HH 25x7.7 [M5] / N38 - through hole magnetic holder

through hole magnetic holder

Catalog no 370482

GTIN/EAN: 5906301814924

Diameter Ø

25 mm [±1 mm]

Height

7.7 mm [±1 mm]

Weight

23.8 g

Magnetization Direction

↑ axial

Load capacity

17.00 kg / 166.71 N

Coating

[NiCuNi] Nickel

11.44 ZŁ with VAT / pcs + price for transport

9.30 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or contact us using

inquiry form

the contact section.

Lifting power and form of neodymium magnets can be analyzed with our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - HH 25x7.7 [M5] / N38 - through hole magnetic holder

Specification / characteristics - HH 25x7.7 [M5] / N38 - through hole magnetic holder

| properties | values |

|---|---|

| Cat. no. | 370482 |

| GTIN/EAN | 5906301814924 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

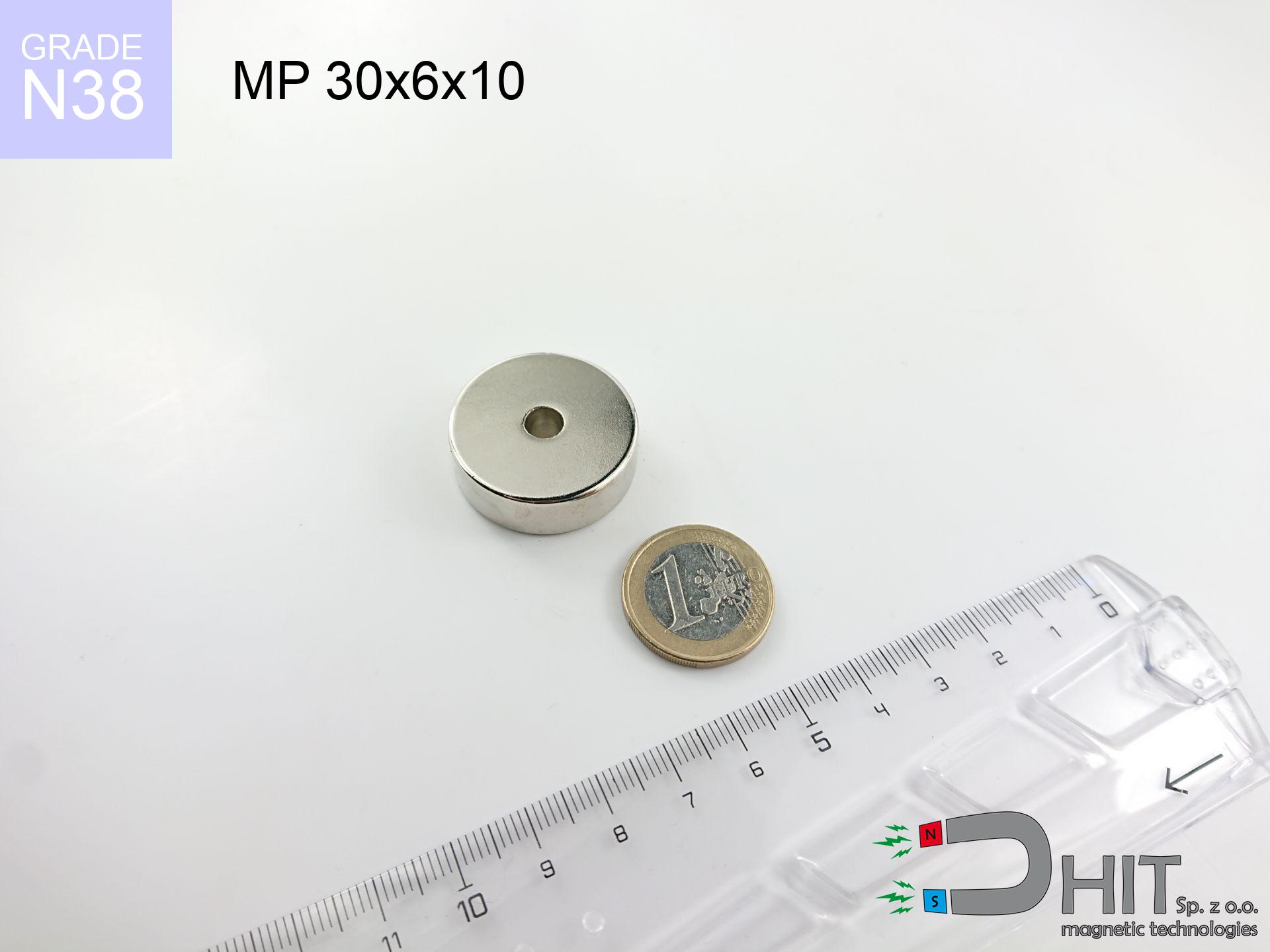

| Diameter Ø | 25 mm [±1 mm] |

| Height | 7.7 mm [±1 mm] |

| Weight | 23.8 g |

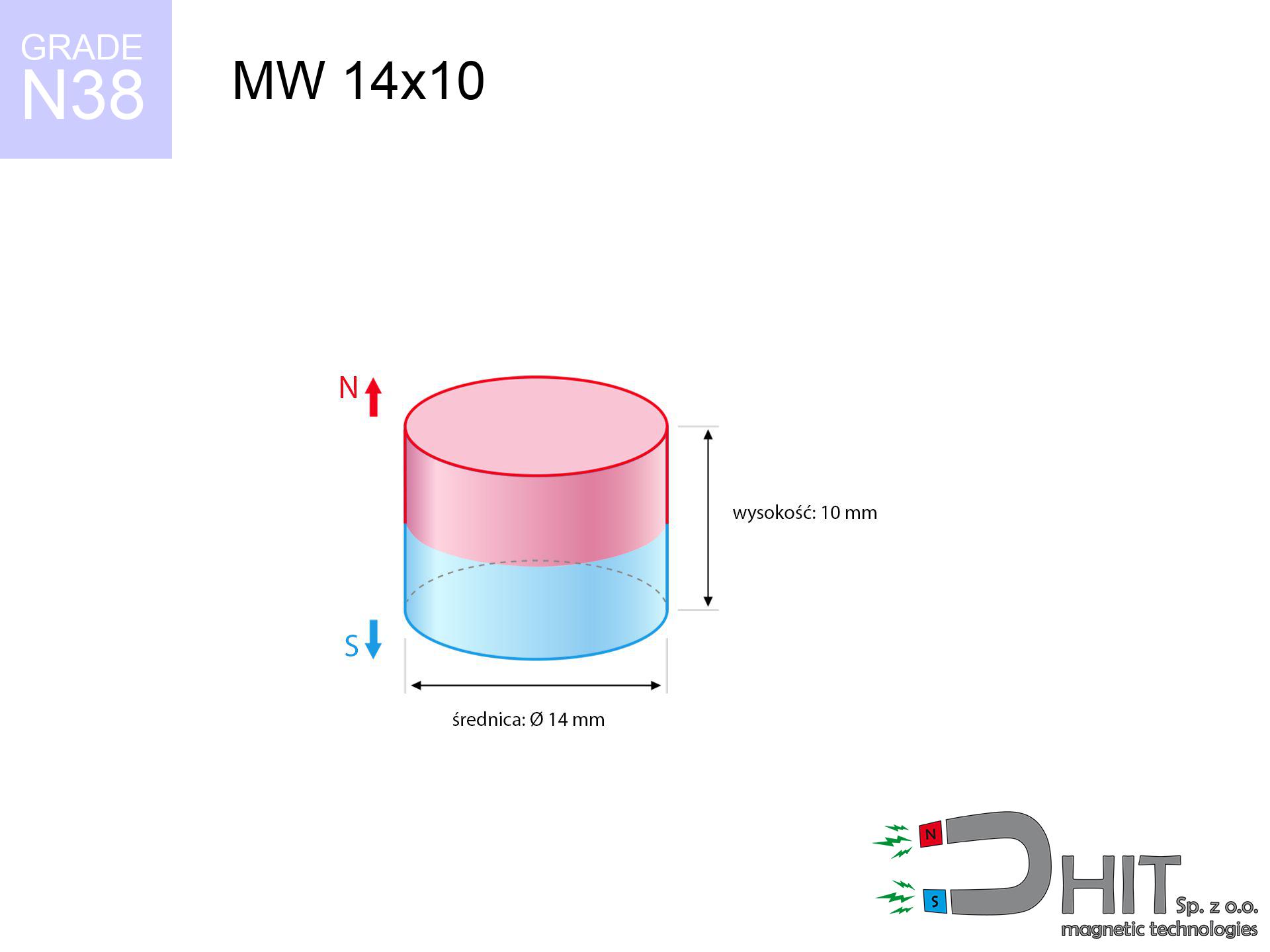

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 17.00 kg / 166.71 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of neodymium magnets.

Strengths

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- Magnets effectively defend themselves against demagnetization caused by external fields,

- In other words, due to the shiny surface of silver, the element gains visual value,

- Magnets have maximum magnetic induction on the working surface,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to the possibility of free forming and customization to unique projects, NdFeB magnets can be modeled in a broad palette of shapes and sizes, which amplifies use scope,

- Wide application in future technologies – they are utilized in computer drives, motor assemblies, medical devices, as well as technologically advanced constructions.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Weaknesses

- Brittleness is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We suggest casing - magnetic mechanism, due to difficulties in creating threads inside the magnet and complex shapes.

- Possible danger to health – tiny shards of magnets pose a threat, in case of ingestion, which gains importance in the aspect of protecting the youngest. Additionally, small elements of these devices are able to disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum magnetic pulling force – what it depends on?

- with the application of a yoke made of special test steel, ensuring maximum field concentration

- with a cross-section no less than 10 mm

- characterized by even structure

- under conditions of gap-free contact (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Distance – the presence of any layer (paint, dirt, air) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Plate thickness – insufficiently thick sheet causes magnetic saturation, causing part of the power to be wasted to the other side.

- Steel type – mild steel gives the best results. Higher carbon content decrease magnetic properties and lifting capacity.

- Plate texture – smooth surfaces ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Temperature influence – high temperature reduces magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under perpendicular forces, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate decreases the load capacity.

Precautions when working with neodymium magnets

Medical implants

Patients with a pacemaker have to keep an absolute distance from magnets. The magnetism can stop the operation of the life-saving device.

Dust explosion hazard

Dust created during grinding of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

Cards and drives

Avoid bringing magnets close to a wallet, laptop, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Heat sensitivity

Control the heat. Heating the magnet to high heat will permanently weaken its properties and strength.

Compass and GPS

Navigation devices and smartphones are extremely susceptible to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Eye protection

Despite metallic appearance, neodymium is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

No play value

NdFeB magnets are not intended for children. Swallowing multiple magnets can lead to them pinching intestinal walls, which poses a severe health hazard and requires immediate surgery.

Avoid contact if allergic

Nickel alert: The Ni-Cu-Ni coating contains nickel. If an allergic reaction appears, immediately stop working with magnets and use protective gear.

Hand protection

Pinching hazard: The attraction force is so great that it can cause hematomas, crushing, and broken bones. Protective gloves are recommended.

Immense force

Handle with care. Neodymium magnets act from a distance and snap with huge force, often faster than you can move away.

![Magnet with hole HH 25x7.7 [M5] / N38 Magnet with hole HH 25x7.7 [M5] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)