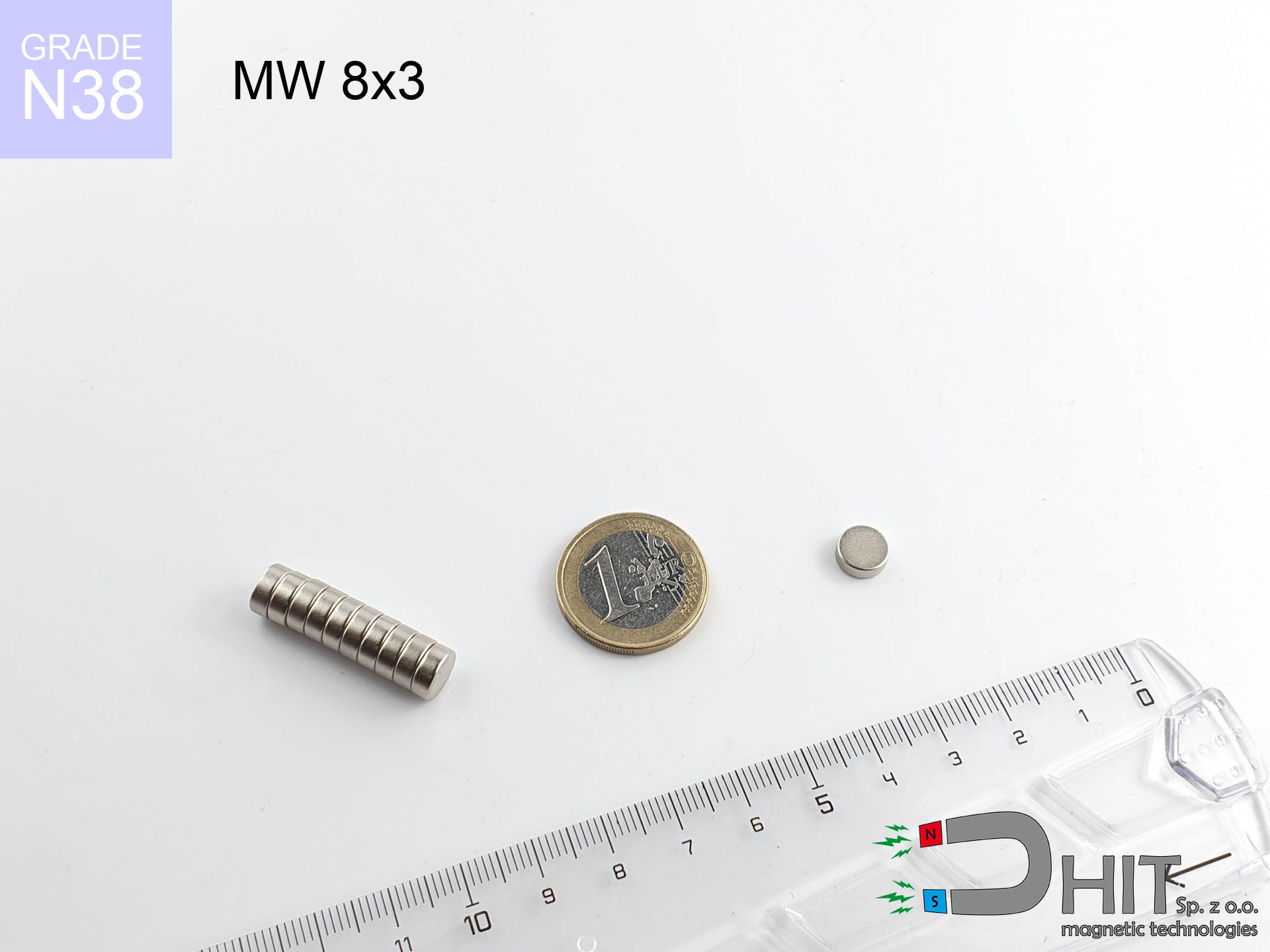

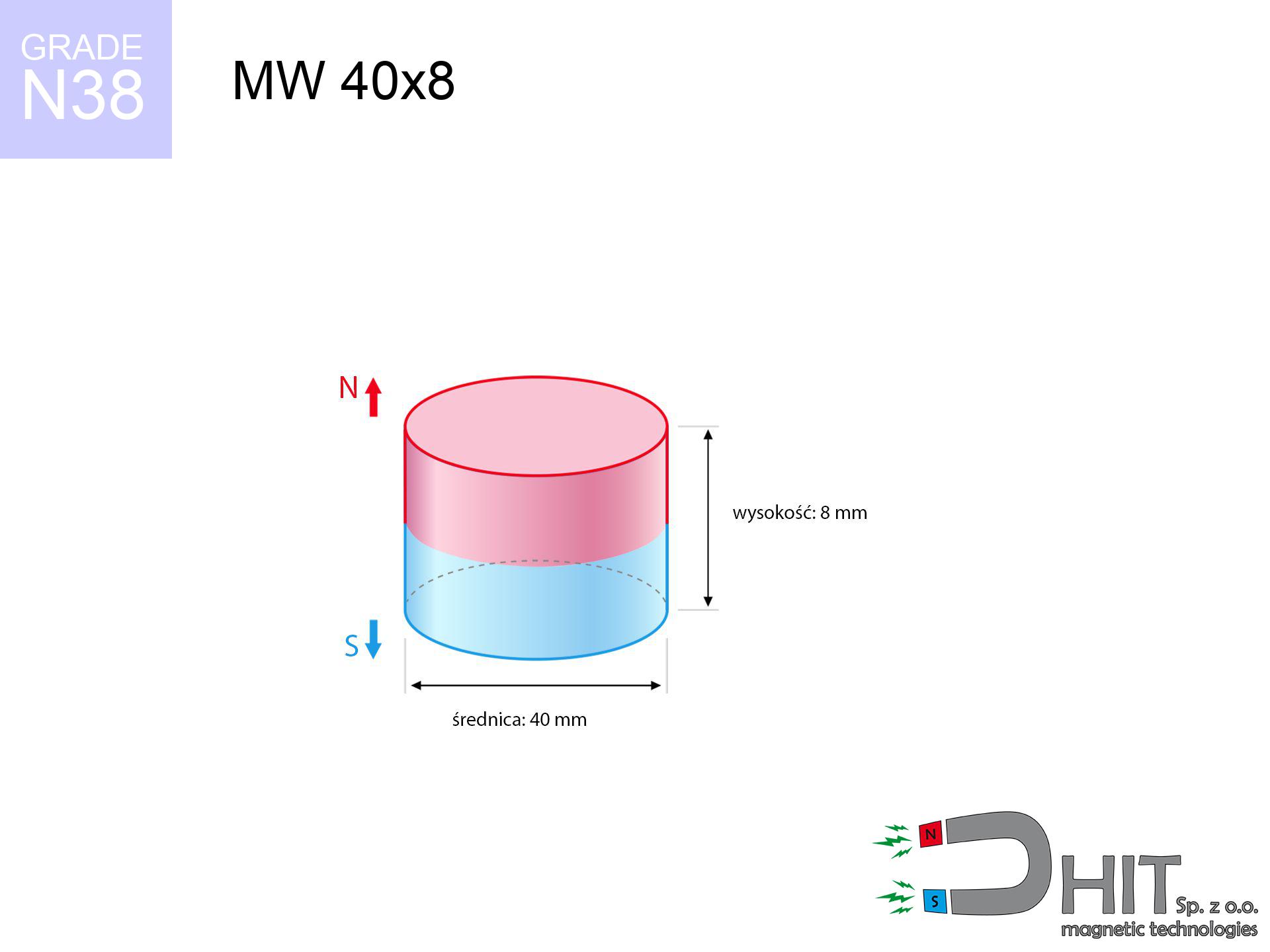

MW 40x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010069

GTIN/EAN: 5906301810681

Diameter Ø

40 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

75.4 g

Magnetization Direction

↑ axial

Load capacity

20.43 kg / 200.39 N

Magnetic Induction

230.22 mT / 2302 Gs

Coating

[NiCuNi] Nickel

31.27 ZŁ with VAT / pcs + price for transport

25.42 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively send us a note via

inquiry form

the contact page.

Weight along with appearance of magnetic components can be calculated with our

power calculator.

Same-day processing for orders placed before 14:00.

Product card - MW 40x8 / N38 - cylindrical magnet

Specification / characteristics - MW 40x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010069 |

| GTIN/EAN | 5906301810681 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 40 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 75.4 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 20.43 kg / 200.39 N |

| Magnetic Induction ~ ? | 230.22 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - report

The following information represent the direct effect of a physical calculation. Results were calculated on models for the class Nd2Fe14B. Operational performance may differ. Use these data as a preliminary roadmap when designing systems.

Table 1: Static force (force vs distance) - power drop

MW 40x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2302 Gs

230.2 mT

|

20.43 kg / 45.04 pounds

20430.0 g / 200.4 N

|

dangerous! |

| 1 mm |

2235 Gs

223.5 mT

|

19.25 kg / 42.44 pounds

19252.0 g / 188.9 N

|

dangerous! |

| 2 mm |

2156 Gs

215.6 mT

|

17.92 kg / 39.50 pounds

17917.4 g / 175.8 N

|

dangerous! |

| 3 mm |

2068 Gs

206.8 mT

|

16.49 kg / 36.36 pounds

16490.6 g / 161.8 N

|

dangerous! |

| 5 mm |

1875 Gs

187.5 mT

|

13.56 kg / 29.89 pounds

13556.7 g / 133.0 N

|

dangerous! |

| 10 mm |

1375 Gs

137.5 mT

|

7.29 kg / 16.07 pounds

7287.4 g / 71.5 N

|

strong |

| 15 mm |

959 Gs

95.9 mT

|

3.54 kg / 7.81 pounds

3542.3 g / 34.8 N

|

strong |

| 20 mm |

661 Gs

66.1 mT

|

1.68 kg / 3.71 pounds

1684.9 g / 16.5 N

|

safe |

| 30 mm |

328 Gs

32.8 mT

|

0.41 kg / 0.91 pounds

414.2 g / 4.1 N

|

safe |

| 50 mm |

105 Gs

10.5 mT

|

0.04 kg / 0.09 pounds

42.3 g / 0.4 N

|

safe |

Table 2: Sliding capacity (wall)

MW 40x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.09 kg / 9.01 pounds

4086.0 g / 40.1 N

|

| 1 mm | Stal (~0.2) |

3.85 kg / 8.49 pounds

3850.0 g / 37.8 N

|

| 2 mm | Stal (~0.2) |

3.58 kg / 7.90 pounds

3584.0 g / 35.2 N

|

| 3 mm | Stal (~0.2) |

3.30 kg / 7.27 pounds

3298.0 g / 32.4 N

|

| 5 mm | Stal (~0.2) |

2.71 kg / 5.98 pounds

2712.0 g / 26.6 N

|

| 10 mm | Stal (~0.2) |

1.46 kg / 3.21 pounds

1458.0 g / 14.3 N

|

| 15 mm | Stal (~0.2) |

0.71 kg / 1.56 pounds

708.0 g / 6.9 N

|

| 20 mm | Stal (~0.2) |

0.34 kg / 0.74 pounds

336.0 g / 3.3 N

|

| 30 mm | Stal (~0.2) |

0.08 kg / 0.18 pounds

82.0 g / 0.8 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

8.0 g / 0.1 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 40x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

6.13 kg / 13.51 pounds

6129.0 g / 60.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.09 kg / 9.01 pounds

4086.0 g / 40.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.04 kg / 4.50 pounds

2043.0 g / 20.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

10.22 kg / 22.52 pounds

10215.0 g / 100.2 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 40x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.02 kg / 2.25 pounds

1021.5 g / 10.0 N

|

| 1 mm |

|

2.55 kg / 5.63 pounds

2553.8 g / 25.1 N

|

| 2 mm |

|

5.11 kg / 11.26 pounds

5107.5 g / 50.1 N

|

| 3 mm |

|

7.66 kg / 16.89 pounds

7661.3 g / 75.2 N

|

| 5 mm |

|

12.77 kg / 28.15 pounds

12768.8 g / 125.3 N

|

| 10 mm |

|

20.43 kg / 45.04 pounds

20430.0 g / 200.4 N

|

| 11 mm |

|

20.43 kg / 45.04 pounds

20430.0 g / 200.4 N

|

| 12 mm |

|

20.43 kg / 45.04 pounds

20430.0 g / 200.4 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 40x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

20.43 kg / 45.04 pounds

20430.0 g / 200.4 N

|

OK |

| 40 °C | -2.2% |

19.98 kg / 44.05 pounds

19980.5 g / 196.0 N

|

OK |

| 60 °C | -4.4% |

19.53 kg / 43.06 pounds

19531.1 g / 191.6 N

|

|

| 80 °C | -6.6% |

19.08 kg / 42.07 pounds

19081.6 g / 187.2 N

|

|

| 100 °C | -28.8% |

14.55 kg / 32.07 pounds

14546.2 g / 142.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 40x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

41.05 kg / 90.51 pounds

3 871 Gs

|

6.16 kg / 13.58 pounds

6158 g / 60.4 N

|

N/A |

| 1 mm |

39.92 kg / 88.02 pounds

4 540 Gs

|

5.99 kg / 13.20 pounds

5989 g / 58.7 N

|

35.93 kg / 79.22 pounds

~0 Gs

|

| 2 mm |

38.69 kg / 85.29 pounds

4 469 Gs

|

5.80 kg / 12.79 pounds

5803 g / 56.9 N

|

34.82 kg / 76.76 pounds

~0 Gs

|

| 3 mm |

37.38 kg / 82.40 pounds

4 393 Gs

|

5.61 kg / 12.36 pounds

5606 g / 55.0 N

|

33.64 kg / 74.16 pounds

~0 Gs

|

| 5 mm |

34.59 kg / 76.25 pounds

4 226 Gs

|

5.19 kg / 11.44 pounds

5188 g / 50.9 N

|

31.13 kg / 68.63 pounds

~0 Gs

|

| 10 mm |

27.24 kg / 60.06 pounds

3 750 Gs

|

4.09 kg / 9.01 pounds

4086 g / 40.1 N

|

24.52 kg / 54.05 pounds

~0 Gs

|

| 20 mm |

14.64 kg / 32.28 pounds

2 750 Gs

|

2.20 kg / 4.84 pounds

2197 g / 21.5 N

|

13.18 kg / 29.06 pounds

~0 Gs

|

| 50 mm |

1.65 kg / 3.63 pounds

922 Gs

|

0.25 kg / 0.54 pounds

247 g / 2.4 N

|

1.48 kg / 3.26 pounds

~0 Gs

|

| 60 mm |

0.83 kg / 1.84 pounds

656 Gs

|

0.12 kg / 0.28 pounds

125 g / 1.2 N

|

0.75 kg / 1.65 pounds

~0 Gs

|

| 70 mm |

0.44 kg / 0.97 pounds

477 Gs

|

0.07 kg / 0.15 pounds

66 g / 0.6 N

|

0.40 kg / 0.87 pounds

~0 Gs

|

| 80 mm |

0.24 kg / 0.54 pounds

355 Gs

|

0.04 kg / 0.08 pounds

37 g / 0.4 N

|

0.22 kg / 0.49 pounds

~0 Gs

|

| 90 mm |

0.14 kg / 0.31 pounds

270 Gs

|

0.02 kg / 0.05 pounds

21 g / 0.2 N

|

0.13 kg / 0.28 pounds

~0 Gs

|

| 100 mm |

0.09 kg / 0.19 pounds

210 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 40x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 15.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 12.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 9.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 7.5 cm |

| Remote | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 40x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.96 km/h

(5.54 m/s)

|

1.16 J | |

| 30 mm |

29.12 km/h

(8.09 m/s)

|

2.47 J | |

| 50 mm |

37.17 km/h

(10.32 m/s)

|

4.02 J | |

| 100 mm |

52.50 km/h

(14.58 m/s)

|

8.02 J |

Table 9: Surface protection spec

MW 40x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 40x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 33 553 Mx | 335.5 µWb |

| Pc Coefficient | 0.29 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 40x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 20.43 kg | Standard |

| Water (riverbed) |

23.39 kg

(+2.96 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet retains just a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) severely weakens the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.29

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths as well as weaknesses of neodymium magnets.

Pros

- They do not lose magnetism, even during approximately ten years – the drop in power is only ~1% (based on measurements),

- Magnets perfectly defend themselves against loss of magnetization caused by ambient magnetic noise,

- Thanks to the shimmering finish, the coating of nickel, gold, or silver gives an clean appearance,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of detailed creating as well as adjusting to atypical applications,

- Key role in modern industrial fields – they serve a role in mass storage devices, brushless drives, advanced medical instruments, also technologically advanced constructions.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing nuts and complicated forms in magnets, we propose using casing - magnetic holder.

- Health risk related to microscopic parts of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. Additionally, small elements of these devices are able to complicate diagnosis medical after entering the body.

- Due to neodymium price, their price is relatively high,

Lifting parameters

Highest magnetic holding force – what contributes to it?

- on a plate made of mild steel, optimally conducting the magnetic flux

- with a thickness minimum 10 mm

- characterized by even structure

- under conditions of no distance (metal-to-metal)

- under axial application of breakaway force (90-degree angle)

- in stable room temperature

Impact of factors on magnetic holding capacity in practice

- Distance – the presence of any layer (rust, dirt, air) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Direction of force – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is standardly many times lower (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick steel causes magnetic saturation, causing part of the flux to be lost into the air.

- Steel grade – ideal substrate is pure iron steel. Stainless steels may have worse magnetic properties.

- Plate texture – ground elements ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Temperature – heating the magnet results in weakening of induction. Check the maximum operating temperature for a given model.

Lifting capacity was measured with the use of a smooth steel plate of suitable thickness (min. 20 mm), under vertically applied force, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a minimal clearance between the magnet and the plate decreases the holding force.

Precautions when working with NdFeB magnets

No play value

Absolutely store magnets out of reach of children. Choking hazard is high, and the consequences of magnets connecting inside the body are fatal.

Conscious usage

Before starting, read the rules. Sudden snapping can break the magnet or injure your hand. Be predictive.

Fire risk

Mechanical processing of NdFeB material carries a risk of fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Pacemakers

Patients with a pacemaker must maintain an safe separation from magnets. The magnetism can stop the functioning of the life-saving device.

Electronic hazard

Avoid bringing magnets near a wallet, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Warning for allergy sufferers

Medical facts indicate that nickel (the usual finish) is a strong allergen. If your skin reacts to metals, refrain from touching magnets with bare hands or opt for versions in plastic housing.

Magnet fragility

NdFeB magnets are sintered ceramics, which means they are fragile like glass. Clashing of two magnets will cause them cracking into shards.

Permanent damage

Standard neodymium magnets (N-type) undergo demagnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Threat to navigation

GPS units and smartphones are extremely susceptible to magnetic fields. Direct contact with a strong magnet can permanently damage the sensors in your phone.

Crushing force

Mind your fingers. Two powerful magnets will join instantly with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

![AM ucho [M12] - magnetic accessories AM ucho [M12] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m12-maz.jpg)

![SM 32x250 [2xM8] / N42 - magnetic separator SM 32x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-kex.jpg)