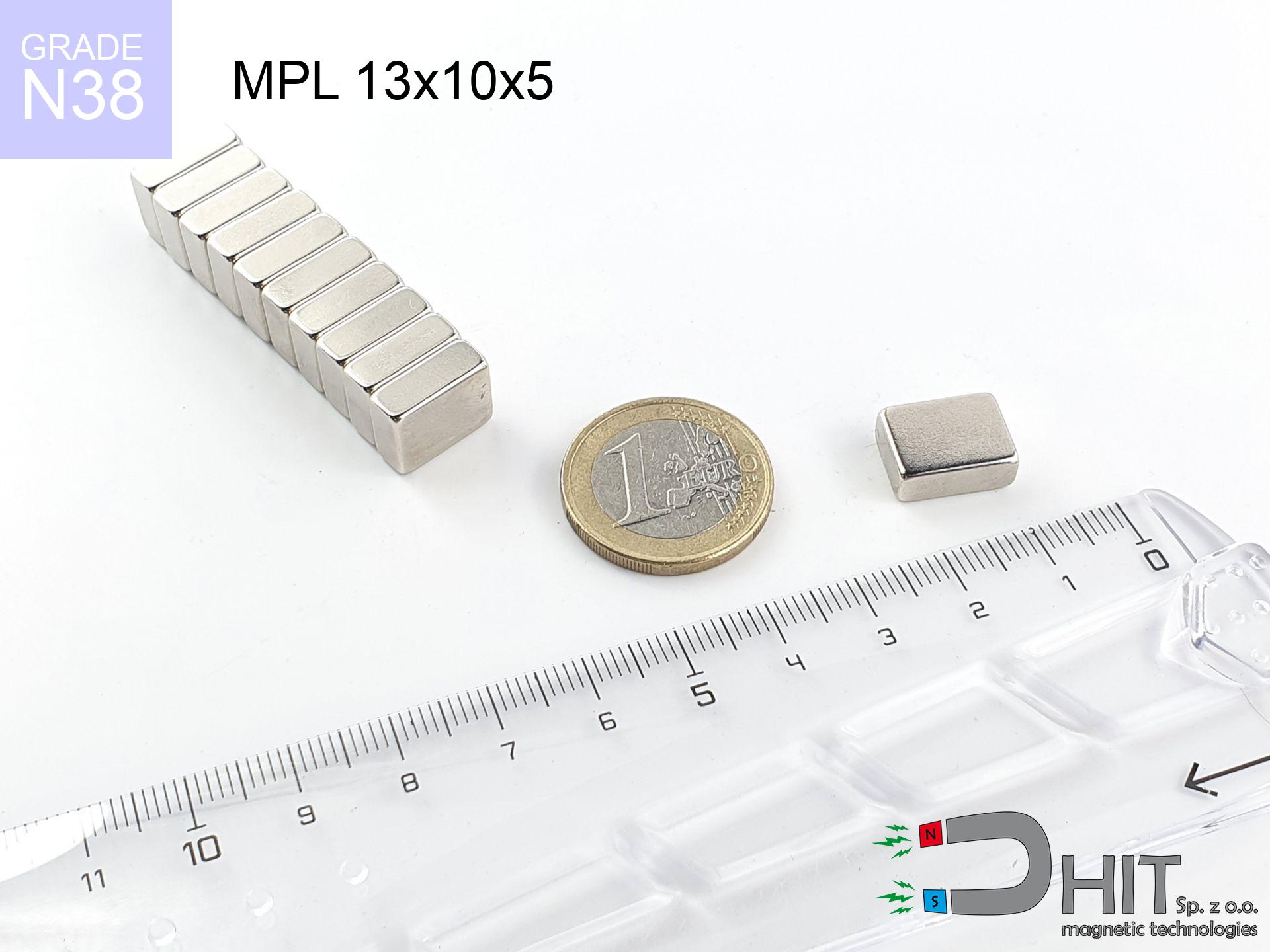

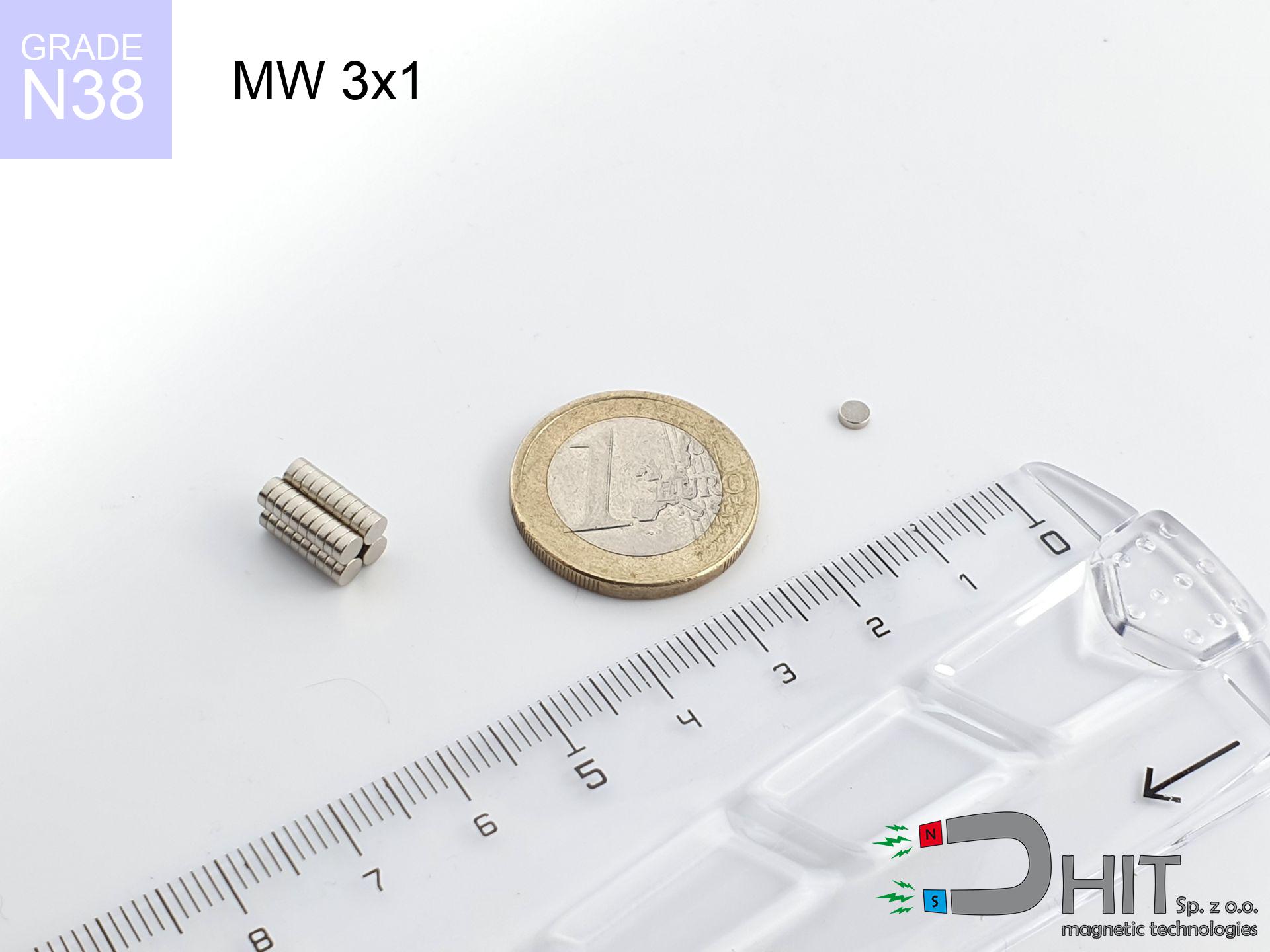

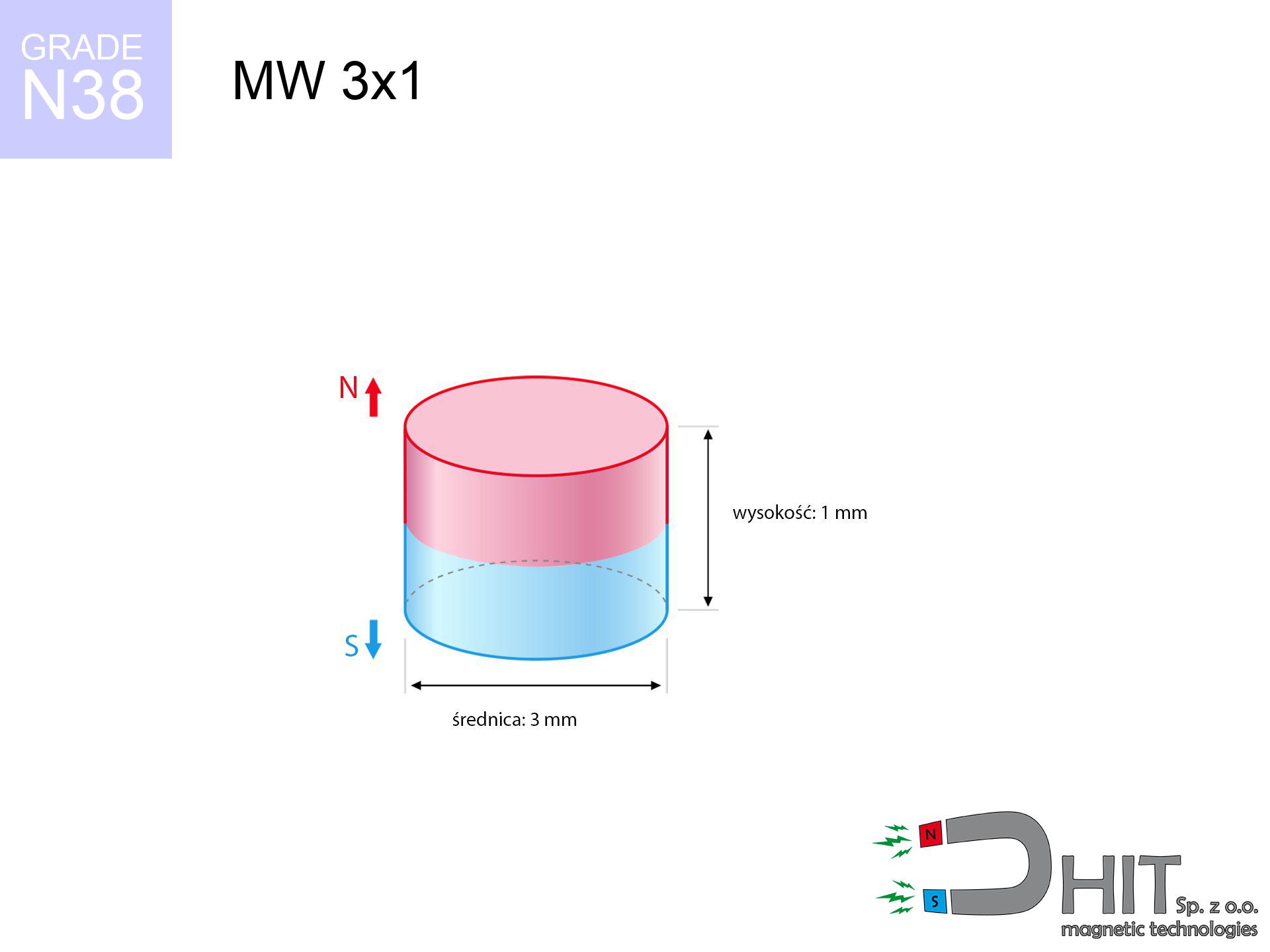

MW 3x1 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010063

GTIN/EAN: 5906301810629

Diameter Ø

3 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

0.05 g

Magnetization Direction

↑ axial

Load capacity

0.21 kg / 2.10 N

Magnetic Induction

342.82 mT / 3428 Gs

Coating

[NiCuNi] Nickel

0.1353 ZŁ with VAT / pcs + price for transport

0.1100 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

or send us a note via

our online form

the contact section.

Strength as well as structure of a magnet can be checked using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical details - MW 3x1 / N38 - cylindrical magnet

Specification / characteristics - MW 3x1 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010063 |

| GTIN/EAN | 5906301810629 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 3 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 0.05 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.21 kg / 2.10 N |

| Magnetic Induction ~ ? | 342.82 mT / 3428 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

The following values constitute the direct effect of a physical analysis. Values were calculated on algorithms for the class Nd2Fe14B. Actual performance may deviate from the simulation results. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs distance) - power drop

MW 3x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3422 Gs

342.2 mT

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

weak grip |

| 1 mm |

1521 Gs

152.1 mT

|

0.04 kg / 0.09 lbs

41.5 g / 0.4 N

|

weak grip |

| 2 mm |

585 Gs

58.5 mT

|

0.01 kg / 0.01 lbs

6.1 g / 0.1 N

|

weak grip |

| 3 mm |

260 Gs

26.0 mT

|

0.00 kg / 0.00 lbs

1.2 g / 0.0 N

|

weak grip |

| 5 mm |

76 Gs

7.6 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

weak grip |

| 10 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 15 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 20 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding load (wall)

MW 3x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.04 kg / 0.09 lbs

42.0 g / 0.4 N

|

| 1 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 3x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.06 kg / 0.14 lbs

63.0 g / 0.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.04 kg / 0.09 lbs

42.0 g / 0.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.02 kg / 0.05 lbs

21.0 g / 0.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.11 kg / 0.23 lbs

105.0 g / 1.0 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 3x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.02 kg / 0.05 lbs

21.0 g / 0.2 N

|

| 1 mm |

|

0.05 kg / 0.12 lbs

52.5 g / 0.5 N

|

| 2 mm |

|

0.11 kg / 0.23 lbs

105.0 g / 1.0 N

|

| 3 mm |

|

0.16 kg / 0.35 lbs

157.5 g / 1.5 N

|

| 5 mm |

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

| 10 mm |

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

| 11 mm |

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

| 12 mm |

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 3x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

OK |

| 40 °C | -2.2% |

0.21 kg / 0.45 lbs

205.4 g / 2.0 N

|

OK |

| 60 °C | -4.4% |

0.20 kg / 0.44 lbs

200.8 g / 2.0 N

|

|

| 80 °C | -6.6% |

0.20 kg / 0.43 lbs

196.1 g / 1.9 N

|

|

| 100 °C | -28.8% |

0.15 kg / 0.33 lbs

149.5 g / 1.5 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 3x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.51 kg / 1.12 lbs

4 928 Gs

|

0.08 kg / 0.17 lbs

77 g / 0.8 N

|

N/A |

| 1 mm |

0.26 kg / 0.56 lbs

4 847 Gs

|

0.04 kg / 0.08 lbs

38 g / 0.4 N

|

0.23 kg / 0.51 lbs

~0 Gs

|

| 2 mm |

0.10 kg / 0.22 lbs

3 042 Gs

|

0.02 kg / 0.03 lbs

15 g / 0.1 N

|

0.09 kg / 0.20 lbs

~0 Gs

|

| 3 mm |

0.04 kg / 0.08 lbs

1 865 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.03 kg / 0.08 lbs

~0 Gs

|

| 5 mm |

0.01 kg / 0.01 lbs

764 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 lbs

153 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

23 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

0 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

0 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

0 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 3x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 1.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 1.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 1.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.0 cm |

| Remote | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MW 3x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

65.36 km/h

(18.16 m/s)

|

0.01 J | |

| 30 mm |

113.21 km/h

(31.45 m/s)

|

0.02 J | |

| 50 mm |

146.15 km/h

(40.60 m/s)

|

0.04 J | |

| 100 mm |

206.68 km/h

(57.41 m/s)

|

0.08 J |

Table 9: Corrosion resistance

MW 3x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 3x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 257 Mx | 2.6 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Submerged application

MW 3x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.21 kg | Standard |

| Water (riverbed) |

0.24 kg

(+0.03 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains only ~20% of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros and cons of neodymium magnets.

Advantages

- They retain attractive force for almost 10 years – the loss is just ~1% (in theory),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of precise forming as well as optimizing to defined requirements,

- Wide application in high-tech industry – they serve a role in hard drives, electric drive systems, precision medical tools, as well as multitasking production systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in creating threads and complicated shapes in magnets, we propose using casing - magnetic mechanism.

- Potential hazard resulting from small fragments of magnets are risky, in case of ingestion, which becomes key in the context of child safety. Additionally, tiny parts of these products are able to be problematic in diagnostics medical when they are in the body.

- With mass production the cost of neodymium magnets is a challenge,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what affects it?

- using a base made of mild steel, serving as a ideal flux conductor

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- with an polished touching surface

- with direct contact (no coatings)

- during pulling in a direction perpendicular to the plane

- in stable room temperature

Lifting capacity in real conditions – factors

- Gap (betwixt the magnet and the metal), as even a microscopic distance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to paint, rust or dirt).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Plate thickness – too thin steel causes magnetic saturation, causing part of the flux to be lost to the other side.

- Material composition – different alloys reacts the same. Alloy additives weaken the interaction with the magnet.

- Surface condition – ground elements ensure maximum contact, which increases field saturation. Uneven metal weaken the grip.

- Temperature – heating the magnet causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under perpendicular forces, whereas under attempts to slide the magnet the holding force is lower. In addition, even a small distance between the magnet’s surface and the plate lowers the holding force.

Safety rules for work with NdFeB magnets

Crushing force

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Danger to pacemakers

Individuals with a ICD must maintain an absolute distance from magnets. The magnetic field can interfere with the operation of the implant.

Handling rules

Before starting, check safety instructions. Sudden snapping can break the magnet or injure your hand. Think ahead.

Skin irritation risks

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If skin irritation happens, immediately stop working with magnets and wear gloves.

Electronic hazard

Very strong magnetic fields can erase data on payment cards, hard drives, and storage devices. Keep a distance of at least 10 cm.

Product not for children

Strictly keep magnets out of reach of children. Choking hazard is high, and the consequences of magnets clamping inside the body are tragic.

Heat warning

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and strength.

Dust explosion hazard

Combustion risk: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this risks ignition.

Protective goggles

NdFeB magnets are sintered ceramics, which means they are very brittle. Collision of two magnets will cause them breaking into small pieces.

Magnetic interference

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Maintain a safe distance from your phone, device, and navigation systems.

![HH 25x7.7 [M5] / N38 - through hole magnetic holder HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)

![MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl40x10x4x27-3.5-suw.jpg)

![SM 18x250 [2xM5] / N42 - magnetic separator SM 18x250 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x250-2xm5-raz.jpg)