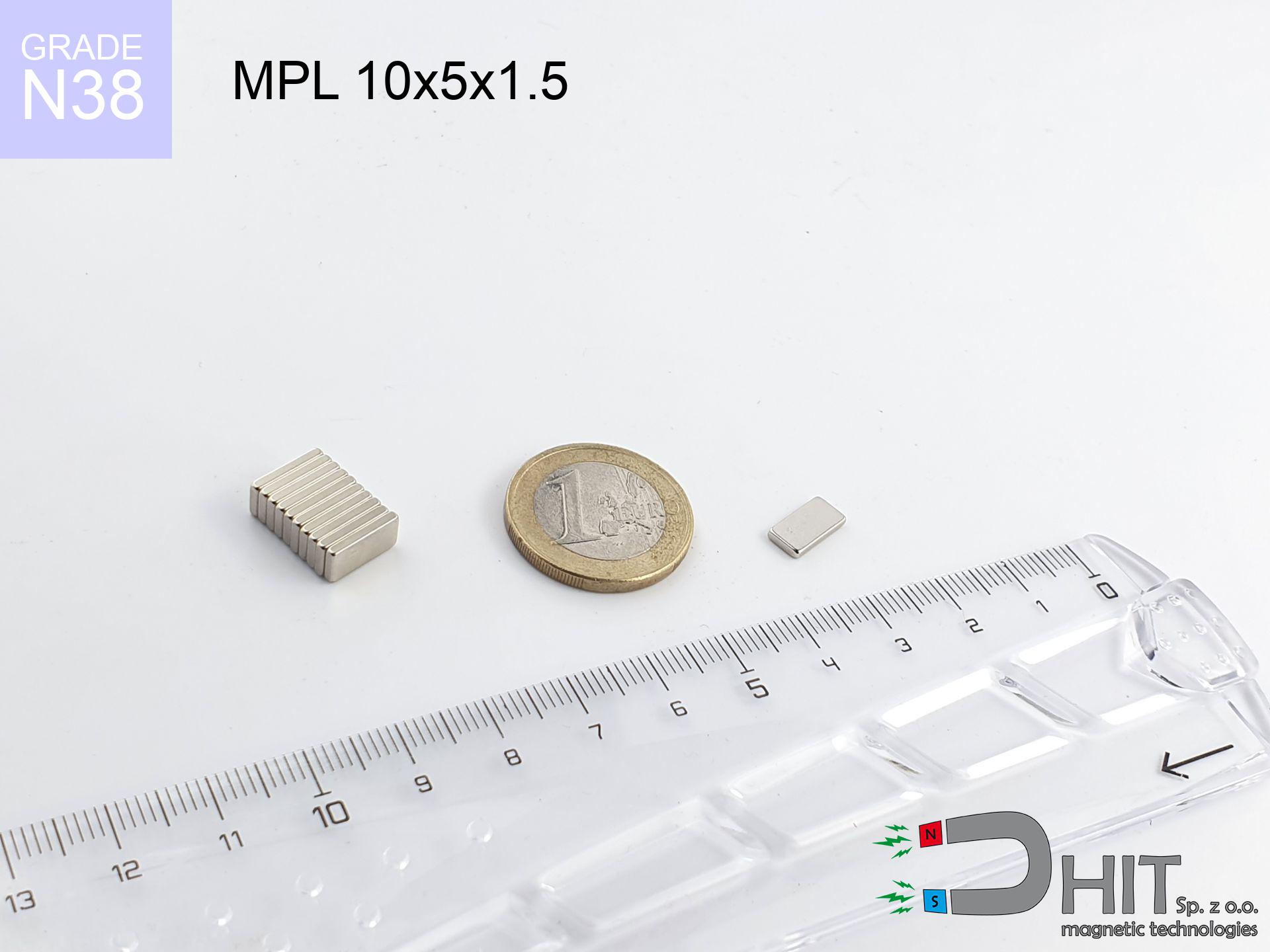

MPL 10x5x1.5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020114

GTIN/EAN: 5906301811206

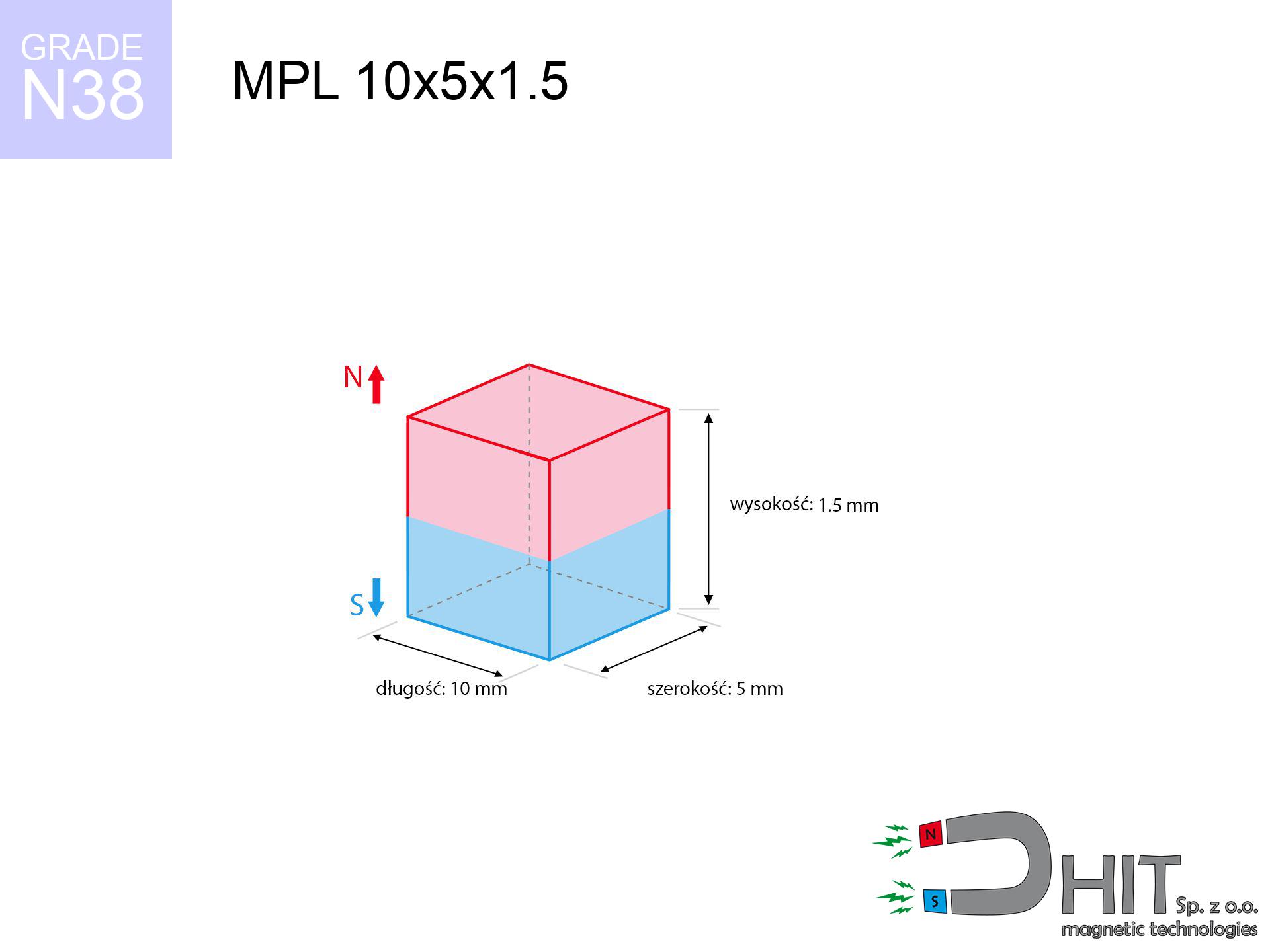

length

10 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

0.56 g

Magnetization Direction

↑ axial

Load capacity

0.86 kg / 8.47 N

Magnetic Induction

239.33 mT / 2393 Gs

Coating

[NiCuNi] Nickel

0.381 ZŁ with VAT / pcs + price for transport

0.310 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

if you prefer drop us a message through

request form

the contact page.

Strength as well as structure of magnetic components can be calculated on our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MPL 10x5x1.5 / N38 - lamellar magnet

Specification / characteristics - MPL 10x5x1.5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020114 |

| GTIN/EAN | 5906301811206 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 10 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 0.56 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.86 kg / 8.47 N |

| Magnetic Induction ~ ? | 239.33 mT / 2393 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the product - data

Presented data represent the result of a physical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Operational performance may differ. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs distance) - power drop

MPL 10x5x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2392 Gs

239.2 mT

|

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

safe |

| 1 mm |

1814 Gs

181.4 mT

|

0.49 kg / 1.09 LBS

494.9 g / 4.9 N

|

safe |

| 2 mm |

1242 Gs

124.2 mT

|

0.23 kg / 0.51 LBS

232.1 g / 2.3 N

|

safe |

| 3 mm |

836 Gs

83.6 mT

|

0.11 kg / 0.23 LBS

105.1 g / 1.0 N

|

safe |

| 5 mm |

399 Gs

39.9 mT

|

0.02 kg / 0.05 LBS

23.9 g / 0.2 N

|

safe |

| 10 mm |

94 Gs

9.4 mT

|

0.00 kg / 0.00 LBS

1.3 g / 0.0 N

|

safe |

| 15 mm |

34 Gs

3.4 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

safe |

| 20 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Sliding force (vertical surface)

MPL 10x5x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.17 kg / 0.38 LBS

172.0 g / 1.7 N

|

| 1 mm | Stal (~0.2) |

0.10 kg / 0.22 LBS

98.0 g / 1.0 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.10 LBS

46.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

22.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 10x5x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.26 kg / 0.57 LBS

258.0 g / 2.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.17 kg / 0.38 LBS

172.0 g / 1.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.09 kg / 0.19 LBS

86.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.43 kg / 0.95 LBS

430.0 g / 4.2 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 10x5x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.09 kg / 0.19 LBS

86.0 g / 0.8 N

|

| 1 mm |

|

0.22 kg / 0.47 LBS

215.0 g / 2.1 N

|

| 2 mm |

|

0.43 kg / 0.95 LBS

430.0 g / 4.2 N

|

| 3 mm |

|

0.65 kg / 1.42 LBS

645.0 g / 6.3 N

|

| 5 mm |

|

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

| 10 mm |

|

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

| 11 mm |

|

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

| 12 mm |

|

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 10x5x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

OK |

| 40 °C | -2.2% |

0.84 kg / 1.85 LBS

841.1 g / 8.3 N

|

OK |

| 60 °C | -4.4% |

0.82 kg / 1.81 LBS

822.2 g / 8.1 N

|

|

| 80 °C | -6.6% |

0.80 kg / 1.77 LBS

803.2 g / 7.9 N

|

|

| 100 °C | -28.8% |

0.61 kg / 1.35 LBS

612.3 g / 6.0 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 10x5x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.76 kg / 3.89 LBS

3 896 Gs

|

0.26 kg / 0.58 LBS

264 g / 2.6 N

|

N/A |

| 1 mm |

1.39 kg / 3.07 LBS

4 254 Gs

|

0.21 kg / 0.46 LBS

209 g / 2.1 N

|

1.26 kg / 2.77 LBS

~0 Gs

|

| 2 mm |

1.01 kg / 2.24 LBS

3 628 Gs

|

0.15 kg / 0.34 LBS

152 g / 1.5 N

|

0.91 kg / 2.01 LBS

~0 Gs

|

| 3 mm |

0.70 kg / 1.55 LBS

3 020 Gs

|

0.11 kg / 0.23 LBS

105 g / 1.0 N

|

0.63 kg / 1.39 LBS

~0 Gs

|

| 5 mm |

0.32 kg / 0.70 LBS

2 037 Gs

|

0.05 kg / 0.11 LBS

48 g / 0.5 N

|

0.29 kg / 0.63 LBS

~0 Gs

|

| 10 mm |

0.05 kg / 0.11 LBS

798 Gs

|

0.01 kg / 0.02 LBS

7 g / 0.1 N

|

0.04 kg / 0.10 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 LBS

188 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

10 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MPL 10x5x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (cracking risk) - warning

MPL 10x5x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

39.56 km/h

(10.99 m/s)

|

0.03 J | |

| 30 mm |

68.45 km/h

(19.02 m/s)

|

0.10 J | |

| 50 mm |

88.37 km/h

(24.55 m/s)

|

0.17 J | |

| 100 mm |

124.98 km/h

(34.72 m/s)

|

0.34 J |

Table 9: Corrosion resistance

MPL 10x5x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 10x5x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 281 Mx | 12.8 µWb |

| Pc Coefficient | 0.27 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 10x5x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.86 kg | Standard |

| Water (riverbed) |

0.98 kg

(+0.12 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet holds just ~20% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.27

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over nearly 10 years their attraction force decreases symbolically – ~1% (according to theory),

- Neodymium magnets are distinguished by extremely resistant to demagnetization caused by external magnetic fields,

- The use of an metallic finish of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- They show high magnetic induction at the operating surface, making them more effective,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures reaching 230°C and above...

- Thanks to versatility in constructing and the ability to modify to unusual requirements,

- Wide application in modern technologies – they are utilized in hard drives, motor assemblies, medical equipment, and industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in small systems

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- NdFeB magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited possibility of making threads in the magnet and complicated forms - recommended is a housing - mounting mechanism.

- Possible danger to health – tiny shards of magnets are risky, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these products are able to be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- using a base made of high-permeability steel, functioning as a ideal flux conductor

- whose thickness equals approx. 10 mm

- with an ground touching surface

- with direct contact (without paint)

- under vertical force vector (90-degree angle)

- in stable room temperature

Key elements affecting lifting force

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Steel thickness – insufficiently thick sheet causes magnetic saturation, causing part of the power to be escaped to the other side.

- Steel type – mild steel gives the best results. Alloy admixtures reduce magnetic permeability and lifting capacity.

- Surface finish – ideal contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Temperature influence – high temperature reduces magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity was measured using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, in contrast under shearing force the load capacity is reduced by as much as fivefold. Moreover, even a small distance between the magnet’s surface and the plate decreases the holding force.

Precautions when working with neodymium magnets

Dust explosion hazard

Dust generated during grinding of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Phone sensors

GPS units and mobile phones are extremely susceptible to magnetism. Direct contact with a strong magnet can decalibrate the internal compass in your phone.

ICD Warning

Health Alert: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Crushing force

Danger of trauma: The attraction force is so immense that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Caution required

Before use, read the rules. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Warning for allergy sufferers

Certain individuals have a sensitization to Ni, which is the standard coating for NdFeB magnets. Frequent touching can result in a rash. We recommend use protective gloves.

Permanent damage

Do not overheat. Neodymium magnets are sensitive to heat. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Beware of splinters

Despite metallic appearance, neodymium is delicate and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Choking Hazard

Only for adults. Tiny parts pose a choking risk, leading to serious injuries. Keep away from kids and pets.

Electronic hazard

Powerful magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

![UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-75x34x18-m10-gz-xid.jpg)

![SM 25x275 [2xM8] / N42 - magnetic separator SM 25x275 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x275-2xm8-boc.jpg)

![MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x10x5x27-3.5-miw.jpg)