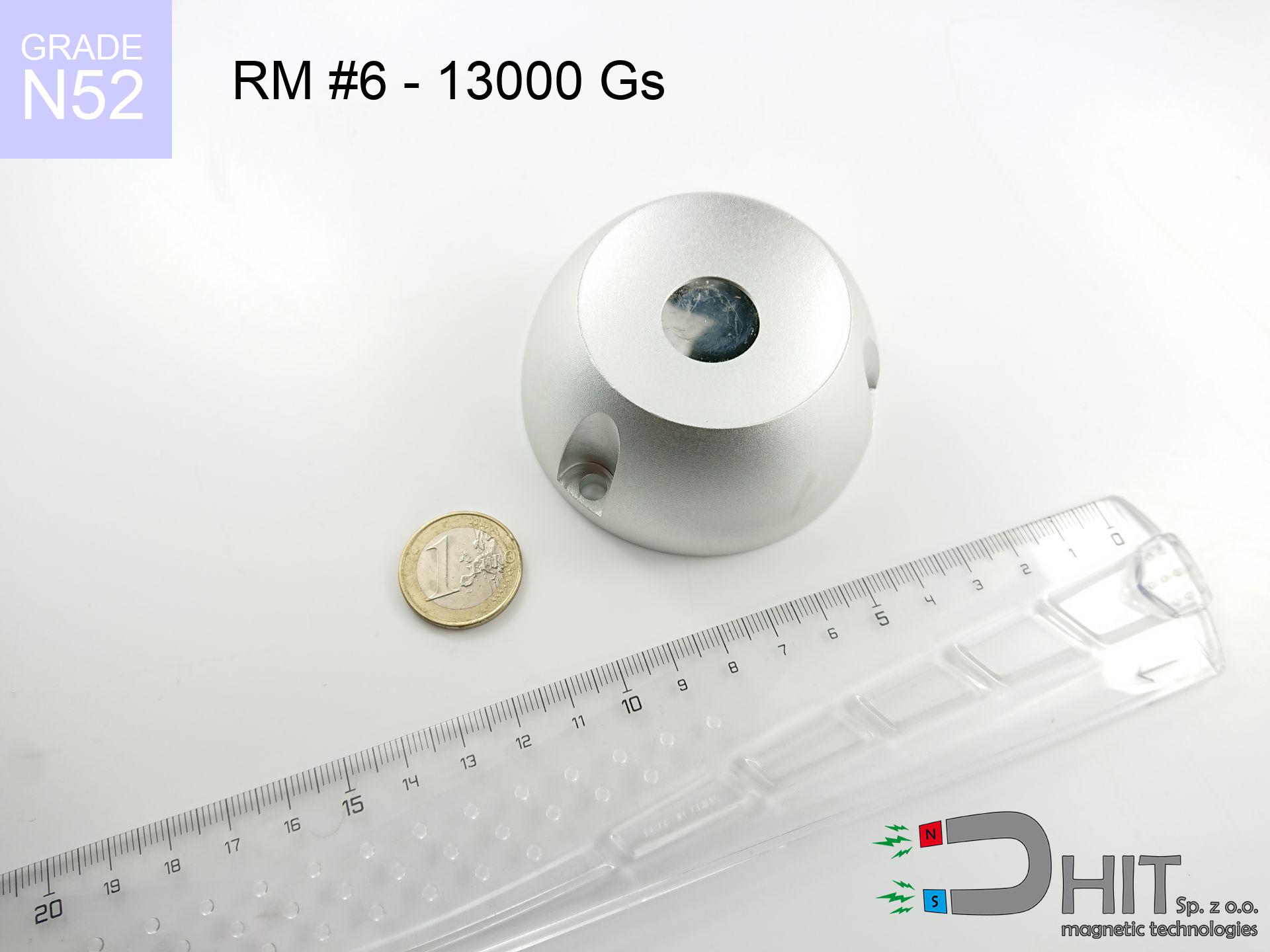

RM R6 GOLF - 13000 Gs / N52 - magnetic distributor

magnetic distributor

Catalog no 280398

GTIN/EAN: 5906301814474

Weight

343 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

150.00 ZŁ with VAT / pcs + price for transport

121.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively contact us via

contact form

the contact form page.

Weight as well as shape of a neodymium magnet can be checked with our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Technical specification - RM R6 GOLF - 13000 Gs / N52 - magnetic distributor

Specification / characteristics - RM R6 GOLF - 13000 Gs / N52 - magnetic distributor

| properties | values |

|---|---|

| Cat. no. | 280398 |

| GTIN/EAN | 5906301814474 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 343 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros as well as cons of rare earth magnets.

Benefits

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (according to theory),

- Magnets effectively protect themselves against loss of magnetization caused by external fields,

- The use of an elegant finish of noble metals (nickel, gold, silver) causes the element to look better,

- They feature high magnetic induction at the operating surface, which affects their effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to the option of precise molding and adaptation to unique needs, neodymium magnets can be manufactured in a wide range of geometric configurations, which increases their versatility,

- Huge importance in high-tech industry – they find application in hard drives, brushless drives, advanced medical instruments, as well as modern systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Disadvantages

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Due to limitations in realizing threads and complicated shapes in magnets, we propose using cover - magnetic holder.

- Possible danger to health – tiny shards of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child health protection. It is also worth noting that small elements of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Due to neodymium price, their price exceeds standard values,

Pull force analysis

Highest magnetic holding force – what contributes to it?

- with the application of a yoke made of special test steel, ensuring maximum field concentration

- whose transverse dimension is min. 10 mm

- with a surface perfectly flat

- under conditions of gap-free contact (metal-to-metal)

- under axial force vector (90-degree angle)

- in temp. approx. 20°C

Practical lifting capacity: influencing factors

- Gap (betwixt the magnet and the plate), as even a microscopic distance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Load vector – highest force is available only during perpendicular pulling. The shear force of the magnet along the plate is standardly several times lower (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Plate material – low-carbon steel attracts best. Higher carbon content reduce magnetic properties and lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves force. Uneven metal weaken the grip.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under a perpendicular pulling force, however under parallel forces the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet and the plate decreases the load capacity.

Precautions when working with NdFeB magnets

Medical interference

Patients with a pacemaker have to maintain an absolute distance from magnets. The magnetic field can interfere with the operation of the life-saving device.

Swallowing risk

Strictly store magnets out of reach of children. Ingestion danger is significant, and the effects of magnets clamping inside the body are very dangerous.

Sensitization to coating

A percentage of the population experience a contact allergy to nickel, which is the typical protective layer for NdFeB magnets. Frequent touching can result in a rash. It is best to use protective gloves.

Electronic hazard

Avoid bringing magnets near a wallet, laptop, or TV. The magnetism can permanently damage these devices and erase data from cards.

Flammability

Fire hazard: Neodymium dust is highly flammable. Do not process magnets without safety gear as this may cause fire.

Immense force

Before starting, read the rules. Sudden snapping can break the magnet or hurt your hand. Be predictive.

Hand protection

Mind your fingers. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing anything in their path. Be careful!

GPS Danger

Navigation devices and mobile phones are extremely susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can ruin the sensors in your phone.

Beware of splinters

Beware of splinters. Magnets can explode upon violent connection, launching shards into the air. Eye protection is mandatory.

Demagnetization risk

Watch the temperature. Heating the magnet to high heat will permanently weaken its magnetic structure and strength.

![SM 25x150 [2xM8] / N42 - magnetic separator SM 25x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x150-2xm8-cim.jpg)

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)

![SM 19x225 [2xM6] / N50 - magnetic separator SM 19x225 [2xM6] / N50 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-19x225-2xm6-jis.jpg)