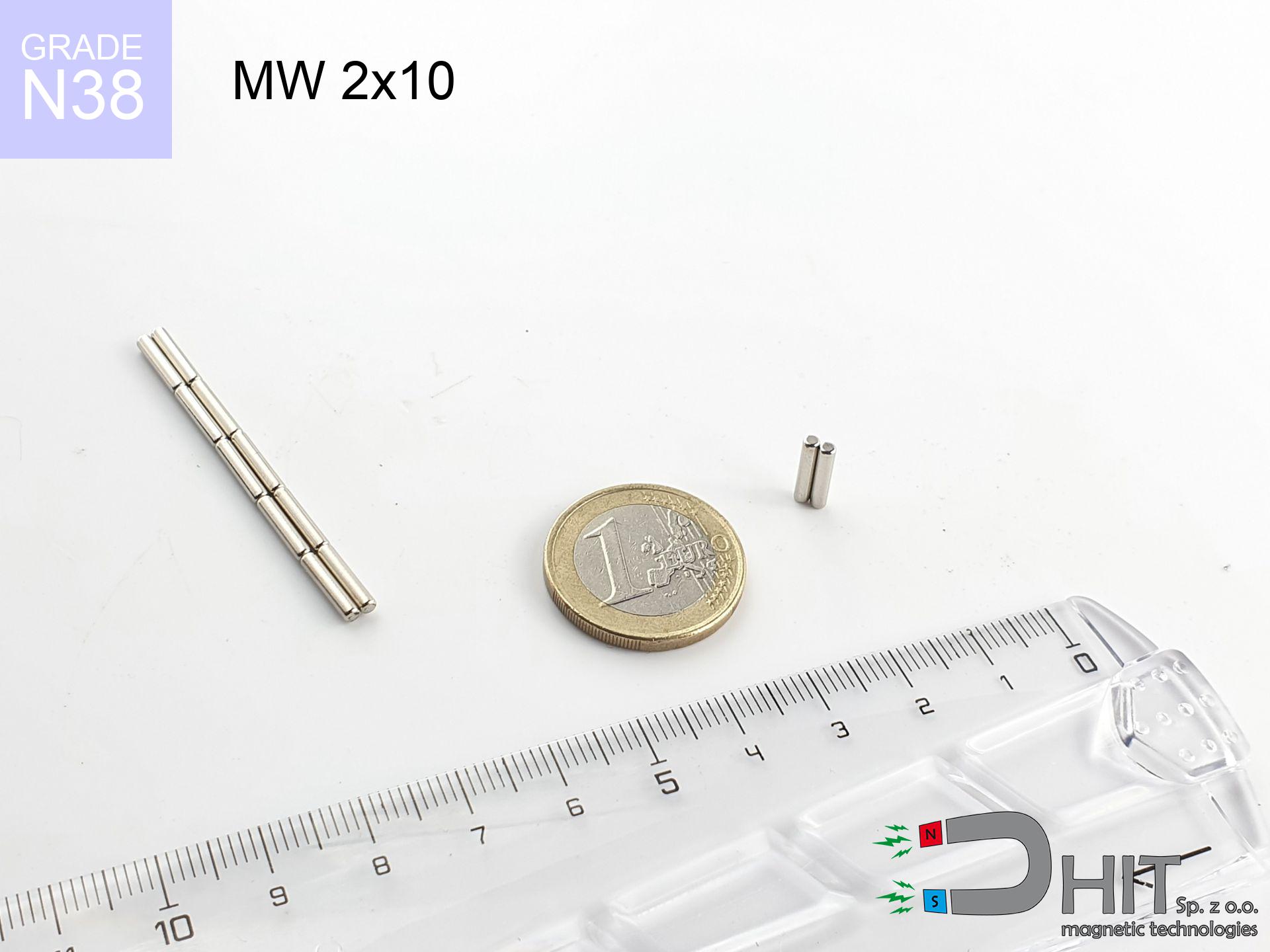

MW 2x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010054

GTIN/EAN: 5906301810537

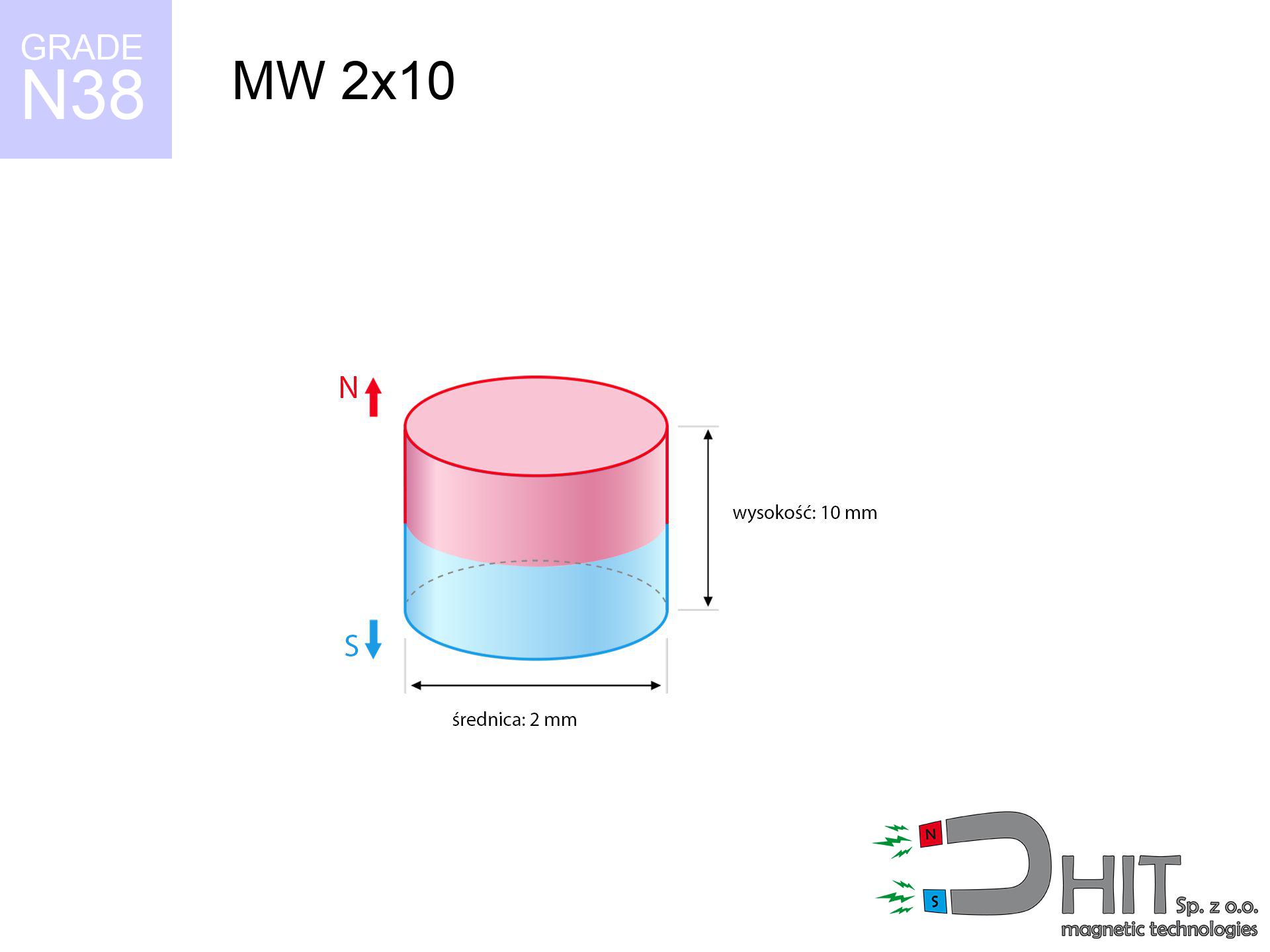

Diameter Ø

2 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

0.24 g

Magnetization Direction

↑ axial

Load capacity

0.07 kg / 0.70 N

Magnetic Induction

613.08 mT / 6131 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

or get in touch via

our online form

our website.

Weight as well as structure of a neodymium magnet can be verified with our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MW 2x10 / N38 - cylindrical magnet

Specification / characteristics - MW 2x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010054 |

| GTIN/EAN | 5906301810537 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 2 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 0.24 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.07 kg / 0.70 N |

| Magnetic Induction ~ ? | 613.08 mT / 6131 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - technical parameters

Presented information represent the outcome of a physical simulation. Values were calculated on algorithms for the material Nd2Fe14B. Actual parameters might slightly deviate from the simulation results. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static force (pull vs distance) - power drop

MW 2x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6107 Gs

610.7 mT

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

safe |

| 1 mm |

1790 Gs

179.0 mT

|

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

safe |

| 2 mm |

633 Gs

63.3 mT

|

0.00 kg / 0.00 LBS

0.8 g / 0.0 N

|

safe |

| 3 mm |

300 Gs

30.0 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

safe |

| 5 mm |

107 Gs

10.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 10 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 15 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 20 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Vertical force (vertical surface)

MW 2x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| 1 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 2x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.02 kg / 0.05 LBS

21.0 g / 0.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.01 kg / 0.02 LBS

7.0 g / 0.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.04 kg / 0.08 LBS

35.0 g / 0.3 N

|

Table 4: Steel thickness (saturation) - power losses

MW 2x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.01 kg / 0.02 LBS

7.0 g / 0.1 N

|

| 1 mm |

|

0.02 kg / 0.04 LBS

17.5 g / 0.2 N

|

| 2 mm |

|

0.04 kg / 0.08 LBS

35.0 g / 0.3 N

|

| 3 mm |

|

0.05 kg / 0.12 LBS

52.5 g / 0.5 N

|

| 5 mm |

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 10 mm |

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 11 mm |

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 12 mm |

|

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 2x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

OK |

| 40 °C | -2.2% |

0.07 kg / 0.15 LBS

68.5 g / 0.7 N

|

OK |

| 60 °C | -4.4% |

0.07 kg / 0.15 LBS

66.9 g / 0.7 N

|

OK |

| 80 °C | -6.6% |

0.07 kg / 0.14 LBS

65.4 g / 0.6 N

|

|

| 100 °C | -28.8% |

0.05 kg / 0.11 LBS

49.8 g / 0.5 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 2x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.72 kg / 1.59 LBS

6 130 Gs

|

0.11 kg / 0.24 LBS

108 g / 1.1 N

|

N/A |

| 1 mm |

0.22 kg / 0.49 LBS

6 799 Gs

|

0.03 kg / 0.07 LBS

34 g / 0.3 N

|

0.20 kg / 0.44 LBS

~0 Gs

|

| 2 mm |

0.06 kg / 0.14 LBS

3 581 Gs

|

0.01 kg / 0.02 LBS

9 g / 0.1 N

|

0.06 kg / 0.12 LBS

~0 Gs

|

| 3 mm |

0.02 kg / 0.04 LBS

2 036 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 5 mm |

0.00 kg / 0.01 LBS

847 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 LBS

213 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

46 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MW 2x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 1.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 1.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 2x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.22 km/h

(4.78 m/s)

|

0.00 J | |

| 30 mm |

29.83 km/h

(8.29 m/s)

|

0.01 J | |

| 50 mm |

38.51 km/h

(10.70 m/s)

|

0.01 J | |

| 100 mm |

54.47 km/h

(15.13 m/s)

|

0.03 J |

Table 9: Anti-corrosion coating durability

MW 2x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 2x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 232 Mx | 2.3 µWb |

| Pc Coefficient | 1.55 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 2x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.07 kg | Standard |

| Water (riverbed) |

0.08 kg

(+0.01 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains merely ~20% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.55

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (according to literature),

- They retain their magnetic properties even under strong external field,

- In other words, due to the glossy layer of gold, the element gains visual value,

- The surface of neodymium magnets generates a powerful magnetic field – this is a distinguishing feature,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures reaching 230°C and above...

- Thanks to versatility in constructing and the ability to adapt to complex applications,

- Key role in electronics industry – they find application in data components, motor assemblies, medical equipment, and industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of producing nuts in the magnet and complicated forms - recommended is a housing - mounting mechanism.

- Possible danger to health – tiny shards of magnets pose a threat, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, tiny parts of these products are able to complicate diagnosis medical when they are in the body.

- Due to complex production process, their price is relatively high,

Lifting parameters

Best holding force of the magnet in ideal parameters – what affects it?

- with the contact of a sheet made of low-carbon steel, ensuring full magnetic saturation

- whose thickness equals approx. 10 mm

- characterized by smoothness

- under conditions of no distance (metal-to-metal)

- for force acting at a right angle (pull-off, not shear)

- in stable room temperature

Key elements affecting lifting force

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) drastically reduces the pulling force, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Steel grade – the best choice is pure iron steel. Cast iron may attract less.

- Surface quality – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Roughness creates an air distance.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures gain strength (up to a certain limit).

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under attempts to slide the magnet the lifting capacity is smaller. In addition, even a slight gap between the magnet and the plate reduces the lifting capacity.

Precautions when working with NdFeB magnets

Magnets are brittle

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Demagnetization risk

Monitor thermal conditions. Heating the magnet to high heat will permanently weaken its magnetic structure and pulling force.

Phone sensors

GPS units and mobile phones are highly sensitive to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Data carriers

Intense magnetic fields can erase data on credit cards, HDDs, and storage devices. Stay away of min. 10 cm.

Flammability

Dust generated during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Physical harm

Big blocks can smash fingers instantly. Never place your hand between two strong magnets.

Product not for children

Always store magnets out of reach of children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are very dangerous.

Avoid contact if allergic

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If redness happens, immediately stop handling magnets and use protective gear.

Safe operation

Handle with care. Neodymium magnets act from a long distance and connect with huge force, often faster than you can move away.

Warning for heart patients

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.