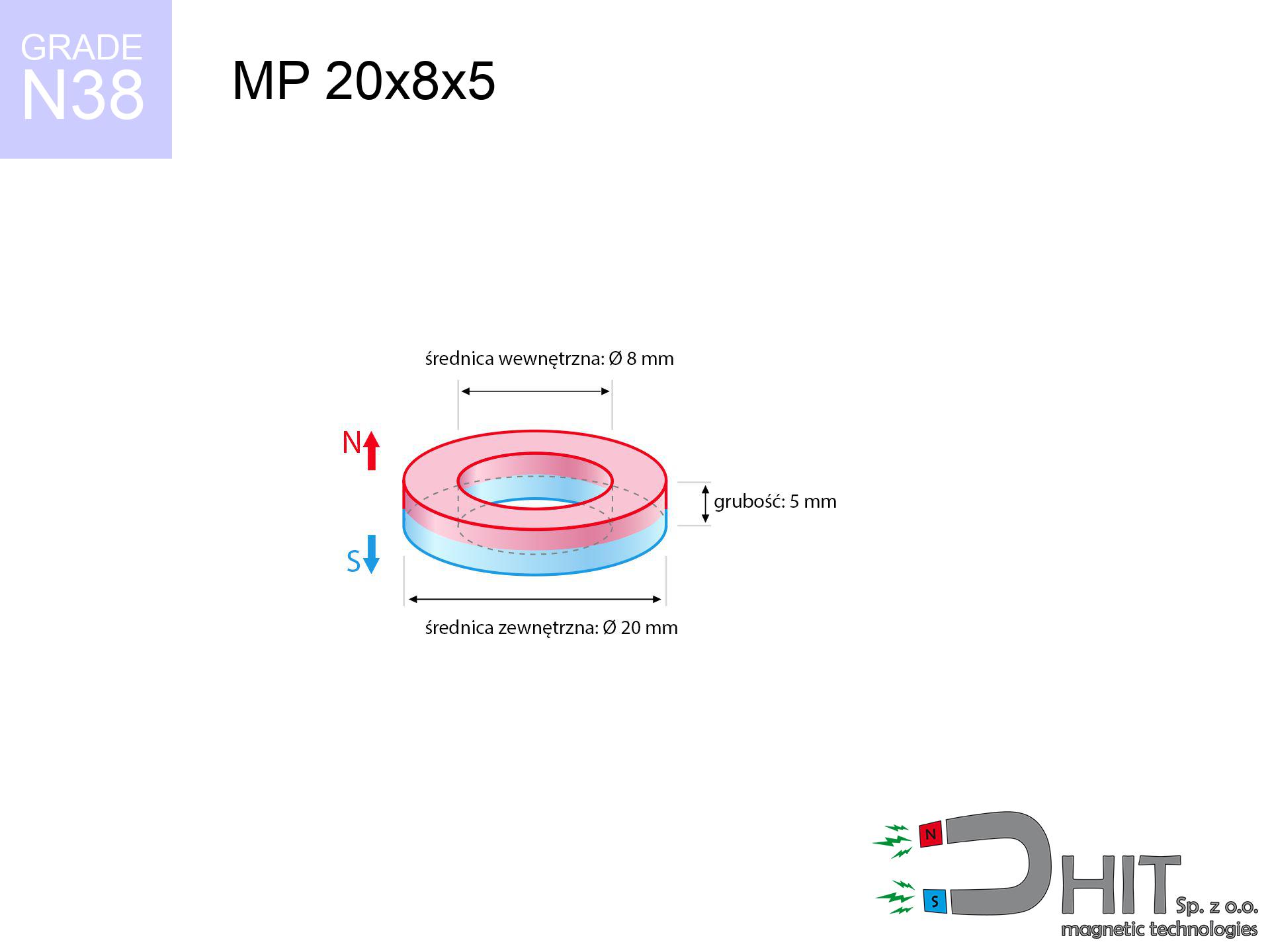

MP 20x8x5 / N38 - ring magnet

ring magnet

Catalog no 030188

GTIN/EAN: 5906301812050

Diameter

20 mm [±0,1 mm]

internal diameter Ø

8 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

9.9 g

Magnetization Direction

↑ axial

Load capacity

5.82 kg / 57.06 N

Magnetic Induction

277.16 mT / 2772 Gs

Coating

[NiCuNi] Nickel

3.80 ZŁ with VAT / pcs + price for transport

3.09 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively send us a note through

contact form

the contact section.

Strength along with shape of a neodymium magnet can be verified on our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical of the product - MP 20x8x5 / N38 - ring magnet

Specification / characteristics - MP 20x8x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030188 |

| GTIN/EAN | 5906301812050 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 8 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 9.9 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.82 kg / 57.06 N |

| Magnetic Induction ~ ? | 277.16 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the product - report

The following values are the direct effect of a physical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Real-world conditions might slightly differ. Use these data as a reference point during assembly planning.

Table 1: Static force (force vs gap) - characteristics

MP 20x8x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5917 Gs

591.7 mT

|

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

strong |

| 1 mm |

5321 Gs

532.1 mT

|

4.71 kg / 10.38 lbs

4707.4 g / 46.2 N

|

strong |

| 2 mm |

4736 Gs

473.6 mT

|

3.73 kg / 8.22 lbs

3729.5 g / 36.6 N

|

strong |

| 3 mm |

4184 Gs

418.4 mT

|

2.91 kg / 6.42 lbs

2910.0 g / 28.5 N

|

strong |

| 5 mm |

3216 Gs

321.6 mT

|

1.72 kg / 3.79 lbs

1719.3 g / 16.9 N

|

low risk |

| 10 mm |

1650 Gs

165.0 mT

|

0.45 kg / 1.00 lbs

452.4 g / 4.4 N

|

low risk |

| 15 mm |

907 Gs

90.7 mT

|

0.14 kg / 0.30 lbs

136.8 g / 1.3 N

|

low risk |

| 20 mm |

544 Gs

54.4 mT

|

0.05 kg / 0.11 lbs

49.2 g / 0.5 N

|

low risk |

| 30 mm |

240 Gs

24.0 mT

|

0.01 kg / 0.02 lbs

9.6 g / 0.1 N

|

low risk |

| 50 mm |

75 Gs

7.5 mT

|

0.00 kg / 0.00 lbs

0.9 g / 0.0 N

|

low risk |

Table 2: Slippage hold (vertical surface)

MP 20x8x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.16 kg / 2.57 lbs

1164.0 g / 11.4 N

|

| 1 mm | Stal (~0.2) |

0.94 kg / 2.08 lbs

942.0 g / 9.2 N

|

| 2 mm | Stal (~0.2) |

0.75 kg / 1.64 lbs

746.0 g / 7.3 N

|

| 3 mm | Stal (~0.2) |

0.58 kg / 1.28 lbs

582.0 g / 5.7 N

|

| 5 mm | Stal (~0.2) |

0.34 kg / 0.76 lbs

344.0 g / 3.4 N

|

| 10 mm | Stal (~0.2) |

0.09 kg / 0.20 lbs

90.0 g / 0.9 N

|

| 15 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

28.0 g / 0.3 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 20x8x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.75 kg / 3.85 lbs

1746.0 g / 17.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.16 kg / 2.57 lbs

1164.0 g / 11.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.58 kg / 1.28 lbs

582.0 g / 5.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.91 kg / 6.42 lbs

2910.0 g / 28.5 N

|

Table 4: Steel thickness (substrate influence) - power losses

MP 20x8x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.58 kg / 1.28 lbs

582.0 g / 5.7 N

|

| 1 mm |

|

1.46 kg / 3.21 lbs

1455.0 g / 14.3 N

|

| 2 mm |

|

2.91 kg / 6.42 lbs

2910.0 g / 28.5 N

|

| 3 mm |

|

4.37 kg / 9.62 lbs

4365.0 g / 42.8 N

|

| 5 mm |

|

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

| 10 mm |

|

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

| 11 mm |

|

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

| 12 mm |

|

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MP 20x8x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.82 kg / 12.83 lbs

5820.0 g / 57.1 N

|

OK |

| 40 °C | -2.2% |

5.69 kg / 12.55 lbs

5692.0 g / 55.8 N

|

OK |

| 60 °C | -4.4% |

5.56 kg / 12.27 lbs

5563.9 g / 54.6 N

|

OK |

| 80 °C | -6.6% |

5.44 kg / 11.98 lbs

5435.9 g / 53.3 N

|

|

| 100 °C | -28.8% |

4.14 kg / 9.14 lbs

4143.8 g / 40.7 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 20x8x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

54.03 kg / 119.11 lbs

6 121 Gs

|

8.10 kg / 17.87 lbs

8104 g / 79.5 N

|

N/A |

| 1 mm |

48.76 kg / 107.50 lbs

11 242 Gs

|

7.31 kg / 16.13 lbs

7314 g / 71.8 N

|

43.89 kg / 96.75 lbs

~0 Gs

|

| 2 mm |

43.70 kg / 96.34 lbs

10 642 Gs

|

6.55 kg / 14.45 lbs

6555 g / 64.3 N

|

39.33 kg / 86.71 lbs

~0 Gs

|

| 3 mm |

38.98 kg / 85.94 lbs

10 051 Gs

|

5.85 kg / 12.89 lbs

5847 g / 57.4 N

|

35.08 kg / 77.34 lbs

~0 Gs

|

| 5 mm |

30.63 kg / 67.54 lbs

8 910 Gs

|

4.60 kg / 10.13 lbs

4595 g / 45.1 N

|

27.57 kg / 60.78 lbs

~0 Gs

|

| 10 mm |

15.96 kg / 35.19 lbs

6 432 Gs

|

2.39 kg / 5.28 lbs

2394 g / 23.5 N

|

14.36 kg / 31.67 lbs

~0 Gs

|

| 20 mm |

4.20 kg / 9.26 lbs

3 299 Gs

|

0.63 kg / 1.39 lbs

630 g / 6.2 N

|

3.78 kg / 8.33 lbs

~0 Gs

|

| 50 mm |

0.19 kg / 0.42 lbs

702 Gs

|

0.03 kg / 0.06 lbs

29 g / 0.3 N

|

0.17 kg / 0.38 lbs

~0 Gs

|

| 60 mm |

0.09 kg / 0.20 lbs

480 Gs

|

0.01 kg / 0.03 lbs

13 g / 0.1 N

|

0.08 kg / 0.18 lbs

~0 Gs

|

| 70 mm |

0.05 kg / 0.10 lbs

342 Gs

|

0.01 kg / 0.01 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 80 mm |

0.02 kg / 0.05 lbs

253 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 lbs

193 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 lbs

150 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MP 20x8x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 9.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 20x8x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.61 km/h

(7.11 m/s)

|

0.25 J | |

| 30 mm |

42.40 km/h

(11.78 m/s)

|

0.69 J | |

| 50 mm |

54.68 km/h

(15.19 m/s)

|

1.14 J | |

| 100 mm |

77.33 km/h

(21.48 m/s)

|

2.28 J |

Table 9: Anti-corrosion coating durability

MP 20x8x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 20x8x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 116 Mx | 161.2 µWb |

| Pc Coefficient | 1.13 | High (Stable) |

Table 11: Physics of underwater searching

MP 20x8x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.82 kg | Standard |

| Water (riverbed) |

6.66 kg

(+0.84 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds just ~20% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Temperature resistance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.13

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros and cons of neodymium magnets.

Advantages

- Their strength is durable, and after around ten years it drops only by ~1% (according to research),

- They are noted for resistance to demagnetization induced by external disturbances,

- Thanks to the glossy finish, the layer of nickel, gold, or silver gives an visually attractive appearance,

- Magnets exhibit extremely high magnetic induction on the active area,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to versatility in designing and the capacity to customize to specific needs,

- Fundamental importance in modern industrial fields – they find application in HDD drives, motor assemblies, medical devices, also modern systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Weaknesses

- At strong impacts they can crack, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Due to limitations in realizing threads and complicated forms in magnets, we propose using casing - magnetic holder.

- Possible danger to health – tiny shards of magnets are risky, in case of ingestion, which gains importance in the context of child safety. Additionally, tiny parts of these devices can be problematic in diagnostics medical in case of swallowing.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Best holding force of the magnet in ideal parameters – what it depends on?

- with the use of a yoke made of low-carbon steel, ensuring maximum field concentration

- with a thickness minimum 10 mm

- with an ideally smooth touching surface

- with zero gap (no impurities)

- during pulling in a direction perpendicular to the mounting surface

- at conditions approx. 20°C

Practical aspects of lifting capacity – factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Steel grade – ideal substrate is pure iron steel. Stainless steels may have worse magnetic properties.

- Base smoothness – the more even the surface, the better the adhesion and higher the lifting capacity. Roughness creates an air distance.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity was measured with the use of a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, whereas under parallel forces the holding force is lower. Moreover, even a slight gap between the magnet and the plate decreases the holding force.

Warnings

Do not give to children

Absolutely store magnets away from children. Ingestion danger is high, and the effects of magnets connecting inside the body are life-threatening.

Skin irritation risks

Some people have a contact allergy to nickel, which is the typical protective layer for NdFeB magnets. Frequent touching might lead to dermatitis. We suggest use protective gloves.

Thermal limits

Monitor thermal conditions. Exposing the magnet to high heat will ruin its magnetic structure and pulling force.

Medical implants

For implant holders: Strong magnetic fields affect electronics. Maintain at least 30 cm distance or request help to work with the magnets.

Cards and drives

Very strong magnetic fields can destroy records on payment cards, hard drives, and storage devices. Stay away of min. 10 cm.

Magnetic interference

A powerful magnetic field disrupts the functioning of magnetometers in phones and navigation systems. Keep magnets close to a device to prevent damaging the sensors.

Fragile material

Neodymium magnets are ceramic materials, which means they are prone to chipping. Collision of two magnets will cause them shattering into small pieces.

Immense force

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Fire warning

Combustion risk: Neodymium dust is highly flammable. Do not process magnets in home conditions as this risks ignition.

Serious injuries

Big blocks can break fingers in a fraction of a second. Never put your hand betwixt two strong magnets.