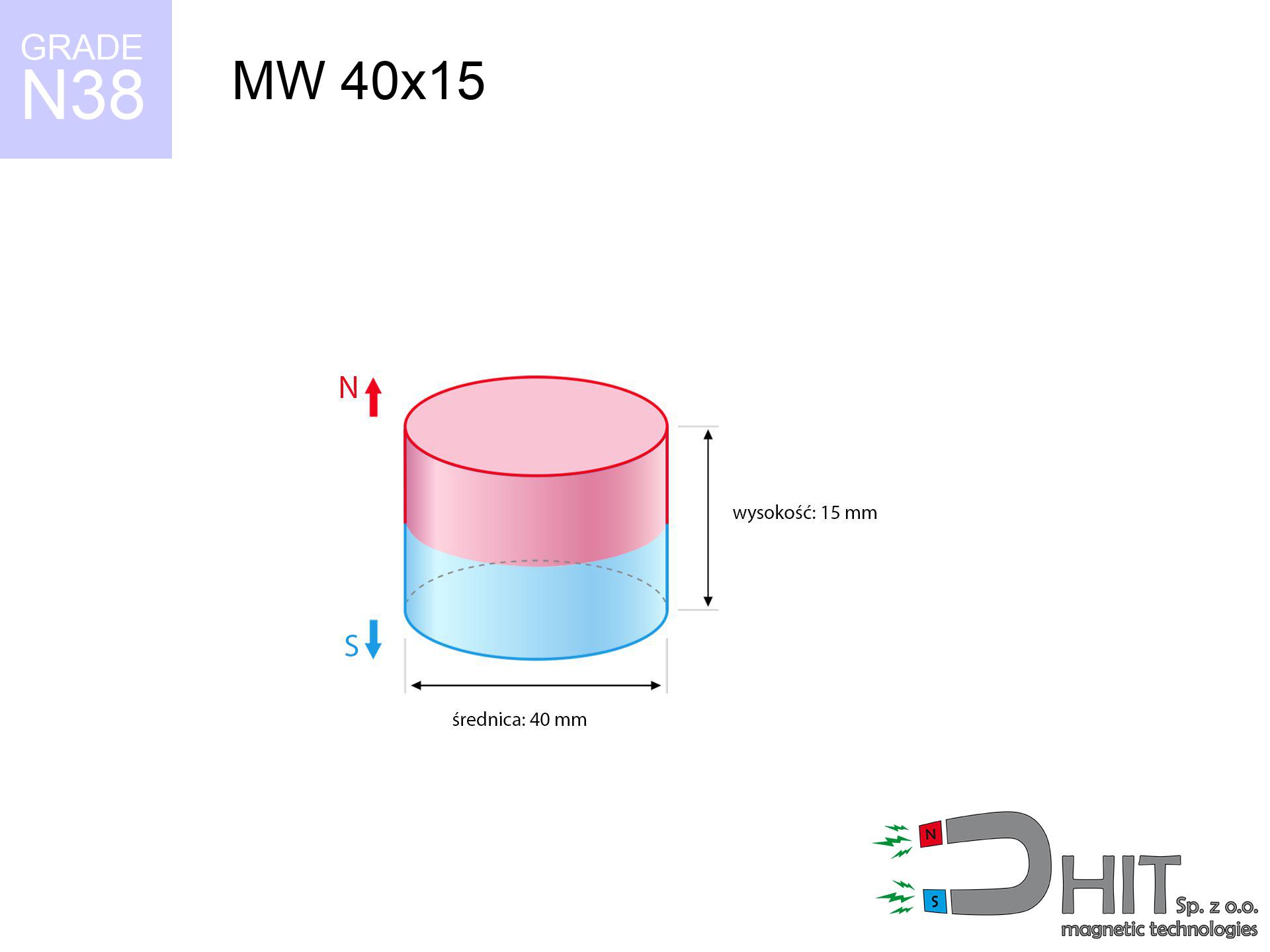

MW 40x15 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010067

GTIN/EAN: 5906301810667

Diameter Ø

40 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

141.37 g

Magnetization Direction

↑ axial

Load capacity

42.64 kg / 418.33 N

Magnetic Induction

371.91 mT / 3719 Gs

Coating

[NiCuNi] Nickel

65.93 ZŁ with VAT / pcs + price for transport

53.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise send us a note via

form

the contact form page.

Specifications along with structure of neodymium magnets can be tested using our

power calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - MW 40x15 / N38 - cylindrical magnet

Specification / characteristics - MW 40x15 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010067 |

| GTIN/EAN | 5906301810667 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 40 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 141.37 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 42.64 kg / 418.33 N |

| Magnetic Induction ~ ? | 371.91 mT / 3719 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the assembly - technical parameters

The following values are the outcome of a physical simulation. Results rely on algorithms for the material Nd2Fe14B. Actual parameters might slightly deviate from the simulation results. Treat these calculations as a supplementary guide for designers.

Table 1: Static force (force vs distance) - power drop

MW 40x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3718 Gs

371.8 mT

|

42.64 kg / 94.00 lbs

42640.0 g / 418.3 N

|

dangerous! |

| 1 mm |

3563 Gs

356.3 mT

|

39.16 kg / 86.33 lbs

39159.5 g / 384.2 N

|

dangerous! |

| 2 mm |

3398 Gs

339.8 mT

|

35.62 kg / 78.52 lbs

35617.1 g / 349.4 N

|

dangerous! |

| 3 mm |

3228 Gs

322.8 mT

|

32.13 kg / 70.84 lbs

32130.5 g / 315.2 N

|

dangerous! |

| 5 mm |

2880 Gs

288.0 mT

|

25.58 kg / 56.40 lbs

25584.2 g / 251.0 N

|

dangerous! |

| 10 mm |

2069 Gs

206.9 mT

|

13.20 kg / 29.09 lbs

13196.7 g / 129.5 N

|

dangerous! |

| 15 mm |

1439 Gs

143.9 mT

|

6.38 kg / 14.07 lbs

6383.1 g / 62.6 N

|

strong |

| 20 mm |

999 Gs

99.9 mT

|

3.08 kg / 6.79 lbs

3077.9 g / 30.2 N

|

strong |

| 30 mm |

507 Gs

50.7 mT

|

0.79 kg / 1.75 lbs

792.4 g / 7.8 N

|

safe |

| 50 mm |

169 Gs

16.9 mT

|

0.09 kg / 0.19 lbs

88.4 g / 0.9 N

|

safe |

Table 2: Shear capacity (vertical surface)

MW 40x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

8.53 kg / 18.80 lbs

8528.0 g / 83.7 N

|

| 1 mm | Stal (~0.2) |

7.83 kg / 17.27 lbs

7832.0 g / 76.8 N

|

| 2 mm | Stal (~0.2) |

7.12 kg / 15.71 lbs

7124.0 g / 69.9 N

|

| 3 mm | Stal (~0.2) |

6.43 kg / 14.17 lbs

6426.0 g / 63.0 N

|

| 5 mm | Stal (~0.2) |

5.12 kg / 11.28 lbs

5116.0 g / 50.2 N

|

| 10 mm | Stal (~0.2) |

2.64 kg / 5.82 lbs

2640.0 g / 25.9 N

|

| 15 mm | Stal (~0.2) |

1.28 kg / 2.81 lbs

1276.0 g / 12.5 N

|

| 20 mm | Stal (~0.2) |

0.62 kg / 1.36 lbs

616.0 g / 6.0 N

|

| 30 mm | Stal (~0.2) |

0.16 kg / 0.35 lbs

158.0 g / 1.5 N

|

| 50 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

18.0 g / 0.2 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 40x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

12.79 kg / 28.20 lbs

12792.0 g / 125.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

8.53 kg / 18.80 lbs

8528.0 g / 83.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.26 kg / 9.40 lbs

4264.0 g / 41.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

21.32 kg / 47.00 lbs

21320.0 g / 209.1 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 40x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.13 kg / 4.70 lbs

2132.0 g / 20.9 N

|

| 1 mm |

|

5.33 kg / 11.75 lbs

5330.0 g / 52.3 N

|

| 2 mm |

|

10.66 kg / 23.50 lbs

10660.0 g / 104.6 N

|

| 3 mm |

|

15.99 kg / 35.25 lbs

15990.0 g / 156.9 N

|

| 5 mm |

|

26.65 kg / 58.75 lbs

26650.0 g / 261.4 N

|

| 10 mm |

|

42.64 kg / 94.00 lbs

42640.0 g / 418.3 N

|

| 11 mm |

|

42.64 kg / 94.00 lbs

42640.0 g / 418.3 N

|

| 12 mm |

|

42.64 kg / 94.00 lbs

42640.0 g / 418.3 N

|

Table 5: Working in heat (stability) - power drop

MW 40x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

42.64 kg / 94.00 lbs

42640.0 g / 418.3 N

|

OK |

| 40 °C | -2.2% |

41.70 kg / 91.94 lbs

41701.9 g / 409.1 N

|

OK |

| 60 °C | -4.4% |

40.76 kg / 89.87 lbs

40763.8 g / 399.9 N

|

|

| 80 °C | -6.6% |

39.83 kg / 87.80 lbs

39825.8 g / 390.7 N

|

|

| 100 °C | -28.8% |

30.36 kg / 66.93 lbs

30359.7 g / 297.8 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 40x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

107.12 kg / 236.16 lbs

5 156 Gs

|

16.07 kg / 35.42 lbs

16068 g / 157.6 N

|

N/A |

| 1 mm |

102.82 kg / 226.67 lbs

7 286 Gs

|

15.42 kg / 34.00 lbs

15422 g / 151.3 N

|

92.53 kg / 204.00 lbs

~0 Gs

|

| 2 mm |

98.38 kg / 216.89 lbs

7 127 Gs

|

14.76 kg / 32.53 lbs

14757 g / 144.8 N

|

88.54 kg / 195.20 lbs

~0 Gs

|

| 3 mm |

93.92 kg / 207.06 lbs

6 964 Gs

|

14.09 kg / 31.06 lbs

14088 g / 138.2 N

|

84.53 kg / 186.36 lbs

~0 Gs

|

| 5 mm |

85.07 kg / 187.55 lbs

6 627 Gs

|

12.76 kg / 28.13 lbs

12760 g / 125.2 N

|

76.56 kg / 168.79 lbs

~0 Gs

|

| 10 mm |

64.27 kg / 141.70 lbs

5 761 Gs

|

9.64 kg / 21.25 lbs

9641 g / 94.6 N

|

57.85 kg / 127.53 lbs

~0 Gs

|

| 20 mm |

33.15 kg / 73.09 lbs

4 137 Gs

|

4.97 kg / 10.96 lbs

4973 g / 48.8 N

|

29.84 kg / 65.78 lbs

~0 Gs

|

| 50 mm |

3.84 kg / 8.47 lbs

1 408 Gs

|

0.58 kg / 1.27 lbs

576 g / 5.7 N

|

3.46 kg / 7.62 lbs

~0 Gs

|

| 60 mm |

1.99 kg / 4.39 lbs

1 014 Gs

|

0.30 kg / 0.66 lbs

299 g / 2.9 N

|

1.79 kg / 3.95 lbs

~0 Gs

|

| 70 mm |

1.08 kg / 2.38 lbs

747 Gs

|

0.16 kg / 0.36 lbs

162 g / 1.6 N

|

0.97 kg / 2.14 lbs

~0 Gs

|

| 80 mm |

0.61 kg / 1.35 lbs

563 Gs

|

0.09 kg / 0.20 lbs

92 g / 0.9 N

|

0.55 kg / 1.22 lbs

~0 Gs

|

| 90 mm |

0.36 kg / 0.80 lbs

432 Gs

|

0.05 kg / 0.12 lbs

54 g / 0.5 N

|

0.33 kg / 0.72 lbs

~0 Gs

|

| 100 mm |

0.22 kg / 0.49 lbs

339 Gs

|

0.03 kg / 0.07 lbs

33 g / 0.3 N

|

0.20 kg / 0.44 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 40x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 19.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 15.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 11.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 9.0 cm |

| Remote | 50 Gs (5.0 mT) | 8.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (cracking risk) - warning

MW 40x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.63 km/h

(5.73 m/s)

|

2.32 J | |

| 30 mm |

30.69 km/h

(8.52 m/s)

|

5.14 J | |

| 50 mm |

39.22 km/h

(10.89 m/s)

|

8.39 J | |

| 100 mm |

55.39 km/h

(15.39 m/s)

|

16.73 J |

Table 9: Corrosion resistance

MW 40x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 40x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 48 650 Mx | 486.5 µWb |

| Pc Coefficient | 0.48 | Low (Flat) |

Table 11: Submerged application

MW 40x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 42.64 kg | Standard |

| Water (riverbed) |

48.82 kg

(+6.18 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet retains only a fraction of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Temperature resistance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.48

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more products

Strengths as well as weaknesses of rare earth magnets.

Strengths

- They do not lose power, even during nearly 10 years – the drop in lifting capacity is only ~1% (theoretically),

- Magnets perfectly resist against loss of magnetization caused by ambient magnetic noise,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to look better,

- They feature high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to versatility in constructing and the ability to customize to complex applications,

- Significant place in future technologies – they find application in computer drives, drive modules, diagnostic systems, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in small systems

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We recommend casing - magnetic holder, due to difficulties in creating threads inside the magnet and complicated shapes.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which becomes key in the aspect of protecting the youngest. Additionally, tiny parts of these products can complicate diagnosis medical after entering the body.

- With large orders the cost of neodymium magnets is a challenge,

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- with the application of a yoke made of special test steel, ensuring full magnetic saturation

- possessing a massiveness of min. 10 mm to ensure full flux closure

- characterized by smoothness

- without the slightest air gap between the magnet and steel

- during detachment in a direction vertical to the plane

- at room temperature

Practical lifting capacity: influencing factors

- Distance – existence of any layer (paint, dirt, air) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Plate thickness – too thin steel does not close the flux, causing part of the power to be wasted into the air.

- Chemical composition of the base – mild steel gives the best results. Higher carbon content lower magnetic properties and holding force.

- Surface structure – the more even the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Temperature – heating the magnet causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was assessed by applying a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, however under attempts to slide the magnet the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate lowers the load capacity.

Precautions when working with neodymium magnets

Fire risk

Mechanical processing of NdFeB material carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Bone fractures

Danger of trauma: The attraction force is so immense that it can cause blood blisters, pinching, and broken bones. Protective gloves are recommended.

Magnetic media

Data protection: Neodymium magnets can damage data carriers and delicate electronics (pacemakers, hearing aids, timepieces).

Implant safety

Medical warning: Neodymium magnets can deactivate heart devices and defibrillators. Do not approach if you have medical devices.

Allergic reactions

Allergy Notice: The Ni-Cu-Ni coating consists of nickel. If skin irritation occurs, immediately stop working with magnets and use protective gear.

GPS Danger

GPS units and mobile phones are extremely sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

This is not a toy

Strictly keep magnets out of reach of children. Risk of swallowing is significant, and the consequences of magnets clamping inside the body are tragic.

Immense force

Before use, read the rules. Uncontrolled attraction can break the magnet or hurt your hand. Be predictive.

Do not overheat magnets

Watch the temperature. Heating the magnet above 80 degrees Celsius will ruin its properties and strength.

Risk of cracking

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. Wear goggles.

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)