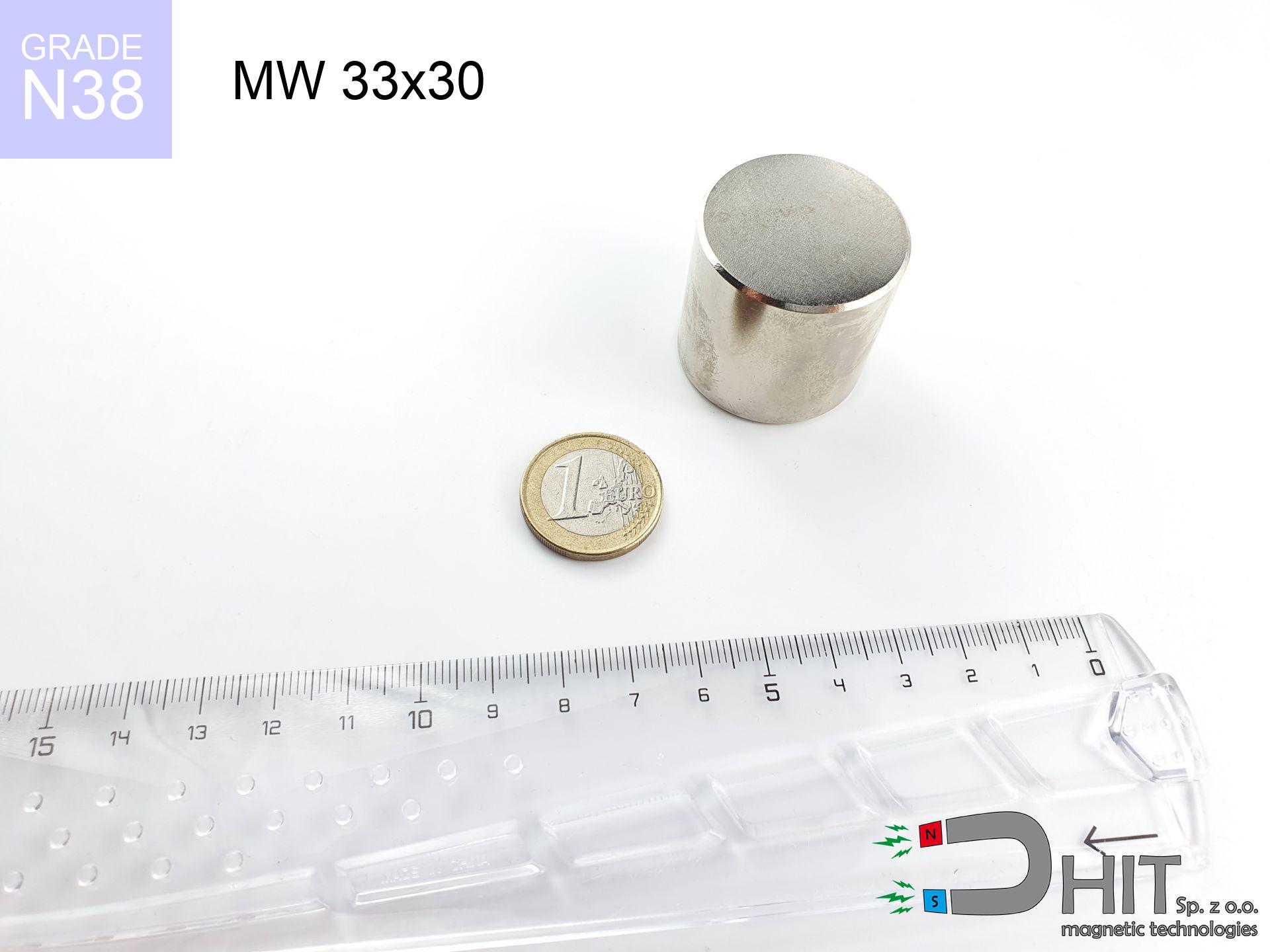

MW 33x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010058

GTIN/EAN: 5906301810575

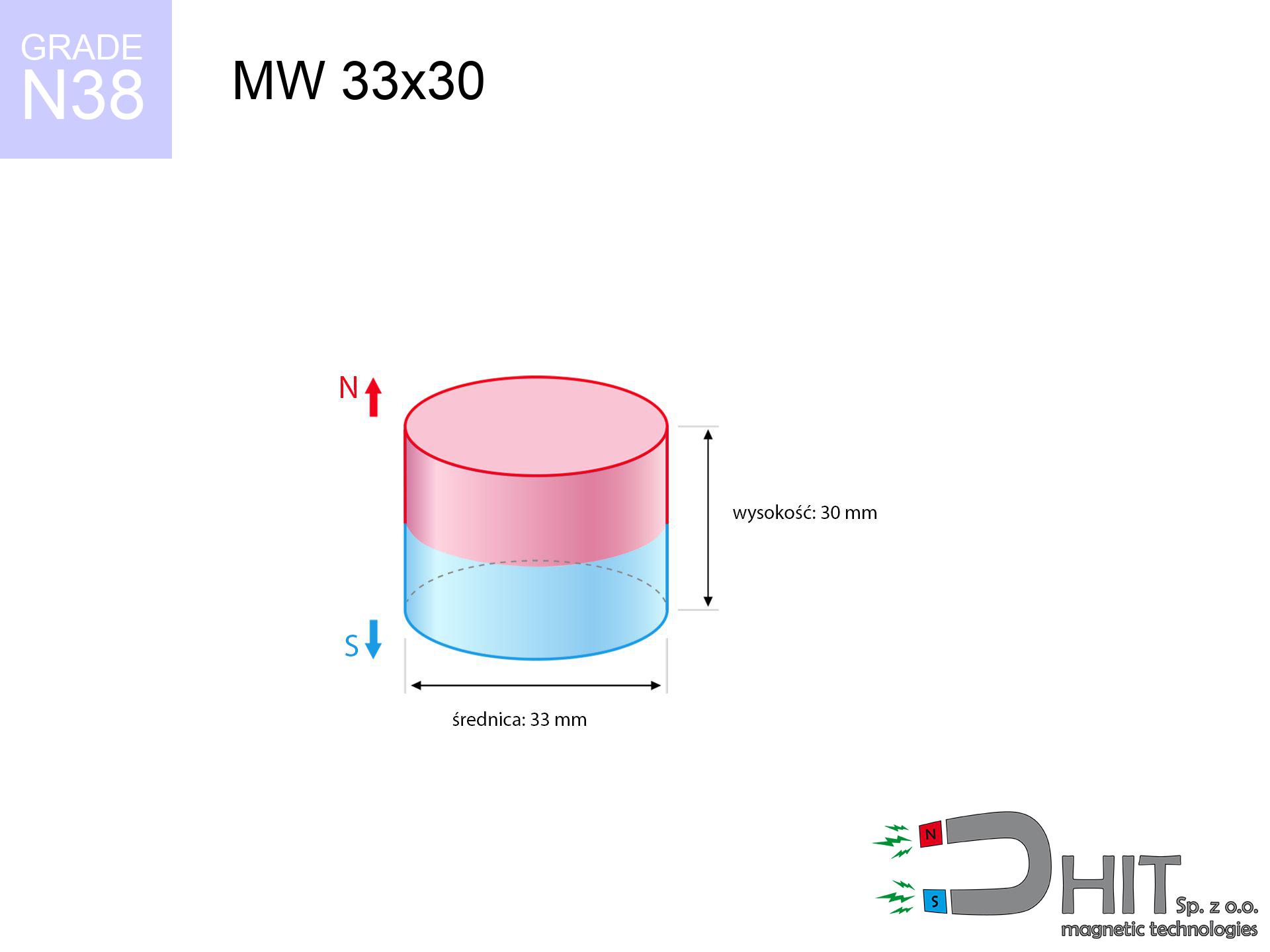

Diameter Ø

33 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

192.44 g

Magnetization Direction

↑ axial

Load capacity

35.84 kg / 351.54 N

Magnetic Induction

543.05 mT / 5430 Gs

Coating

[NiCuNi] Nickel

52.89 ZŁ with VAT / pcs + price for transport

43.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer send us a note through

our online form

our website.

Specifications as well as structure of neodymium magnets can be calculated with our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical specification - MW 33x30 / N38 - cylindrical magnet

Specification / characteristics - MW 33x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010058 |

| GTIN/EAN | 5906301810575 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 33 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 192.44 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 35.84 kg / 351.54 N |

| Magnetic Induction ~ ? | 543.05 mT / 5430 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - technical parameters

These information constitute the outcome of a mathematical simulation. Values are based on models for the class Nd2Fe14B. Operational parameters may differ. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static force (pull vs gap) - interaction chart

MW 33x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5429 Gs

542.9 mT

|

35.84 kg / 79.01 lbs

35840.0 g / 351.6 N

|

dangerous! |

| 1 mm |

5098 Gs

509.8 mT

|

31.60 kg / 69.67 lbs

31600.1 g / 310.0 N

|

dangerous! |

| 2 mm |

4765 Gs

476.5 mT

|

27.60 kg / 60.85 lbs

27601.7 g / 270.8 N

|

dangerous! |

| 3 mm |

4436 Gs

443.6 mT

|

23.93 kg / 52.76 lbs

23930.4 g / 234.8 N

|

dangerous! |

| 5 mm |

3810 Gs

381.0 mT

|

17.65 kg / 38.91 lbs

17650.2 g / 173.1 N

|

dangerous! |

| 10 mm |

2518 Gs

251.8 mT

|

7.71 kg / 17.00 lbs

7709.5 g / 75.6 N

|

medium risk |

| 15 mm |

1650 Gs

165.0 mT

|

3.31 kg / 7.30 lbs

3312.1 g / 32.5 N

|

medium risk |

| 20 mm |

1105 Gs

110.5 mT

|

1.49 kg / 3.27 lbs

1485.1 g / 14.6 N

|

weak grip |

| 30 mm |

546 Gs

54.6 mT

|

0.36 kg / 0.80 lbs

361.9 g / 3.5 N

|

weak grip |

| 50 mm |

184 Gs

18.4 mT

|

0.04 kg / 0.09 lbs

41.4 g / 0.4 N

|

weak grip |

Table 2: Vertical capacity (wall)

MW 33x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

7.17 kg / 15.80 lbs

7168.0 g / 70.3 N

|

| 1 mm | Stal (~0.2) |

6.32 kg / 13.93 lbs

6320.0 g / 62.0 N

|

| 2 mm | Stal (~0.2) |

5.52 kg / 12.17 lbs

5520.0 g / 54.2 N

|

| 3 mm | Stal (~0.2) |

4.79 kg / 10.55 lbs

4786.0 g / 47.0 N

|

| 5 mm | Stal (~0.2) |

3.53 kg / 7.78 lbs

3530.0 g / 34.6 N

|

| 10 mm | Stal (~0.2) |

1.54 kg / 3.40 lbs

1542.0 g / 15.1 N

|

| 15 mm | Stal (~0.2) |

0.66 kg / 1.46 lbs

662.0 g / 6.5 N

|

| 20 mm | Stal (~0.2) |

0.30 kg / 0.66 lbs

298.0 g / 2.9 N

|

| 30 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

72.0 g / 0.7 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 33x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

10.75 kg / 23.70 lbs

10752.0 g / 105.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

7.17 kg / 15.80 lbs

7168.0 g / 70.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

3.58 kg / 7.90 lbs

3584.0 g / 35.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

17.92 kg / 39.51 lbs

17920.0 g / 175.8 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 33x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.79 kg / 3.95 lbs

1792.0 g / 17.6 N

|

| 1 mm |

|

4.48 kg / 9.88 lbs

4480.0 g / 43.9 N

|

| 2 mm |

|

8.96 kg / 19.75 lbs

8960.0 g / 87.9 N

|

| 3 mm |

|

13.44 kg / 29.63 lbs

13440.0 g / 131.8 N

|

| 5 mm |

|

22.40 kg / 49.38 lbs

22400.0 g / 219.7 N

|

| 10 mm |

|

35.84 kg / 79.01 lbs

35840.0 g / 351.6 N

|

| 11 mm |

|

35.84 kg / 79.01 lbs

35840.0 g / 351.6 N

|

| 12 mm |

|

35.84 kg / 79.01 lbs

35840.0 g / 351.6 N

|

Table 5: Thermal resistance (stability) - power drop

MW 33x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

35.84 kg / 79.01 lbs

35840.0 g / 351.6 N

|

OK |

| 40 °C | -2.2% |

35.05 kg / 77.28 lbs

35051.5 g / 343.9 N

|

OK |

| 60 °C | -4.4% |

34.26 kg / 75.54 lbs

34263.0 g / 336.1 N

|

OK |

| 80 °C | -6.6% |

33.47 kg / 73.80 lbs

33474.6 g / 328.4 N

|

|

| 100 °C | -28.8% |

25.52 kg / 56.26 lbs

25518.1 g / 250.3 N

|

Table 6: Two magnets (repulsion) - field range

MW 33x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

155.43 kg / 342.66 lbs

5 974 Gs

|

23.31 kg / 51.40 lbs

23314 g / 228.7 N

|

N/A |

| 1 mm |

146.19 kg / 322.29 lbs

10 531 Gs

|

21.93 kg / 48.34 lbs

21928 g / 215.1 N

|

131.57 kg / 290.06 lbs

~0 Gs

|

| 2 mm |

137.04 kg / 302.12 lbs

10 196 Gs

|

20.56 kg / 45.32 lbs

20556 g / 201.7 N

|

123.34 kg / 271.91 lbs

~0 Gs

|

| 3 mm |

128.20 kg / 282.64 lbs

9 862 Gs

|

19.23 kg / 42.40 lbs

19230 g / 188.6 N

|

115.38 kg / 254.37 lbs

~0 Gs

|

| 5 mm |

111.55 kg / 245.93 lbs

9 199 Gs

|

16.73 kg / 36.89 lbs

16733 g / 164.2 N

|

100.40 kg / 221.34 lbs

~0 Gs

|

| 10 mm |

76.54 kg / 168.75 lbs

7 620 Gs

|

11.48 kg / 25.31 lbs

11481 g / 112.6 N

|

68.89 kg / 151.87 lbs

~0 Gs

|

| 20 mm |

33.43 kg / 73.71 lbs

5 036 Gs

|

5.02 kg / 11.06 lbs

5015 g / 49.2 N

|

30.09 kg / 66.34 lbs

~0 Gs

|

| 50 mm |

3.08 kg / 6.78 lbs

1 528 Gs

|

0.46 kg / 1.02 lbs

462 g / 4.5 N

|

2.77 kg / 6.11 lbs

~0 Gs

|

| 60 mm |

1.57 kg / 3.46 lbs

1 091 Gs

|

0.24 kg / 0.52 lbs

235 g / 2.3 N

|

1.41 kg / 3.11 lbs

~0 Gs

|

| 70 mm |

0.85 kg / 1.87 lbs

803 Gs

|

0.13 kg / 0.28 lbs

127 g / 1.2 N

|

0.76 kg / 1.69 lbs

~0 Gs

|

| 80 mm |

0.48 kg / 1.07 lbs

606 Gs

|

0.07 kg / 0.16 lbs

73 g / 0.7 N

|

0.44 kg / 0.96 lbs

~0 Gs

|

| 90 mm |

0.29 kg / 0.64 lbs

468 Gs

|

0.04 kg / 0.10 lbs

43 g / 0.4 N

|

0.26 kg / 0.57 lbs

~0 Gs

|

| 100 mm |

0.18 kg / 0.40 lbs

369 Gs

|

0.03 kg / 0.06 lbs

27 g / 0.3 N

|

0.16 kg / 0.36 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 33x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 20.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 16.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 12.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 9.5 cm |

| Car key | 50 Gs (5.0 mT) | 9.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 33x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.50 km/h

(4.31 m/s)

|

1.78 J | |

| 30 mm |

23.99 km/h

(6.66 m/s)

|

4.27 J | |

| 50 mm |

30.80 km/h

(8.55 m/s)

|

7.04 J | |

| 100 mm |

43.52 km/h

(12.09 m/s)

|

14.06 J |

Table 9: Surface protection spec

MW 33x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 33x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 47 447 Mx | 474.5 µWb |

| Pc Coefficient | 0.85 | High (Stable) |

Table 11: Physics of underwater searching

MW 33x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 35.84 kg | Standard |

| Water (riverbed) |

41.04 kg

(+5.20 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds merely a fraction of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) drastically weakens the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.85

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of Nd2Fe14B magnets.

Advantages

- They retain attractive force for nearly ten years – the drop is just ~1% (based on simulations),

- They feature excellent resistance to magnetic field loss due to external fields,

- In other words, due to the smooth surface of gold, the element looks attractive,

- Magnetic induction on the working part of the magnet remains exceptional,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to the ability of free forming and adaptation to individualized solutions, NdFeB magnets can be produced in a wide range of geometric configurations, which increases their versatility,

- Fundamental importance in future technologies – they are utilized in HDD drives, motor assemblies, medical equipment, and industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a special holder, which not only secures them against impacts but also increases their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Due to limitations in producing nuts and complicated forms in magnets, we recommend using casing - magnetic mount.

- Health risk related to microscopic parts of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. Additionally, small components of these magnets are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- on a plate made of structural steel, optimally conducting the magnetic field

- with a cross-section minimum 10 mm

- characterized by even structure

- with direct contact (no coatings)

- under vertical application of breakaway force (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

- Gap between magnet and steel – every millimeter of separation (caused e.g. by veneer or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Steel grade – the best choice is high-permeability steel. Stainless steels may have worse magnetic properties.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Rough surfaces reduce efficiency.

- Temperature influence – high temperature reduces magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

Safety rules for work with NdFeB magnets

Impact on smartphones

GPS units and smartphones are highly sensitive to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Crushing risk

Mind your fingers. Two powerful magnets will snap together instantly with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Cards and drives

Intense magnetic fields can erase data on payment cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

Machining danger

Dust produced during cutting of magnets is flammable. Do not drill into magnets without proper cooling and knowledge.

Shattering risk

Protect your eyes. Magnets can explode upon violent connection, ejecting shards into the air. Wear goggles.

Permanent damage

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Handling guide

Handle magnets consciously. Their powerful strength can shock even experienced users. Be vigilant and do not underestimate their power.

Sensitization to coating

Nickel alert: The Ni-Cu-Ni coating contains nickel. If skin irritation appears, immediately stop working with magnets and wear gloves.

Swallowing risk

Product intended for adults. Tiny parts pose a choking risk, leading to serious injuries. Keep away from children and animals.

ICD Warning

Health Alert: Neodymium magnets can deactivate pacemakers and defibrillators. Do not approach if you have medical devices.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)