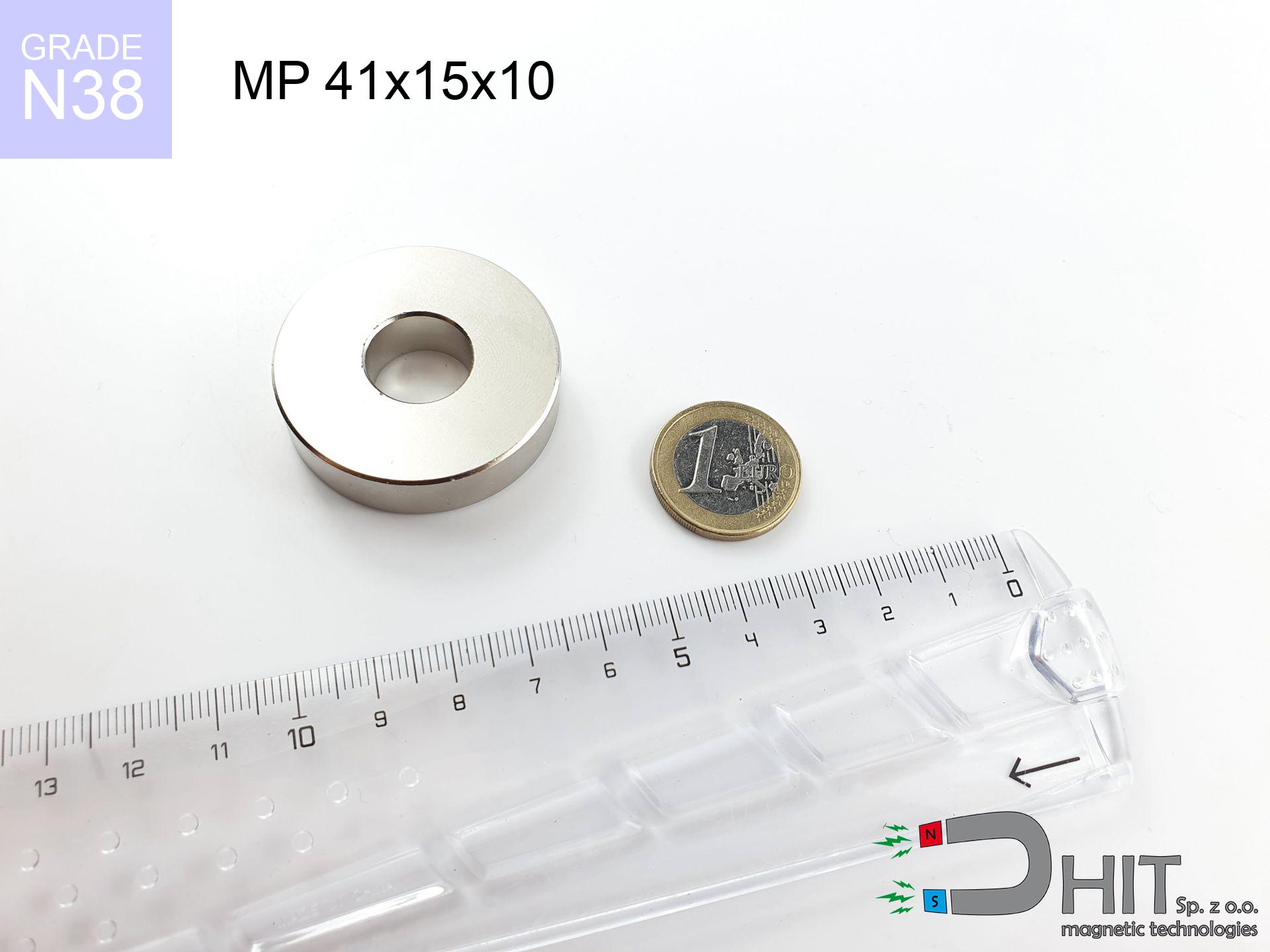

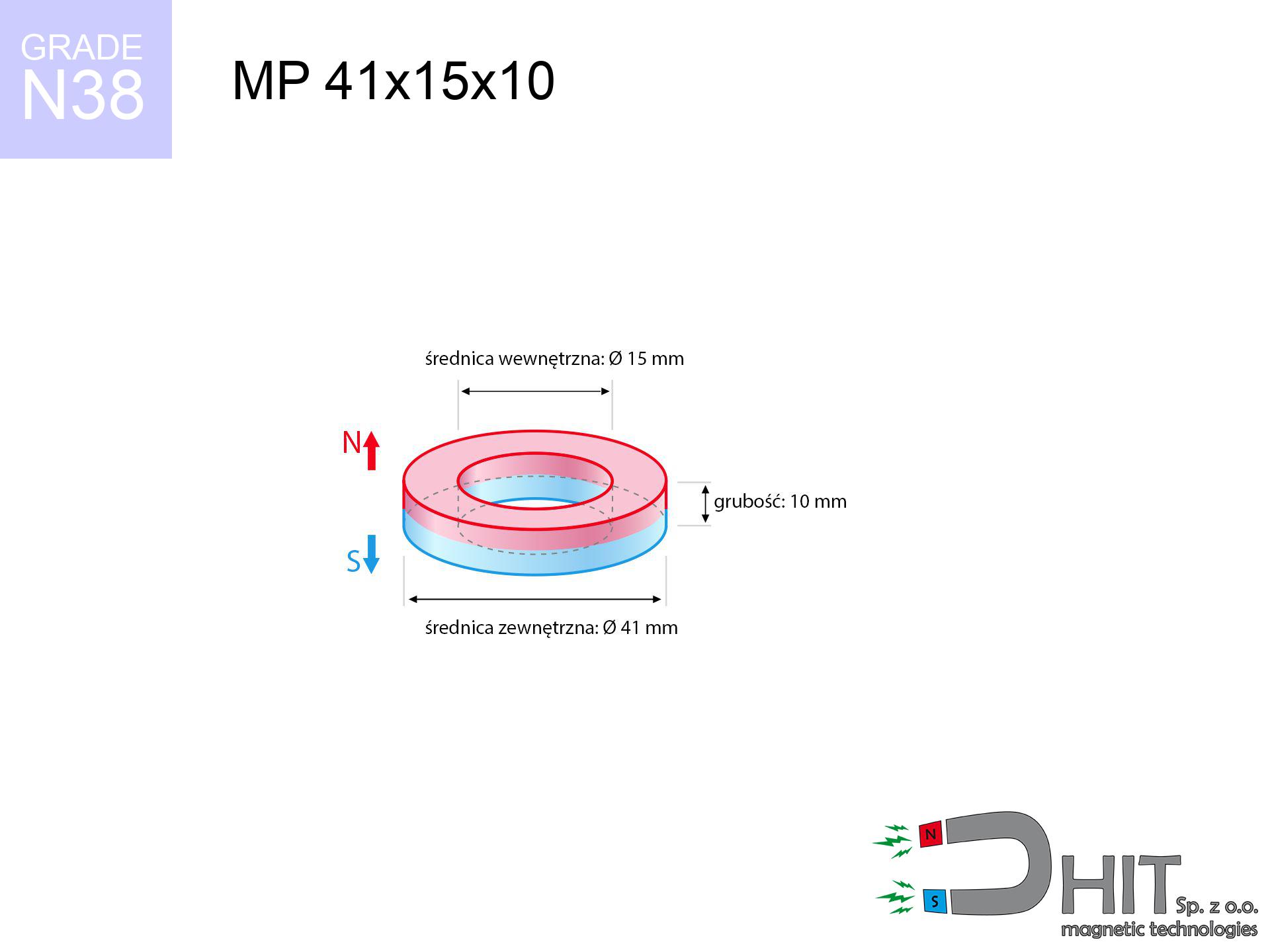

MP 41x15x10 / N38 - ring magnet

ring magnet

Catalog no 030200

GTIN/EAN: 5906301812173

Diameter

41 mm [±0,1 mm]

internal diameter Ø

15 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

85.77 g

Magnetization Direction

↑ axial

Load capacity

24.44 kg / 239.78 N

Magnetic Induction

271.77 mT / 2718 Gs

Coating

[NiCuNi] Nickel

50.00 ZŁ with VAT / pcs + price for transport

40.65 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

or send us a note by means of

request form

our website.

Weight along with structure of magnets can be calculated on our

magnetic mass calculator.

Order by 14:00 and we’ll ship today!

Technical details - MP 41x15x10 / N38 - ring magnet

Specification / characteristics - MP 41x15x10 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030200 |

| GTIN/EAN | 5906301812173 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 41 mm [±0,1 mm] |

| internal diameter Ø | 15 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 85.77 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 24.44 kg / 239.78 N |

| Magnetic Induction ~ ? | 271.77 mT / 2718 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

Presented information are the direct effect of a physical calculation. Results are based on algorithms for the material Nd2Fe14B. Operational performance may differ from theoretical values. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - interaction chart

MP 41x15x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5232 Gs

523.2 mT

|

24.44 kg / 53.88 lbs

24440.0 g / 239.8 N

|

dangerous! |

| 1 mm |

4978 Gs

497.8 mT

|

22.12 kg / 48.77 lbs

22120.4 g / 217.0 N

|

dangerous! |

| 2 mm |

4720 Gs

472.0 mT

|

19.89 kg / 43.85 lbs

19888.8 g / 195.1 N

|

dangerous! |

| 3 mm |

4464 Gs

446.4 mT

|

17.79 kg / 39.22 lbs

17788.4 g / 174.5 N

|

dangerous! |

| 5 mm |

3964 Gs

396.4 mT

|

14.03 kg / 30.93 lbs

14030.8 g / 137.6 N

|

dangerous! |

| 10 mm |

2861 Gs

286.1 mT

|

7.31 kg / 16.11 lbs

7308.1 g / 71.7 N

|

strong |

| 15 mm |

2028 Gs

202.8 mT

|

3.67 kg / 8.09 lbs

3670.1 g / 36.0 N

|

strong |

| 20 mm |

1443 Gs

144.3 mT

|

1.86 kg / 4.10 lbs

1858.4 g / 18.2 N

|

low risk |

| 30 mm |

770 Gs

77.0 mT

|

0.53 kg / 1.17 lbs

529.8 g / 5.2 N

|

low risk |

| 50 mm |

280 Gs

28.0 mT

|

0.07 kg / 0.15 lbs

69.8 g / 0.7 N

|

low risk |

Table 2: Slippage capacity (wall)

MP 41x15x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.89 kg / 10.78 lbs

4888.0 g / 48.0 N

|

| 1 mm | Stal (~0.2) |

4.42 kg / 9.75 lbs

4424.0 g / 43.4 N

|

| 2 mm | Stal (~0.2) |

3.98 kg / 8.77 lbs

3978.0 g / 39.0 N

|

| 3 mm | Stal (~0.2) |

3.56 kg / 7.84 lbs

3558.0 g / 34.9 N

|

| 5 mm | Stal (~0.2) |

2.81 kg / 6.19 lbs

2806.0 g / 27.5 N

|

| 10 mm | Stal (~0.2) |

1.46 kg / 3.22 lbs

1462.0 g / 14.3 N

|

| 15 mm | Stal (~0.2) |

0.73 kg / 1.62 lbs

734.0 g / 7.2 N

|

| 20 mm | Stal (~0.2) |

0.37 kg / 0.82 lbs

372.0 g / 3.6 N

|

| 30 mm | Stal (~0.2) |

0.11 kg / 0.23 lbs

106.0 g / 1.0 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 41x15x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

7.33 kg / 16.16 lbs

7332.0 g / 71.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.89 kg / 10.78 lbs

4888.0 g / 48.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.44 kg / 5.39 lbs

2444.0 g / 24.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

12.22 kg / 26.94 lbs

12220.0 g / 119.9 N

|

Table 4: Steel thickness (saturation) - power losses

MP 41x15x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.22 kg / 2.69 lbs

1222.0 g / 12.0 N

|

| 1 mm |

|

3.06 kg / 6.74 lbs

3055.0 g / 30.0 N

|

| 2 mm |

|

6.11 kg / 13.47 lbs

6110.0 g / 59.9 N

|

| 3 mm |

|

9.17 kg / 20.21 lbs

9165.0 g / 89.9 N

|

| 5 mm |

|

15.28 kg / 33.68 lbs

15275.0 g / 149.8 N

|

| 10 mm |

|

24.44 kg / 53.88 lbs

24440.0 g / 239.8 N

|

| 11 mm |

|

24.44 kg / 53.88 lbs

24440.0 g / 239.8 N

|

| 12 mm |

|

24.44 kg / 53.88 lbs

24440.0 g / 239.8 N

|

Table 5: Working in heat (stability) - power drop

MP 41x15x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

24.44 kg / 53.88 lbs

24440.0 g / 239.8 N

|

OK |

| 40 °C | -2.2% |

23.90 kg / 52.70 lbs

23902.3 g / 234.5 N

|

OK |

| 60 °C | -4.4% |

23.36 kg / 51.51 lbs

23364.6 g / 229.2 N

|

OK |

| 80 °C | -6.6% |

22.83 kg / 50.32 lbs

22827.0 g / 223.9 N

|

|

| 100 °C | -28.8% |

17.40 kg / 38.36 lbs

17401.3 g / 170.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MP 41x15x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

178.13 kg / 392.71 lbs

5 907 Gs

|

26.72 kg / 58.91 lbs

26719 g / 262.1 N

|

N/A |

| 1 mm |

169.67 kg / 374.06 lbs

10 213 Gs

|

25.45 kg / 56.11 lbs

25451 g / 249.7 N

|

152.70 kg / 336.65 lbs

~0 Gs

|

| 2 mm |

161.22 kg / 355.43 lbs

9 955 Gs

|

24.18 kg / 53.32 lbs

24183 g / 237.2 N

|

145.10 kg / 319.89 lbs

~0 Gs

|

| 3 mm |

152.98 kg / 337.26 lbs

9 697 Gs

|

22.95 kg / 50.59 lbs

22947 g / 225.1 N

|

137.68 kg / 303.53 lbs

~0 Gs

|

| 5 mm |

137.18 kg / 302.42 lbs

9 183 Gs

|

20.58 kg / 45.36 lbs

20577 g / 201.9 N

|

123.46 kg / 272.18 lbs

~0 Gs

|

| 10 mm |

102.26 kg / 225.45 lbs

7 929 Gs

|

15.34 kg / 33.82 lbs

15339 g / 150.5 N

|

92.04 kg / 202.90 lbs

~0 Gs

|

| 20 mm |

53.26 kg / 117.43 lbs

5 722 Gs

|

7.99 kg / 17.61 lbs

7990 g / 78.4 N

|

47.94 kg / 105.69 lbs

~0 Gs

|

| 50 mm |

7.08 kg / 15.62 lbs

2 087 Gs

|

1.06 kg / 2.34 lbs

1063 g / 10.4 N

|

6.38 kg / 14.06 lbs

~0 Gs

|

| 60 mm |

3.86 kg / 8.51 lbs

1 541 Gs

|

0.58 kg / 1.28 lbs

579 g / 5.7 N

|

3.48 kg / 7.66 lbs

~0 Gs

|

| 70 mm |

2.20 kg / 4.84 lbs

1 162 Gs

|

0.33 kg / 0.73 lbs

330 g / 3.2 N

|

1.98 kg / 4.36 lbs

~0 Gs

|

| 80 mm |

1.30 kg / 2.87 lbs

895 Gs

|

0.20 kg / 0.43 lbs

195 g / 1.9 N

|

1.17 kg / 2.58 lbs

~0 Gs

|

| 90 mm |

0.80 kg / 1.76 lbs

701 Gs

|

0.12 kg / 0.26 lbs

120 g / 1.2 N

|

0.72 kg / 1.59 lbs

~0 Gs

|

| 100 mm |

0.51 kg / 1.12 lbs

559 Gs

|

0.08 kg / 0.17 lbs

76 g / 0.7 N

|

0.46 kg / 1.01 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MP 41x15x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 24.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 19.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 15.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 11.5 cm |

| Remote | 50 Gs (5.0 mT) | 10.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MP 41x15x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.95 km/h

(5.54 m/s)

|

1.32 J | |

| 30 mm |

29.88 km/h

(8.30 m/s)

|

2.96 J | |

| 50 mm |

38.13 km/h

(10.59 m/s)

|

4.81 J | |

| 100 mm |

53.84 km/h

(14.96 m/s)

|

9.59 J |

Table 9: Surface protection spec

MP 41x15x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 41x15x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 56 505 Mx | 565.0 µWb |

| Pc Coefficient | 0.80 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 41x15x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 24.44 kg | Standard |

| Water (riverbed) |

27.98 kg

(+3.54 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds only ~20% of its max power.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) drastically limits the holding force.

3. Temperature resistance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.80

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Pros as well as cons of rare earth magnets.

Advantages

- They do not lose power, even over nearly ten years – the decrease in power is only ~1% (theoretically),

- They show high resistance to demagnetization induced by external magnetic fields,

- The use of an aesthetic coating of noble metals (nickel, gold, silver) causes the element to present itself better,

- They are known for high magnetic induction at the operating surface, which affects their effectiveness,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Possibility of exact forming and adjusting to atypical conditions,

- Universal use in electronics industry – they serve a role in mass storage devices, electric drive systems, medical devices, also industrial machines.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Cons

- Brittleness is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic holder, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Potential hazard to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child safety. It is also worth noting that tiny parts of these products are able to complicate diagnosis medical in case of swallowing.

- Due to neodymium price, their price is higher than average,

Lifting parameters

Maximum lifting force for a neodymium magnet – what contributes to it?

- on a plate made of structural steel, optimally conducting the magnetic flux

- whose thickness reaches at least 10 mm

- with a surface perfectly flat

- with total lack of distance (no coatings)

- during pulling in a direction vertical to the plane

- in temp. approx. 20°C

Practical lifting capacity: influencing factors

- Air gap (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) results in a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Material composition – not every steel reacts the same. Alloy additives weaken the interaction with the magnet.

- Smoothness – ideal contact is obtained only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal factor – high temperature weakens magnetic field. Too high temperature can permanently damage the magnet.

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under attempts to slide the magnet the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safety rules for work with neodymium magnets

Dust is flammable

Mechanical processing of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Warning for heart patients

Medical warning: Neodymium magnets can turn off heart devices and defibrillators. Do not approach if you have medical devices.

Immense force

Handle magnets consciously. Their huge power can shock even professionals. Plan your moves and do not underestimate their force.

Eye protection

Despite the nickel coating, neodymium is delicate and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Demagnetization risk

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. The loss of strength is permanent.

Threat to navigation

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Keep a safe distance from your mobile, tablet, and navigation systems.

Avoid contact if allergic

Certain individuals suffer from a sensitization to nickel, which is the common plating for NdFeB magnets. Frequent touching might lead to skin redness. It is best to wear safety gloves.

Keep away from computers

Equipment safety: Neodymium magnets can damage data carriers and sensitive devices (heart implants, medical aids, timepieces).

Do not give to children

Strictly store magnets away from children. Ingestion danger is significant, and the consequences of magnets connecting inside the body are life-threatening.

Bodily injuries

Big blocks can crush fingers instantly. Do not put your hand between two attracting surfaces.

![SM 32x500 [2xM8] / N42 - magnetic separator SM 32x500 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x500-2xm8-jan.jpg)