 45x20 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010071

GTIN/EAN: 5906301810704

Diameter Ø

45 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

238.56 g

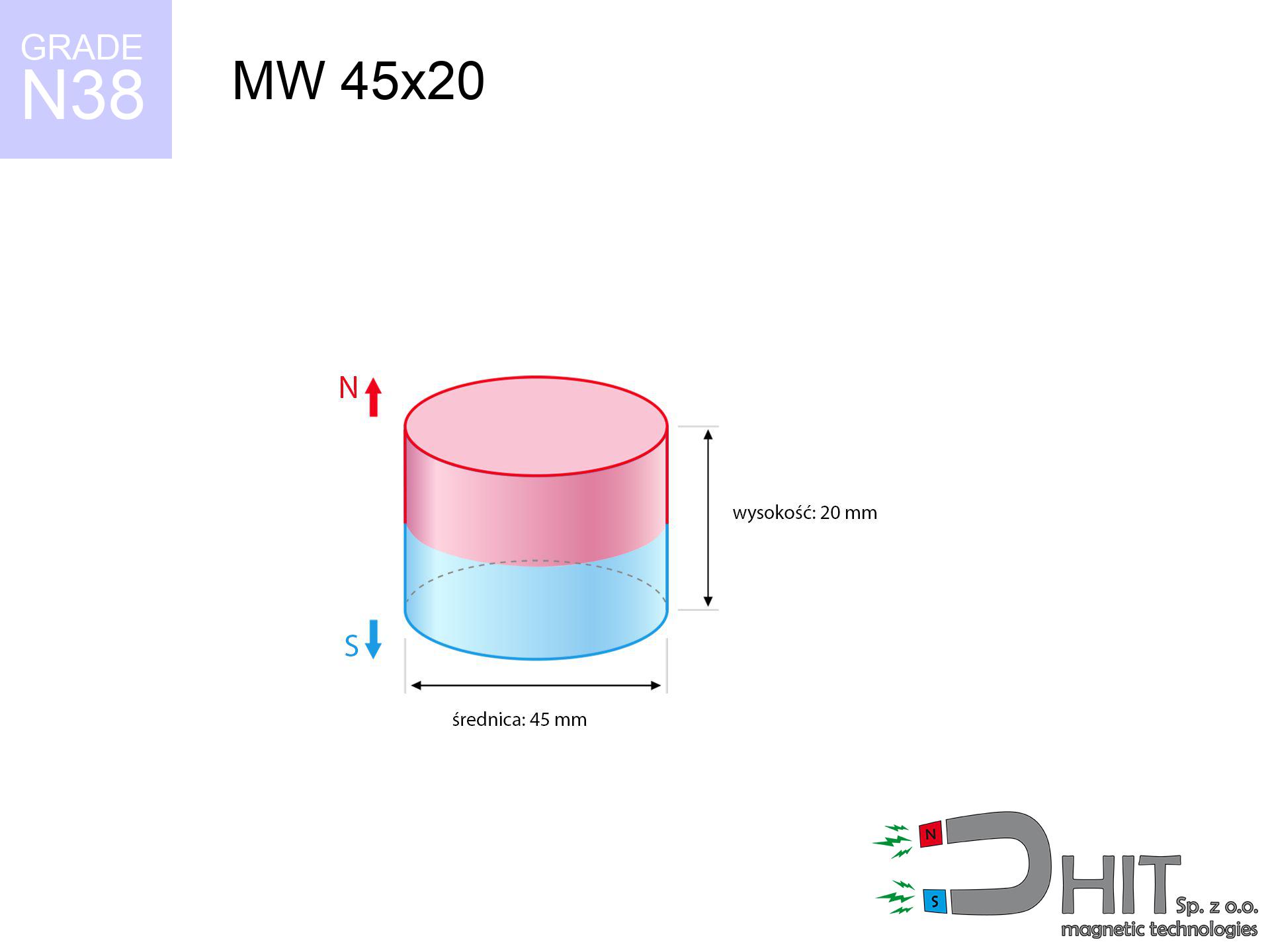

Magnetization Direction

↑ axial

Load capacity

60.94 kg / 597.79 N

Magnetic Induction

411.81 mT / 4118 Gs

Coating

[NiCuNi] Nickel

84.45 ZŁ with VAT / pcs + price for transport

68.66 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or send us a note via

form

the contact page.

Parameters along with structure of a magnet can be calculated on our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical - MW 45x20 / N38 - cylindrical magnet

Specification / characteristics - MW 45x20 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010071 |

| GTIN/EAN | 5906301810704 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 45 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 238.56 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 60.94 kg / 597.79 N |

| Magnetic Induction ~ ? | 411.81 mT / 4118 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

The following information constitute the direct effect of a engineering simulation. Results rely on algorithms for the class Nd2Fe14B. Actual conditions may differ from theoretical values. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (force vs distance) - characteristics

MW 45x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4117 Gs

411.7 mT

|

60.94 kg / 134.35 lbs

60940.0 g / 597.8 N

|

critical level |

| 1 mm |

3955 Gs

395.5 mT

|

56.23 kg / 123.96 lbs

56228.7 g / 551.6 N

|

critical level |

| 2 mm |

3786 Gs

378.6 mT

|

51.51 kg / 113.57 lbs

51512.3 g / 505.3 N

|

critical level |

| 3 mm |

3613 Gs

361.3 mT

|

46.91 kg / 103.42 lbs

46911.0 g / 460.2 N

|

critical level |

| 5 mm |

3263 Gs

326.3 mT

|

38.28 kg / 84.40 lbs

38282.6 g / 375.6 N

|

critical level |

| 10 mm |

2442 Gs

244.2 mT

|

21.43 kg / 47.26 lbs

21434.6 g / 210.3 N

|

critical level |

| 15 mm |

1776 Gs

177.6 mT

|

11.34 kg / 25.00 lbs

11340.0 g / 111.2 N

|

critical level |

| 20 mm |

1285 Gs

128.5 mT

|

5.93 kg / 13.08 lbs

5932.8 g / 58.2 N

|

warning |

| 30 mm |

694 Gs

69.4 mT

|

1.73 kg / 3.82 lbs

1730.8 g / 17.0 N

|

weak grip |

| 50 mm |

249 Gs

24.9 mT

|

0.22 kg / 0.49 lbs

222.3 g / 2.2 N

|

weak grip |

Table 2: Slippage force (wall)

MW 45x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

12.19 kg / 26.87 lbs

12188.0 g / 119.6 N

|

| 1 mm | Stal (~0.2) |

11.25 kg / 24.79 lbs

11246.0 g / 110.3 N

|

| 2 mm | Stal (~0.2) |

10.30 kg / 22.71 lbs

10302.0 g / 101.1 N

|

| 3 mm | Stal (~0.2) |

9.38 kg / 20.68 lbs

9382.0 g / 92.0 N

|

| 5 mm | Stal (~0.2) |

7.66 kg / 16.88 lbs

7656.0 g / 75.1 N

|

| 10 mm | Stal (~0.2) |

4.29 kg / 9.45 lbs

4286.0 g / 42.0 N

|

| 15 mm | Stal (~0.2) |

2.27 kg / 5.00 lbs

2268.0 g / 22.2 N

|

| 20 mm | Stal (~0.2) |

1.19 kg / 2.61 lbs

1186.0 g / 11.6 N

|

| 30 mm | Stal (~0.2) |

0.35 kg / 0.76 lbs

346.0 g / 3.4 N

|

| 50 mm | Stal (~0.2) |

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 45x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

18.28 kg / 40.30 lbs

18282.0 g / 179.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

12.19 kg / 26.87 lbs

12188.0 g / 119.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

6.09 kg / 13.43 lbs

6094.0 g / 59.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

30.47 kg / 67.17 lbs

30470.0 g / 298.9 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 45x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.03 kg / 4.48 lbs

2031.3 g / 19.9 N

|

| 1 mm |

|

5.08 kg / 11.20 lbs

5078.3 g / 49.8 N

|

| 2 mm |

|

10.16 kg / 22.39 lbs

10156.7 g / 99.6 N

|

| 3 mm |

|

15.24 kg / 33.59 lbs

15235.0 g / 149.5 N

|

| 5 mm |

|

25.39 kg / 55.98 lbs

25391.7 g / 249.1 N

|

| 10 mm |

|

50.78 kg / 111.96 lbs

50783.3 g / 498.2 N

|

| 11 mm |

|

55.86 kg / 123.15 lbs

55861.7 g / 548.0 N

|

| 12 mm |

|

60.94 kg / 134.35 lbs

60940.0 g / 597.8 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 45x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

60.94 kg / 134.35 lbs

60940.0 g / 597.8 N

|

OK |

| 40 °C | -2.2% |

59.60 kg / 131.39 lbs

59599.3 g / 584.7 N

|

OK |

| 60 °C | -4.4% |

58.26 kg / 128.44 lbs

58258.6 g / 571.5 N

|

|

| 80 °C | -6.6% |

56.92 kg / 125.48 lbs

56918.0 g / 558.4 N

|

|

| 100 °C | -28.8% |

43.39 kg / 95.66 lbs

43389.3 g / 425.6 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 45x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

166.23 kg / 366.47 lbs

5 401 Gs

|

24.93 kg / 54.97 lbs

24934 g / 244.6 N

|

N/A |

| 1 mm |

159.87 kg / 352.45 lbs

8 076 Gs

|

23.98 kg / 52.87 lbs

23980 g / 235.2 N

|

143.88 kg / 317.20 lbs

~0 Gs

|

| 2 mm |

153.38 kg / 338.14 lbs

7 910 Gs

|

23.01 kg / 50.72 lbs

23007 g / 225.7 N

|

138.04 kg / 304.33 lbs

~0 Gs

|

| 3 mm |

146.92 kg / 323.90 lbs

7 742 Gs

|

22.04 kg / 48.58 lbs

22038 g / 216.2 N

|

132.23 kg / 291.51 lbs

~0 Gs

|

| 5 mm |

134.19 kg / 295.83 lbs

7 399 Gs

|

20.13 kg / 44.37 lbs

20128 g / 197.5 N

|

120.77 kg / 266.25 lbs

~0 Gs

|

| 10 mm |

104.43 kg / 230.22 lbs

6 527 Gs

|

15.66 kg / 34.53 lbs

15664 g / 153.7 N

|

93.98 kg / 207.20 lbs

~0 Gs

|

| 20 mm |

58.47 kg / 128.90 lbs

4 884 Gs

|

8.77 kg / 19.34 lbs

8770 g / 86.0 N

|

52.62 kg / 116.01 lbs

~0 Gs

|

| 50 mm |

8.61 kg / 18.98 lbs

1 874 Gs

|

1.29 kg / 2.85 lbs

1291 g / 12.7 N

|

7.75 kg / 17.08 lbs

~0 Gs

|

| 60 mm |

4.72 kg / 10.41 lbs

1 388 Gs

|

0.71 kg / 1.56 lbs

708 g / 6.9 N

|

4.25 kg / 9.37 lbs

~0 Gs

|

| 70 mm |

2.68 kg / 5.91 lbs

1 046 Gs

|

0.40 kg / 0.89 lbs

402 g / 3.9 N

|

2.41 kg / 5.32 lbs

~0 Gs

|

| 80 mm |

1.58 kg / 3.48 lbs

803 Gs

|

0.24 kg / 0.52 lbs

237 g / 2.3 N

|

1.42 kg / 3.14 lbs

~0 Gs

|

| 90 mm |

0.96 kg / 2.12 lbs

627 Gs

|

0.14 kg / 0.32 lbs

145 g / 1.4 N

|

0.87 kg / 1.91 lbs

~0 Gs

|

| 100 mm |

0.61 kg / 1.34 lbs

497 Gs

|

0.09 kg / 0.20 lbs

91 g / 0.9 N

|

0.55 kg / 1.20 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 45x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 22.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 17.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 14.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 10.5 cm |

| Remote | 50 Gs (5.0 mT) | 10.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Dynamics (cracking risk) - warning

MW 45x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.34 km/h

(5.37 m/s)

|

3.44 J | |

| 30 mm |

28.41 km/h

(7.89 m/s)

|

7.43 J | |

| 50 mm |

36.12 km/h

(10.03 m/s)

|

12.01 J | |

| 100 mm |

50.98 km/h

(14.16 m/s)

|

23.92 J |

Table 9: Anti-corrosion coating durability

MW 45x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 45x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 66 952 Mx | 669.5 µWb |

| Pc Coefficient | 0.54 | Low (Flat) |

Table 11: Submerged application

MW 45x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 60.94 kg | Standard |

| Water (riverbed) |

69.78 kg

(+8.84 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains merely a fraction of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.54

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also offers

Pros and cons of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over more than ten years their performance decreases symbolically – ~1% (in testing),

- They retain their magnetic properties even under close interference source,

- Thanks to the glossy finish, the plating of nickel, gold-plated, or silver-plated gives an modern appearance,

- Neodymium magnets achieve maximum magnetic induction on a their surface, which increases force concentration,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of precise modeling as well as adapting to precise conditions,

- Universal use in advanced technology sectors – they are utilized in computer drives, drive modules, medical devices, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which allows their use in small systems

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- We recommend cover - magnetic holder, due to difficulties in producing threads inside the magnet and complicated shapes.

- Health risk resulting from small fragments of magnets are risky, in case of ingestion, which is particularly important in the context of child safety. Additionally, tiny parts of these products are able to disrupt the diagnostic process medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Highest magnetic holding force – what it depends on?

- using a base made of low-carbon steel, acting as a magnetic yoke

- possessing a thickness of minimum 10 mm to avoid saturation

- with an ideally smooth contact surface

- with direct contact (without impurities)

- for force acting at a right angle (in the magnet axis)

- in neutral thermal conditions

What influences lifting capacity in practice

- Space between surfaces – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Steel thickness – insufficiently thick steel causes magnetic saturation, causing part of the power to be escaped to the other side.

- Metal type – different alloys reacts the same. Alloy additives weaken the attraction effect.

- Surface finish – ideal contact is possible only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Temperature influence – hot environment reduces pulling force. Too high temperature can permanently demagnetize the magnet.

Lifting capacity testing was carried out on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

Warnings

Do not overheat magnets

Regular neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Fire warning

Dust generated during machining of magnets is self-igniting. Do not drill into magnets without proper cooling and knowledge.

Pacemakers

Life threat: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have electronic implants.

Handling rules

Exercise caution. Neodymium magnets act from a long distance and snap with massive power, often faster than you can react.

GPS Danger

GPS units and smartphones are extremely sensitive to magnetic fields. Close proximity with a strong magnet can permanently damage the sensors in your phone.

Magnetic media

Intense magnetic fields can destroy records on payment cards, HDDs, and storage devices. Maintain a gap of min. 10 cm.

Allergic reactions

Certain individuals suffer from a hypersensitivity to Ni, which is the standard coating for NdFeB magnets. Prolonged contact might lead to skin redness. We strongly advise use safety gloves.

Beware of splinters

Beware of splinters. Magnets can explode upon violent connection, ejecting shards into the air. Eye protection is mandatory.

Serious injuries

Protect your hands. Two powerful magnets will join instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

No play value

Strictly keep magnets away from children. Ingestion danger is significant, and the effects of magnets connecting inside the body are tragic.