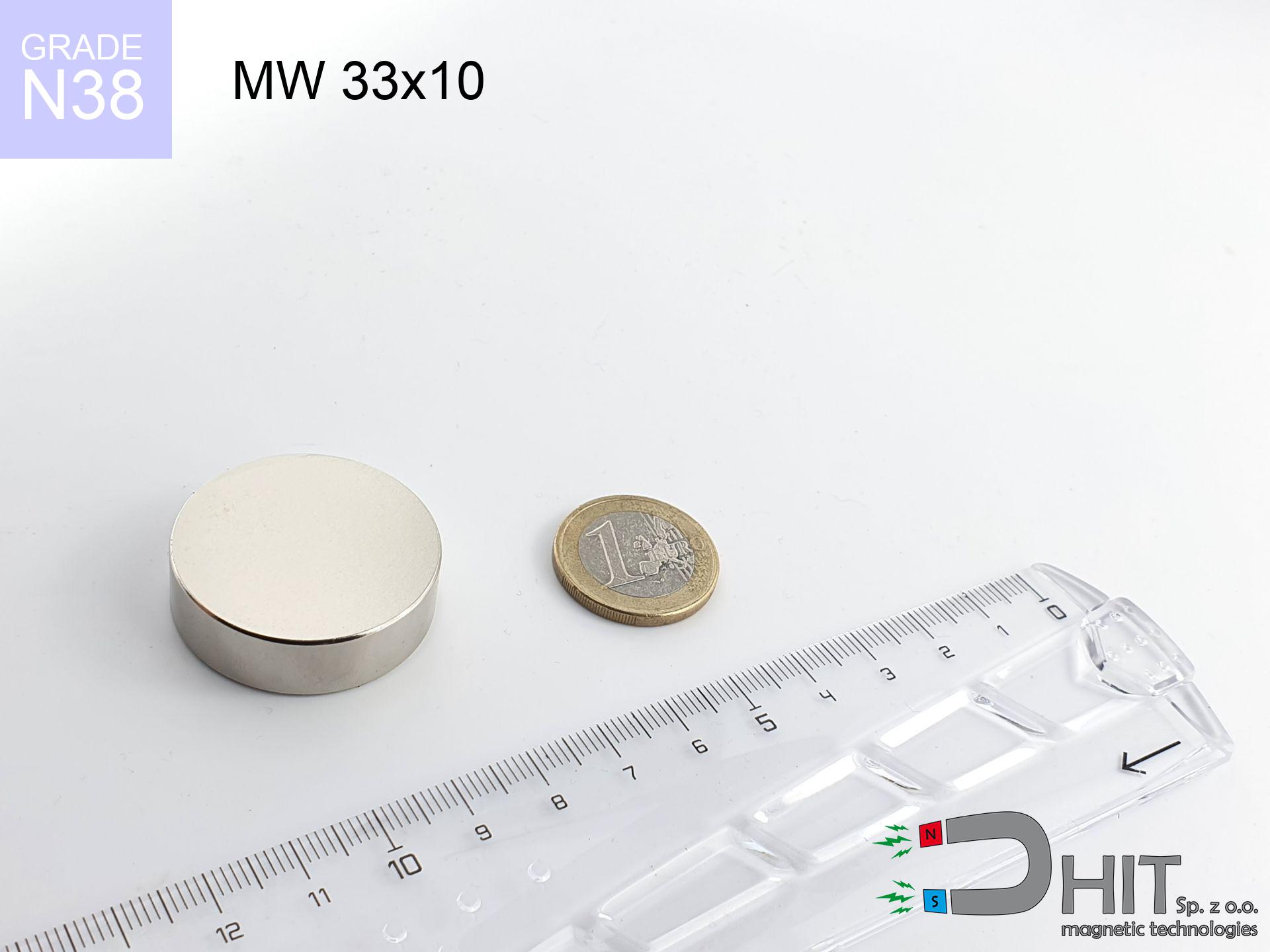

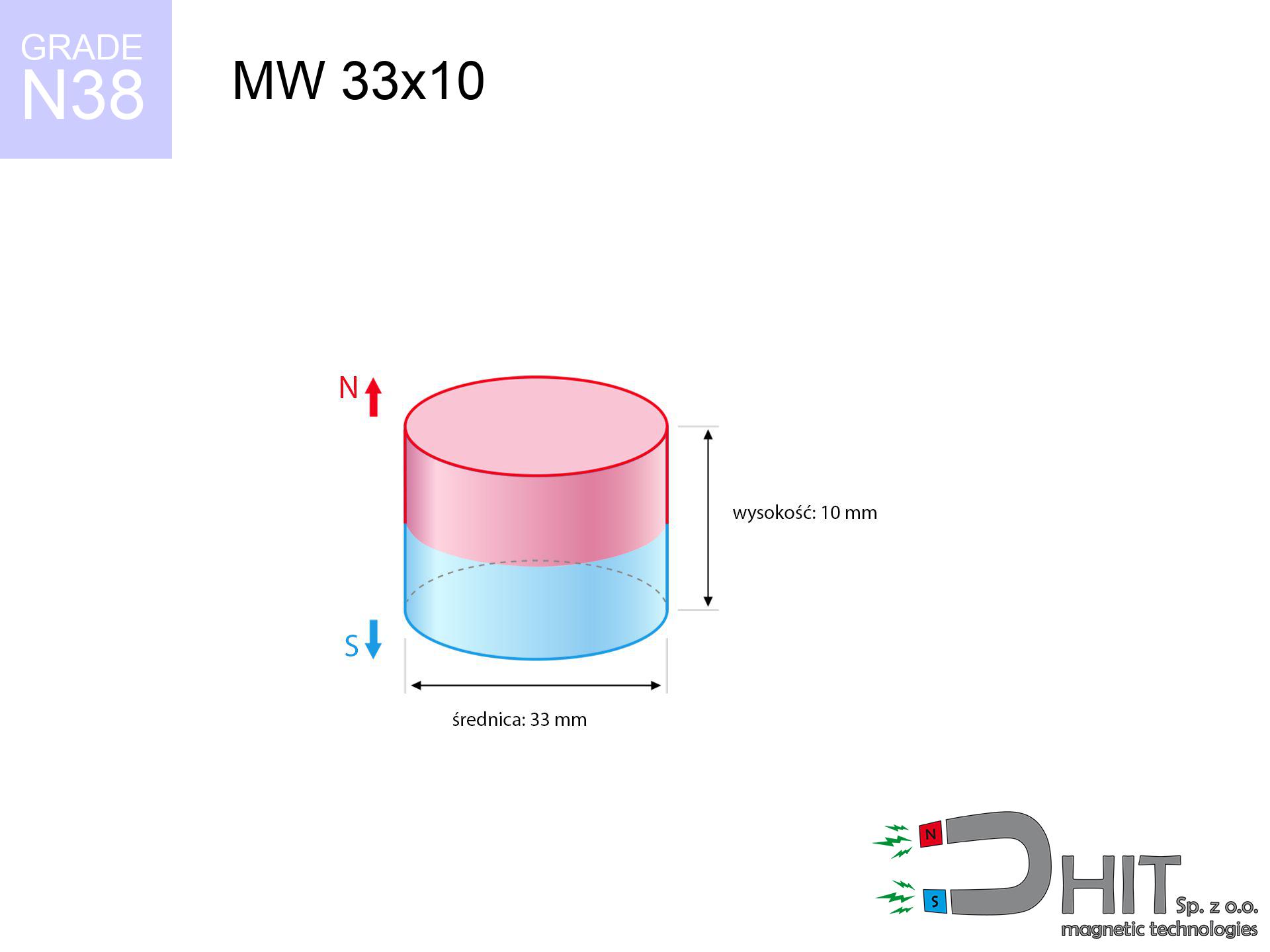

MW 33x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010057

GTIN/EAN: 5906301810568

Diameter Ø

33 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

64.15 g

Magnetization Direction

↑ axial

Load capacity

23.67 kg / 232.15 N

Magnetic Induction

321.26 mT / 3213 Gs

Coating

[NiCuNi] Nickel

26.52 ZŁ with VAT / pcs + price for transport

21.56 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer contact us by means of

form

the contact page.

Lifting power and appearance of magnets can be verified using our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MW 33x10 / N38 - cylindrical magnet

Specification / characteristics - MW 33x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010057 |

| GTIN/EAN | 5906301810568 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 33 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 64.15 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 23.67 kg / 232.15 N |

| Magnetic Induction ~ ? | 321.26 mT / 3213 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - technical parameters

The following values are the outcome of a engineering analysis. Values are based on algorithms for the material Nd2Fe14B. Real-world performance might slightly deviate from the simulation results. Treat these data as a preliminary roadmap for designers.

Table 1: Static pull force (pull vs gap) - characteristics

MW 33x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3212 Gs

321.2 mT

|

23.67 kg / 52.18 lbs

23670.0 g / 232.2 N

|

dangerous! |

| 1 mm |

3064 Gs

306.4 mT

|

21.54 kg / 47.49 lbs

21539.1 g / 211.3 N

|

dangerous! |

| 2 mm |

2901 Gs

290.1 mT

|

19.30 kg / 42.55 lbs

19302.3 g / 189.4 N

|

dangerous! |

| 3 mm |

2728 Gs

272.8 mT

|

17.07 kg / 37.64 lbs

17072.3 g / 167.5 N

|

dangerous! |

| 5 mm |

2373 Gs

237.3 mT

|

12.91 kg / 28.47 lbs

12913.7 g / 126.7 N

|

dangerous! |

| 10 mm |

1569 Gs

156.9 mT

|

5.65 kg / 12.45 lbs

5648.1 g / 55.4 N

|

warning |

| 15 mm |

1004 Gs

100.4 mT

|

2.31 kg / 5.10 lbs

2312.6 g / 22.7 N

|

warning |

| 20 mm |

650 Gs

65.0 mT

|

0.97 kg / 2.14 lbs

969.4 g / 9.5 N

|

weak grip |

| 30 mm |

299 Gs

29.9 mT

|

0.21 kg / 0.45 lbs

205.1 g / 2.0 N

|

weak grip |

| 50 mm |

90 Gs

9.0 mT

|

0.02 kg / 0.04 lbs

18.7 g / 0.2 N

|

weak grip |

Table 2: Vertical load (vertical surface)

MW 33x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.73 kg / 10.44 lbs

4734.0 g / 46.4 N

|

| 1 mm | Stal (~0.2) |

4.31 kg / 9.50 lbs

4308.0 g / 42.3 N

|

| 2 mm | Stal (~0.2) |

3.86 kg / 8.51 lbs

3860.0 g / 37.9 N

|

| 3 mm | Stal (~0.2) |

3.41 kg / 7.53 lbs

3414.0 g / 33.5 N

|

| 5 mm | Stal (~0.2) |

2.58 kg / 5.69 lbs

2582.0 g / 25.3 N

|

| 10 mm | Stal (~0.2) |

1.13 kg / 2.49 lbs

1130.0 g / 11.1 N

|

| 15 mm | Stal (~0.2) |

0.46 kg / 1.02 lbs

462.0 g / 4.5 N

|

| 20 mm | Stal (~0.2) |

0.19 kg / 0.43 lbs

194.0 g / 1.9 N

|

| 30 mm | Stal (~0.2) |

0.04 kg / 0.09 lbs

42.0 g / 0.4 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 33x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

7.10 kg / 15.66 lbs

7101.0 g / 69.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.73 kg / 10.44 lbs

4734.0 g / 46.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.37 kg / 5.22 lbs

2367.0 g / 23.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

11.84 kg / 26.09 lbs

11835.0 g / 116.1 N

|

Table 4: Steel thickness (saturation) - power losses

MW 33x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.18 kg / 2.61 lbs

1183.5 g / 11.6 N

|

| 1 mm |

|

2.96 kg / 6.52 lbs

2958.8 g / 29.0 N

|

| 2 mm |

|

5.92 kg / 13.05 lbs

5917.5 g / 58.1 N

|

| 3 mm |

|

8.88 kg / 19.57 lbs

8876.3 g / 87.1 N

|

| 5 mm |

|

14.79 kg / 32.61 lbs

14793.8 g / 145.1 N

|

| 10 mm |

|

23.67 kg / 52.18 lbs

23670.0 g / 232.2 N

|

| 11 mm |

|

23.67 kg / 52.18 lbs

23670.0 g / 232.2 N

|

| 12 mm |

|

23.67 kg / 52.18 lbs

23670.0 g / 232.2 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MW 33x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

23.67 kg / 52.18 lbs

23670.0 g / 232.2 N

|

OK |

| 40 °C | -2.2% |

23.15 kg / 51.04 lbs

23149.3 g / 227.1 N

|

OK |

| 60 °C | -4.4% |

22.63 kg / 49.89 lbs

22628.5 g / 222.0 N

|

|

| 80 °C | -6.6% |

22.11 kg / 48.74 lbs

22107.8 g / 216.9 N

|

|

| 100 °C | -28.8% |

16.85 kg / 37.15 lbs

16853.0 g / 165.3 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 33x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

54.40 kg / 119.94 lbs

4 780 Gs

|

8.16 kg / 17.99 lbs

8160 g / 80.1 N

|

N/A |

| 1 mm |

52.02 kg / 114.68 lbs

6 282 Gs

|

7.80 kg / 17.20 lbs

7803 g / 76.5 N

|

46.82 kg / 103.21 lbs

~0 Gs

|

| 2 mm |

49.51 kg / 109.14 lbs

6 128 Gs

|

7.43 kg / 16.37 lbs

7426 g / 72.8 N

|

44.55 kg / 98.23 lbs

~0 Gs

|

| 3 mm |

46.95 kg / 103.50 lbs

5 968 Gs

|

7.04 kg / 15.52 lbs

7042 g / 69.1 N

|

42.25 kg / 93.15 lbs

~0 Gs

|

| 5 mm |

41.79 kg / 92.13 lbs

5 630 Gs

|

6.27 kg / 13.82 lbs

6268 g / 61.5 N

|

37.61 kg / 82.91 lbs

~0 Gs

|

| 10 mm |

29.68 kg / 65.43 lbs

4 745 Gs

|

4.45 kg / 9.82 lbs

4452 g / 43.7 N

|

26.71 kg / 58.89 lbs

~0 Gs

|

| 20 mm |

12.98 kg / 28.62 lbs

3 138 Gs

|

1.95 kg / 4.29 lbs

1947 g / 19.1 N

|

11.68 kg / 25.76 lbs

~0 Gs

|

| 50 mm |

0.99 kg / 2.18 lbs

867 Gs

|

0.15 kg / 0.33 lbs

149 g / 1.5 N

|

0.89 kg / 1.97 lbs

~0 Gs

|

| 60 mm |

0.47 kg / 1.04 lbs

598 Gs

|

0.07 kg / 0.16 lbs

71 g / 0.7 N

|

0.42 kg / 0.94 lbs

~0 Gs

|

| 70 mm |

0.24 kg / 0.53 lbs

426 Gs

|

0.04 kg / 0.08 lbs

36 g / 0.4 N

|

0.22 kg / 0.47 lbs

~0 Gs

|

| 80 mm |

0.13 kg / 0.28 lbs

312 Gs

|

0.02 kg / 0.04 lbs

19 g / 0.2 N

|

0.12 kg / 0.26 lbs

~0 Gs

|

| 90 mm |

0.07 kg / 0.16 lbs

235 Gs

|

0.01 kg / 0.02 lbs

11 g / 0.1 N

|

0.07 kg / 0.14 lbs

~0 Gs

|

| 100 mm |

0.04 kg / 0.09 lbs

181 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 33x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 9.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 7.0 cm |

| Car key | 50 Gs (5.0 mT) | 6.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 33x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.07 km/h

(6.13 m/s)

|

1.21 J | |

| 30 mm |

33.74 km/h

(9.37 m/s)

|

2.82 J | |

| 50 mm |

43.34 km/h

(12.04 m/s)

|

4.65 J | |

| 100 mm |

61.26 km/h

(17.02 m/s)

|

9.29 J |

Table 9: Corrosion resistance

MW 33x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 33x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 29 509 Mx | 295.1 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Submerged application

MW 33x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 23.67 kg | Standard |

| Water (riverbed) |

27.10 kg

(+3.43 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical wall, the magnet holds just ~20% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically weakens the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over more than 10 years their attraction force decreases symbolically – ~1% (in testing),

- They possess excellent resistance to magnetism drop due to external magnetic sources,

- In other words, due to the shiny surface of gold, the element looks attractive,

- They show high magnetic induction at the operating surface, making them more effective,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in forming and the capacity to modify to complex applications,

- Key role in future technologies – they are used in HDD drives, electric drive systems, medical devices, as well as other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also increases its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- We recommend casing - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated forms.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Additionally, small elements of these devices are able to disrupt the diagnostic process medical after entering the body.

- Due to complex production process, their price is relatively high,

Lifting parameters

Maximum magnetic pulling force – what it depends on?

- using a plate made of high-permeability steel, serving as a ideal flux conductor

- whose transverse dimension is min. 10 mm

- with a surface free of scratches

- without the slightest clearance between the magnet and steel

- during pulling in a direction perpendicular to the plane

- at temperature room level

Lifting capacity in practice – influencing factors

- Clearance – the presence of foreign body (paint, tape, gap) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Force direction – note that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Surface finish – full contact is possible only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was performed on a smooth plate of suitable thickness, under perpendicular forces, in contrast under shearing force the holding force is lower. In addition, even a slight gap between the magnet’s surface and the plate decreases the holding force.

Safe handling of neodymium magnets

Health Danger

Medical warning: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Magnet fragility

Protect your eyes. Magnets can explode upon uncontrolled impact, ejecting sharp fragments into the air. Eye protection is mandatory.

Mechanical processing

Combustion risk: Rare earth powder is explosive. Avoid machining magnets in home conditions as this risks ignition.

Immense force

Be careful. Neodymium magnets act from a distance and connect with huge force, often faster than you can react.

Threat to navigation

A powerful magnetic field negatively affects the operation of compasses in smartphones and GPS navigation. Keep magnets near a smartphone to prevent damaging the sensors.

Product not for children

Only for adults. Small elements can be swallowed, causing severe trauma. Store out of reach of kids and pets.

Heat warning

Control the heat. Heating the magnet above 80 degrees Celsius will permanently weaken its magnetic structure and pulling force.

Magnetic media

Do not bring magnets near a wallet, computer, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Bone fractures

Danger of trauma: The pulling power is so immense that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Metal Allergy

Allergy Notice: The Ni-Cu-Ni coating consists of nickel. If an allergic reaction happens, immediately stop handling magnets and use protective gear.

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)