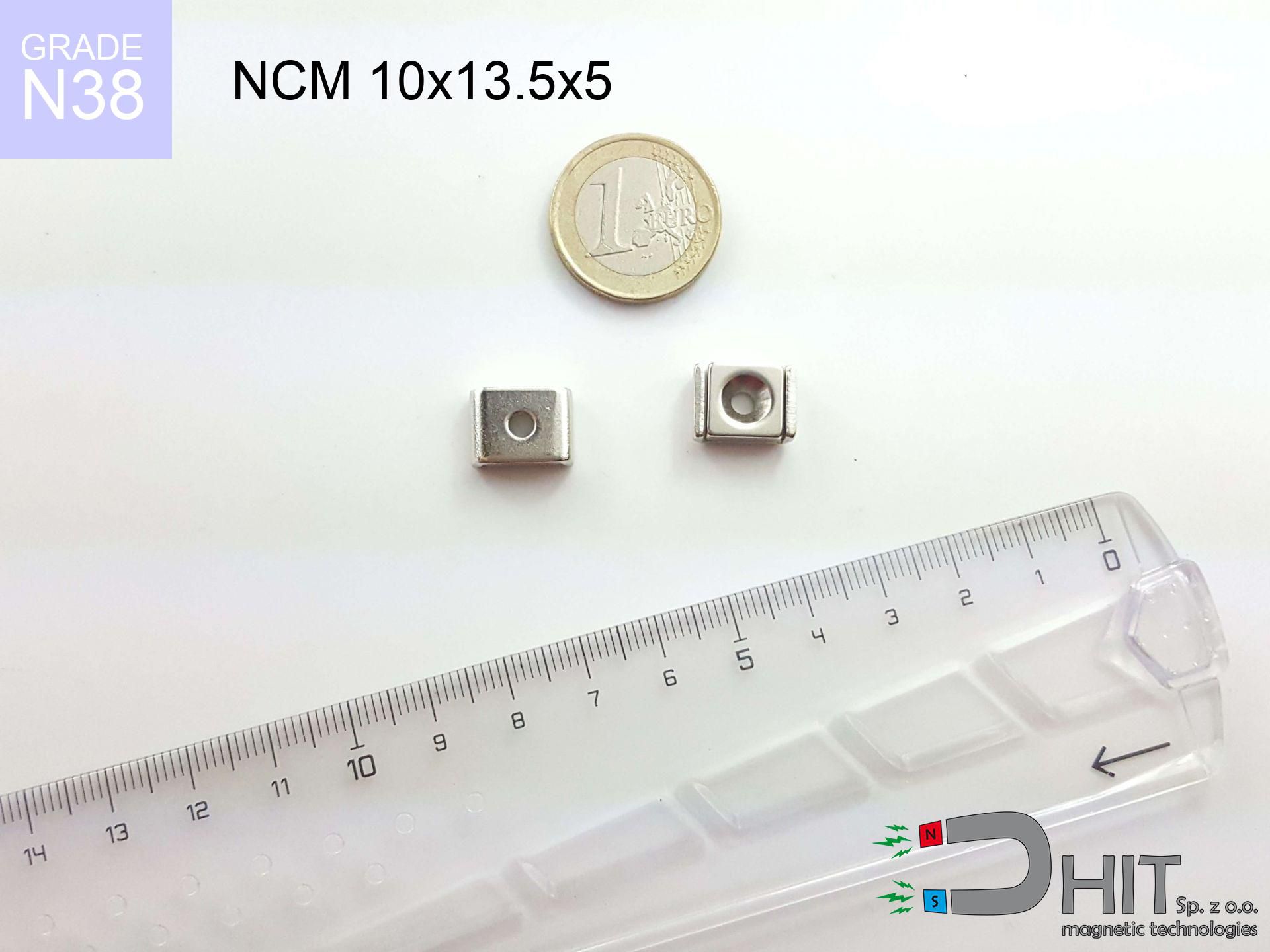

NCM 10x13.5x5 / N38 - channel magnetic holder

channel magnetic holder

Catalog no 360485

GTIN/EAN: 5906301814849

Diameter Ø

10 mm [±1 mm]

Height

13.5 mm [±1 mm]

Weight

4.5 g

Magnetization Direction

↑ axial

Load capacity

4.00 kg / 39.23 N

Coating

[NiCuNi] Nickel

3.39 ZŁ with VAT / pcs + price for transport

2.76 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively contact us via

form

through our site.

Lifting power and shape of a neodymium magnet can be checked on our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - NCM 10x13.5x5 / N38 - channel magnetic holder

Specification / characteristics - NCM 10x13.5x5 / N38 - channel magnetic holder

| properties | values |

|---|---|

| Cat. no. | 360485 |

| GTIN/EAN | 5906301814849 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±1 mm] |

| Height | 13.5 mm [±1 mm] |

| Weight | 4.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.00 kg / 39.23 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (in laboratory conditions),

- Magnets perfectly resist against loss of magnetization caused by ambient magnetic noise,

- The use of an elegant finish of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling functioning at temperatures reaching 230°C and above...

- Thanks to modularity in designing and the capacity to customize to client solutions,

- Fundamental importance in electronics industry – they are commonly used in computer drives, electric drive systems, medical devices, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in miniature devices

Disadvantages

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- We suggest casing - magnetic mechanism, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Health risk to health – tiny shards of magnets can be dangerous, if swallowed, which is particularly important in the context of child health protection. Furthermore, small components of these magnets can disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting capacity of the magnet – what affects it?

- with the contact of a sheet made of low-carbon steel, ensuring full magnetic saturation

- with a thickness no less than 10 mm

- with a surface free of scratches

- under conditions of gap-free contact (metal-to-metal)

- under axial force vector (90-degree angle)

- at temperature room level

Practical aspects of lifting capacity – factors

- Space between surfaces – every millimeter of distance (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds much less (often approx. 20-30% of maximum force).

- Element thickness – for full efficiency, the steel must be adequately massive. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material type – the best choice is pure iron steel. Hardened steels may attract less.

- Plate texture – ground elements guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal environment – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was assessed by applying a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the holding force is lower. In addition, even a slight gap between the magnet’s surface and the plate reduces the holding force.

Precautions when working with neodymium magnets

Conscious usage

Use magnets consciously. Their powerful strength can shock even professionals. Stay alert and respect their force.

Danger to the youngest

Always store magnets away from children. Choking hazard is high, and the consequences of magnets connecting inside the body are very dangerous.

Material brittleness

Neodymium magnets are sintered ceramics, meaning they are prone to chipping. Clashing of two magnets will cause them shattering into small pieces.

Threat to navigation

Remember: rare earth magnets generate a field that confuses precision electronics. Keep a safe distance from your phone, device, and navigation systems.

Flammability

Dust produced during grinding of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Physical harm

Large magnets can smash fingers in a fraction of a second. Under no circumstances place your hand between two strong magnets.

Keep away from computers

Avoid bringing magnets near a wallet, computer, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Do not overheat magnets

Standard neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. The loss of strength is permanent.

Life threat

Patients with a ICD have to maintain an safe separation from magnets. The magnetic field can disrupt the operation of the life-saving device.

Allergic reactions

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If redness happens, immediately stop working with magnets and use protective gear.

![UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gz-bas.jpg)