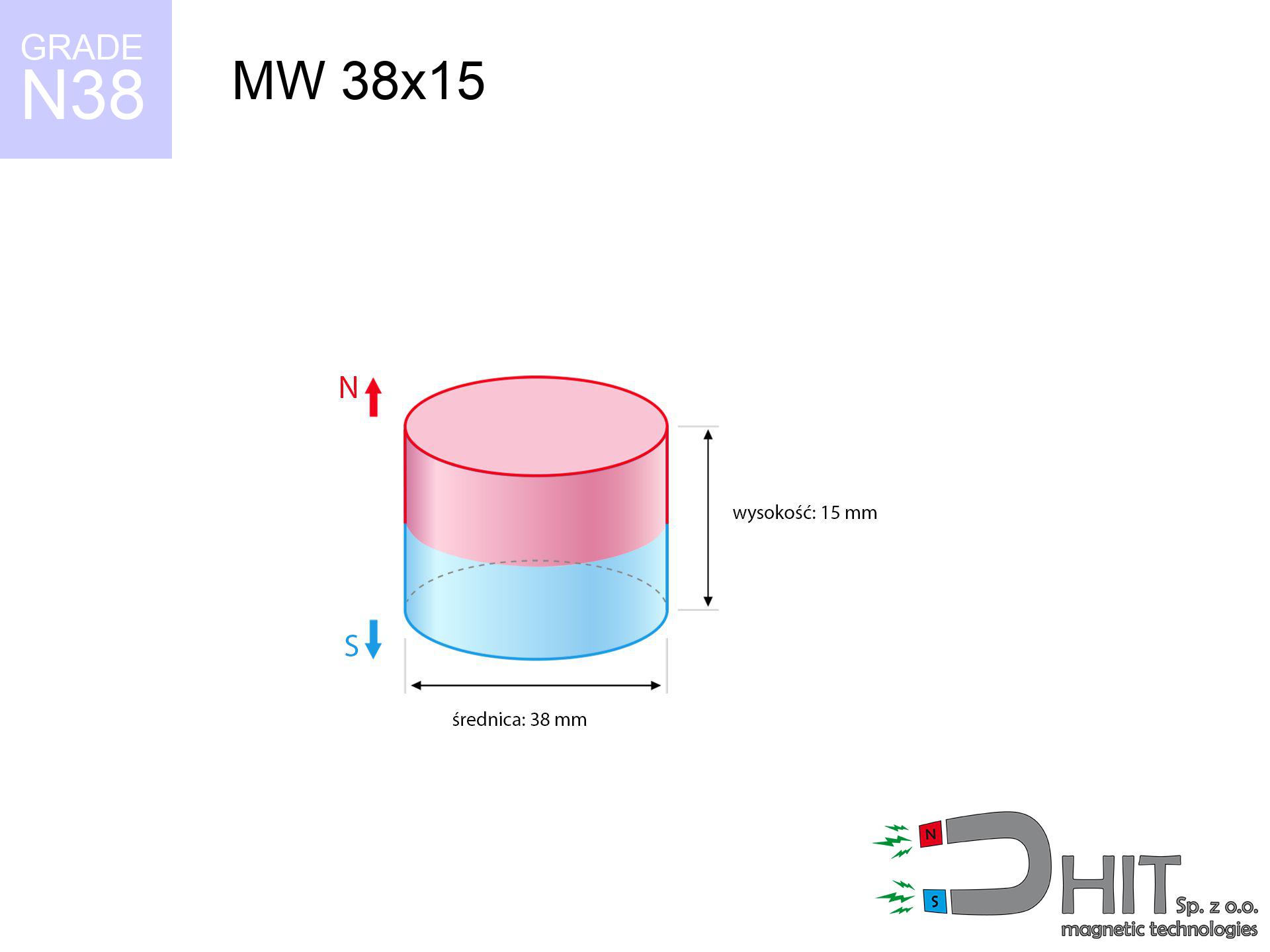

MW 38x15 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010061

GTIN/EAN: 5906301810605

Diameter Ø

38 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

127.59 g

Magnetization Direction

↑ axial

Load capacity

40.08 kg / 393.18 N

Magnetic Induction

384.07 mT / 3841 Gs

Coating

[NiCuNi] Nickel

70.00 ZŁ with VAT / pcs + price for transport

56.91 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or contact us by means of

our online form

the contact section.

Specifications as well as form of neodymium magnets can be calculated with our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Product card - MW 38x15 / N38 - cylindrical magnet

Specification / characteristics - MW 38x15 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010061 |

| GTIN/EAN | 5906301810605 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 38 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 127.59 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 40.08 kg / 393.18 N |

| Magnetic Induction ~ ? | 384.07 mT / 3841 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - data

These values constitute the result of a mathematical calculation. Results rely on algorithms for the material Nd2Fe14B. Real-world conditions may differ. Use these data as a reference point for designers.

Table 1: Static pull force (force vs gap) - characteristics

MW 38x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3840 Gs

384.0 mT

|

40.08 kg / 88.36 pounds

40080.0 g / 393.2 N

|

critical level |

| 1 mm |

3668 Gs

366.8 mT

|

36.56 kg / 80.61 pounds

36563.4 g / 358.7 N

|

critical level |

| 2 mm |

3485 Gs

348.5 mT

|

33.01 kg / 72.78 pounds

33011.6 g / 323.8 N

|

critical level |

| 3 mm |

3297 Gs

329.7 mT

|

29.55 kg / 65.14 pounds

29545.5 g / 289.8 N

|

critical level |

| 5 mm |

2917 Gs

291.7 mT

|

23.13 kg / 50.99 pounds

23128.9 g / 226.9 N

|

critical level |

| 10 mm |

2049 Gs

204.9 mT

|

11.41 kg / 25.15 pounds

11406.3 g / 111.9 N

|

critical level |

| 15 mm |

1396 Gs

139.6 mT

|

5.30 kg / 11.68 pounds

5297.4 g / 52.0 N

|

warning |

| 20 mm |

954 Gs

95.4 mT

|

2.47 kg / 5.45 pounds

2473.1 g / 24.3 N

|

warning |

| 30 mm |

474 Gs

47.4 mT

|

0.61 kg / 1.35 pounds

610.3 g / 6.0 N

|

low risk |

| 50 mm |

155 Gs

15.5 mT

|

0.07 kg / 0.14 pounds

65.6 g / 0.6 N

|

low risk |

Table 2: Shear capacity (wall)

MW 38x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

8.02 kg / 17.67 pounds

8016.0 g / 78.6 N

|

| 1 mm | Stal (~0.2) |

7.31 kg / 16.12 pounds

7312.0 g / 71.7 N

|

| 2 mm | Stal (~0.2) |

6.60 kg / 14.55 pounds

6602.0 g / 64.8 N

|

| 3 mm | Stal (~0.2) |

5.91 kg / 13.03 pounds

5910.0 g / 58.0 N

|

| 5 mm | Stal (~0.2) |

4.63 kg / 10.20 pounds

4626.0 g / 45.4 N

|

| 10 mm | Stal (~0.2) |

2.28 kg / 5.03 pounds

2282.0 g / 22.4 N

|

| 15 mm | Stal (~0.2) |

1.06 kg / 2.34 pounds

1060.0 g / 10.4 N

|

| 20 mm | Stal (~0.2) |

0.49 kg / 1.09 pounds

494.0 g / 4.8 N

|

| 30 mm | Stal (~0.2) |

0.12 kg / 0.27 pounds

122.0 g / 1.2 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

14.0 g / 0.1 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 38x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

12.02 kg / 26.51 pounds

12024.0 g / 118.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

8.02 kg / 17.67 pounds

8016.0 g / 78.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.01 kg / 8.84 pounds

4008.0 g / 39.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

20.04 kg / 44.18 pounds

20040.0 g / 196.6 N

|

Table 4: Steel thickness (saturation) - power losses

MW 38x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.00 kg / 4.42 pounds

2004.0 g / 19.7 N

|

| 1 mm |

|

5.01 kg / 11.05 pounds

5010.0 g / 49.1 N

|

| 2 mm |

|

10.02 kg / 22.09 pounds

10020.0 g / 98.3 N

|

| 3 mm |

|

15.03 kg / 33.14 pounds

15030.0 g / 147.4 N

|

| 5 mm |

|

25.05 kg / 55.23 pounds

25050.0 g / 245.7 N

|

| 10 mm |

|

40.08 kg / 88.36 pounds

40080.0 g / 393.2 N

|

| 11 mm |

|

40.08 kg / 88.36 pounds

40080.0 g / 393.2 N

|

| 12 mm |

|

40.08 kg / 88.36 pounds

40080.0 g / 393.2 N

|

Table 5: Thermal stability (stability) - resistance threshold

MW 38x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

40.08 kg / 88.36 pounds

40080.0 g / 393.2 N

|

OK |

| 40 °C | -2.2% |

39.20 kg / 86.42 pounds

39198.2 g / 384.5 N

|

OK |

| 60 °C | -4.4% |

38.32 kg / 84.47 pounds

38316.5 g / 375.9 N

|

|

| 80 °C | -6.6% |

37.43 kg / 82.53 pounds

37434.7 g / 367.2 N

|

|

| 100 °C | -28.8% |

28.54 kg / 62.91 pounds

28537.0 g / 279.9 N

|

Table 6: Two magnets (repulsion) - field range

MW 38x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

103.10 kg / 227.31 pounds

5 235 Gs

|

15.47 kg / 34.10 pounds

15466 g / 151.7 N

|

N/A |

| 1 mm |

98.64 kg / 217.47 pounds

7 512 Gs

|

14.80 kg / 32.62 pounds

14796 g / 145.2 N

|

88.78 kg / 195.72 pounds

~0 Gs

|

| 2 mm |

94.06 kg / 207.36 pounds

7 336 Gs

|

14.11 kg / 31.10 pounds

14109 g / 138.4 N

|

84.65 kg / 186.63 pounds

~0 Gs

|

| 3 mm |

89.48 kg / 197.26 pounds

7 155 Gs

|

13.42 kg / 29.59 pounds

13421 g / 131.7 N

|

80.53 kg / 177.53 pounds

~0 Gs

|

| 5 mm |

80.42 kg / 177.30 pounds

6 783 Gs

|

12.06 kg / 26.60 pounds

12064 g / 118.3 N

|

72.38 kg / 159.57 pounds

~0 Gs

|

| 10 mm |

59.50 kg / 131.17 pounds

5 834 Gs

|

8.92 kg / 19.68 pounds

8925 g / 87.6 N

|

53.55 kg / 118.05 pounds

~0 Gs

|

| 20 mm |

29.34 kg / 64.69 pounds

4 097 Gs

|

4.40 kg / 9.70 pounds

4401 g / 43.2 N

|

26.41 kg / 58.22 pounds

~0 Gs

|

| 50 mm |

3.08 kg / 6.80 pounds

1 328 Gs

|

0.46 kg / 1.02 pounds

463 g / 4.5 N

|

2.78 kg / 6.12 pounds

~0 Gs

|

| 60 mm |

1.57 kg / 3.46 pounds

948 Gs

|

0.24 kg / 0.52 pounds

236 g / 2.3 N

|

1.41 kg / 3.12 pounds

~0 Gs

|

| 70 mm |

0.84 kg / 1.85 pounds

694 Gs

|

0.13 kg / 0.28 pounds

126 g / 1.2 N

|

0.76 kg / 1.67 pounds

~0 Gs

|

| 80 mm |

0.47 kg / 1.04 pounds

520 Gs

|

0.07 kg / 0.16 pounds

71 g / 0.7 N

|

0.42 kg / 0.94 pounds

~0 Gs

|

| 90 mm |

0.28 kg / 0.61 pounds

398 Gs

|

0.04 kg / 0.09 pounds

42 g / 0.4 N

|

0.25 kg / 0.55 pounds

~0 Gs

|

| 100 mm |

0.17 kg / 0.37 pounds

311 Gs

|

0.03 kg / 0.06 pounds

25 g / 0.2 N

|

0.15 kg / 0.33 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 38x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 18.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 14.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 11.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 9.0 cm |

| Car key | 50 Gs (5.0 mT) | 8.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 38x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.81 km/h

(5.78 m/s)

|

2.13 J | |

| 30 mm |

31.25 km/h

(8.68 m/s)

|

4.81 J | |

| 50 mm |

40.01 km/h

(11.11 m/s)

|

7.88 J | |

| 100 mm |

56.53 km/h

(15.70 m/s)

|

15.73 J |

Table 9: Surface protection spec

MW 38x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 38x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 45 065 Mx | 450.7 µWb |

| Pc Coefficient | 0.50 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 38x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 40.08 kg | Standard |

| Water (riverbed) |

45.89 kg

(+5.81 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet retains merely a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) severely limits the holding force.

3. Temperature resistance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.50

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more deals

Pros and cons of rare earth magnets.

Pros

- They have unchanged lifting capacity, and over around ten years their performance decreases symbolically – ~1% (according to theory),

- They show high resistance to demagnetization induced by external disturbances,

- In other words, due to the glossy finish of nickel, the element looks attractive,

- Neodymium magnets generate maximum magnetic induction on a small area, which allows for strong attraction,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- In view of the potential of accurate forming and customization to unique solutions, neodymium magnets can be produced in a variety of shapes and sizes, which amplifies use scope,

- Huge importance in modern technologies – they are commonly used in magnetic memories, electric motors, diagnostic systems, also modern systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Disadvantages

- Brittleness is one of their disadvantages. Upon strong impact they can break. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited possibility of creating nuts in the magnet and complex shapes - recommended is cover - magnet mounting.

- Possible danger related to microscopic parts of magnets can be dangerous, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small elements of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Pull force analysis

Magnetic strength at its maximum – what affects it?

- using a plate made of low-carbon steel, serving as a magnetic yoke

- with a cross-section of at least 10 mm

- characterized by smoothness

- with zero gap (no impurities)

- during pulling in a direction vertical to the plane

- at standard ambient temperature

Determinants of lifting force in real conditions

- Clearance – existence of foreign body (rust, dirt, gap) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Load vector – highest force is obtained only during pulling at a 90° angle. The shear force of the magnet along the surface is usually several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin plate does not close the flux, causing part of the flux to be lost to the other side.

- Steel grade – the best choice is high-permeability steel. Cast iron may attract less.

- Smoothness – full contact is obtained only on smooth steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a small distance between the magnet and the plate lowers the lifting capacity.

Safe handling of neodymium magnets

Pacemakers

For implant holders: Strong magnetic fields affect medical devices. Maintain at least 30 cm distance or request help to work with the magnets.

Risk of cracking

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Allergy Warning

Some people have a hypersensitivity to Ni, which is the standard coating for NdFeB magnets. Frequent touching may cause dermatitis. It is best to use protective gloves.

Choking Hazard

Adult use only. Small elements pose a choking risk, causing severe trauma. Store out of reach of kids and pets.

Keep away from electronics

A strong magnetic field interferes with the operation of compasses in smartphones and navigation systems. Do not bring magnets close to a smartphone to avoid damaging the sensors.

Protect data

Device Safety: Neodymium magnets can ruin data carriers and sensitive devices (pacemakers, medical aids, timepieces).

Operating temperature

Control the heat. Heating the magnet above 80 degrees Celsius will ruin its properties and pulling force.

Physical harm

Danger of trauma: The pulling power is so immense that it can cause blood blisters, crushing, and even bone fractures. Use thick gloves.

Handling guide

Handle with care. Neodymium magnets attract from a distance and snap with massive power, often quicker than you can react.

Flammability

Dust created during machining of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

![SM 32x150 [2xM8] / N42 - magnetic separator SM 32x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xus.jpg)

![UI 45x13x6 [Z323] / N38 - badge holder UI 45x13x6 [Z323] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui45x13x6-z323-fap.jpg)