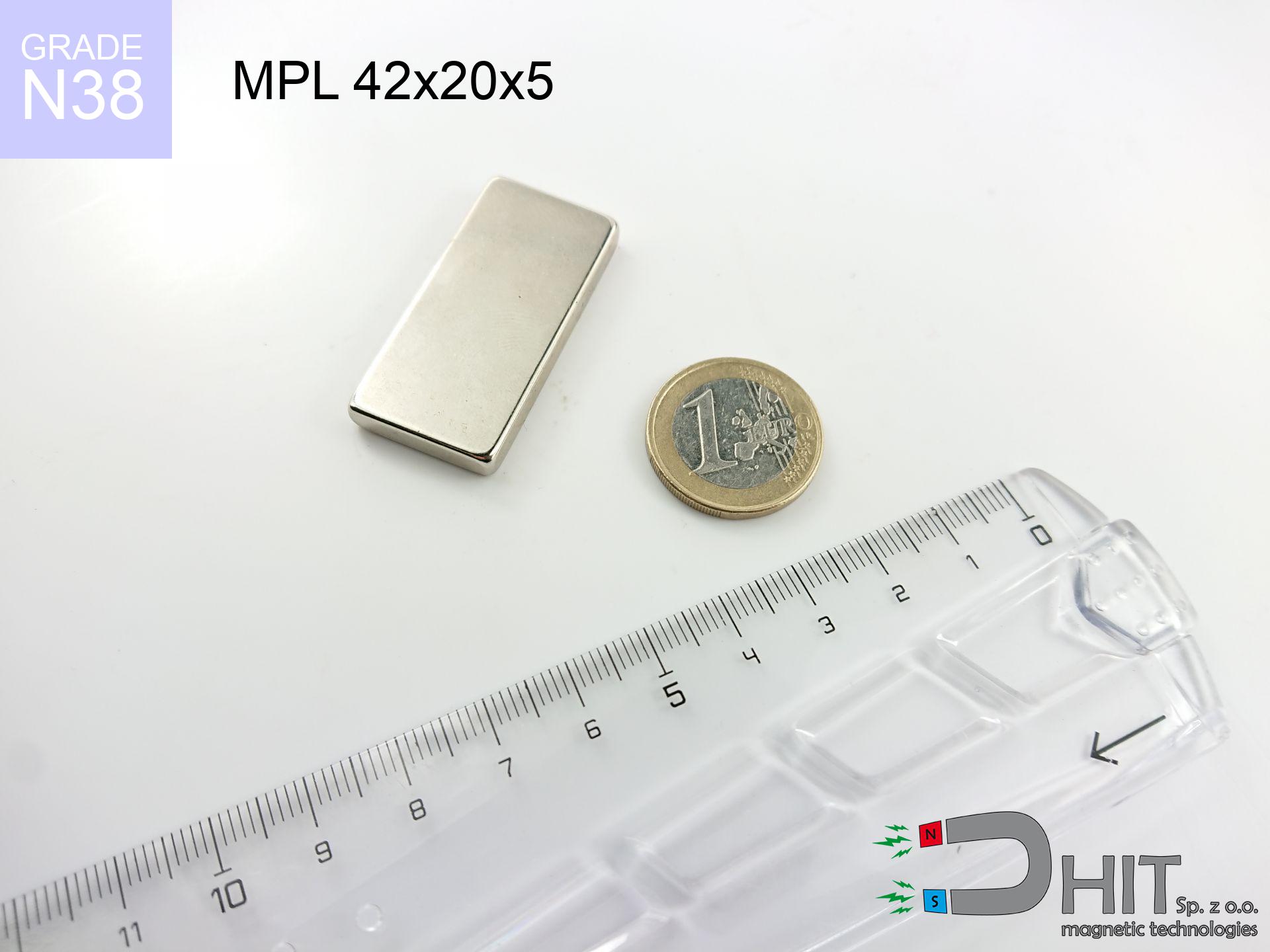

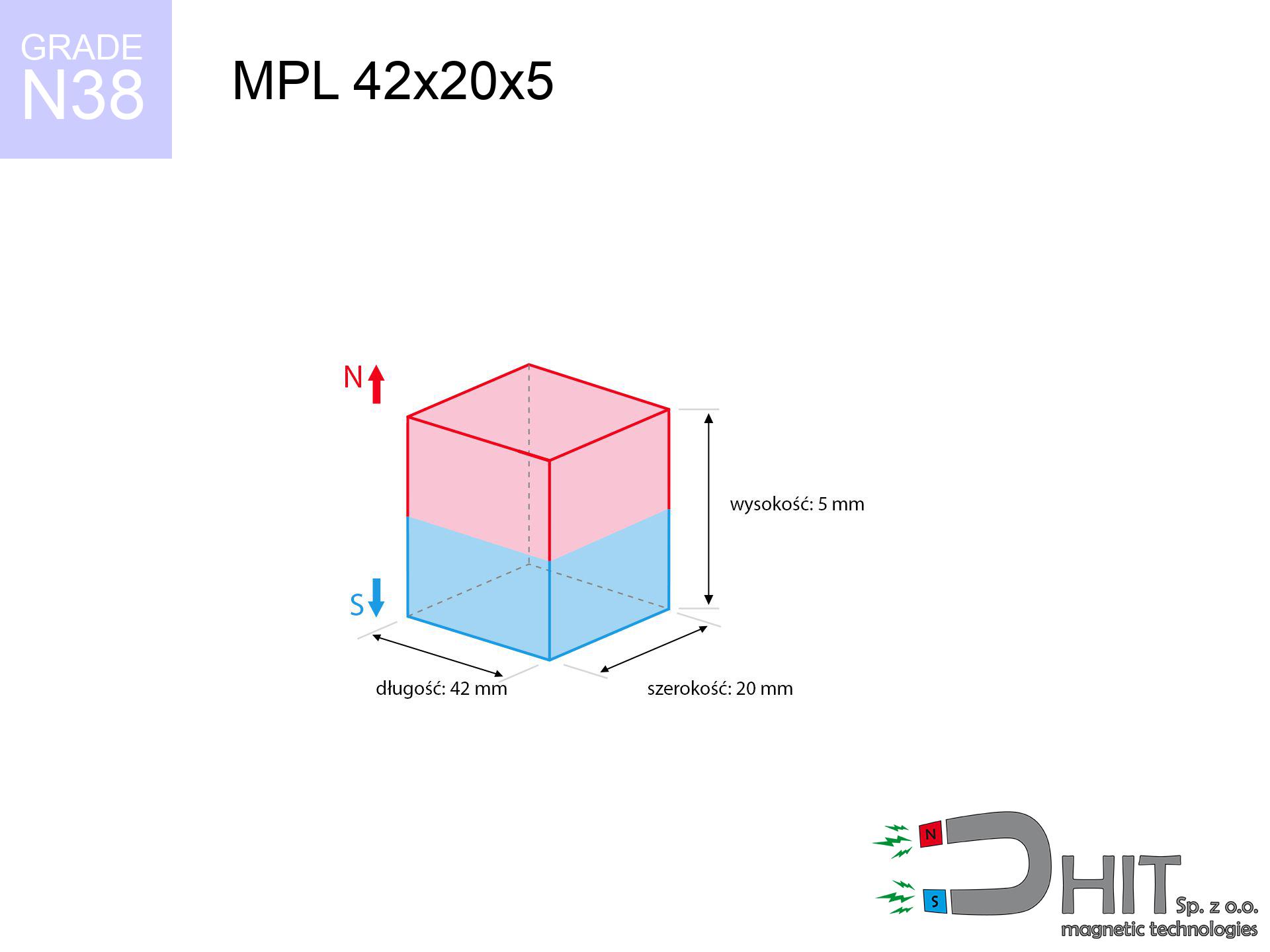

MPL 42x20x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020163

GTIN/EAN: 5906301811695

length

42 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

31.5 g

Magnetization Direction

↑ axial

Load capacity

11.06 kg / 108.46 N

Magnetic Induction

203.37 mT / 2034 Gs

Coating

[NiCuNi] Nickel

15.62 ZŁ with VAT / pcs + price for transport

12.70 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise send us a note using

contact form

the contact section.

Parameters and shape of magnetic components can be checked on our

modular calculator.

Same-day processing for orders placed before 14:00.

Technical parameters - MPL 42x20x5 / N38 - lamellar magnet

Specification / characteristics - MPL 42x20x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020163 |

| GTIN/EAN | 5906301811695 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 42 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 31.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 11.06 kg / 108.46 N |

| Magnetic Induction ~ ? | 203.37 mT / 2034 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - report

Presented data constitute the outcome of a engineering simulation. Values are based on algorithms for the class Nd2Fe14B. Actual conditions might slightly deviate from the simulation results. Please consider these data as a preliminary roadmap for designers.

Table 1: Static force (force vs distance) - power drop

MPL 42x20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2033 Gs

203.3 mT

|

11.06 kg / 24.38 LBS

11060.0 g / 108.5 N

|

dangerous! |

| 1 mm |

1938 Gs

193.8 mT

|

10.05 kg / 22.15 LBS

10049.3 g / 98.6 N

|

dangerous! |

| 2 mm |

1823 Gs

182.3 mT

|

8.89 kg / 19.60 LBS

8888.2 g / 87.2 N

|

strong |

| 3 mm |

1696 Gs

169.6 mT

|

7.69 kg / 16.96 LBS

7691.7 g / 75.5 N

|

strong |

| 5 mm |

1433 Gs

143.3 mT

|

5.49 kg / 12.10 LBS

5490.3 g / 53.9 N

|

strong |

| 10 mm |

885 Gs

88.5 mT

|

2.09 kg / 4.62 LBS

2093.5 g / 20.5 N

|

strong |

| 15 mm |

547 Gs

54.7 mT

|

0.80 kg / 1.76 LBS

799.6 g / 7.8 N

|

low risk |

| 20 mm |

350 Gs

35.0 mT

|

0.33 kg / 0.72 LBS

327.0 g / 3.2 N

|

low risk |

| 30 mm |

160 Gs

16.0 mT

|

0.07 kg / 0.15 LBS

68.5 g / 0.7 N

|

low risk |

| 50 mm |

48 Gs

4.8 mT

|

0.01 kg / 0.01 LBS

6.2 g / 0.1 N

|

low risk |

Table 2: Shear force (vertical surface)

MPL 42x20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.21 kg / 4.88 LBS

2212.0 g / 21.7 N

|

| 1 mm | Stal (~0.2) |

2.01 kg / 4.43 LBS

2010.0 g / 19.7 N

|

| 2 mm | Stal (~0.2) |

1.78 kg / 3.92 LBS

1778.0 g / 17.4 N

|

| 3 mm | Stal (~0.2) |

1.54 kg / 3.39 LBS

1538.0 g / 15.1 N

|

| 5 mm | Stal (~0.2) |

1.10 kg / 2.42 LBS

1098.0 g / 10.8 N

|

| 10 mm | Stal (~0.2) |

0.42 kg / 0.92 LBS

418.0 g / 4.1 N

|

| 15 mm | Stal (~0.2) |

0.16 kg / 0.35 LBS

160.0 g / 1.6 N

|

| 20 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

66.0 g / 0.6 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MPL 42x20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.32 kg / 7.31 LBS

3318.0 g / 32.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.21 kg / 4.88 LBS

2212.0 g / 21.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.11 kg / 2.44 LBS

1106.0 g / 10.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.53 kg / 12.19 LBS

5530.0 g / 54.2 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 42x20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.55 kg / 1.22 LBS

553.0 g / 5.4 N

|

| 1 mm |

|

1.38 kg / 3.05 LBS

1382.5 g / 13.6 N

|

| 2 mm |

|

2.77 kg / 6.10 LBS

2765.0 g / 27.1 N

|

| 3 mm |

|

4.15 kg / 9.14 LBS

4147.5 g / 40.7 N

|

| 5 mm |

|

6.91 kg / 15.24 LBS

6912.5 g / 67.8 N

|

| 10 mm |

|

11.06 kg / 24.38 LBS

11060.0 g / 108.5 N

|

| 11 mm |

|

11.06 kg / 24.38 LBS

11060.0 g / 108.5 N

|

| 12 mm |

|

11.06 kg / 24.38 LBS

11060.0 g / 108.5 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MPL 42x20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

11.06 kg / 24.38 LBS

11060.0 g / 108.5 N

|

OK |

| 40 °C | -2.2% |

10.82 kg / 23.85 LBS

10816.7 g / 106.1 N

|

OK |

| 60 °C | -4.4% |

10.57 kg / 23.31 LBS

10573.4 g / 103.7 N

|

|

| 80 °C | -6.6% |

10.33 kg / 22.77 LBS

10330.0 g / 101.3 N

|

|

| 100 °C | -28.8% |

7.87 kg / 17.36 LBS

7874.7 g / 77.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MPL 42x20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

21.41 kg / 47.21 LBS

3 465 Gs

|

3.21 kg / 7.08 LBS

3212 g / 31.5 N

|

N/A |

| 1 mm |

20.49 kg / 45.17 LBS

3 978 Gs

|

3.07 kg / 6.78 LBS

3074 g / 30.2 N

|

18.44 kg / 40.66 LBS

~0 Gs

|

| 2 mm |

19.46 kg / 42.89 LBS

3 877 Gs

|

2.92 kg / 6.43 LBS

2918 g / 28.6 N

|

17.51 kg / 38.60 LBS

~0 Gs

|

| 3 mm |

18.35 kg / 40.46 LBS

3 765 Gs

|

2.75 kg / 6.07 LBS

2753 g / 27.0 N

|

16.52 kg / 36.41 LBS

~0 Gs

|

| 5 mm |

16.05 kg / 35.38 LBS

3 521 Gs

|

2.41 kg / 5.31 LBS

2407 g / 23.6 N

|

14.44 kg / 31.84 LBS

~0 Gs

|

| 10 mm |

10.63 kg / 23.43 LBS

2 865 Gs

|

1.59 kg / 3.52 LBS

1594 g / 15.6 N

|

9.57 kg / 21.09 LBS

~0 Gs

|

| 20 mm |

4.05 kg / 8.94 LBS

1 769 Gs

|

0.61 kg / 1.34 LBS

608 g / 6.0 N

|

3.65 kg / 8.04 LBS

~0 Gs

|

| 50 mm |

0.28 kg / 0.62 LBS

465 Gs

|

0.04 kg / 0.09 LBS

42 g / 0.4 N

|

0.25 kg / 0.55 LBS

~0 Gs

|

| 60 mm |

0.13 kg / 0.29 LBS

320 Gs

|

0.02 kg / 0.04 LBS

20 g / 0.2 N

|

0.12 kg / 0.26 LBS

~0 Gs

|

| 70 mm |

0.07 kg / 0.15 LBS

228 Gs

|

0.01 kg / 0.02 LBS

10 g / 0.1 N

|

0.06 kg / 0.13 LBS

~0 Gs

|

| 80 mm |

0.04 kg / 0.08 LBS

167 Gs

|

0.01 kg / 0.01 LBS

5 g / 0.1 N

|

0.03 kg / 0.07 LBS

~0 Gs

|

| 90 mm |

0.02 kg / 0.04 LBS

125 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 100 mm |

0.01 kg / 0.03 LBS

96 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 42x20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 42x20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.01 km/h

(5.84 m/s)

|

0.54 J | |

| 30 mm |

32.86 km/h

(9.13 m/s)

|

1.31 J | |

| 50 mm |

42.27 km/h

(11.74 m/s)

|

2.17 J | |

| 100 mm |

59.76 km/h

(16.60 m/s)

|

4.34 J |

Table 9: Coating parameters (durability)

MPL 42x20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 42x20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 18 614 Mx | 186.1 µWb |

| Pc Coefficient | 0.23 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 42x20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 11.06 kg | Standard |

| Water (riverbed) |

12.66 kg

(+1.60 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet retains merely ~20% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) severely weakens the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.23

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Strengths as well as weaknesses of rare earth magnets.

Strengths

- Their strength remains stable, and after around ten years it drops only by ~1% (theoretically),

- They feature excellent resistance to magnetism drop when exposed to opposing magnetic fields,

- Thanks to the glossy finish, the plating of nickel, gold-plated, or silver-plated gives an elegant appearance,

- Magnetic induction on the working part of the magnet is exceptional,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Due to the possibility of flexible shaping and adaptation to specialized projects, magnetic components can be modeled in a variety of shapes and sizes, which amplifies use scope,

- Fundamental importance in modern technologies – they serve a role in mass storage devices, electric drive systems, diagnostic systems, also other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a strong case, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Due to limitations in creating nuts and complex forms in magnets, we propose using cover - magnetic mount.

- Possible danger resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which gains importance in the context of child safety. It is also worth noting that tiny parts of these products can disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- with the use of a yoke made of low-carbon steel, ensuring maximum field concentration

- with a thickness of at least 10 mm

- with a plane cleaned and smooth

- without any clearance between the magnet and steel

- during detachment in a direction perpendicular to the plane

- in stable room temperature

Magnet lifting force in use – key factors

- Air gap (betwixt the magnet and the metal), as even a very small distance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to paint, rust or dirt).

- Angle of force application – maximum parameter is reached only during perpendicular pulling. The force required to slide of the magnet along the plate is usually many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Material type – the best choice is pure iron steel. Cast iron may have worse magnetic properties.

- Surface structure – the smoother and more polished the plate, the larger the contact zone and higher the lifting capacity. Roughness creates an air distance.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

H&S for magnets

ICD Warning

Health Alert: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Hand protection

Big blocks can crush fingers in a fraction of a second. Do not place your hand betwixt two strong magnets.

Respect the power

Exercise caution. Rare earth magnets attract from a distance and connect with massive power, often faster than you can react.

Impact on smartphones

Navigation devices and smartphones are highly susceptible to magnetic fields. Direct contact with a strong magnet can permanently damage the internal compass in your phone.

Thermal limits

Avoid heat. Neodymium magnets are sensitive to temperature. If you require resistance above 80°C, look for HT versions (H, SH, UH).

Cards and drives

Avoid bringing magnets close to a wallet, laptop, or TV. The magnetism can permanently damage these devices and wipe information from cards.

Keep away from children

These products are not suitable for play. Swallowing several magnets can lead to them attracting across intestines, which poses a direct threat to life and necessitates immediate surgery.

Allergic reactions

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness happens, cease handling magnets and wear gloves.

Combustion hazard

Dust generated during machining of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Beware of splinters

Watch out for shards. Magnets can explode upon violent connection, launching shards into the air. Eye protection is mandatory.

![SM 25x275 [2xM8] / N42 - magnetic separator SM 25x275 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x275-2xm8-boc.jpg)