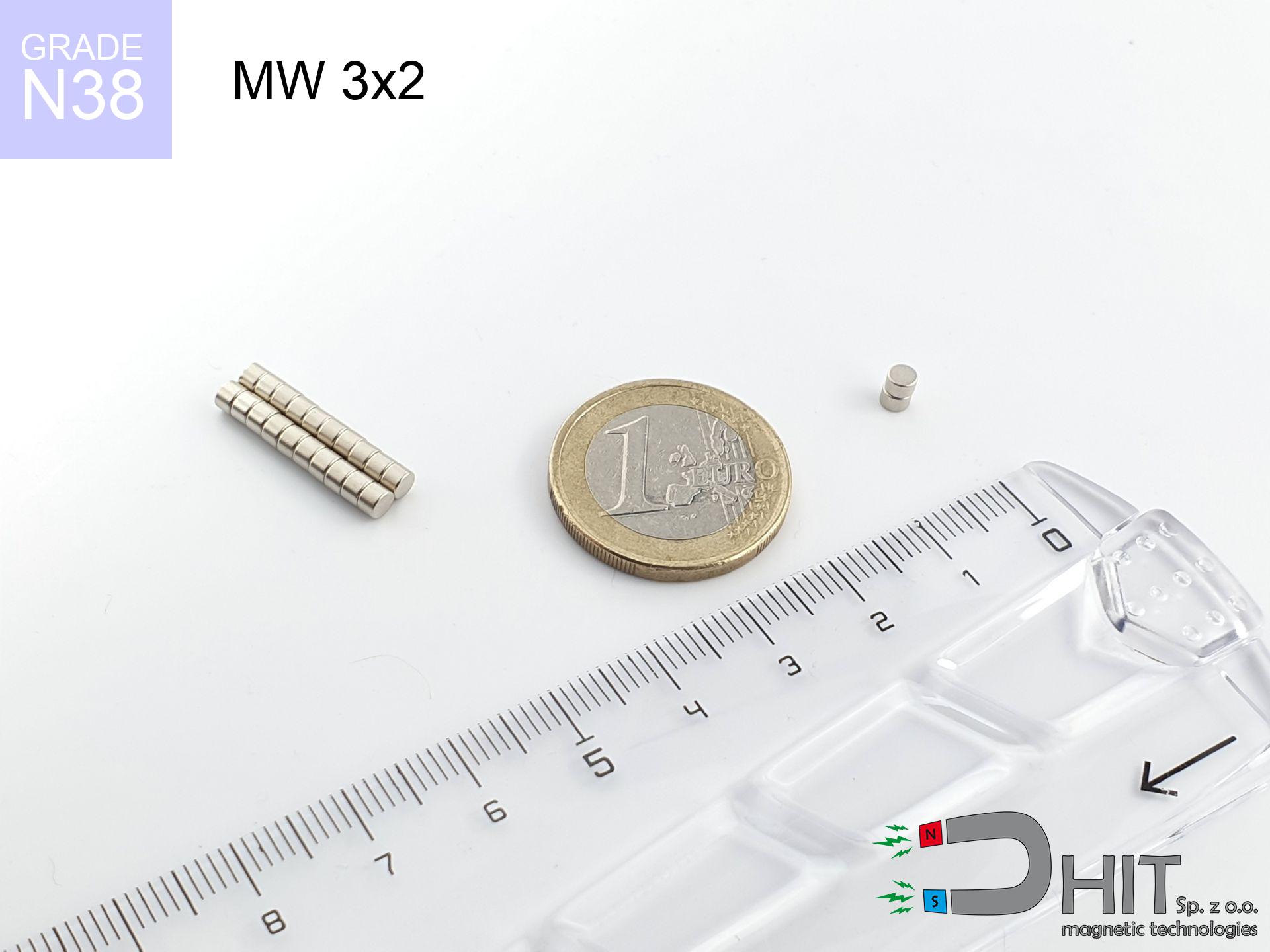

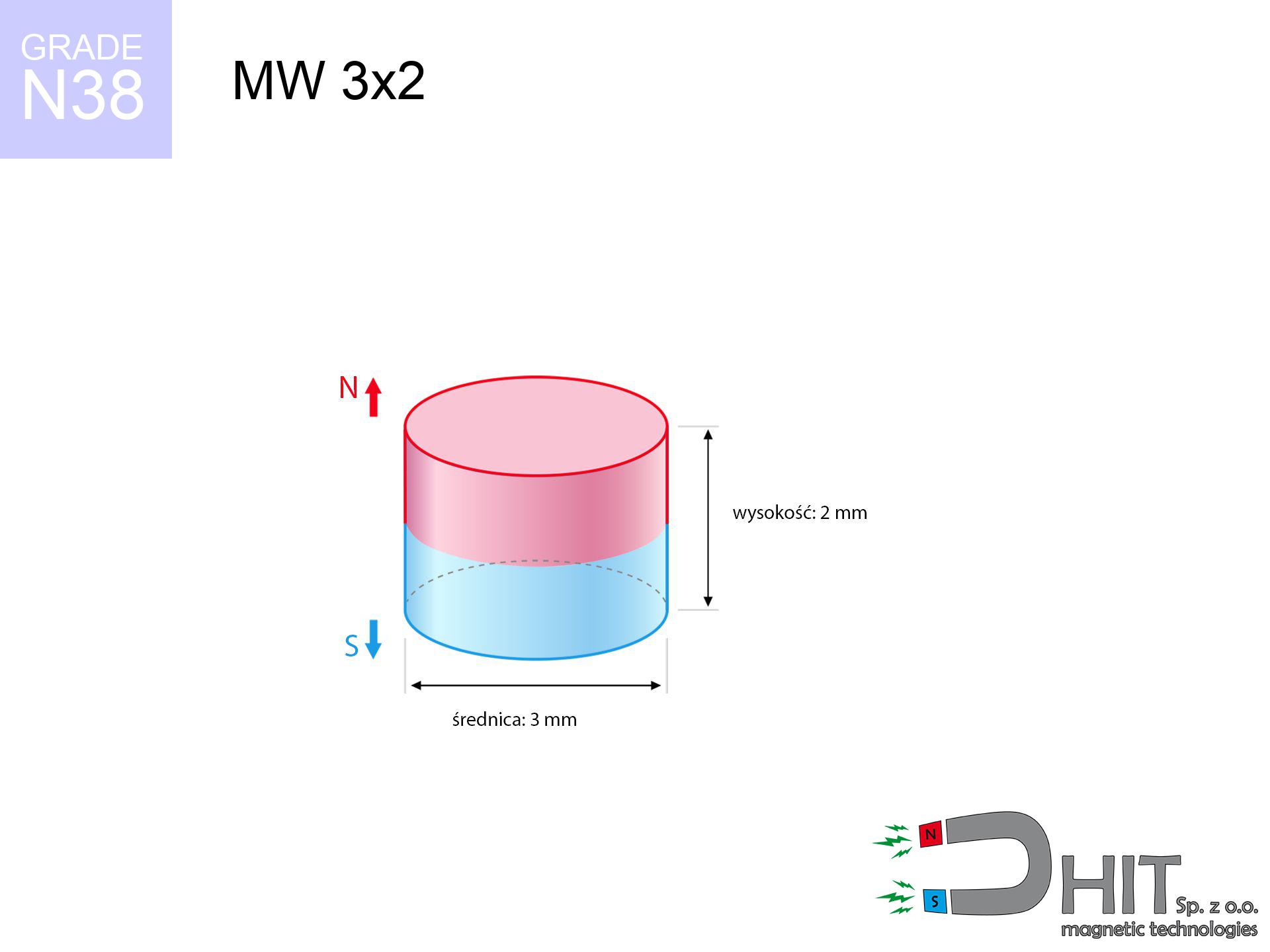

MW 3x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010064

GTIN/EAN: 5906301810636

Diameter Ø

3 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.11 g

Magnetization Direction

↑ axial

Load capacity

0.30 kg / 2.99 N

Magnetic Induction

493.99 mT / 4940 Gs

Coating

[NiCuNi] Nickel

0.1476 ZŁ with VAT / pcs + price for transport

0.1200 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

if you prefer drop us a message via

form

our website.

Specifications along with appearance of magnetic components can be analyzed with our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Detailed specification - MW 3x2 / N38 - cylindrical magnet

Specification / characteristics - MW 3x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010064 |

| GTIN/EAN | 5906301810636 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 3 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.11 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.30 kg / 2.99 N |

| Magnetic Induction ~ ? | 493.99 mT / 4940 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - data

The following data represent the direct effect of a engineering simulation. Results were calculated on models for the material Nd2Fe14B. Operational parameters may differ from theoretical values. Treat these calculations as a preliminary roadmap for designers.

Table 1: Static force (force vs gap) - characteristics

MW 3x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4928 Gs

492.8 mT

|

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

safe |

| 1 mm |

2106 Gs

210.6 mT

|

0.05 kg / 0.12 LBS

54.8 g / 0.5 N

|

safe |

| 2 mm |

845 Gs

84.5 mT

|

0.01 kg / 0.02 LBS

8.8 g / 0.1 N

|

safe |

| 3 mm |

393 Gs

39.3 mT

|

0.00 kg / 0.00 LBS

1.9 g / 0.0 N

|

safe |

| 5 mm |

124 Gs

12.4 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

safe |

| 10 mm |

21 Gs

2.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 15 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 20 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Shear force (wall)

MW 3x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.06 kg / 0.13 LBS

60.0 g / 0.6 N

|

| 1 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 3x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.06 kg / 0.13 LBS

60.0 g / 0.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.07 LBS

30.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 3x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.07 LBS

30.0 g / 0.3 N

|

| 1 mm |

|

0.08 kg / 0.17 LBS

75.0 g / 0.7 N

|

| 2 mm |

|

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

| 3 mm |

|

0.22 kg / 0.50 LBS

225.0 g / 2.2 N

|

| 5 mm |

|

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

| 10 mm |

|

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

| 11 mm |

|

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

| 12 mm |

|

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

Table 5: Working in heat (stability) - resistance threshold

MW 3x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.30 kg / 0.66 LBS

300.0 g / 2.9 N

|

OK |

| 40 °C | -2.2% |

0.29 kg / 0.65 LBS

293.4 g / 2.9 N

|

OK |

| 60 °C | -4.4% |

0.29 kg / 0.63 LBS

286.8 g / 2.8 N

|

OK |

| 80 °C | -6.6% |

0.28 kg / 0.62 LBS

280.2 g / 2.7 N

|

|

| 100 °C | -28.8% |

0.21 kg / 0.47 LBS

213.6 g / 2.1 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 3x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.06 kg / 2.33 LBS

5 766 Gs

|

0.16 kg / 0.35 LBS

159 g / 1.6 N

|

N/A |

| 1 mm |

0.49 kg / 1.08 LBS

6 712 Gs

|

0.07 kg / 0.16 LBS

74 g / 0.7 N

|

0.44 kg / 0.97 LBS

~0 Gs

|

| 2 mm |

0.19 kg / 0.43 LBS

4 213 Gs

|

0.03 kg / 0.06 LBS

29 g / 0.3 N

|

0.17 kg / 0.38 LBS

~0 Gs

|

| 3 mm |

0.08 kg / 0.17 LBS

2 629 Gs

|

0.01 kg / 0.02 LBS

11 g / 0.1 N

|

0.07 kg / 0.15 LBS

~0 Gs

|

| 5 mm |

0.01 kg / 0.03 LBS

1 131 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 LBS

248 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

0 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MW 3x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 1.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.0 cm |

| Remote | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 3x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

52.67 km/h

(14.63 m/s)

|

0.01 J | |

| 30 mm |

91.22 km/h

(25.34 m/s)

|

0.04 J | |

| 50 mm |

117.77 km/h

(32.71 m/s)

|

0.06 J | |

| 100 mm |

166.55 km/h

(46.26 m/s)

|

0.12 J |

Table 9: Surface protection spec

MW 3x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 3x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 353 Mx | 3.5 µWb |

| Pc Coefficient | 0.71 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 3x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.30 kg | Standard |

| Water (riverbed) |

0.34 kg

(+0.04 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet holds only approx. 20-30% of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.71

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Benefits

- They retain magnetic properties for nearly 10 years – the drop is just ~1% (according to analyses),

- Neodymium magnets are characterized by exceptionally resistant to loss of magnetic properties caused by magnetic disturbances,

- By applying a decorative layer of silver, the element presents an professional look,

- They show high magnetic induction at the operating surface, which increases their power,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to the potential of accurate molding and adaptation to unique projects, magnetic components can be produced in a wide range of geometric configurations, which expands the range of possible applications,

- Universal use in electronics industry – they find application in computer drives, motor assemblies, advanced medical instruments, and modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Limitations

- At very strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited ability of creating threads in the magnet and complex forms - preferred is casing - magnet mounting.

- Possible danger to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Furthermore, small components of these products are able to be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets is a challenge,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- using a base made of high-permeability steel, functioning as a magnetic yoke

- with a cross-section of at least 10 mm

- with a surface free of scratches

- under conditions of gap-free contact (metal-to-metal)

- for force applied at a right angle (pull-off, not shear)

- in neutral thermal conditions

What influences lifting capacity in practice

- Distance (betwixt the magnet and the metal), as even a tiny clearance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of maximum force).

- Steel thickness – insufficiently thick sheet does not accept the full field, causing part of the power to be lost into the air.

- Material type – the best choice is pure iron steel. Stainless steels may have worse magnetic properties.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Uneven metal reduce efficiency.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the holding force is lower. In addition, even a small distance between the magnet’s surface and the plate lowers the holding force.

H&S for magnets

Heat warning

Avoid heat. Neodymium magnets are susceptible to heat. If you require operation above 80°C, inquire about HT versions (H, SH, UH).

Threat to navigation

A strong magnetic field interferes with the operation of compasses in phones and navigation systems. Maintain magnets close to a device to avoid breaking the sensors.

No play value

These products are not intended for children. Accidental ingestion of a few magnets can lead to them connecting inside the digestive tract, which poses a critical condition and necessitates urgent medical intervention.

Immense force

Handle magnets consciously. Their powerful strength can surprise even professionals. Plan your moves and respect their power.

Material brittleness

Beware of splinters. Magnets can explode upon uncontrolled impact, ejecting shards into the air. We recommend safety glasses.

Do not drill into magnets

Combustion risk: Rare earth powder is explosive. Do not process magnets without safety gear as this risks ignition.

Nickel coating and allergies

Warning for allergy sufferers: The Ni-Cu-Ni coating consists of nickel. If an allergic reaction happens, immediately stop working with magnets and use protective gear.

Electronic devices

Powerful magnetic fields can erase data on credit cards, hard drives, and storage devices. Maintain a gap of min. 10 cm.

ICD Warning

Medical warning: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Serious injuries

Big blocks can smash fingers in a fraction of a second. Do not put your hand between two attracting surfaces.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)

![SM 32x450 [2xM8] / N52 - magnetic separator SM 32x450 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bir.jpg)

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)