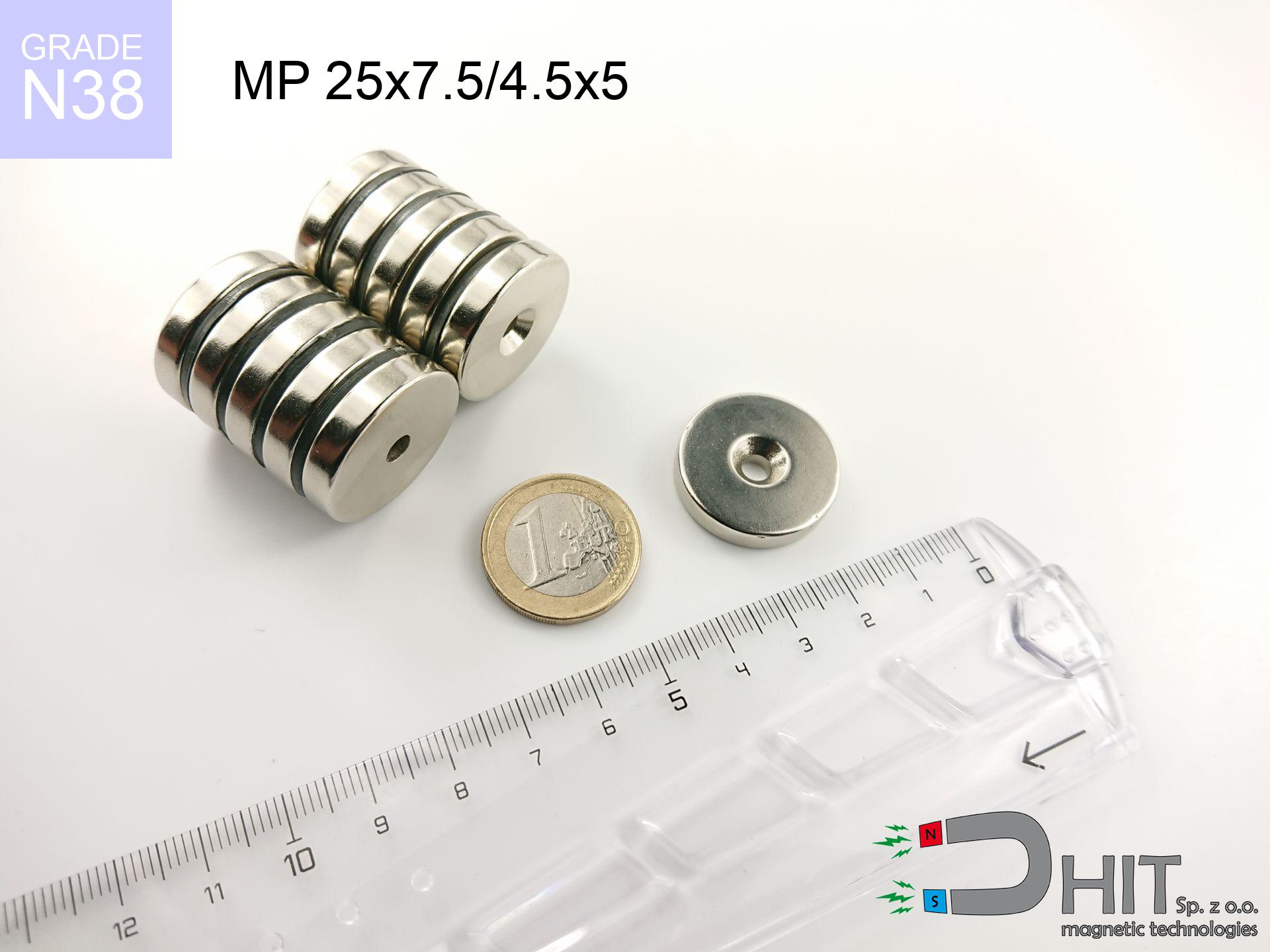

MP 25x7.5/4.5x5 / N38 - ring magnet

ring magnet

Catalog no 030194

GTIN/EAN: 5906301812111

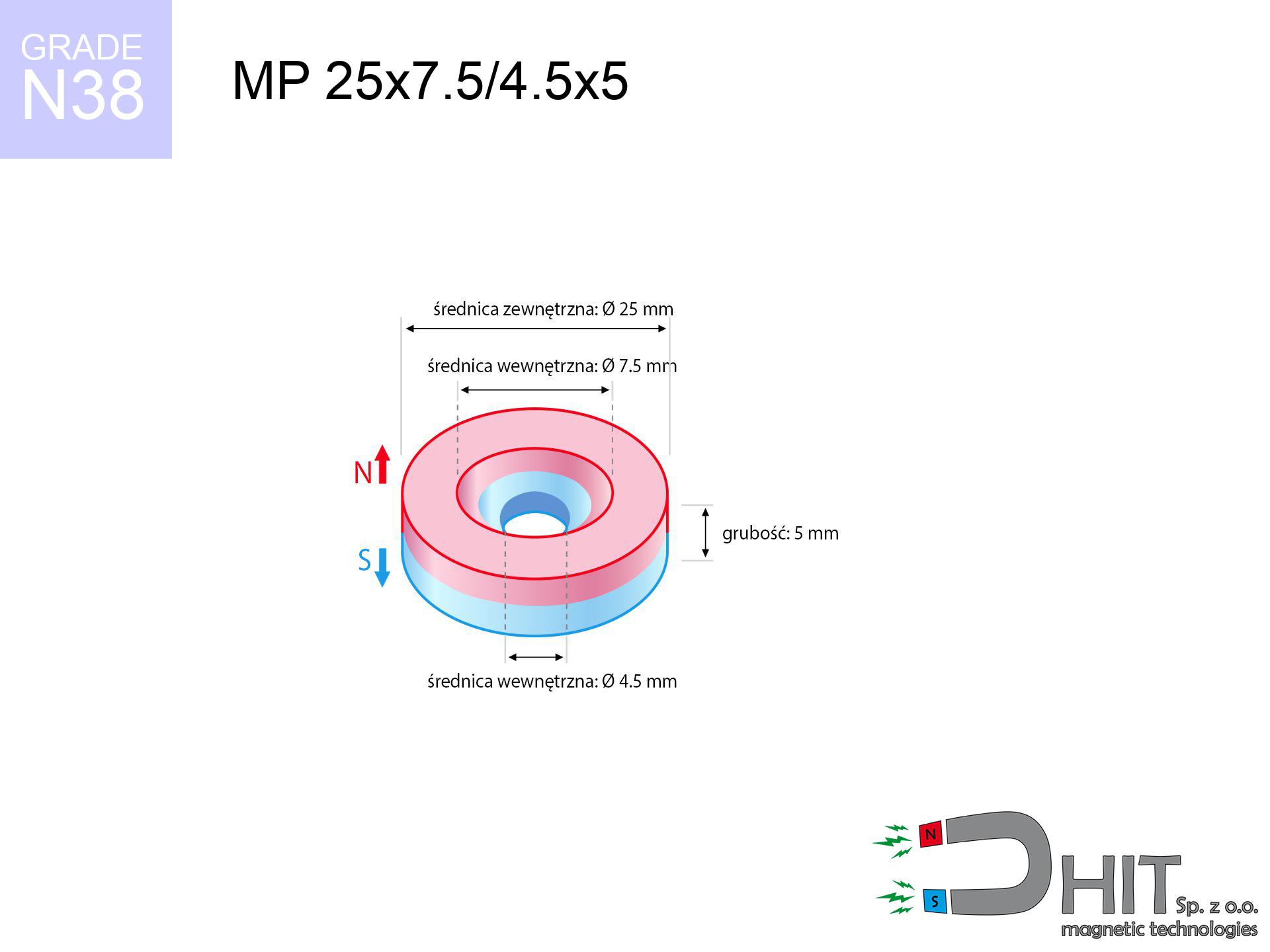

Diameter

25 mm [±0,1 mm]

internal diameter Ø

7.5/4.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

17.81 g

Magnetization Direction

↑ axial

Load capacity

7.72 kg / 75.69 N

Magnetic Induction

230.20 mT / 2302 Gs

Coating

[NiCuNi] Nickel

8.00 ZŁ with VAT / pcs + price for transport

6.50 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively drop us a message using

form

the contact form page.

Specifications along with form of a neodymium magnet can be tested with our

modular calculator.

Same-day processing for orders placed before 14:00.

Technical data of the product - MP 25x7.5/4.5x5 / N38 - ring magnet

Specification / characteristics - MP 25x7.5/4.5x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030194 |

| GTIN/EAN | 5906301812111 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 7.5/4.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 17.81 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.72 kg / 75.69 N |

| Magnetic Induction ~ ? | 230.20 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the magnet - data

The following values represent the result of a physical calculation. Results rely on models for the material Nd2Fe14B. Actual conditions may differ from theoretical values. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (pull vs distance) - characteristics

MP 25x7.5/4.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1995 Gs

199.5 mT

|

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

strong |

| 1 mm |

1906 Gs

190.6 mT

|

7.05 kg / 15.54 LBS

7049.4 g / 69.2 N

|

strong |

| 2 mm |

1793 Gs

179.3 mT

|

6.24 kg / 13.75 LBS

6236.8 g / 61.2 N

|

strong |

| 3 mm |

1664 Gs

166.4 mT

|

5.37 kg / 11.84 LBS

5368.9 g / 52.7 N

|

strong |

| 5 mm |

1385 Gs

138.5 mT

|

3.72 kg / 8.21 LBS

3722.8 g / 36.5 N

|

strong |

| 10 mm |

788 Gs

78.8 mT

|

1.20 kg / 2.65 LBS

1203.8 g / 11.8 N

|

safe |

| 15 mm |

437 Gs

43.7 mT

|

0.37 kg / 0.82 LBS

370.3 g / 3.6 N

|

safe |

| 20 mm |

253 Gs

25.3 mT

|

0.12 kg / 0.27 LBS

124.5 g / 1.2 N

|

safe |

| 30 mm |

101 Gs

10.1 mT

|

0.02 kg / 0.04 LBS

19.8 g / 0.2 N

|

safe |

| 50 mm |

27 Gs

2.7 mT

|

0.00 kg / 0.00 LBS

1.4 g / 0.0 N

|

safe |

Table 2: Slippage capacity (vertical surface)

MP 25x7.5/4.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.54 kg / 3.40 LBS

1544.0 g / 15.1 N

|

| 1 mm | Stal (~0.2) |

1.41 kg / 3.11 LBS

1410.0 g / 13.8 N

|

| 2 mm | Stal (~0.2) |

1.25 kg / 2.75 LBS

1248.0 g / 12.2 N

|

| 3 mm | Stal (~0.2) |

1.07 kg / 2.37 LBS

1074.0 g / 10.5 N

|

| 5 mm | Stal (~0.2) |

0.74 kg / 1.64 LBS

744.0 g / 7.3 N

|

| 10 mm | Stal (~0.2) |

0.24 kg / 0.53 LBS

240.0 g / 2.4 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.16 LBS

74.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 25x7.5/4.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.32 kg / 5.11 LBS

2316.0 g / 22.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.54 kg / 3.40 LBS

1544.0 g / 15.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.77 kg / 1.70 LBS

772.0 g / 7.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.86 kg / 8.51 LBS

3860.0 g / 37.9 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MP 25x7.5/4.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.77 kg / 1.70 LBS

772.0 g / 7.6 N

|

| 1 mm |

|

1.93 kg / 4.25 LBS

1930.0 g / 18.9 N

|

| 2 mm |

|

3.86 kg / 8.51 LBS

3860.0 g / 37.9 N

|

| 3 mm |

|

5.79 kg / 12.76 LBS

5790.0 g / 56.8 N

|

| 5 mm |

|

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

| 10 mm |

|

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

| 11 mm |

|

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

| 12 mm |

|

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MP 25x7.5/4.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.72 kg / 17.02 LBS

7720.0 g / 75.7 N

|

OK |

| 40 °C | -2.2% |

7.55 kg / 16.65 LBS

7550.2 g / 74.1 N

|

OK |

| 60 °C | -4.4% |

7.38 kg / 16.27 LBS

7380.3 g / 72.4 N

|

|

| 80 °C | -6.6% |

7.21 kg / 15.90 LBS

7210.5 g / 70.7 N

|

|

| 100 °C | -28.8% |

5.50 kg / 12.12 LBS

5496.6 g / 53.9 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MP 25x7.5/4.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.91 kg / 21.84 LBS

3 484 Gs

|

1.49 kg / 3.28 LBS

1486 g / 14.6 N

|

N/A |

| 1 mm |

9.51 kg / 20.96 LBS

3 909 Gs

|

1.43 kg / 3.14 LBS

1426 g / 14.0 N

|

8.56 kg / 18.87 LBS

~0 Gs

|

| 2 mm |

9.05 kg / 19.94 LBS

3 813 Gs

|

1.36 kg / 2.99 LBS

1357 g / 13.3 N

|

8.14 kg / 17.95 LBS

~0 Gs

|

| 3 mm |

8.54 kg / 18.83 LBS

3 705 Gs

|

1.28 kg / 2.82 LBS

1281 g / 12.6 N

|

7.69 kg / 16.94 LBS

~0 Gs

|

| 5 mm |

7.45 kg / 16.42 LBS

3 460 Gs

|

1.12 kg / 2.46 LBS

1117 g / 11.0 N

|

6.70 kg / 14.78 LBS

~0 Gs

|

| 10 mm |

4.78 kg / 10.53 LBS

2 771 Gs

|

0.72 kg / 1.58 LBS

717 g / 7.0 N

|

4.30 kg / 9.48 LBS

~0 Gs

|

| 20 mm |

1.54 kg / 3.41 LBS

1 576 Gs

|

0.23 kg / 0.51 LBS

232 g / 2.3 N

|

1.39 kg / 3.06 LBS

~0 Gs

|

| 50 mm |

0.06 kg / 0.13 LBS

312 Gs

|

0.01 kg / 0.02 LBS

9 g / 0.1 N

|

0.05 kg / 0.12 LBS

~0 Gs

|

| 60 mm |

0.03 kg / 0.06 LBS

202 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.02 kg / 0.05 LBS

~0 Gs

|

| 70 mm |

0.01 kg / 0.03 LBS

138 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 80 mm |

0.01 kg / 0.01 LBS

97 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 LBS

71 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

54 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MP 25x7.5/4.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.5 cm |

| Remote | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 25x7.5/4.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.95 km/h

(6.38 m/s)

|

0.36 J | |

| 30 mm |

36.43 km/h

(10.12 m/s)

|

0.91 J | |

| 50 mm |

46.96 km/h

(13.04 m/s)

|

1.52 J | |

| 100 mm |

66.40 km/h

(18.44 m/s)

|

3.03 J |

Table 9: Coating parameters (durability)

MP 25x7.5/4.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 25x7.5/4.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 9 759 Mx | 97.6 µWb |

| Pc Coefficient | 0.25 | Low (Flat) |

Table 11: Physics of underwater searching

MP 25x7.5/4.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.72 kg | Standard |

| Water (riverbed) |

8.84 kg

(+1.12 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet holds merely ~20% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.25

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages and disadvantages of Nd2Fe14B magnets.

Advantages

- They retain magnetic properties for around 10 years – the drop is just ~1% (according to analyses),

- Neodymium magnets are characterized by exceptionally resistant to magnetic field loss caused by external magnetic fields,

- A magnet with a shiny gold surface is more attractive,

- Magnets have excellent magnetic induction on the outer layer,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for action at temperatures approaching 230°C and above...

- Possibility of accurate creating and optimizing to defined requirements,

- Huge importance in future technologies – they are used in computer drives, electric motors, precision medical tools, also industrial machines.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a steel housing, which not only protects them against impacts but also increases their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited ability of making nuts in the magnet and complex forms - recommended is cover - mounting mechanism.

- Potential hazard resulting from small fragments of magnets are risky, in case of ingestion, which gains importance in the context of child safety. It is also worth noting that small components of these magnets are able to complicate diagnosis medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Highest magnetic holding force – what it depends on?

- on a block made of structural steel, effectively closing the magnetic field

- whose thickness equals approx. 10 mm

- characterized by even structure

- with direct contact (without impurities)

- under perpendicular force direction (90-degree angle)

- in stable room temperature

Determinants of practical lifting force of a magnet

- Clearance – the presence of foreign body (rust, dirt, gap) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Steel grade – ideal substrate is pure iron steel. Stainless steels may generate lower lifting capacity.

- Plate texture – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces reduce efficiency.

- Thermal environment – temperature increase results in weakening of force. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was performed on a smooth plate of suitable thickness, under a perpendicular pulling force, however under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a small distance between the magnet’s surface and the plate reduces the load capacity.

Warnings

Precision electronics

Navigation devices and mobile phones are extremely sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Powerful field

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Magnet fragility

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Danger to pacemakers

Warning for patients: Powerful magnets affect medical devices. Maintain minimum 30 cm distance or request help to work with the magnets.

Do not give to children

Always store magnets away from children. Risk of swallowing is high, and the consequences of magnets connecting inside the body are very dangerous.

Keep away from computers

Intense magnetic fields can erase data on payment cards, hard drives, and other magnetic media. Keep a distance of at least 10 cm.

Nickel coating and allergies

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If an allergic reaction happens, immediately stop handling magnets and wear gloves.

Thermal limits

Do not overheat. NdFeB magnets are susceptible to temperature. If you need resistance above 80°C, look for special high-temperature series (H, SH, UH).

Bodily injuries

Protect your hands. Two large magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Fire risk

Drilling and cutting of neodymium magnets poses a fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

![SM 18x200 [2xM5] / N42 - magnetic separator SM 18x200 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x200-2xm5-gig.jpg)

![AM ucho małe [M8] - magnetic accessories AM ucho małe [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-małe-m8-zud.jpg)

![UMH 25x8x45 [M5] / N38 - magnetic holder with hook UMH 25x8x45 [M5] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-25x8x45-m5-cep.jpg)