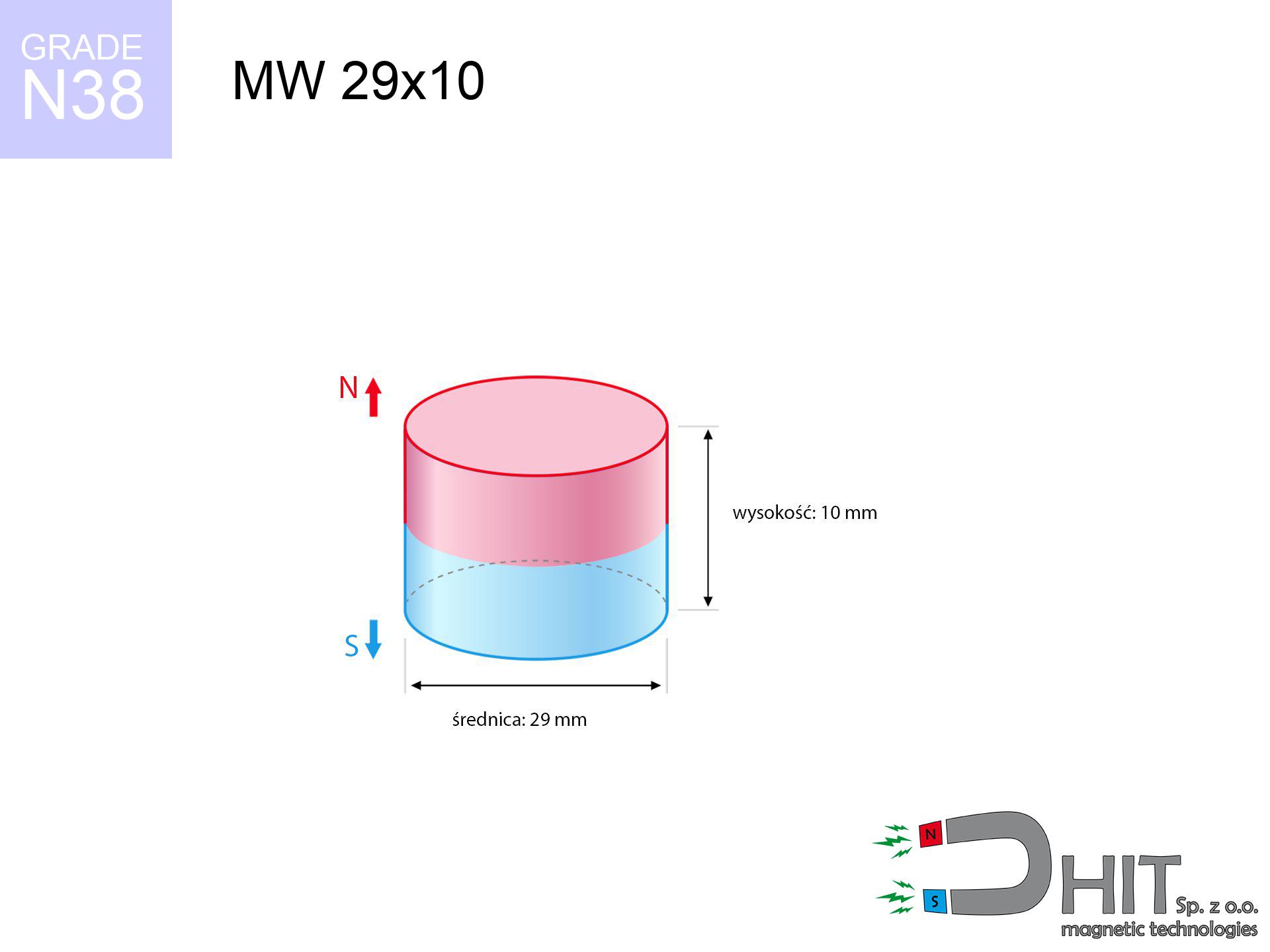

MW 29x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010053

GTIN/EAN: 5906301810520

Diameter Ø

29 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

49.54 g

Magnetization Direction

↑ axial

Load capacity

20.82 kg / 204.22 N

Magnetic Induction

351.88 mT / 3519 Gs

Coating

[NiCuNi] Nickel

17.34 ZŁ with VAT / pcs + price for transport

14.10 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

or drop us a message using

form

our website.

Specifications and shape of a neodymium magnet can be analyzed using our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical - MW 29x10 / N38 - cylindrical magnet

Specification / characteristics - MW 29x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010053 |

| GTIN/EAN | 5906301810520 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 29 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 49.54 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 20.82 kg / 204.22 N |

| Magnetic Induction ~ ? | 351.88 mT / 3519 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - data

The following information are the direct effect of a mathematical calculation. Values rely on models for the material Nd2Fe14B. Real-world parameters may differ from theoretical values. Treat these data as a reference point during assembly planning.

Table 1: Static pull force (pull vs distance) - characteristics

MW 29x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3518 Gs

351.8 mT

|

20.82 kg / 45.90 lbs

20820.0 g / 204.2 N

|

crushing |

| 1 mm |

3321 Gs

332.1 mT

|

18.55 kg / 40.89 lbs

18548.8 g / 182.0 N

|

crushing |

| 2 mm |

3106 Gs

310.6 mT

|

16.23 kg / 35.77 lbs

16226.1 g / 159.2 N

|

crushing |

| 3 mm |

2883 Gs

288.3 mT

|

13.98 kg / 30.82 lbs

13978.2 g / 137.1 N

|

crushing |

| 5 mm |

2437 Gs

243.7 mT

|

9.99 kg / 22.02 lbs

9987.1 g / 98.0 N

|

medium risk |

| 10 mm |

1500 Gs

150.0 mT

|

3.78 kg / 8.34 lbs

3783.1 g / 37.1 N

|

medium risk |

| 15 mm |

905 Gs

90.5 mT

|

1.38 kg / 3.04 lbs

1379.2 g / 13.5 N

|

low risk |

| 20 mm |

563 Gs

56.3 mT

|

0.53 kg / 1.17 lbs

532.4 g / 5.2 N

|

low risk |

| 30 mm |

247 Gs

24.7 mT

|

0.10 kg / 0.23 lbs

102.4 g / 1.0 N

|

low risk |

| 50 mm |

72 Gs

7.2 mT

|

0.01 kg / 0.02 lbs

8.7 g / 0.1 N

|

low risk |

Table 2: Sliding capacity (wall)

MW 29x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.16 kg / 9.18 lbs

4164.0 g / 40.8 N

|

| 1 mm | Stal (~0.2) |

3.71 kg / 8.18 lbs

3710.0 g / 36.4 N

|

| 2 mm | Stal (~0.2) |

3.25 kg / 7.16 lbs

3246.0 g / 31.8 N

|

| 3 mm | Stal (~0.2) |

2.80 kg / 6.16 lbs

2796.0 g / 27.4 N

|

| 5 mm | Stal (~0.2) |

2.00 kg / 4.40 lbs

1998.0 g / 19.6 N

|

| 10 mm | Stal (~0.2) |

0.76 kg / 1.67 lbs

756.0 g / 7.4 N

|

| 15 mm | Stal (~0.2) |

0.28 kg / 0.61 lbs

276.0 g / 2.7 N

|

| 20 mm | Stal (~0.2) |

0.11 kg / 0.23 lbs

106.0 g / 1.0 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 29x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

6.25 kg / 13.77 lbs

6246.0 g / 61.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.16 kg / 9.18 lbs

4164.0 g / 40.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.08 kg / 4.59 lbs

2082.0 g / 20.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

10.41 kg / 22.95 lbs

10410.0 g / 102.1 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 29x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.04 kg / 2.30 lbs

1041.0 g / 10.2 N

|

| 1 mm |

|

2.60 kg / 5.74 lbs

2602.5 g / 25.5 N

|

| 2 mm |

|

5.21 kg / 11.48 lbs

5205.0 g / 51.1 N

|

| 3 mm |

|

7.81 kg / 17.21 lbs

7807.5 g / 76.6 N

|

| 5 mm |

|

13.01 kg / 28.69 lbs

13012.5 g / 127.7 N

|

| 10 mm |

|

20.82 kg / 45.90 lbs

20820.0 g / 204.2 N

|

| 11 mm |

|

20.82 kg / 45.90 lbs

20820.0 g / 204.2 N

|

| 12 mm |

|

20.82 kg / 45.90 lbs

20820.0 g / 204.2 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MW 29x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

20.82 kg / 45.90 lbs

20820.0 g / 204.2 N

|

OK |

| 40 °C | -2.2% |

20.36 kg / 44.89 lbs

20362.0 g / 199.8 N

|

OK |

| 60 °C | -4.4% |

19.90 kg / 43.88 lbs

19903.9 g / 195.3 N

|

|

| 80 °C | -6.6% |

19.45 kg / 42.87 lbs

19445.9 g / 190.8 N

|

|

| 100 °C | -28.8% |

14.82 kg / 32.68 lbs

14823.8 g / 145.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 29x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

50.40 kg / 111.11 lbs

5 016 Gs

|

7.56 kg / 16.67 lbs

7560 g / 74.2 N

|

N/A |

| 1 mm |

47.70 kg / 105.17 lbs

6 845 Gs

|

7.16 kg / 15.78 lbs

7156 g / 70.2 N

|

42.93 kg / 94.65 lbs

~0 Gs

|

| 2 mm |

44.90 kg / 98.99 lbs

6 641 Gs

|

6.74 kg / 14.85 lbs

6735 g / 66.1 N

|

40.41 kg / 89.09 lbs

~0 Gs

|

| 3 mm |

42.08 kg / 92.77 lbs

6 429 Gs

|

6.31 kg / 13.92 lbs

6312 g / 61.9 N

|

37.87 kg / 83.50 lbs

~0 Gs

|

| 5 mm |

36.52 kg / 80.52 lbs

5 990 Gs

|

5.48 kg / 12.08 lbs

5478 g / 53.7 N

|

32.87 kg / 72.47 lbs

~0 Gs

|

| 10 mm |

24.18 kg / 53.30 lbs

4 873 Gs

|

3.63 kg / 7.99 lbs

3626 g / 35.6 N

|

21.76 kg / 47.97 lbs

~0 Gs

|

| 20 mm |

9.16 kg / 20.19 lbs

2 999 Gs

|

1.37 kg / 3.03 lbs

1374 g / 13.5 N

|

8.24 kg / 18.17 lbs

~0 Gs

|

| 50 mm |

0.54 kg / 1.19 lbs

729 Gs

|

0.08 kg / 0.18 lbs

81 g / 0.8 N

|

0.49 kg / 1.07 lbs

~0 Gs

|

| 60 mm |

0.25 kg / 0.55 lbs

493 Gs

|

0.04 kg / 0.08 lbs

37 g / 0.4 N

|

0.22 kg / 0.49 lbs

~0 Gs

|

| 70 mm |

0.12 kg / 0.27 lbs

347 Gs

|

0.02 kg / 0.04 lbs

18 g / 0.2 N

|

0.11 kg / 0.24 lbs

~0 Gs

|

| 80 mm |

0.06 kg / 0.14 lbs

252 Gs

|

0.01 kg / 0.02 lbs

10 g / 0.1 N

|

0.06 kg / 0.13 lbs

~0 Gs

|

| 90 mm |

0.04 kg / 0.08 lbs

188 Gs

|

0.01 kg / 0.01 lbs

5 g / 0.1 N

|

0.03 kg / 0.07 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 lbs

144 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 29x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 8.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - warning

MW 29x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.90 km/h

(6.36 m/s)

|

1.00 J | |

| 30 mm |

35.92 km/h

(9.98 m/s)

|

2.47 J | |

| 50 mm |

46.24 km/h

(12.85 m/s)

|

4.09 J | |

| 100 mm |

65.38 km/h

(18.16 m/s)

|

8.17 J |

Table 9: Coating parameters (durability)

MW 29x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 29x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 24 471 Mx | 244.7 µWb |

| Pc Coefficient | 0.45 | Low (Flat) |

Table 11: Submerged application

MW 29x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 20.82 kg | Standard |

| Water (riverbed) |

23.84 kg

(+3.02 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet retains merely approx. 20-30% of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.45

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

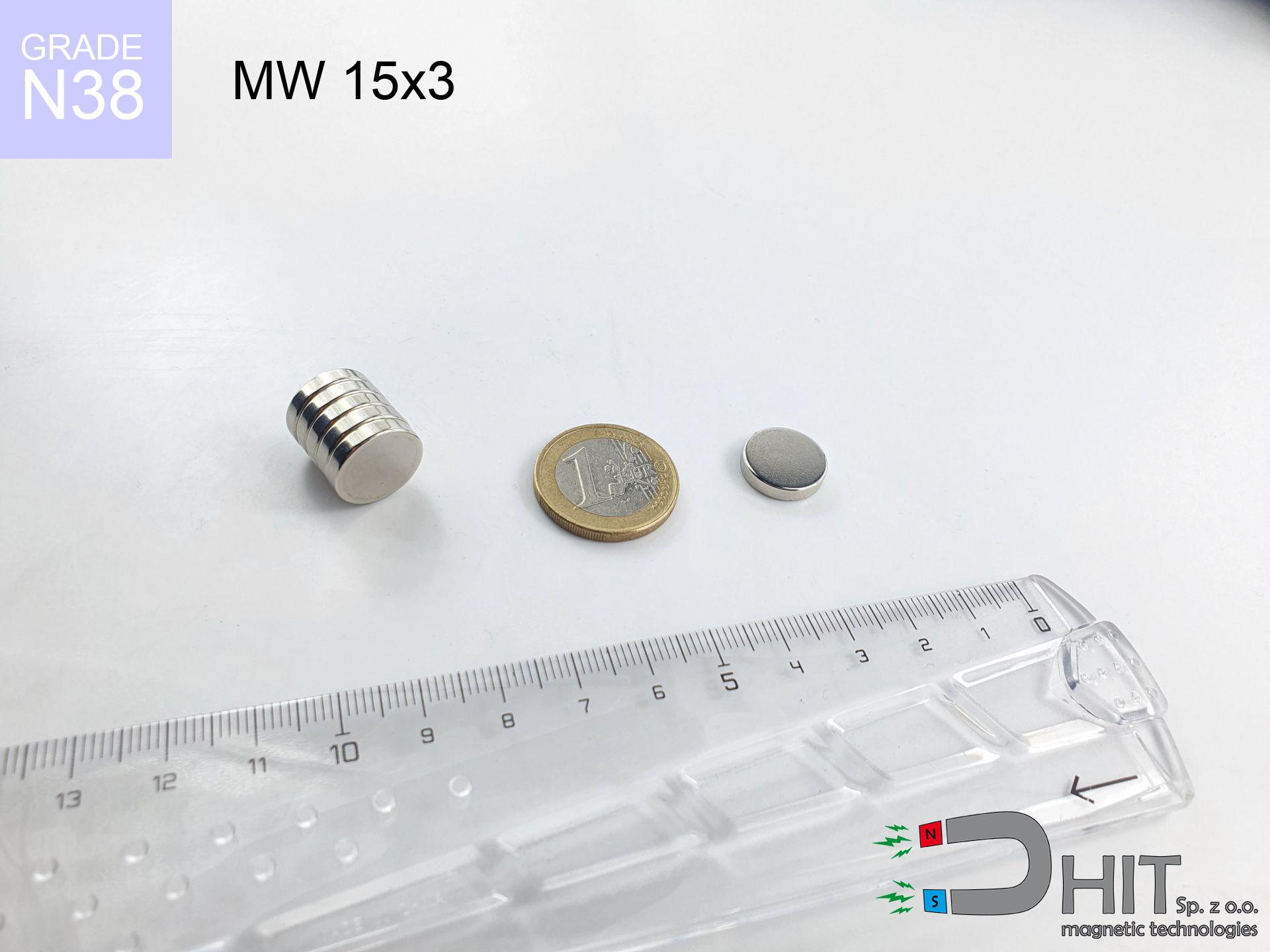

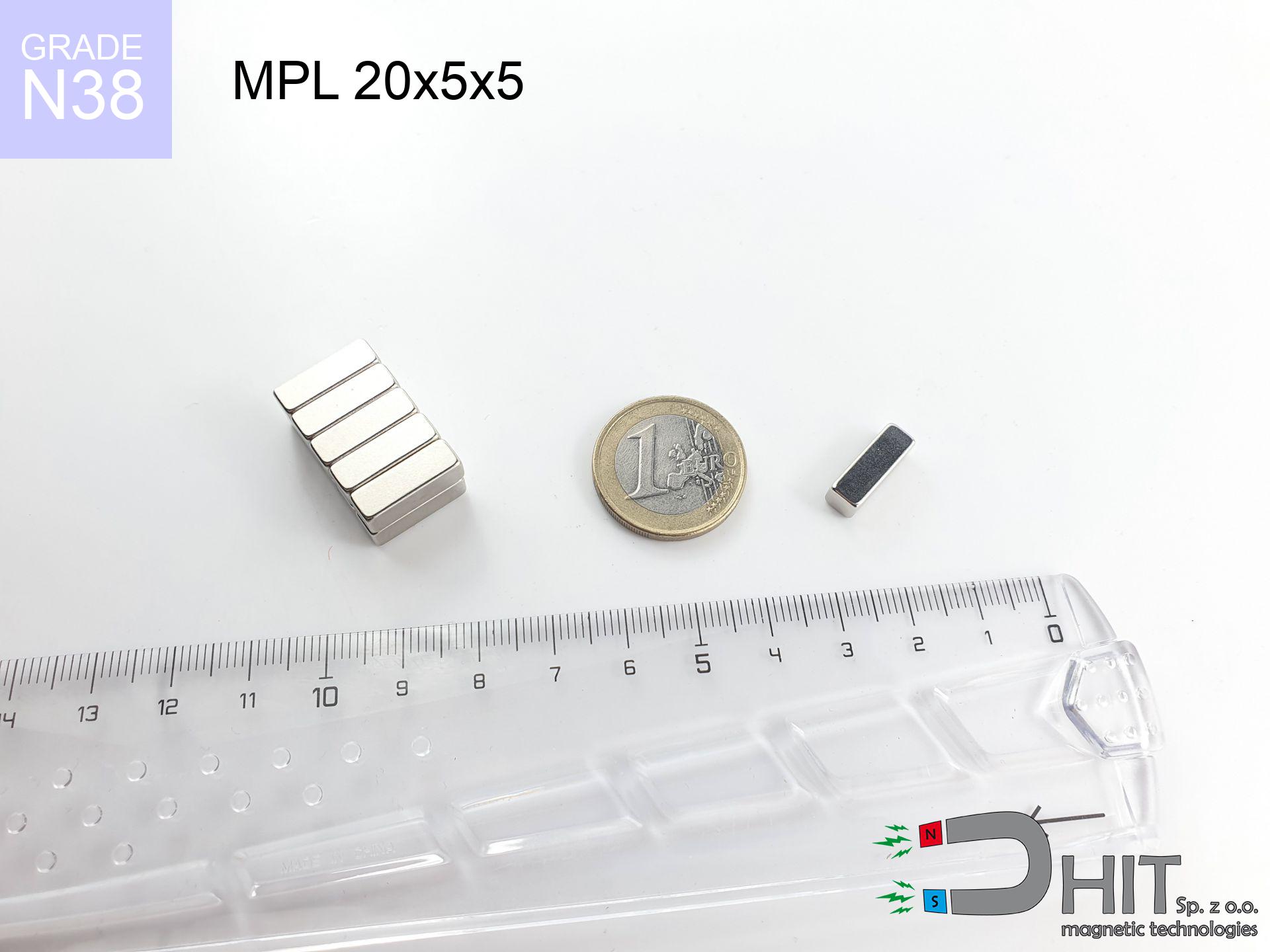

Other products

Advantages and disadvantages of rare earth magnets.

Advantages

- They do not lose magnetism, even during nearly ten years – the drop in lifting capacity is only ~1% (according to tests),

- Neodymium magnets prove to be exceptionally resistant to loss of magnetic properties caused by external magnetic fields,

- In other words, due to the reflective finish of nickel, the element gains a professional look,

- Magnets exhibit extremely high magnetic induction on the outer side,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of custom creating as well as modifying to individual applications,

- Wide application in modern technologies – they are commonly used in hard drives, electromotive mechanisms, advanced medical instruments, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which allows their use in small systems

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They oxidize in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited ability of creating nuts in the magnet and complex forms - recommended is a housing - magnetic holder.

- Health risk related to microscopic parts of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. Additionally, small components of these products are able to disrupt the diagnostic process medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Lifting parameters

Maximum holding power of the magnet – what contributes to it?

- with the application of a sheet made of low-carbon steel, ensuring maximum field concentration

- possessing a massiveness of minimum 10 mm to avoid saturation

- with a plane perfectly flat

- with zero gap (no coatings)

- for force applied at a right angle (in the magnet axis)

- at conditions approx. 20°C

Determinants of practical lifting force of a magnet

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel attracts identically. High carbon content worsen the attraction effect.

- Smoothness – ideal contact is obtained only on smooth steel. Any scratches and bumps create air cushions, reducing force.

- Temperature influence – hot environment reduces pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was measured with the use of a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the holding force is lower. Additionally, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

H&S for magnets

Cards and drives

Avoid bringing magnets close to a purse, computer, or screen. The magnetism can destroy these devices and wipe information from cards.

Warning for heart patients

For implant holders: Powerful magnets disrupt medical devices. Maintain at least 30 cm distance or request help to handle the magnets.

Maximum temperature

Standard neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Hand protection

Mind your fingers. Two large magnets will join instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Protective goggles

Despite the nickel coating, the material is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Metal Allergy

Nickel alert: The nickel-copper-nickel coating contains nickel. If skin irritation happens, cease handling magnets and use protective gear.

Product not for children

Neodymium magnets are not toys. Eating multiple magnets may result in them pinching intestinal walls, which constitutes a critical condition and requires immediate surgery.

Flammability

Powder produced during machining of magnets is flammable. Avoid drilling into magnets unless you are an expert.

Handling rules

Before starting, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

GPS and phone interference

Note: rare earth magnets generate a field that disrupts precision electronics. Keep a separation from your mobile, device, and navigation systems.