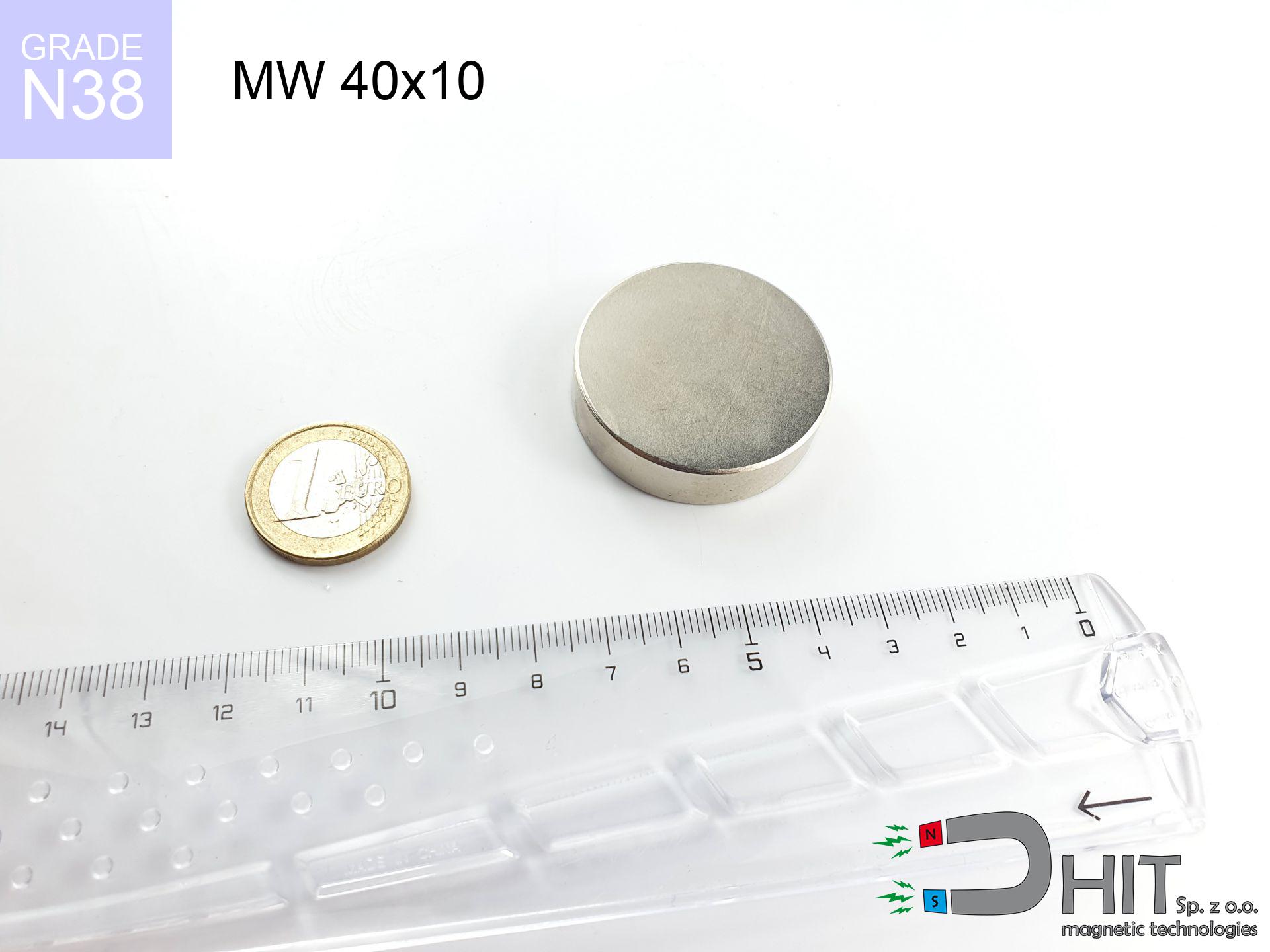

MW 40x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010066

GTIN/EAN: 5906301810650

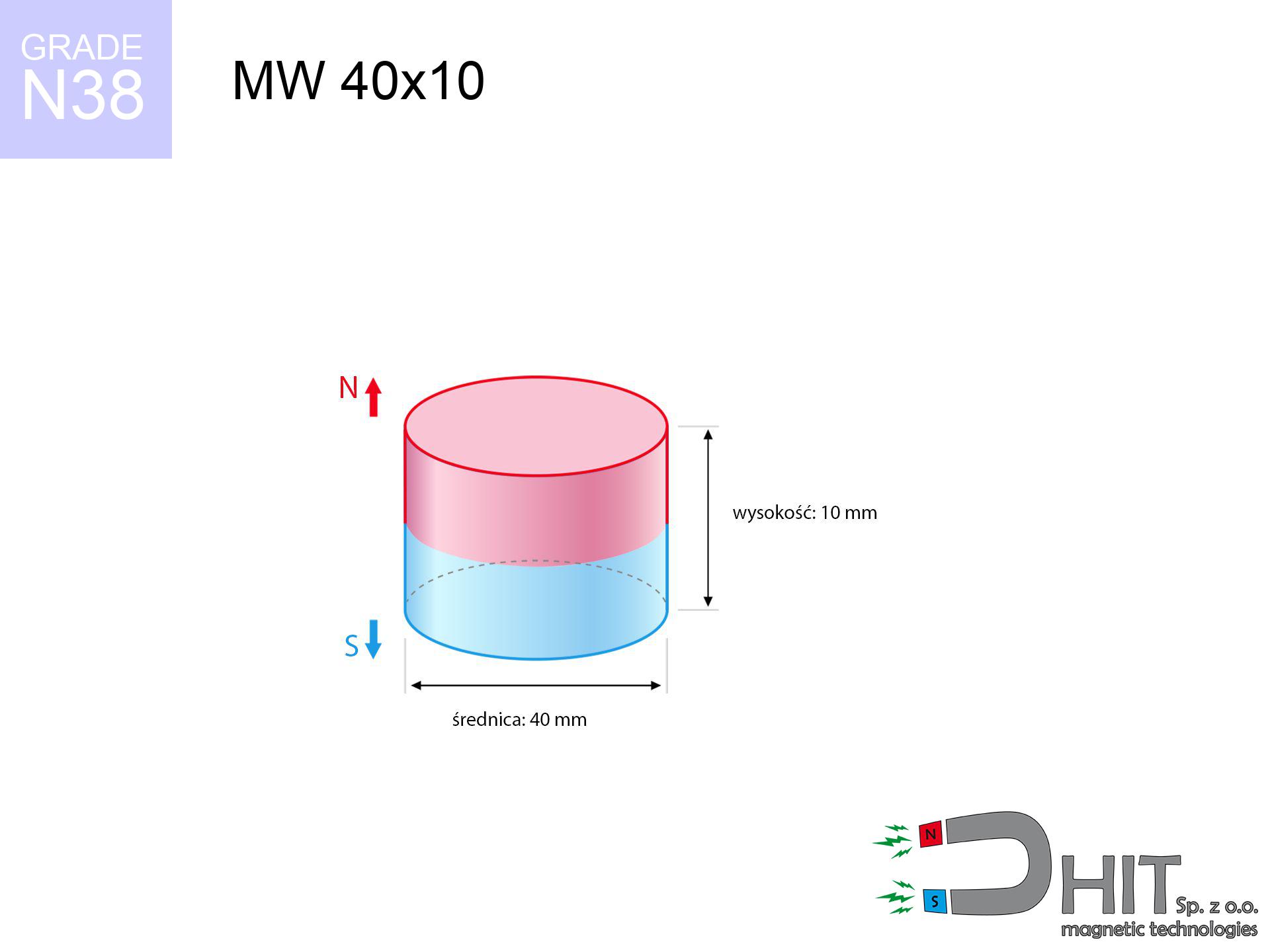

Diameter Ø

40 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

94.25 g

Magnetization Direction

↑ axial

Load capacity

27.73 kg / 271.99 N

Magnetic Induction

277.22 mT / 2772 Gs

Coating

[NiCuNi] Nickel

36.57 ZŁ with VAT / pcs + price for transport

29.73 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer contact us through

request form

our website.

Parameters along with shape of a neodymium magnet can be analyzed on our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical of the product - MW 40x10 / N38 - cylindrical magnet

Specification / characteristics - MW 40x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010066 |

| GTIN/EAN | 5906301810650 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 40 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 94.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 27.73 kg / 271.99 N |

| Magnetic Induction ~ ? | 277.22 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - technical parameters

These data represent the result of a physical analysis. Values are based on models for the material Nd2Fe14B. Real-world performance may differ from theoretical values. Please consider these data as a supplementary guide for designers.

Table 1: Static pull force (pull vs distance) - power drop

MW 40x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2772 Gs

277.2 mT

|

27.73 kg / 61.13 pounds

27730.0 g / 272.0 N

|

crushing |

| 1 mm |

2678 Gs

267.8 mT

|

25.89 kg / 57.08 pounds

25889.6 g / 254.0 N

|

crushing |

| 2 mm |

2573 Gs

257.3 mT

|

23.89 kg / 52.68 pounds

23893.3 g / 234.4 N

|

crushing |

| 3 mm |

2459 Gs

245.9 mT

|

21.83 kg / 48.12 pounds

21827.6 g / 214.1 N

|

crushing |

| 5 mm |

2216 Gs

221.6 mT

|

17.73 kg / 39.08 pounds

17728.1 g / 173.9 N

|

crushing |

| 10 mm |

1611 Gs

161.1 mT

|

9.37 kg / 20.66 pounds

9371.0 g / 91.9 N

|

medium risk |

| 15 mm |

1121 Gs

112.1 mT

|

4.54 kg / 10.01 pounds

4538.6 g / 44.5 N

|

medium risk |

| 20 mm |

775 Gs

77.5 mT

|

2.17 kg / 4.77 pounds

2165.8 g / 21.2 N

|

medium risk |

| 30 mm |

387 Gs

38.7 mT

|

0.54 kg / 1.19 pounds

539.8 g / 5.3 N

|

weak grip |

| 50 mm |

125 Gs

12.5 mT

|

0.06 kg / 0.12 pounds

56.6 g / 0.6 N

|

weak grip |

Table 2: Vertical capacity (wall)

MW 40x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

5.55 kg / 12.23 pounds

5546.0 g / 54.4 N

|

| 1 mm | Stal (~0.2) |

5.18 kg / 11.42 pounds

5178.0 g / 50.8 N

|

| 2 mm | Stal (~0.2) |

4.78 kg / 10.53 pounds

4778.0 g / 46.9 N

|

| 3 mm | Stal (~0.2) |

4.37 kg / 9.63 pounds

4366.0 g / 42.8 N

|

| 5 mm | Stal (~0.2) |

3.55 kg / 7.82 pounds

3546.0 g / 34.8 N

|

| 10 mm | Stal (~0.2) |

1.87 kg / 4.13 pounds

1874.0 g / 18.4 N

|

| 15 mm | Stal (~0.2) |

0.91 kg / 2.00 pounds

908.0 g / 8.9 N

|

| 20 mm | Stal (~0.2) |

0.43 kg / 0.96 pounds

434.0 g / 4.3 N

|

| 30 mm | Stal (~0.2) |

0.11 kg / 0.24 pounds

108.0 g / 1.1 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 40x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

8.32 kg / 18.34 pounds

8319.0 g / 81.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

5.55 kg / 12.23 pounds

5546.0 g / 54.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.77 kg / 6.11 pounds

2773.0 g / 27.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

13.87 kg / 30.57 pounds

13865.0 g / 136.0 N

|

Table 4: Steel thickness (saturation) - power losses

MW 40x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.39 kg / 3.06 pounds

1386.5 g / 13.6 N

|

| 1 mm |

|

3.47 kg / 7.64 pounds

3466.3 g / 34.0 N

|

| 2 mm |

|

6.93 kg / 15.28 pounds

6932.5 g / 68.0 N

|

| 3 mm |

|

10.40 kg / 22.93 pounds

10398.8 g / 102.0 N

|

| 5 mm |

|

17.33 kg / 38.21 pounds

17331.3 g / 170.0 N

|

| 10 mm |

|

27.73 kg / 61.13 pounds

27730.0 g / 272.0 N

|

| 11 mm |

|

27.73 kg / 61.13 pounds

27730.0 g / 272.0 N

|

| 12 mm |

|

27.73 kg / 61.13 pounds

27730.0 g / 272.0 N

|

Table 5: Working in heat (stability) - thermal limit

MW 40x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

27.73 kg / 61.13 pounds

27730.0 g / 272.0 N

|

OK |

| 40 °C | -2.2% |

27.12 kg / 59.79 pounds

27119.9 g / 266.0 N

|

OK |

| 60 °C | -4.4% |

26.51 kg / 58.44 pounds

26509.9 g / 260.1 N

|

|

| 80 °C | -6.6% |

25.90 kg / 57.10 pounds

25899.8 g / 254.1 N

|

|

| 100 °C | -28.8% |

19.74 kg / 43.53 pounds

19743.8 g / 193.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 40x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

59.52 kg / 131.22 pounds

4 382 Gs

|

8.93 kg / 19.68 pounds

8928 g / 87.6 N

|

N/A |

| 1 mm |

57.61 kg / 127.01 pounds

5 454 Gs

|

8.64 kg / 19.05 pounds

8642 g / 84.8 N

|

51.85 kg / 114.31 pounds

~0 Gs

|

| 2 mm |

55.57 kg / 122.52 pounds

5 357 Gs

|

8.34 kg / 18.38 pounds

8336 g / 81.8 N

|

50.01 kg / 110.26 pounds

~0 Gs

|

| 3 mm |

53.46 kg / 117.85 pounds

5 254 Gs

|

8.02 kg / 17.68 pounds

8019 g / 78.7 N

|

48.11 kg / 106.07 pounds

~0 Gs

|

| 5 mm |

49.08 kg / 108.20 pounds

5 034 Gs

|

7.36 kg / 16.23 pounds

7362 g / 72.2 N

|

44.17 kg / 97.38 pounds

~0 Gs

|

| 10 mm |

38.05 kg / 83.89 pounds

4 433 Gs

|

5.71 kg / 12.58 pounds

5708 g / 56.0 N

|

34.25 kg / 75.50 pounds

~0 Gs

|

| 20 mm |

20.11 kg / 44.35 pounds

3 223 Gs

|

3.02 kg / 6.65 pounds

3017 g / 29.6 N

|

18.10 kg / 39.91 pounds

~0 Gs

|

| 50 mm |

2.27 kg / 5.01 pounds

1 083 Gs

|

0.34 kg / 0.75 pounds

341 g / 3.3 N

|

2.05 kg / 4.51 pounds

~0 Gs

|

| 60 mm |

1.16 kg / 2.55 pounds

773 Gs

|

0.17 kg / 0.38 pounds

174 g / 1.7 N

|

1.04 kg / 2.30 pounds

~0 Gs

|

| 70 mm |

0.62 kg / 1.36 pounds

565 Gs

|

0.09 kg / 0.20 pounds

93 g / 0.9 N

|

0.56 kg / 1.23 pounds

~0 Gs

|

| 80 mm |

0.35 kg / 0.76 pounds

422 Gs

|

0.05 kg / 0.11 pounds

52 g / 0.5 N

|

0.31 kg / 0.69 pounds

~0 Gs

|

| 90 mm |

0.20 kg / 0.44 pounds

322 Gs

|

0.03 kg / 0.07 pounds

30 g / 0.3 N

|

0.18 kg / 0.40 pounds

~0 Gs

|

| 100 mm |

0.12 kg / 0.27 pounds

251 Gs

|

0.02 kg / 0.04 pounds

18 g / 0.2 N

|

0.11 kg / 0.24 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 40x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.0 cm |

| Remote | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 40x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.63 km/h

(5.73 m/s)

|

1.55 J | |

| 30 mm |

30.32 km/h

(8.42 m/s)

|

3.34 J | |

| 50 mm |

38.73 km/h

(10.76 m/s)

|

5.45 J | |

| 100 mm |

54.71 km/h

(15.20 m/s)

|

10.88 J |

Table 9: Coating parameters (durability)

MW 40x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 40x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 38 700 Mx | 387.0 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Submerged application

MW 40x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 27.73 kg | Standard |

| Water (riverbed) |

31.75 kg

(+4.02 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet retains merely a fraction of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) drastically limits the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- They do not lose strength, even over nearly 10 years – the drop in strength is only ~1% (based on measurements),

- They have excellent resistance to magnetism drop when exposed to external fields,

- The use of an refined coating of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- The surface of neodymium magnets generates a maximum magnetic field – this is a distinguishing feature,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of exact forming as well as modifying to defined requirements,

- Significant place in modern industrial fields – they find application in hard drives, electric motors, medical equipment, as well as technologically advanced constructions.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Weaknesses

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in producing nuts and complicated shapes in magnets, we propose using cover - magnetic mount.

- Health risk to health – tiny shards of magnets pose a threat, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these magnets can disrupt the diagnostic process medical in case of swallowing.

- With budget limitations the cost of neodymium magnets is a challenge,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a plate made of low-carbon steel, serving as a ideal flux conductor

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with a surface perfectly flat

- without the slightest insulating layer between the magnet and steel

- under axial force vector (90-degree angle)

- in temp. approx. 20°C

Practical lifting capacity: influencing factors

- Gap (between the magnet and the plate), since even a tiny distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to varnish, corrosion or debris).

- Force direction – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Steel thickness – too thin plate does not close the flux, causing part of the power to be lost into the air.

- Material composition – not every steel reacts the same. High carbon content worsen the attraction effect.

- Surface condition – smooth surfaces ensure maximum contact, which improves force. Uneven metal reduce efficiency.

- Thermal factor – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. Additionally, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Flammability

Fire hazard: Neodymium dust is highly flammable. Do not process magnets without safety gear as this may cause fire.

Danger to the youngest

These products are not intended for children. Accidental ingestion of several magnets can lead to them connecting inside the digestive tract, which constitutes a direct threat to life and requires immediate surgery.

Bodily injuries

Large magnets can break fingers in a fraction of a second. Do not place your hand betwixt two attracting surfaces.

Magnetic interference

Note: neodymium magnets produce a field that disrupts sensitive sensors. Keep a safe distance from your mobile, tablet, and navigation systems.

Heat sensitivity

Standard neodymium magnets (grade N) lose power when the temperature goes above 80°C. This process is irreversible.

Shattering risk

Neodymium magnets are ceramic materials, which means they are prone to chipping. Impact of two magnets leads to them breaking into shards.

Data carriers

Do not bring magnets close to a purse, laptop, or screen. The magnetism can destroy these devices and erase data from cards.

Immense force

Before starting, check safety instructions. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Allergy Warning

Studies show that nickel (the usual finish) is a potent allergen. For allergy sufferers, refrain from direct skin contact or choose versions in plastic housing.

Implant safety

Individuals with a pacemaker must maintain an safe separation from magnets. The magnetic field can interfere with the functioning of the implant.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)