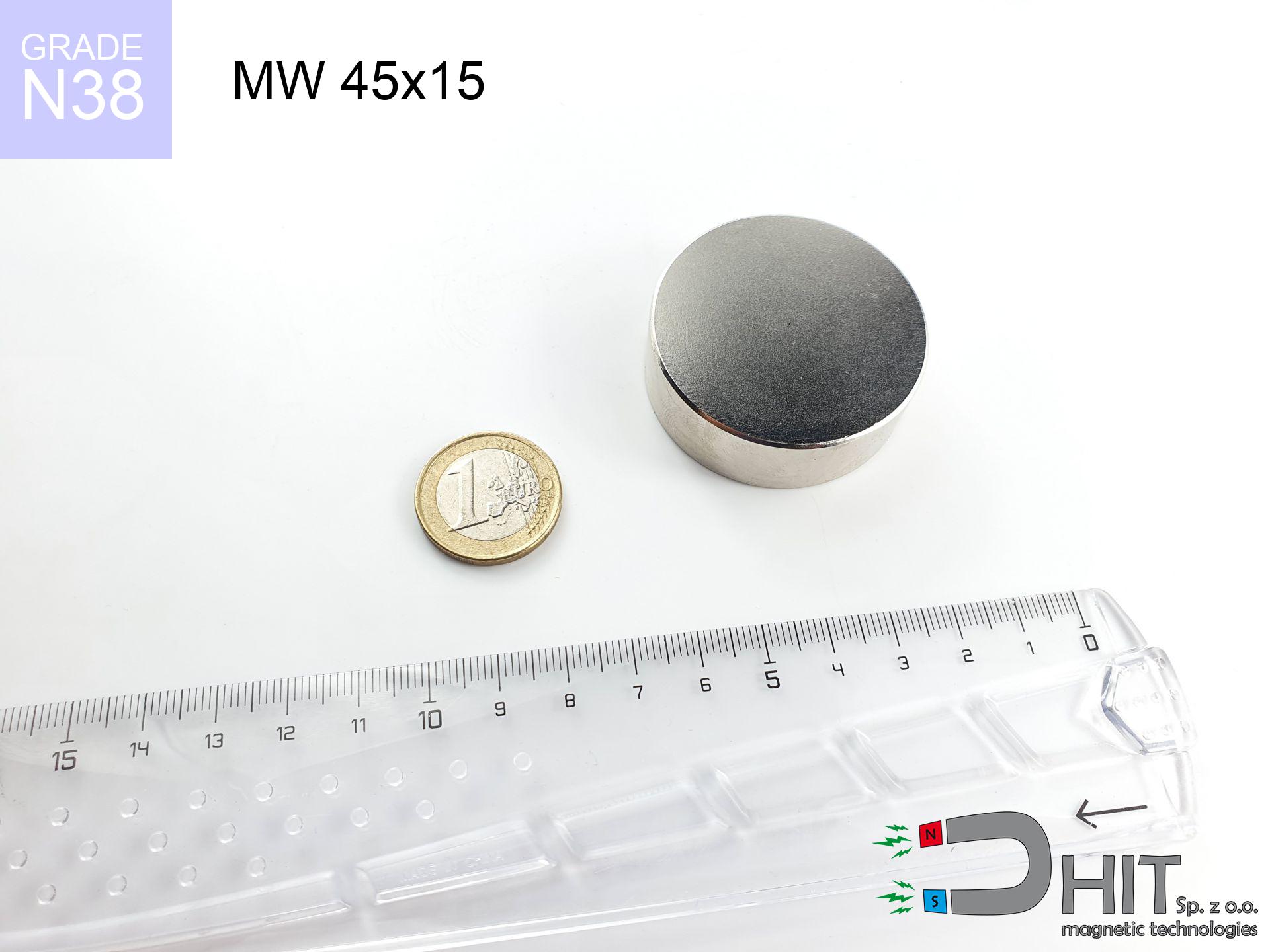

MW 45x15 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010070

GTIN/EAN: 5906301810698

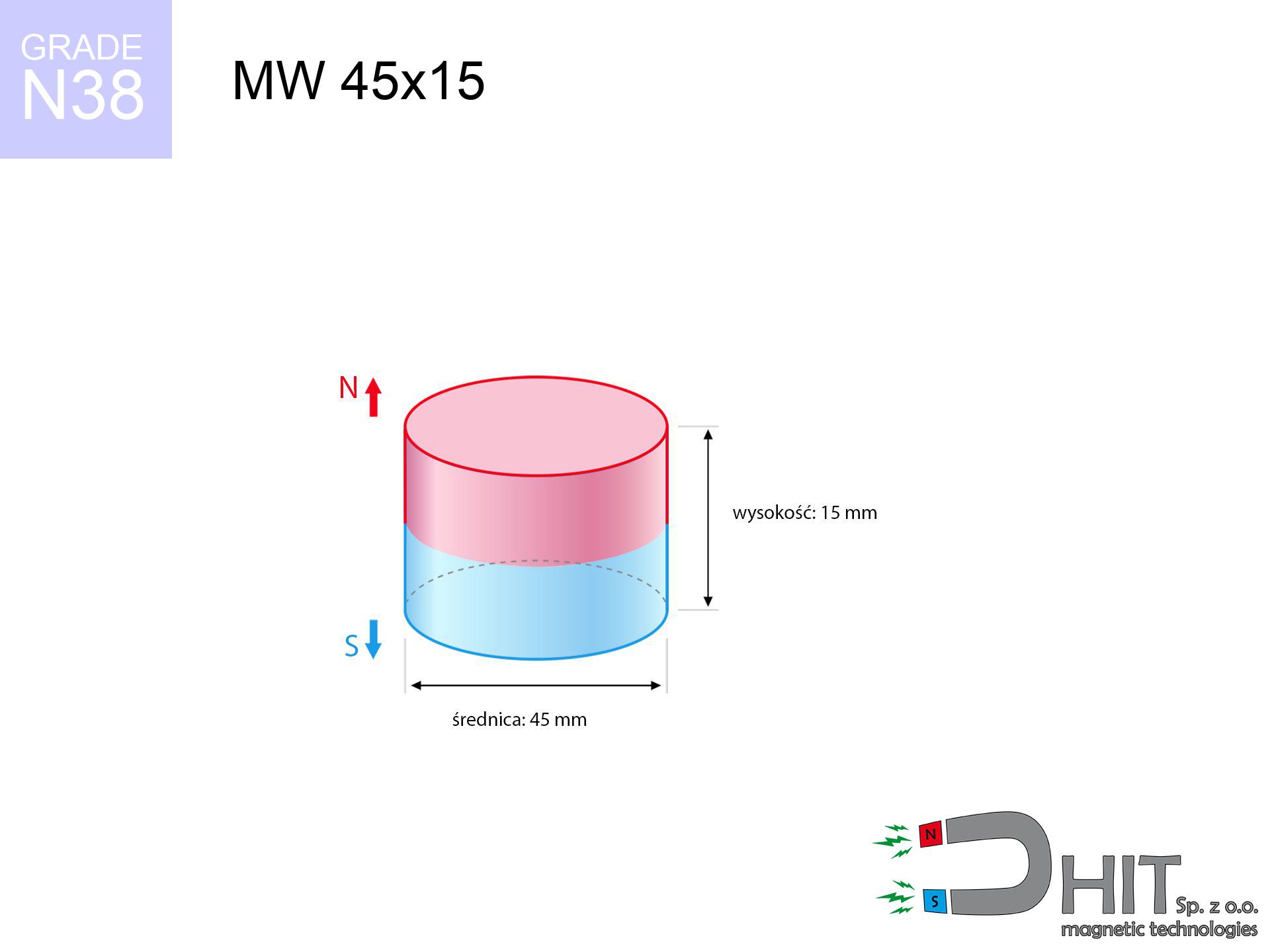

Diameter Ø

45 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

178.92 g

Magnetization Direction

↑ axial

Load capacity

48.55 kg / 476.32 N

Magnetic Induction

343.84 mT / 3438 Gs

Coating

[NiCuNi] Nickel

61.84 ZŁ with VAT / pcs + price for transport

50.28 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively get in touch using

contact form

the contact section.

Specifications as well as form of neodymium magnets can be calculated on our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MW 45x15 / N38 - cylindrical magnet

Specification / characteristics - MW 45x15 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010070 |

| GTIN/EAN | 5906301810698 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 45 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 178.92 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 48.55 kg / 476.32 N |

| Magnetic Induction ~ ? | 343.84 mT / 3438 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - technical parameters

The following information are the outcome of a physical calculation. Values were calculated on models for the class Nd2Fe14B. Operational performance might slightly differ from theoretical values. Use these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs distance) - characteristics

MW 45x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3438 Gs

343.8 mT

|

48.55 kg / 107.03 lbs

48550.0 g / 476.3 N

|

crushing |

| 1 mm |

3318 Gs

331.8 mT

|

45.21 kg / 99.68 lbs

45214.3 g / 443.6 N

|

crushing |

| 2 mm |

3189 Gs

318.9 mT

|

41.76 kg / 92.07 lbs

41762.8 g / 409.7 N

|

crushing |

| 3 mm |

3054 Gs

305.4 mT

|

38.30 kg / 84.44 lbs

38303.2 g / 375.8 N

|

crushing |

| 5 mm |

2774 Gs

277.4 mT

|

31.61 kg / 69.69 lbs

31610.0 g / 310.1 N

|

crushing |

| 10 mm |

2090 Gs

209.0 mT

|

17.95 kg / 39.57 lbs

17948.5 g / 176.1 N

|

crushing |

| 15 mm |

1521 Gs

152.1 mT

|

9.50 kg / 20.95 lbs

9500.8 g / 93.2 N

|

strong |

| 20 mm |

1096 Gs

109.6 mT

|

4.94 kg / 10.88 lbs

4936.3 g / 48.4 N

|

strong |

| 30 mm |

585 Gs

58.5 mT

|

1.41 kg / 3.10 lbs

1407.9 g / 13.8 N

|

safe |

| 50 mm |

205 Gs

20.5 mT

|

0.17 kg / 0.38 lbs

172.6 g / 1.7 N

|

safe |

Table 2: Slippage load (vertical surface)

MW 45x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

9.71 kg / 21.41 lbs

9710.0 g / 95.3 N

|

| 1 mm | Stal (~0.2) |

9.04 kg / 19.93 lbs

9042.0 g / 88.7 N

|

| 2 mm | Stal (~0.2) |

8.35 kg / 18.41 lbs

8352.0 g / 81.9 N

|

| 3 mm | Stal (~0.2) |

7.66 kg / 16.89 lbs

7660.0 g / 75.1 N

|

| 5 mm | Stal (~0.2) |

6.32 kg / 13.94 lbs

6322.0 g / 62.0 N

|

| 10 mm | Stal (~0.2) |

3.59 kg / 7.91 lbs

3590.0 g / 35.2 N

|

| 15 mm | Stal (~0.2) |

1.90 kg / 4.19 lbs

1900.0 g / 18.6 N

|

| 20 mm | Stal (~0.2) |

0.99 kg / 2.18 lbs

988.0 g / 9.7 N

|

| 30 mm | Stal (~0.2) |

0.28 kg / 0.62 lbs

282.0 g / 2.8 N

|

| 50 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 45x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

14.56 kg / 32.11 lbs

14565.0 g / 142.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

9.71 kg / 21.41 lbs

9710.0 g / 95.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.86 kg / 10.70 lbs

4855.0 g / 47.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

24.28 kg / 53.52 lbs

24275.0 g / 238.1 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 45x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.43 kg / 5.35 lbs

2427.5 g / 23.8 N

|

| 1 mm |

|

6.07 kg / 13.38 lbs

6068.8 g / 59.5 N

|

| 2 mm |

|

12.14 kg / 26.76 lbs

12137.5 g / 119.1 N

|

| 3 mm |

|

18.21 kg / 40.14 lbs

18206.2 g / 178.6 N

|

| 5 mm |

|

30.34 kg / 66.90 lbs

30343.8 g / 297.7 N

|

| 10 mm |

|

48.55 kg / 107.03 lbs

48550.0 g / 476.3 N

|

| 11 mm |

|

48.55 kg / 107.03 lbs

48550.0 g / 476.3 N

|

| 12 mm |

|

48.55 kg / 107.03 lbs

48550.0 g / 476.3 N

|

Table 5: Working in heat (stability) - power drop

MW 45x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

48.55 kg / 107.03 lbs

48550.0 g / 476.3 N

|

OK |

| 40 °C | -2.2% |

47.48 kg / 104.68 lbs

47481.9 g / 465.8 N

|

OK |

| 60 °C | -4.4% |

46.41 kg / 102.32 lbs

46413.8 g / 455.3 N

|

|

| 80 °C | -6.6% |

45.35 kg / 99.97 lbs

45345.7 g / 444.8 N

|

|

| 100 °C | -28.8% |

34.57 kg / 76.21 lbs

34567.6 g / 339.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 45x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

115.89 kg / 255.50 lbs

4 958 Gs

|

17.38 kg / 38.32 lbs

17384 g / 170.5 N

|

N/A |

| 1 mm |

111.99 kg / 246.89 lbs

6 759 Gs

|

16.80 kg / 37.03 lbs

16798 g / 164.8 N

|

100.79 kg / 222.20 lbs

~0 Gs

|

| 2 mm |

107.93 kg / 237.94 lbs

6 636 Gs

|

16.19 kg / 35.69 lbs

16189 g / 158.8 N

|

97.14 kg / 214.15 lbs

~0 Gs

|

| 3 mm |

103.82 kg / 228.89 lbs

6 508 Gs

|

15.57 kg / 34.33 lbs

15573 g / 152.8 N

|

93.44 kg / 206.00 lbs

~0 Gs

|

| 5 mm |

95.55 kg / 210.66 lbs

6 244 Gs

|

14.33 kg / 31.60 lbs

14333 g / 140.6 N

|

86.00 kg / 189.59 lbs

~0 Gs

|

| 10 mm |

75.46 kg / 166.35 lbs

5 548 Gs

|

11.32 kg / 24.95 lbs

11318 g / 111.0 N

|

67.91 kg / 149.72 lbs

~0 Gs

|

| 20 mm |

42.84 kg / 94.46 lbs

4 181 Gs

|

6.43 kg / 14.17 lbs

6427 g / 63.0 N

|

38.56 kg / 85.01 lbs

~0 Gs

|

| 50 mm |

6.20 kg / 13.67 lbs

1 591 Gs

|

0.93 kg / 2.05 lbs

930 g / 9.1 N

|

5.58 kg / 12.31 lbs

~0 Gs

|

| 60 mm |

3.36 kg / 7.41 lbs

1 171 Gs

|

0.50 kg / 1.11 lbs

504 g / 4.9 N

|

3.02 kg / 6.67 lbs

~0 Gs

|

| 70 mm |

1.89 kg / 4.16 lbs

877 Gs

|

0.28 kg / 0.62 lbs

283 g / 2.8 N

|

1.70 kg / 3.74 lbs

~0 Gs

|

| 80 mm |

1.10 kg / 2.42 lbs

669 Gs

|

0.16 kg / 0.36 lbs

165 g / 1.6 N

|

0.99 kg / 2.18 lbs

~0 Gs

|

| 90 mm |

0.66 kg / 1.46 lbs

520 Gs

|

0.10 kg / 0.22 lbs

99 g / 1.0 N

|

0.60 kg / 1.31 lbs

~0 Gs

|

| 100 mm |

0.41 kg / 0.91 lbs

410 Gs

|

0.06 kg / 0.14 lbs

62 g / 0.6 N

|

0.37 kg / 0.82 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 45x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 20.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 16.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 12.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 10.0 cm |

| Car key | 50 Gs (5.0 mT) | 9.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 45x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.09 km/h

(5.58 m/s)

|

2.79 J | |

| 30 mm |

29.29 km/h

(8.14 m/s)

|

5.92 J | |

| 50 mm |

37.23 km/h

(10.34 m/s)

|

9.57 J | |

| 100 mm |

52.54 km/h

(14.59 m/s)

|

19.05 J |

Table 9: Corrosion resistance

MW 45x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 45x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 57 854 Mx | 578.5 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 45x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 48.55 kg | Standard |

| Water (riverbed) |

55.59 kg

(+7.04 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet retains only approx. 20-30% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also offers

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They retain magnetic properties for around 10 years – the loss is just ~1% (based on simulations),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- In other words, due to the smooth finish of nickel, the element looks attractive,

- Neodymium magnets ensure maximum magnetic induction on a contact point, which ensures high operational effectiveness,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of detailed modeling and adjusting to precise applications,

- Key role in innovative solutions – they are utilized in mass storage devices, brushless drives, medical devices, and other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in compact constructions

Cons

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Limited possibility of producing threads in the magnet and complex forms - recommended is a housing - mounting mechanism.

- Health risk resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that tiny parts of these products are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- with the application of a sheet made of low-carbon steel, ensuring maximum field concentration

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with an ideally smooth contact surface

- with zero gap (no paint)

- for force acting at a right angle (pull-off, not shear)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Space between surfaces – every millimeter of distance (caused e.g. by veneer or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet holds much less (often approx. 20-30% of maximum force).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Material type – the best choice is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Surface finish – full contact is possible only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was assessed using a polished steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under parallel forces the lifting capacity is smaller. In addition, even a small distance between the magnet and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Metal Allergy

Certain individuals experience a sensitization to Ni, which is the typical protective layer for neodymium magnets. Prolonged contact may cause a rash. We suggest use protective gloves.

Product not for children

Product intended for adults. Small elements can be swallowed, leading to severe trauma. Store out of reach of kids and pets.

Impact on smartphones

A strong magnetic field interferes with the functioning of magnetometers in phones and GPS navigation. Maintain magnets close to a device to prevent damaging the sensors.

Implant safety

Warning for patients: Strong magnetic fields affect electronics. Maintain at least 30 cm distance or request help to handle the magnets.

Threat to electronics

Do not bring magnets close to a purse, laptop, or TV. The magnetic field can irreversibly ruin these devices and erase data from cards.

Fragile material

NdFeB magnets are ceramic materials, meaning they are prone to chipping. Impact of two magnets will cause them shattering into small pieces.

Power loss in heat

Do not overheat. NdFeB magnets are susceptible to temperature. If you require operation above 80°C, look for HT versions (H, SH, UH).

Fire warning

Drilling and cutting of neodymium magnets poses a fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Handling guide

Before starting, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Hand protection

Risk of injury: The attraction force is so immense that it can cause hematomas, pinching, and even bone fractures. Protective gloves are recommended.