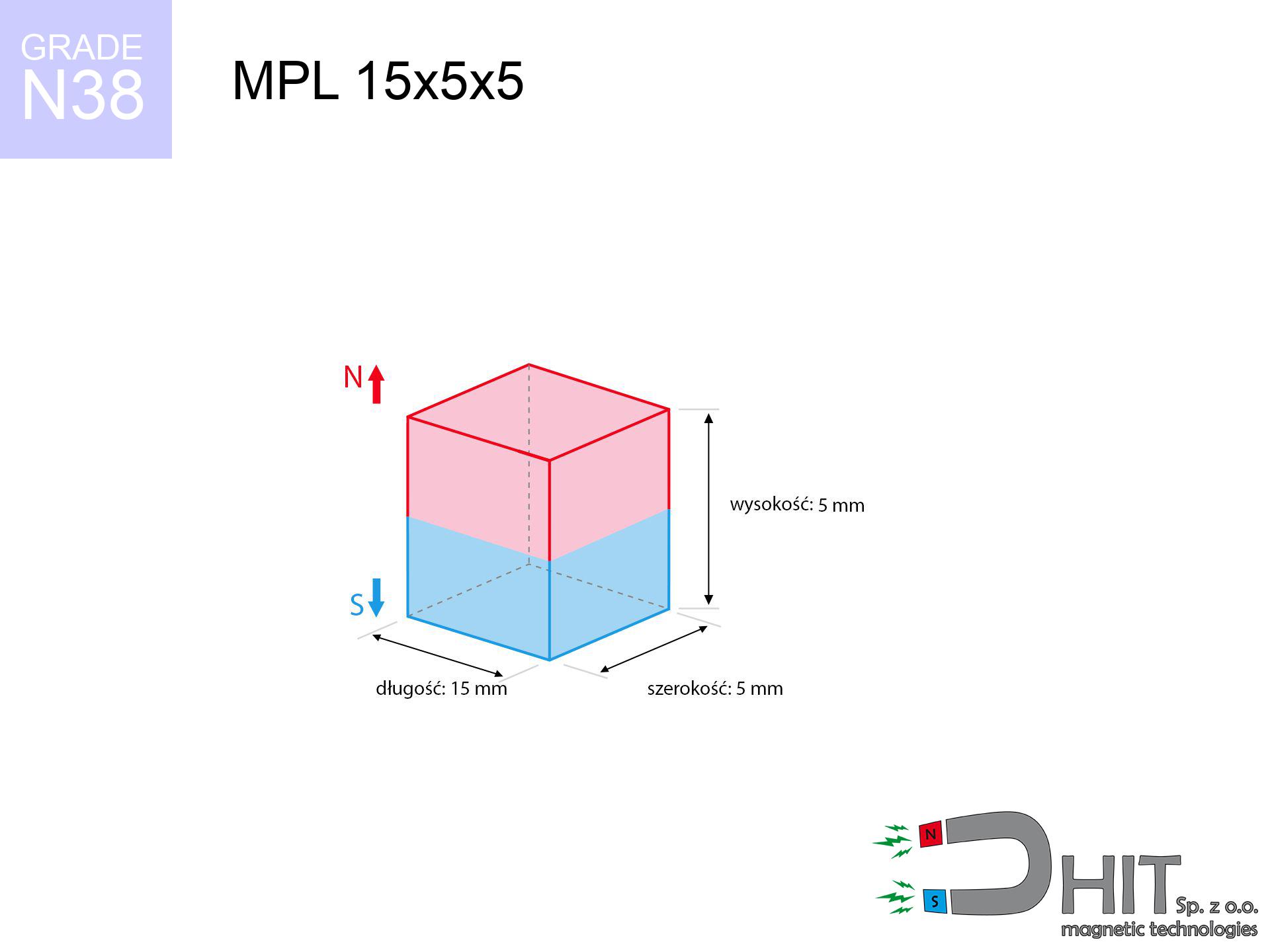

MPL 15x5x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020123

GTIN/EAN: 5906301811299

length

15 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

2.81 g

Magnetization Direction

↑ axial

Load capacity

3.20 kg / 31.38 N

Magnetic Induction

468.69 mT / 4687 Gs

Coating

[NiCuNi] Nickel

1.390 ZŁ with VAT / pcs + price for transport

1.130 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer get in touch by means of

contact form

the contact page.

Strength and structure of magnetic components can be reviewed using our

power calculator.

Same-day shipping for orders placed before 14:00.

Physical properties - MPL 15x5x5 / N38 - lamellar magnet

Specification / characteristics - MPL 15x5x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020123 |

| GTIN/EAN | 5906301811299 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 15 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 2.81 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.20 kg / 31.38 N |

| Magnetic Induction ~ ? | 468.69 mT / 4687 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - report

These values represent the outcome of a mathematical calculation. Values are based on models for the class Nd2Fe14B. Real-world conditions may differ. Use these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs distance) - characteristics

MPL 15x5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4682 Gs

468.2 mT

|

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

warning |

| 1 mm |

3410 Gs

341.0 mT

|

1.70 kg / 3.74 pounds

1697.3 g / 16.7 N

|

safe |

| 2 mm |

2394 Gs

239.4 mT

|

0.84 kg / 1.84 pounds

836.5 g / 8.2 N

|

safe |

| 3 mm |

1701 Gs

170.1 mT

|

0.42 kg / 0.93 pounds

422.6 g / 4.1 N

|

safe |

| 5 mm |

928 Gs

92.8 mT

|

0.13 kg / 0.28 pounds

125.8 g / 1.2 N

|

safe |

| 10 mm |

286 Gs

28.6 mT

|

0.01 kg / 0.03 pounds

11.9 g / 0.1 N

|

safe |

| 15 mm |

119 Gs

11.9 mT

|

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

safe |

| 20 mm |

59 Gs

5.9 mT

|

0.00 kg / 0.00 pounds

0.5 g / 0.0 N

|

safe |

| 30 mm |

21 Gs

2.1 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Vertical force (wall)

MPL 15x5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.64 kg / 1.41 pounds

640.0 g / 6.3 N

|

| 1 mm | Stal (~0.2) |

0.34 kg / 0.75 pounds

340.0 g / 3.3 N

|

| 2 mm | Stal (~0.2) |

0.17 kg / 0.37 pounds

168.0 g / 1.6 N

|

| 3 mm | Stal (~0.2) |

0.08 kg / 0.19 pounds

84.0 g / 0.8 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

26.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 15x5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.96 kg / 2.12 pounds

960.0 g / 9.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.64 kg / 1.41 pounds

640.0 g / 6.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.60 kg / 3.53 pounds

1600.0 g / 15.7 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 15x5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.32 kg / 0.71 pounds

320.0 g / 3.1 N

|

| 1 mm |

|

0.80 kg / 1.76 pounds

800.0 g / 7.8 N

|

| 2 mm |

|

1.60 kg / 3.53 pounds

1600.0 g / 15.7 N

|

| 3 mm |

|

2.40 kg / 5.29 pounds

2400.0 g / 23.5 N

|

| 5 mm |

|

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

| 10 mm |

|

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

| 11 mm |

|

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

| 12 mm |

|

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

Table 5: Thermal stability (stability) - power drop

MPL 15x5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.20 kg / 7.05 pounds

3200.0 g / 31.4 N

|

OK |

| 40 °C | -2.2% |

3.13 kg / 6.90 pounds

3129.6 g / 30.7 N

|

OK |

| 60 °C | -4.4% |

3.06 kg / 6.74 pounds

3059.2 g / 30.0 N

|

|

| 80 °C | -6.6% |

2.99 kg / 6.59 pounds

2988.8 g / 29.3 N

|

|

| 100 °C | -28.8% |

2.28 kg / 5.02 pounds

2278.4 g / 22.4 N

|

Table 6: Two magnets (attraction) - field range

MPL 15x5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.14 kg / 22.35 pounds

5 608 Gs

|

1.52 kg / 3.35 pounds

1520 g / 14.9 N

|

N/A |

| 1 mm |

7.53 kg / 16.60 pounds

8 071 Gs

|

1.13 kg / 2.49 pounds

1129 g / 11.1 N

|

6.78 kg / 14.94 pounds

~0 Gs

|

| 2 mm |

5.38 kg / 11.85 pounds

6 820 Gs

|

0.81 kg / 1.78 pounds

806 g / 7.9 N

|

4.84 kg / 10.67 pounds

~0 Gs

|

| 3 mm |

3.78 kg / 8.33 pounds

5 716 Gs

|

0.57 kg / 1.25 pounds

567 g / 5.6 N

|

3.40 kg / 7.49 pounds

~0 Gs

|

| 5 mm |

1.87 kg / 4.13 pounds

4 024 Gs

|

0.28 kg / 0.62 pounds

281 g / 2.8 N

|

1.68 kg / 3.71 pounds

~0 Gs

|

| 10 mm |

0.40 kg / 0.88 pounds

1 857 Gs

|

0.06 kg / 0.13 pounds

60 g / 0.6 N

|

0.36 kg / 0.79 pounds

~0 Gs

|

| 20 mm |

0.04 kg / 0.08 pounds

572 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.03 kg / 0.08 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

67 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

41 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

27 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

19 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

14 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MPL 15x5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 15x5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.11 km/h

(9.48 m/s)

|

0.13 J | |

| 30 mm |

58.95 km/h

(16.37 m/s)

|

0.38 J | |

| 50 mm |

76.10 km/h

(21.14 m/s)

|

0.63 J | |

| 100 mm |

107.62 km/h

(29.90 m/s)

|

1.26 J |

Table 9: Anti-corrosion coating durability

MPL 15x5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 15x5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 366 Mx | 33.7 µWb |

| Pc Coefficient | 0.60 | Low (Flat) |

Table 11: Submerged application

MPL 15x5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.20 kg | Standard |

| Water (riverbed) |

3.66 kg

(+0.46 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds merely a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.60

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of neodymium magnets.

Pros

- Their magnetic field is maintained, and after approximately 10 years it drops only by ~1% (theoretically),

- They possess excellent resistance to magnetic field loss when exposed to external magnetic sources,

- A magnet with a smooth gold surface has better aesthetics,

- Magnets exhibit huge magnetic induction on the outer side,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- In view of the option of precise shaping and adaptation to custom needs, neodymium magnets can be created in a broad palette of forms and dimensions, which amplifies use scope,

- Versatile presence in innovative solutions – they are used in HDD drives, drive modules, advanced medical instruments, and other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages

- At very strong impacts they can break, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Due to limitations in producing threads and complex shapes in magnets, we recommend using casing - magnetic mount.

- Possible danger to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child health protection. Additionally, small components of these magnets can disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a base made of high-permeability steel, acting as a magnetic yoke

- with a cross-section of at least 10 mm

- with an ground touching surface

- with direct contact (no coatings)

- during detachment in a direction vertical to the mounting surface

- at temperature approx. 20 degrees Celsius

Determinants of practical lifting force of a magnet

- Distance (between the magnet and the metal), since even a very small distance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Angle of force application – maximum parameter is obtained only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is standardly several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Material type – ideal substrate is high-permeability steel. Cast iron may have worse magnetic properties.

- Base smoothness – the smoother and more polished the plate, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal environment – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, whereas under shearing force the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate reduces the load capacity.

Precautions when working with NdFeB magnets

Magnets are brittle

Despite metallic appearance, the material is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Dust explosion hazard

Mechanical processing of neodymium magnets poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Phone sensors

Navigation devices and mobile phones are highly sensitive to magnetic fields. Close proximity with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Do not overheat magnets

Standard neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. This process is irreversible.

Do not give to children

Neodymium magnets are not toys. Eating several magnets can lead to them connecting inside the digestive tract, which poses a severe health hazard and necessitates immediate surgery.

Electronic devices

Data protection: Strong magnets can damage payment cards and delicate electronics (heart implants, hearing aids, timepieces).

Crushing force

Mind your fingers. Two powerful magnets will join instantly with a force of several hundred kilograms, destroying anything in their path. Exercise extreme caution!

Allergic reactions

Certain individuals suffer from a sensitization to nickel, which is the common plating for neodymium magnets. Frequent touching may cause dermatitis. We strongly advise use protective gloves.

Danger to pacemakers

Warning for patients: Strong magnetic fields affect electronics. Keep at least 30 cm distance or request help to work with the magnets.

Immense force

Handle with care. Neodymium magnets attract from a long distance and snap with massive power, often faster than you can move away.

![UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-48x24x11.5-m8-gz-bit.jpg)