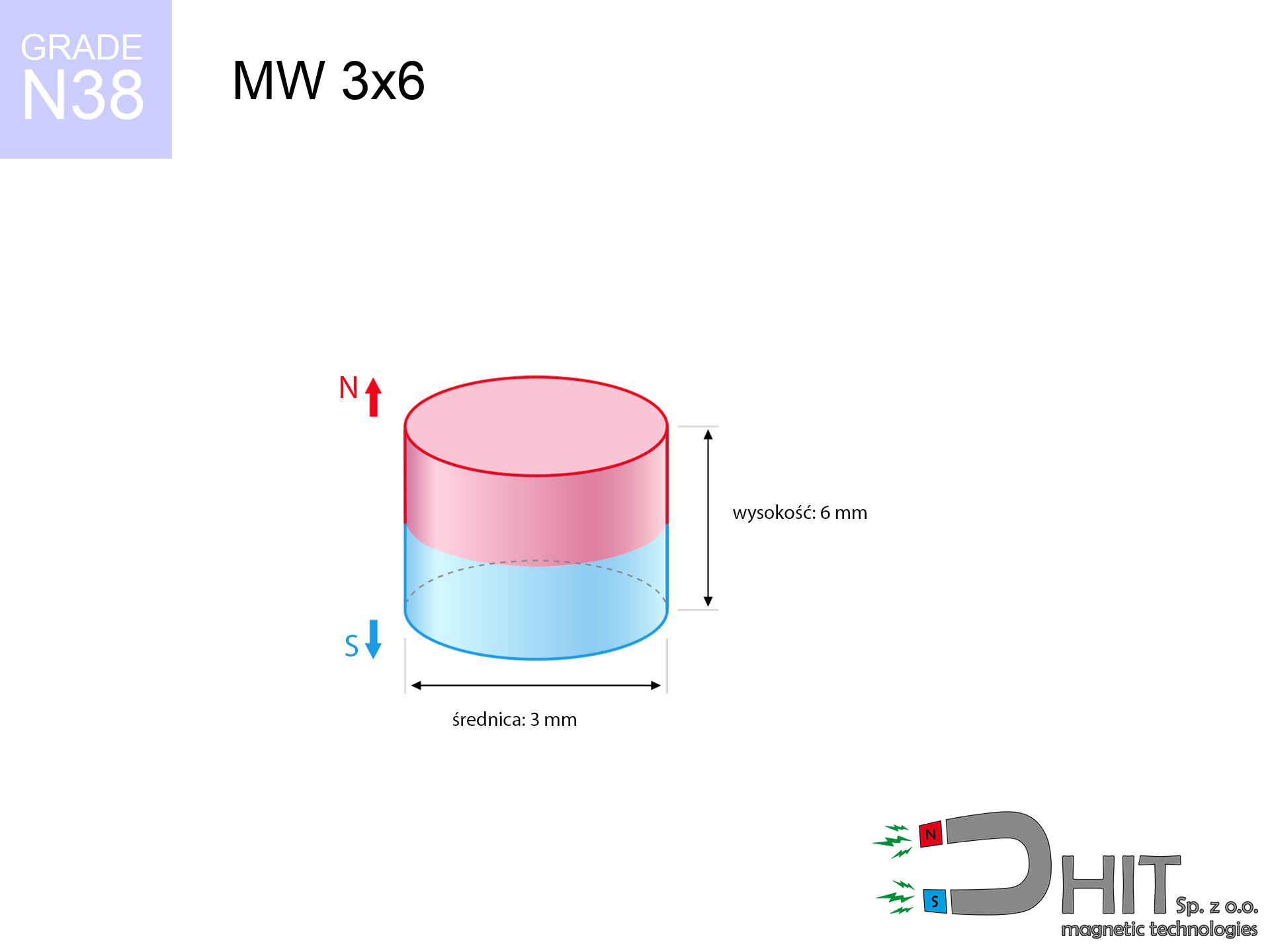

MW 3x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010065

GTIN/EAN: 5906301810643

Diameter Ø

3 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

0.32 g

Magnetization Direction

↑ axial

Load capacity

0.20 kg / 1.95 N

Magnetic Induction

598.96 mT / 5990 Gs

Coating

[NiCuNi] Nickel

0.295 ZŁ with VAT / pcs + price for transport

0.240 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise contact us by means of

form

through our site.

Lifting power as well as form of magnetic components can be verified using our

online calculation tool.

Order by 14:00 and we’ll ship today!

Product card - MW 3x6 / N38 - cylindrical magnet

Specification / characteristics - MW 3x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010065 |

| GTIN/EAN | 5906301810643 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 3 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 0.32 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.20 kg / 1.95 N |

| Magnetic Induction ~ ? | 598.96 mT / 5990 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - report

The following information are the direct effect of a physical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Operational performance may deviate from the simulation results. Use these calculations as a preliminary roadmap for designers.

Table 1: Static force (force vs gap) - interaction chart

MW 3x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5974 Gs

597.4 mT

|

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

safe |

| 1 mm |

2623 Gs

262.3 mT

|

0.04 kg / 0.09 pounds

38.6 g / 0.4 N

|

safe |

| 2 mm |

1134 Gs

113.4 mT

|

0.01 kg / 0.02 pounds

7.2 g / 0.1 N

|

safe |

| 3 mm |

570 Gs

57.0 mT

|

0.00 kg / 0.00 pounds

1.8 g / 0.0 N

|

safe |

| 5 mm |

205 Gs

20.5 mT

|

0.00 kg / 0.00 pounds

0.2 g / 0.0 N

|

safe |

| 10 mm |

42 Gs

4.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 15 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 20 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 30 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Slippage capacity (wall)

MW 3x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.04 kg / 0.09 pounds

40.0 g / 0.4 N

|

| 1 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

8.0 g / 0.1 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 3x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.06 kg / 0.13 pounds

60.0 g / 0.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.04 kg / 0.09 pounds

40.0 g / 0.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.02 kg / 0.04 pounds

20.0 g / 0.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.10 kg / 0.22 pounds

100.0 g / 1.0 N

|

Table 4: Material efficiency (saturation) - power losses

MW 3x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.02 kg / 0.04 pounds

20.0 g / 0.2 N

|

| 1 mm |

|

0.05 kg / 0.11 pounds

50.0 g / 0.5 N

|

| 2 mm |

|

0.10 kg / 0.22 pounds

100.0 g / 1.0 N

|

| 3 mm |

|

0.15 kg / 0.33 pounds

150.0 g / 1.5 N

|

| 5 mm |

|

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

| 10 mm |

|

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

| 11 mm |

|

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

| 12 mm |

|

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 3x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.20 kg / 0.44 pounds

200.0 g / 2.0 N

|

OK |

| 40 °C | -2.2% |

0.20 kg / 0.43 pounds

195.6 g / 1.9 N

|

OK |

| 60 °C | -4.4% |

0.19 kg / 0.42 pounds

191.2 g / 1.9 N

|

OK |

| 80 °C | -6.6% |

0.19 kg / 0.41 pounds

186.8 g / 1.8 N

|

|

| 100 °C | -28.8% |

0.14 kg / 0.31 pounds

142.4 g / 1.4 N

|

Table 6: Two magnets (attraction) - field collision

MW 3x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.56 kg / 3.43 pounds

6 111 Gs

|

0.23 kg / 0.51 pounds

233 g / 2.3 N

|

N/A |

| 1 mm |

0.73 kg / 1.60 pounds

8 161 Gs

|

0.11 kg / 0.24 pounds

109 g / 1.1 N

|

0.65 kg / 1.44 pounds

~0 Gs

|

| 2 mm |

0.30 kg / 0.66 pounds

5 246 Gs

|

0.04 kg / 0.10 pounds

45 g / 0.4 N

|

0.27 kg / 0.60 pounds

~0 Gs

|

| 3 mm |

0.13 kg / 0.28 pounds

3 391 Gs

|

0.02 kg / 0.04 pounds

19 g / 0.2 N

|

0.11 kg / 0.25 pounds

~0 Gs

|

| 5 mm |

0.03 kg / 0.06 pounds

1 578 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 pounds

409 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

83 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

1 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 3x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 1.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (cracking risk) - warning

MW 3x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.21 km/h

(7.00 m/s)

|

0.01 J | |

| 30 mm |

43.67 km/h

(12.13 m/s)

|

0.02 J | |

| 50 mm |

56.38 km/h

(15.66 m/s)

|

0.04 J | |

| 100 mm |

79.73 km/h

(22.15 m/s)

|

0.08 J |

Table 9: Corrosion resistance

MW 3x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 3x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 470 Mx | 4.7 µWb |

| Pc Coefficient | 1.21 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 3x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.20 kg | Standard |

| Water (riverbed) |

0.23 kg

(+0.03 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical surface, the magnet holds just a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) severely weakens the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.21

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths and weaknesses of neodymium magnets.

Strengths

- They do not lose strength, even during nearly 10 years – the decrease in strength is only ~1% (according to tests),

- They show high resistance to demagnetization induced by external field influence,

- In other words, due to the metallic layer of silver, the element gains visual value,

- Magnetic induction on the surface of the magnet is extremely intense,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, enabling functioning at temperatures reaching 230°C and above...

- Possibility of detailed forming as well as adjusting to complex needs,

- Wide application in high-tech industry – they are commonly used in data components, electromotive mechanisms, diagnostic systems, and other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in small dimensions, which makes them useful in small systems

Cons

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of creating nuts in the magnet and complex shapes - recommended is a housing - mounting mechanism.

- Possible danger related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Additionally, tiny parts of these magnets are able to be problematic in diagnostics medical after entering the body.

- With budget limitations the cost of neodymium magnets can be a barrier,

Pull force analysis

Maximum magnetic pulling force – what it depends on?

- on a block made of mild steel, effectively closing the magnetic field

- with a cross-section minimum 10 mm

- characterized by lack of roughness

- under conditions of no distance (metal-to-metal)

- for force acting at a right angle (in the magnet axis)

- in neutral thermal conditions

Determinants of lifting force in real conditions

- Gap (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) leads to a reduction in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Force direction – declared lifting capacity refers to detachment vertically. When slipping, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the flux to be wasted into the air.

- Material composition – not every steel reacts the same. Alloy additives worsen the interaction with the magnet.

- Base smoothness – the more even the surface, the better the adhesion and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal environment – temperature increase causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under parallel forces the load capacity is reduced by as much as 5 times. Moreover, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Safe handling of neodymium magnets

Bodily injuries

Watch your fingers. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing everything in their path. Be careful!

Caution required

Handle magnets with awareness. Their powerful strength can surprise even experienced users. Plan your moves and respect their force.

Shattering risk

Neodymium magnets are sintered ceramics, which means they are fragile like glass. Collision of two magnets leads to them breaking into shards.

Machining danger

Combustion risk: Neodymium dust is explosive. Do not process magnets in home conditions as this may cause fire.

Allergic reactions

Medical facts indicate that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, refrain from direct skin contact and opt for versions in plastic housing.

Magnetic media

Equipment safety: Neodymium magnets can ruin payment cards and sensitive devices (pacemakers, medical aids, timepieces).

Medical implants

Patients with a heart stimulator must maintain an absolute distance from magnets. The magnetic field can stop the operation of the life-saving device.

Phone sensors

GPS units and smartphones are extremely sensitive to magnetism. Close proximity with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Do not overheat magnets

Avoid heat. Neodymium magnets are sensitive to temperature. If you require operation above 80°C, ask us about HT versions (H, SH, UH).

Adults only

These products are not suitable for play. Swallowing several magnets may result in them connecting inside the digestive tract, which poses a direct threat to life and necessitates urgent medical intervention.

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)

![SM 25x325 [2xM8] / N42 - magnetic separator SM 25x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x325-2xm8-man.jpg)